engine CHRYSLER SEBRING 2004 2.G Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: SEBRING, Model: CHRYSLER SEBRING 2004 2.GPages: 273, PDF Size: 4.88 MB

Page 210 of 273

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

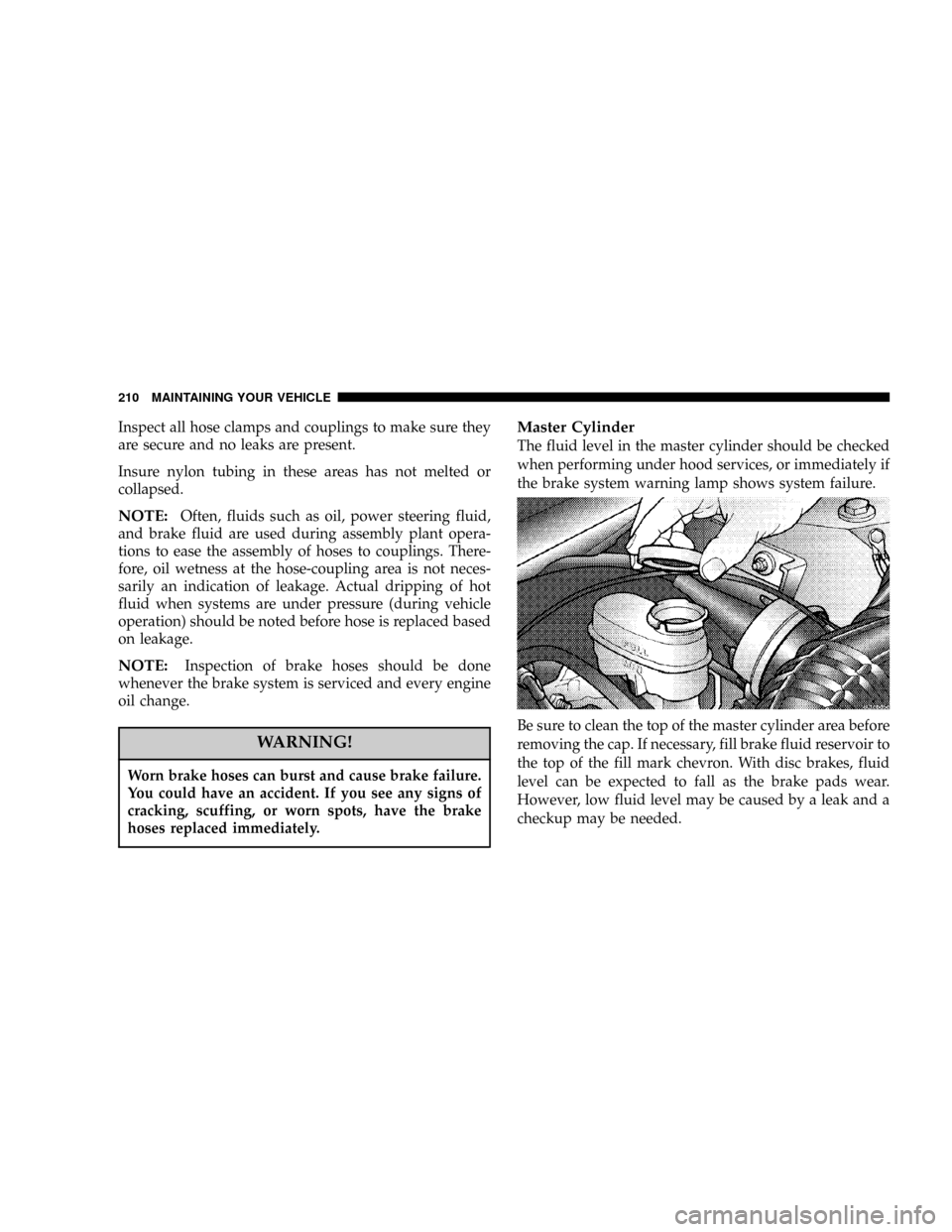

Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp shows system failure.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, fill brake fluid reservoir to

the top of the fill mark chevron. With disc brakes, fluid

level can be expected to fall as the brake pads wear.

However, low fluid level may be caused by a leak and a

checkup may be needed.

210 MAINTAINING YOUR VEHICLE

Page 211 of 273

Use only manufacturer's recommended brake fluid, refer

to Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

WARNING!

Use of a brake fluid that has a lower initial boiling

point than MOPAR DOT 3 Brake Fluid or that is

unidentified as to DOT FMVSS specification may

result in sudden brake failure during hard or pro-

longed braking. You could have an accident.

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.Do not allow petroleum base fluid to contaminate the

brake fluid as seal damage will result!

Fuel System Hoses

Electronic Fuel Injection high pressure fuel systems are

designed with hoses and clamps which have unique

material characteristics to provide adequate sealing and

resist attack by deteriorated gasoline.

You are urged to use only manufacturer specified hoses

and clamps, or their equivalent in material and specifi-

cation, in any fuel system servicing. It is mandatory to

replace all clamps that have been loosened or removed

during service. Care should be taken in installing new

clamps to insure they are properly torqued.

Automatic Transmission

Your front wheel drive vehicle has a transmission and

differential assembly contained within a single housing.

This is referred to as a ªTransaxle.º

MAINTAINING YOUR VEHICLE 211

7

Page 212 of 273

Selection of Lubricant

It is important that the proper lubricant is used in the

transmission to assure optimum transmission perfor-

mance. Use only manufacturers recommended transmis-

sion fluid, refer to Recommended Fluids, Lubricants and

Genuine Parts for correct fluid type. It is important that

the transmission fluid be maintained at the prescribed

level using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

Procedure For Checking Fluid Level

The fluid level in the automatic transaxle should be

checked whenever the vehicle is serviced. Operation with

an improper fluid level will greatly reduce the life of the

transaxle and of the fluid.

To properly check the automatic transaxle fluid level, the

following procedure must be used:

²The vehicle must be on level ground.

²The engine should be running at curb idle speed for a

minimum of 60 seconds.

²Fully apply parking brake.

²Place the gear selector momentarily in each gear

position ending with the lever in P (PARK).

²Wipe the dipstick clean and reinsert until seated.

Remove dipstick and note reading.

²If the fluid is cold (80ÉF / 27ÉC), the reading should be

in the cross hatched area marked ªCOLDº (between

the lower two holes in the dipstick).

212 MAINTAINING YOUR VEHICLE

Page 219 of 273

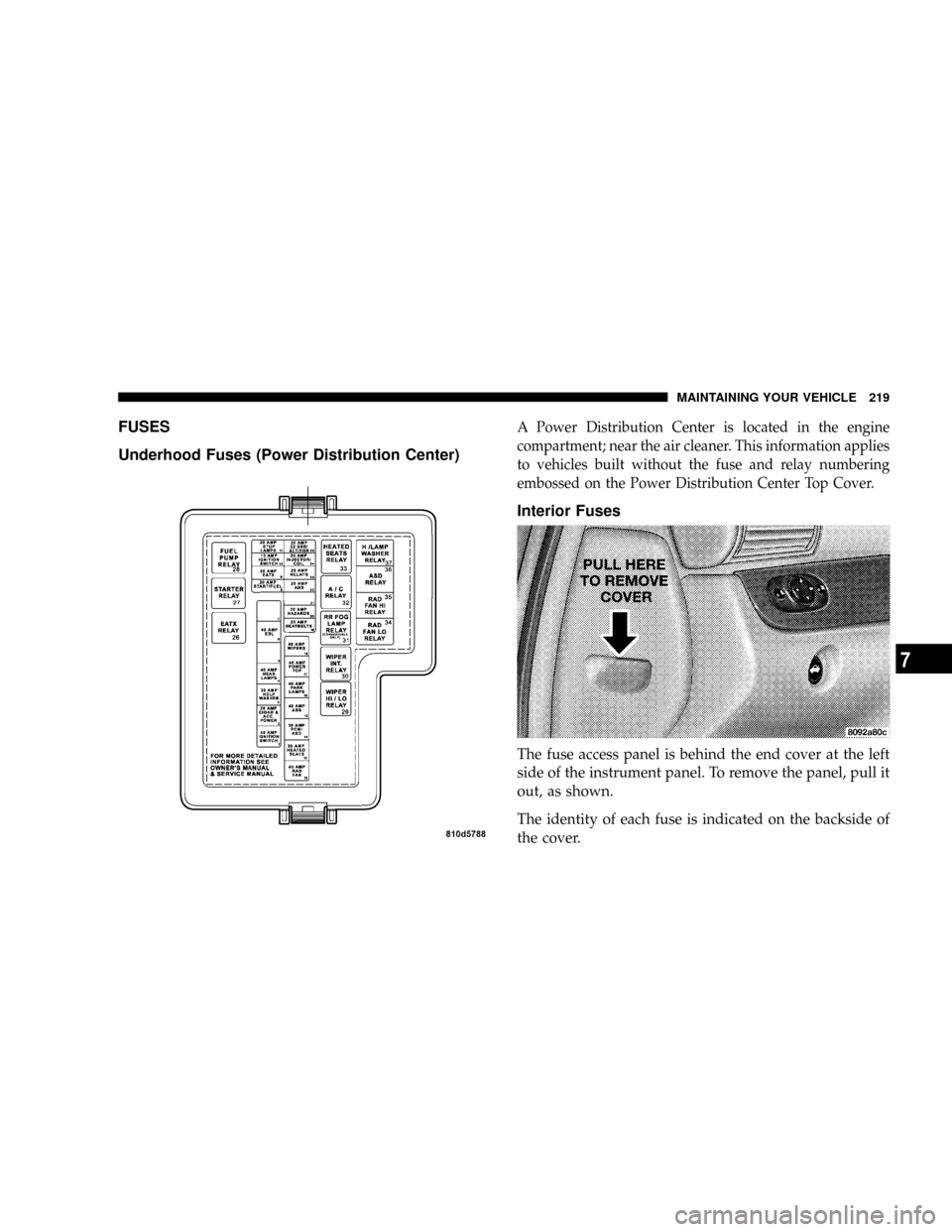

FUSES

Underhood Fuses (Power Distribution Center)A Power Distribution Center is located in the engine

compartment; near the air cleaner. This information applies

to vehicles built without the fuse and relay numbering

embossed on the Power Distribution Center Top Cover.

Interior Fuses

The fuse access panel is behind the end cover at the left

side of the instrument panel. To remove the panel, pull it

out, as shown.

The identity of each fuse is indicated on the backside of

the cover.

MAINTAINING YOUR VEHICLE 219

7

Page 227 of 273

License Plate Bulb Replacement

1. Locate both small slots on the outboard side of the

license lamp. Using a small screwdriver, remove the

entire housing.

2. Turn the bulb socket counterclockwise to remove it

from the housing. Pull the bulb out of the socket. Replace

the bulb and snap it back into place on the housing of the

chrome appliqu×.

Headlight Aiming

The headlights on your new vehicle were aimed at the

factory. The factory setting was made at a no load setting.

A great increase in weight will change the aiming and it

may be necessary to readjust the headlights if carrying an

excessive amount of weight in the trunk, rear seats or

pulling a trailer. To readjust the headlights first mark the

position of the headlights on a wall prior to loading the

vehicle. Load the vehicle and then readjust the headlights

to the original position. If any further adjustments are

necessary contact your manufacturer's dealer. A detailed

service procedure is contained in the manufacturer's

Service Manual. Information on purchasing a Service

Manual can be found at the back of this Owner's Manual.

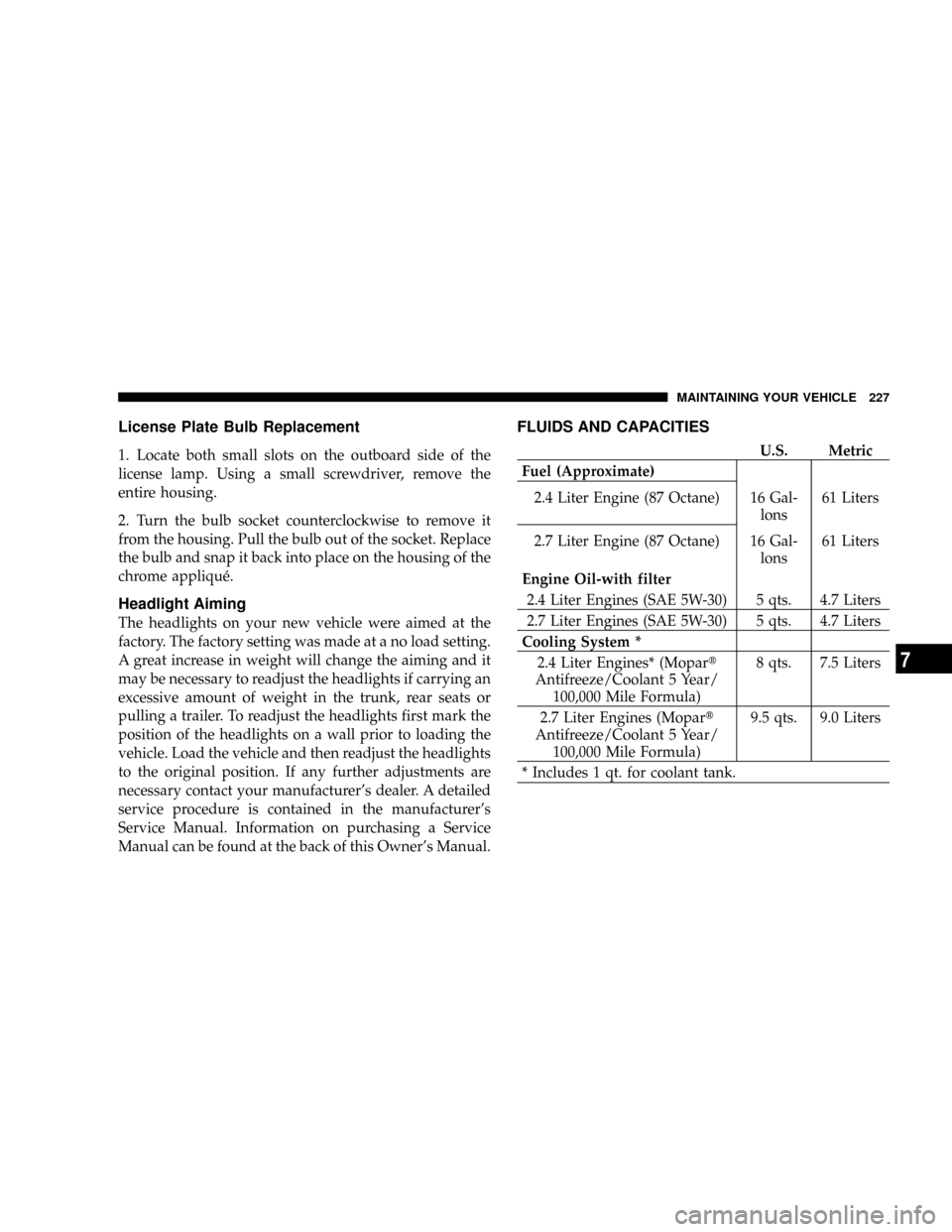

FLUIDS AND CAPACITIES

U.S. Metric

Fuel (Approximate)

2.4 Liter Engine (87 Octane) 16 Gal-

lons61 Liters

2.7 Liter Engine (87 Octane) 16 Gal-

lons61 Liters

Engine Oil-with filter

2.4 Liter Engines (SAE 5W-30) 5 qts. 4.7 Liters

2.7 Liter Engines (SAE 5W-30) 5 qts. 4.7 Liters

Cooling System *

2.4 Liter Engines* (Mopart

Antifreeze/Coolant 5 Year/

100,000 Mile Formula)8 qts. 7.5 Liters

2.7 Liter Engines (Mopart

Antifreeze/Coolant 5 Year/

100,000 Mile Formula)9.5 qts. 9.0 Liters

* Includes 1 qt. for coolant tank.

MAINTAINING YOUR VEHICLE 227

7

Page 228 of 273

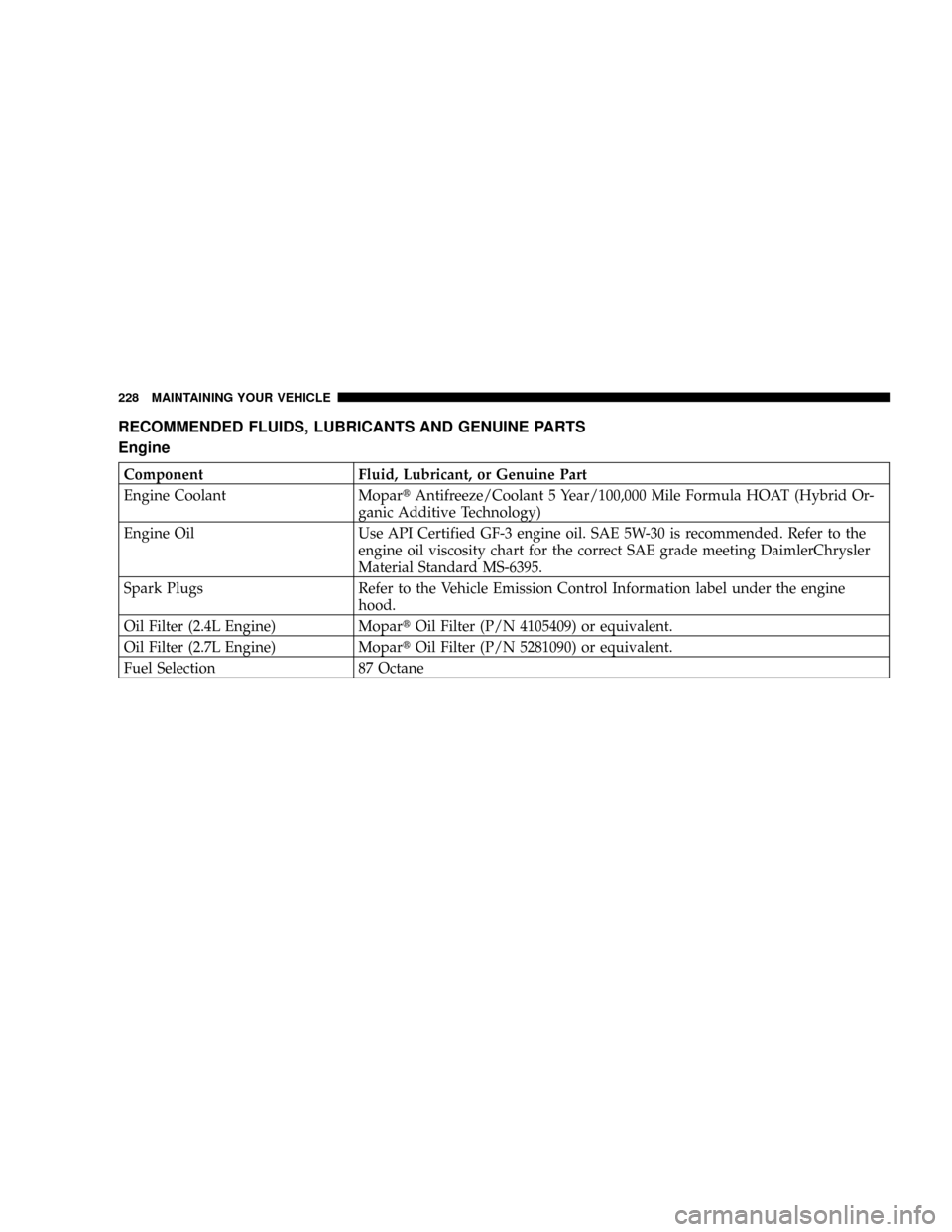

RECOMMENDED FLUIDS, LUBRICANTS AND GENUINE PARTS

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant MopartAntifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or-

ganic Additive Technology)

Engine Oil Use API Certified GF-3 engine oil. SAE 5W-30 is recommended. Refer to the

engine oil viscosity chart for the correct SAE grade meeting DaimlerChrysler

Material Standard MS-6395.

Spark Plugs Refer to the Vehicle Emission Control Information label under the engine

hood.

Oil Filter (2.4L Engine) MopartOil Filter (P/N 4105409) or equivalent.

Oil Filter (2.7L Engine) MopartOil Filter (P/N 5281090) or equivalent.

Fuel Selection 87 Octane

228 MAINTAINING YOUR VEHICLE

Page 233 of 273

NOTE:There are specific instructions regarding when

to change the ignition cables and spark plugs with the

PZEV package in this section. This applies to both

maintenance schedule A and B and will be marked with

an ** or ***.

MAINTENANCE SCHEDULES

There are two maintenance schedules that show the

requiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are operated

under the conditions that are listed below and at the

beginning of the schedule.

²Day or night temperatures are below 32É F (0É C).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16 km).

²More than 50% of your driving is at sustained high

speeds during hot weather, above 90É F (32É C).

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

²If equipped for and operating with E-85 (ethanol)

fuel.

NOTE:IfANYof these apply to you then change your

engine oil every 3,000 miles (5,000 km) or 3 months,

whichever comes first and follow schedule B of the

ªMaintenance Schedulesº section of this manual.

NOTE:Most vehicles are operated under the conditions

listed for Schedule9B9.

Second is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under Sched-

ule9B9.

MAINTENANCE SCHEDULES 233

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 234 of 273

Use the schedule that best describes your driving condi-

tions. Where time and mileage are listed, follow the

interval that occurs first.

NOTE:Under no circumstances should oil change

intervals exceed 6 months or 6,000 miles, whichever

comes first.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²

Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

234 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 235 of 273

Once a Month

²

Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, and transaxle and add as needed.

²Check all lights and all other electrical items for correct

operation.

²Check rubber seals on each side of the radiator for

proper fit.

At Each Oil Change

²

Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake linings, hoses and calipers.

²Inspect the CV joints and front and rear suspension

components.

²Check the automatic transmission fluid level.

²Check the brake master cylinder fluid level.

²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Rotate the tires at each oil change interval shown on

Schedule ªAº 6,000 miles (10 000 km) or every other

interval shown on Schedule ªBº 6,000 miles (10 000

km).

NOTE:In 2.7L Engines equipped with Flex Fuel Engine

(FFV), change engine oil every 5 months or 5,000 miles,

whichever comes first. This applies to both Maintenance

Schedule A and B.

MAINTENANCE SCHEDULES 235

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 236 of 273

SCHEDULE ªBº

Follow schedule ªBº if you usually operate your vehicle

under one or more of the following conditions. Change

the automatic transmission fluid and filter every 60,000

miles (96 000 km) if the vehicle is usually operated under

one or more of the conditions marked with anL.

²Day or night temperatures are below 32É F (0É C).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16.2 km).

²More than 50% of your driving is at sustained high

speeds during hot weather, above 90É F (32É C).

²Trailer towing.L

²Taxi, police or delivery service (commercial ser-

vices).L

²Off-road or desert operation.

²If equipped for and operating with E-85 (ethanol)

fuel.

NOTE:IfANYof these apply to you then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule ªBº of the

9Maintenance Schedules9section of this manual.

236 SCHEDULE ªBº

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S