steering CHRYSLER SEBRING CONVERTIBLE 2004 2.G Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: SEBRING CONVERTIBLE, Model: CHRYSLER SEBRING CONVERTIBLE 2004 2.GPages: 271, PDF Size: 5.31 MB

Page 187 of 271

MAINTAINING YOUR VEHICLE

CONTENTS

m2.4L Engine..........................189

m2.7L Engine..........................190

mOnboard Diagnostic System Ð OBD II......191

mEmissions Inspection And Maintenance

Programs

............................192

mReplacement Parts.....................193

mDealer Service........................193

mMaintenance Procedures.................194

NEngine Oil..........................194

NCrankcase Emission Control System........200

NMaintenance-Free Battery................200

NAir Conditioner......................201NPower Steering Fluid Check..............202

NSuspension Ball Joints..................203

NBody Mechanism Lubrication.............203

NWindshield Wiper Blades................205

NWindshield Washers...................205

NExhaust System......................206

NCooling System.......................207

NHoses And Vacuum/Vapor Harnesses.......211

NBrakes.............................211

NFuel System Hoses....................213

NAutomatic Transmission................213

7

Page 200 of 271

²Do not idle the engine with any spark plug wires

disconnected for prolonged period.

Engine Timing Belt

Replace the engine timing belt (2.4L Only) at the intervals

described in the appropriate maintenance schedule.

Crankcase Emission Control System

Proper operation of this system depends on freedom

from sticking or plugging due to deposits. As vehicle

mileage builds up, the Positive Crankshaft Ventilation

(PCV) valve and passages may accumulate deposits. If a

valve is not working properly, replace it with a new

valve. DO NOT ATTEMPT TO CLEAN THE OLD PCV

VALVE!

Check ventilation hose for indication of damage or

plugging deposits. Replace if necessary.

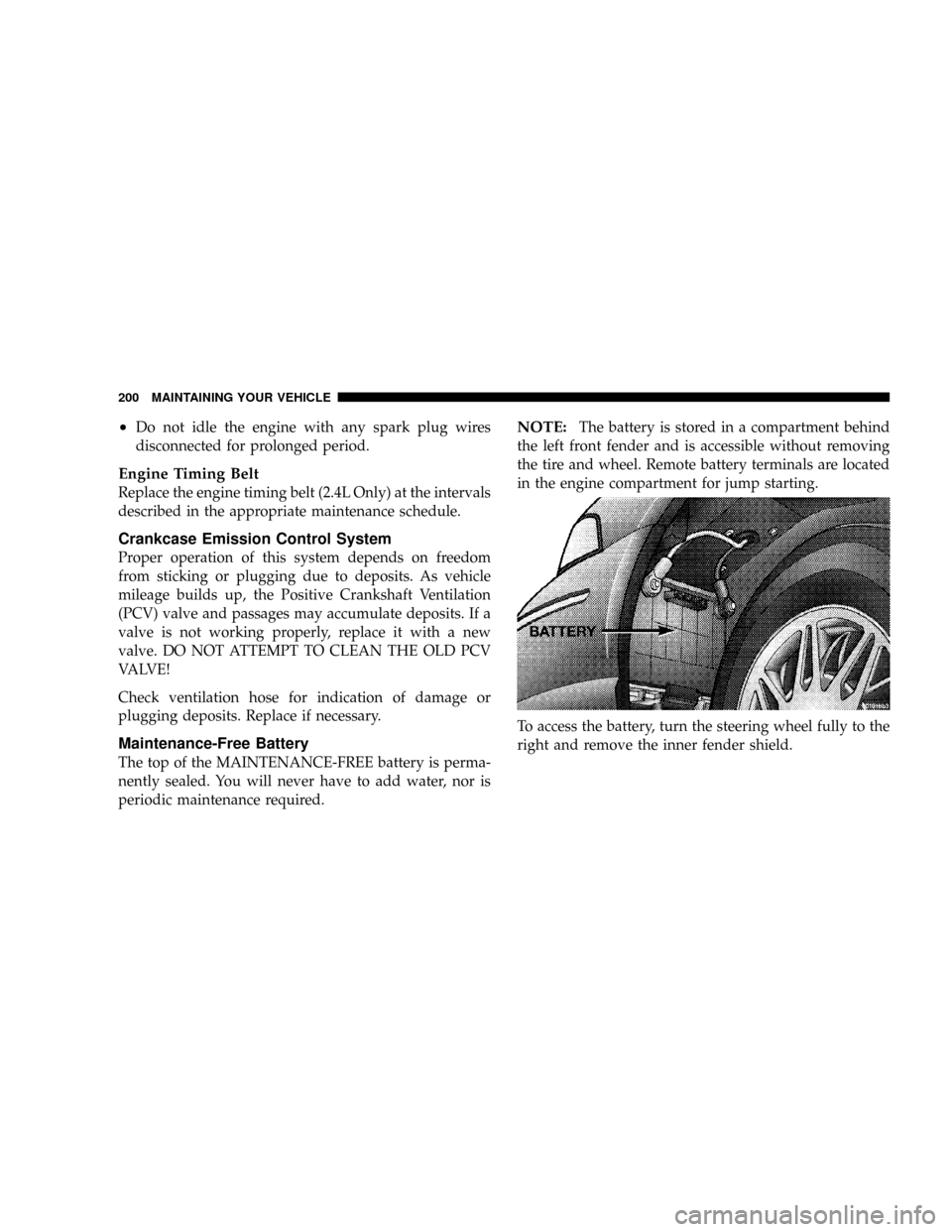

Maintenance-Free Battery

The top of the MAINTENANCE-FREE battery is perma-

nently sealed. You will never have to add water, nor is

periodic maintenance required.

NOTE:The battery is stored in a compartment behind

the left front fender and is accessible without removing

the tire and wheel. Remote battery terminals are located

in the engine compartment for jump starting.

To access the battery, turn the steering wheel fully to the

right and remove the inner fender shield.

200 MAINTAINING YOUR VEHICLE

Page 202 of 271

through the condenser as required. Fabric front fascia

protectors may reduce air flow to the condenser, reducing

air conditioning performance.

WARNING!

The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal injury

or damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced repairman.

Refrigerant Recovery and Recycling

The air conditioning system of your vehicle contains

R-134a, a refrigerant that does not deplete the ozone layer

in the upper atmosphere. The manufacturer recommends

that air conditioning service be done by facilities using

refrigerant recycling and recovery equipment that meets

SAE standard J1991.

Power Steering Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

ªDaimlerChrysler Dealershipº.

Before removing the reservoir cap, wipe the outside of

the cap and reservoir so that no dirt can fall into the

reservoir.

WARNING!

Fluid level should be checked on a level surface with

the engine off to prevent injury from moving parts,

and to insure accurate fluid level reading. Do not

overfill. Use only manufacturer's recommended

fluid.

202 MAINTAINING YOUR VEHICLE

Page 211 of 271

ONLY the correct type thermostat. Other designs may

result in unsatisfactory cooling performance, poor gas

mileage, and increased emissions.

Hoses and Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, checking, tears, cuts, abrasions,

and excessive swelling indicate deterioration of the rub-

ber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed. Inspect all hose connections such as clamps

and couplings to make sure they are secure and no leaks

are present. Components should be replaced immedi-

ately if there is any evidence of degradation that could

cause failure.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in section 8.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You may not have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasion, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

MAINTAINING YOUR VEHICLE 211

7

Page 212 of 271

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

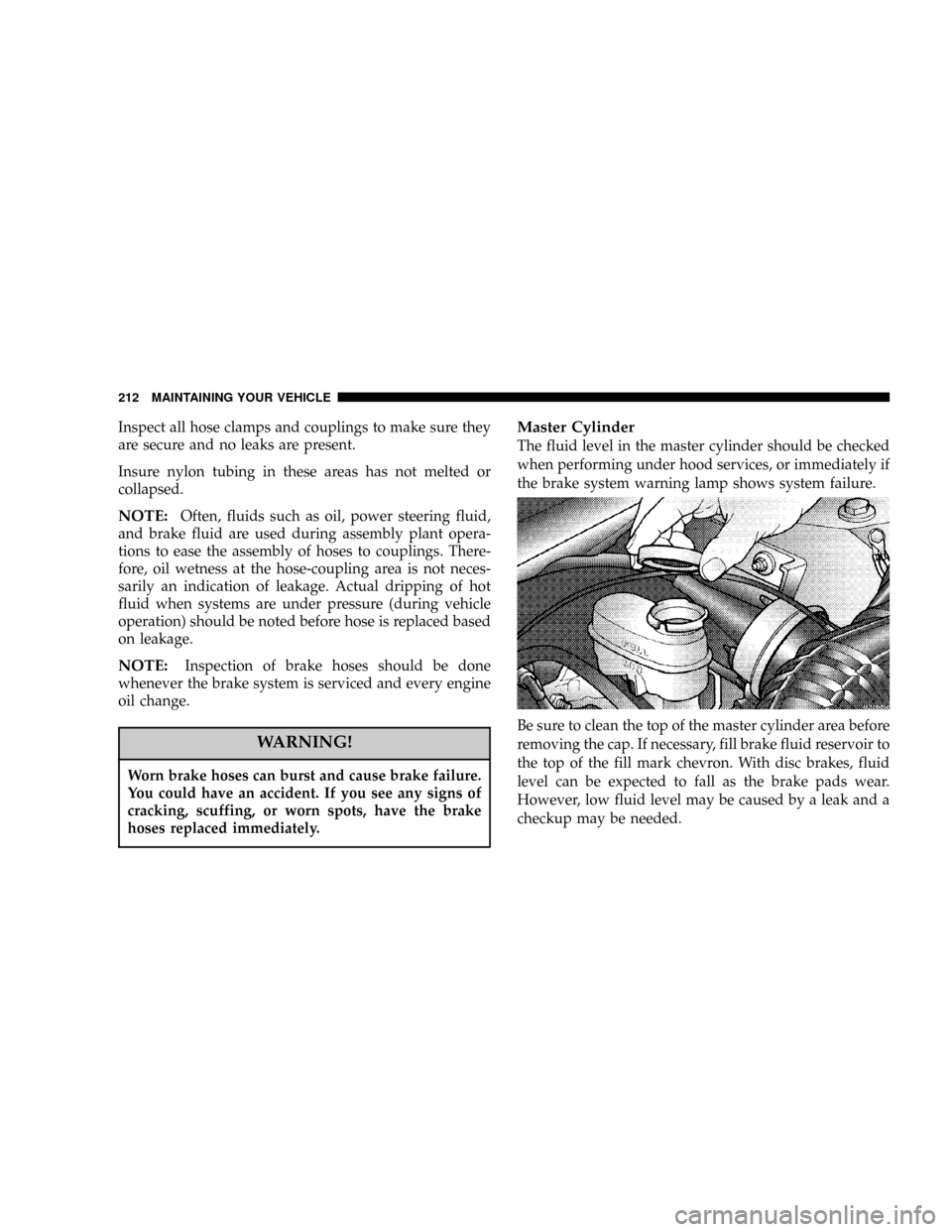

Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp shows system failure.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, fill brake fluid reservoir to

the top of the fill mark chevron. With disc brakes, fluid

level can be expected to fall as the brake pads wear.

However, low fluid level may be caused by a leak and a

checkup may be needed.

212 MAINTAINING YOUR VEHICLE

Page 233 of 271

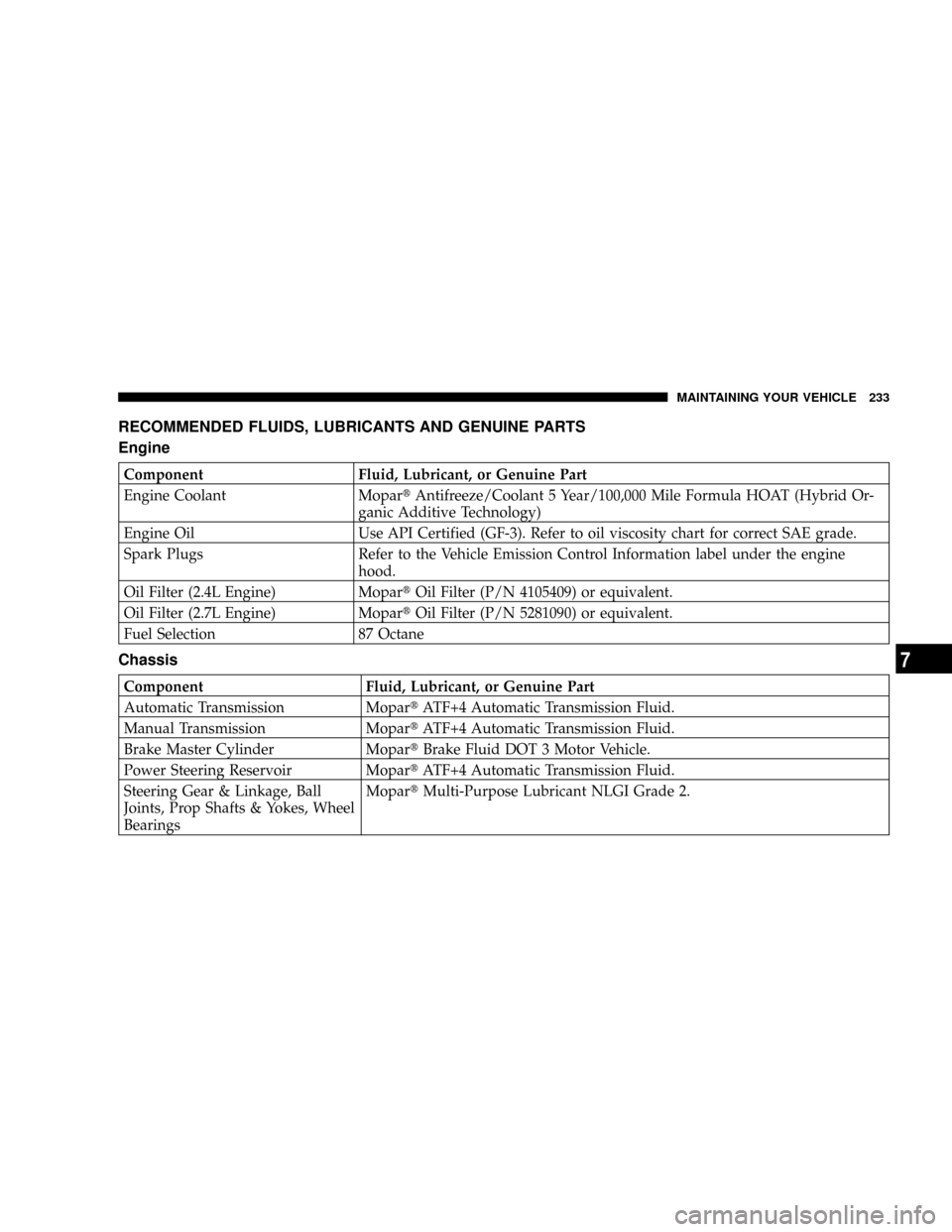

RECOMMENDED FLUIDS, LUBRICANTS AND GENUINE PARTS

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant MopartAntifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or-

ganic Additive Technology)

Engine Oil Use API Certified (GF-3). Refer to oil viscosity chart for correct SAE grade.

Spark Plugs Refer to the Vehicle Emission Control Information label under the engine

hood.

Oil Filter (2.4L Engine) MopartOil Filter (P/N 4105409) or equivalent.

Oil Filter (2.7L Engine) MopartOil Filter (P/N 5281090) or equivalent.

Fuel Selection 87 Octane

Chassis

Component Fluid, Lubricant, or Genuine Part

Automatic Transmission MopartATF+4 Automatic Transmission Fluid.

Manual Transmission MopartATF+4 Automatic Transmission Fluid.

Brake Master Cylinder MopartBrake Fluid DOT 3 Motor Vehicle.

Power Steering Reservoir MopartATF+4 Automatic Transmission Fluid.

Steering Gear & Linkage, Ball

Joints, Prop Shafts & Yokes, Wheel

BearingsMopartMulti-Purpose Lubricant NLGI Grade 2.

MAINTAINING YOUR VEHICLE 233

7

Page 241 of 271

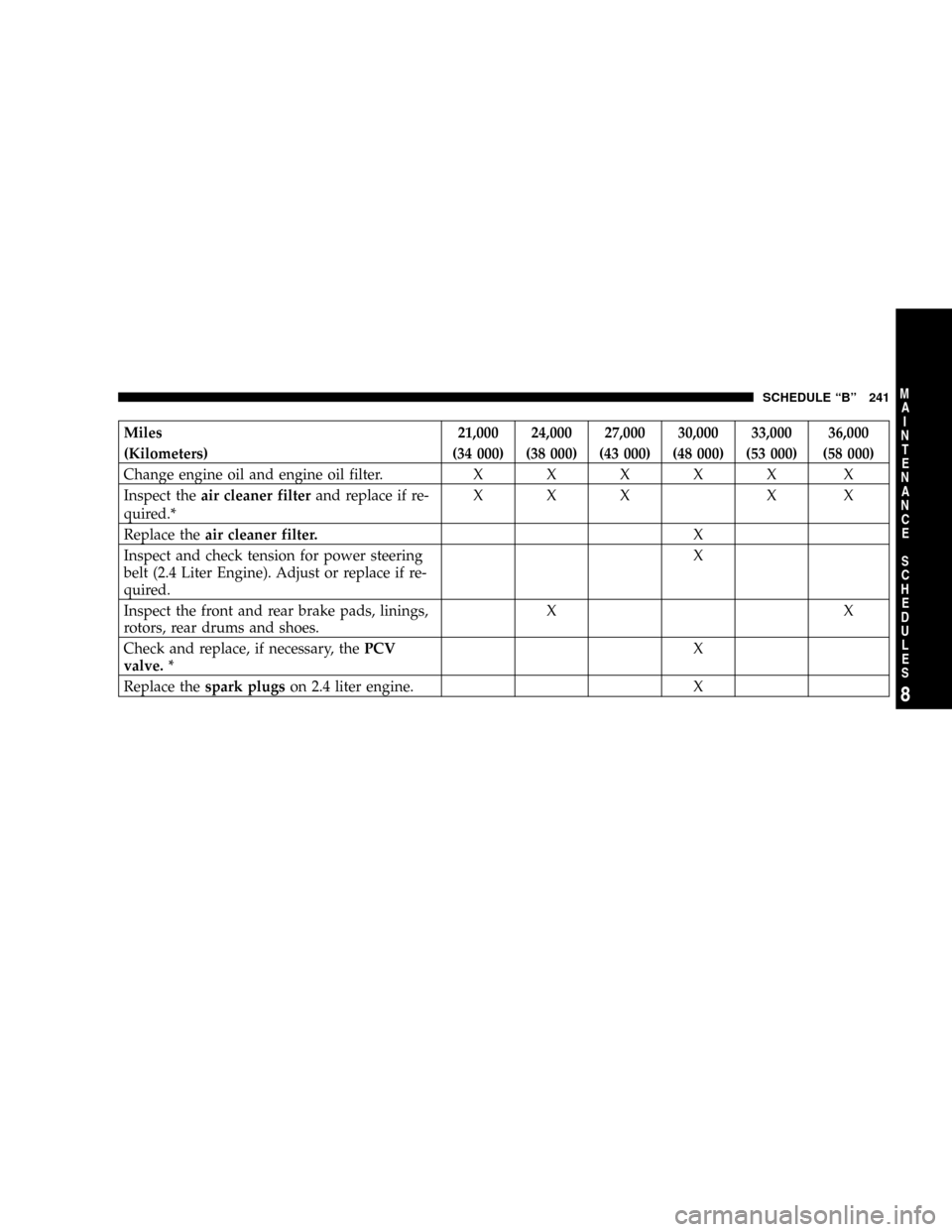

Miles 21,000 24,000 27,000 30,000 33,000 36,000

(Kilometers) (34 000) (38 000) (43 000) (48 000) (53 000) (58 000)

Change engine oil and engine oil filter.XXXXX X

Inspect theair cleaner filterand replace if re-

quired.*XXX X X

Replace theair cleaner filter.X

Inspect and check tension for power steering

belt (2.4 Liter Engine). Adjust or replace if re-

quired.X

Inspect the front and rear brake pads, linings,

rotors, rear drums and shoes.XX

Check and replace, if necessary, thePCV

valve.*X

Replace thespark plugson 2.4 liter engine. X

SCHEDULE ªBº 241

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 243 of 271

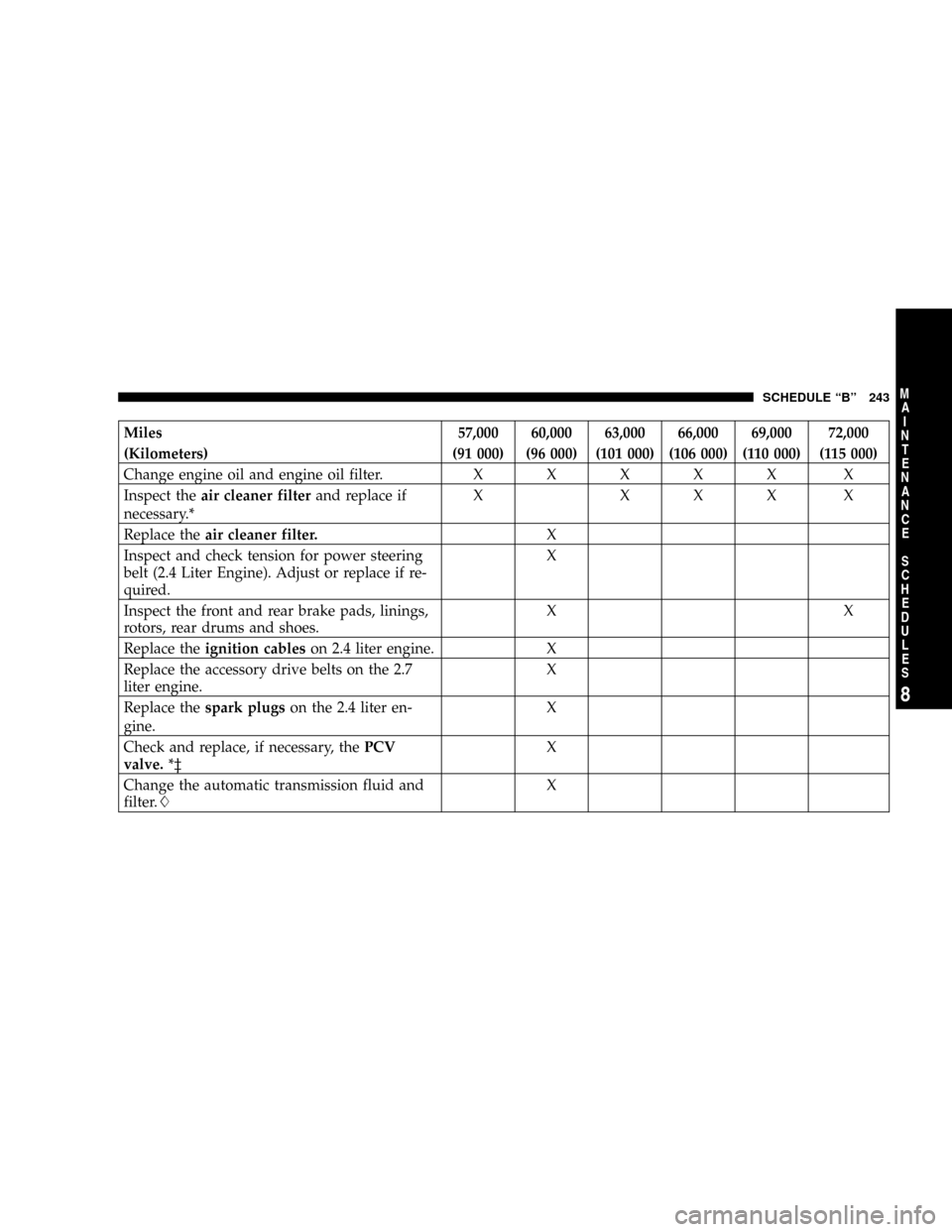

Miles 57,000 60,000 63,000 66,000 69,000 72,000

(Kilometers) (91 000) (96 000) (101 000) (106 000) (110 000) (115 000)

Change engine oil and engine oil filter.XXXXX X

Inspect theair cleaner filterand replace if

necessary.*X XXX X

Replace theair cleaner filter.X

Inspect and check tension for power steering

belt (2.4 Liter Engine). Adjust or replace if re-

quired.X

Inspect the front and rear brake pads, linings,

rotors, rear drums and shoes.XX

Replace theignition cableson 2.4 liter engine. X

Replace the accessory drive belts on the 2.7

liter engine.X

Replace thespark plugson the 2.4 liter en-

gine.X

Check and replace, if necessary, thePCV

valve.*³X

Change the automatic transmission fluid and

filter.LX

SCHEDULE ªBº 243

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 244 of 271

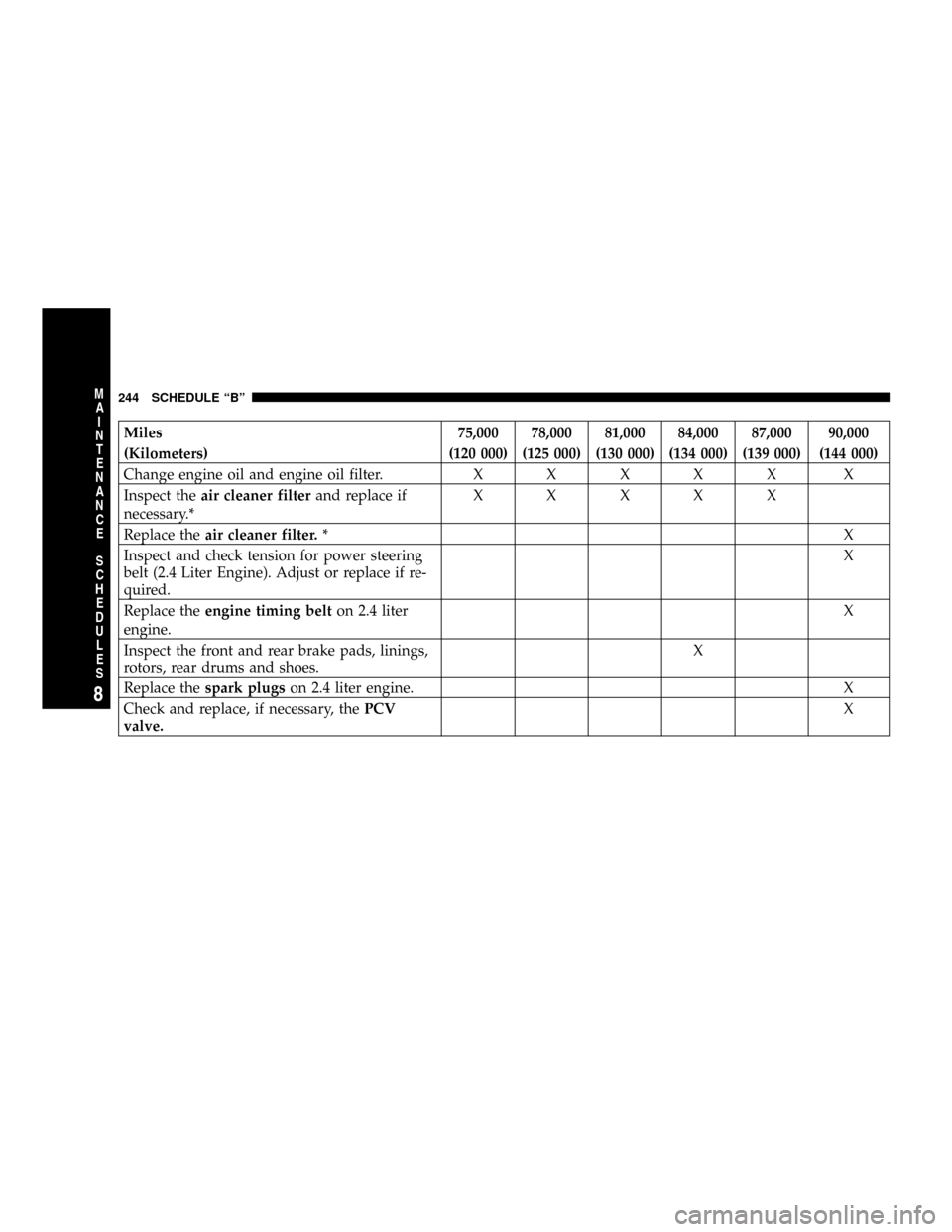

Miles 75,000 78,000 81,000 84,000 87,000 90,000

(Kilometers) (120 000) (125 000) (130 000) (134 000) (139 000) (144 000)

Change engine oil and engine oil filter.XXXXX X

Inspect theair cleaner filterand replace if

necessary.*XXXXX

Replace theair cleaner filter.*X

Inspect and check tension for power steering

belt (2.4 Liter Engine). Adjust or replace if re-

quired.X

Replace theengine timing belton 2.4 liter

engine.X

Inspect the front and rear brake pads, linings,

rotors, rear drums and shoes.X

Replace thespark plugson 2.4 liter engine. X

Check and replace, if necessary, thePCV

valve.X

244 SCHEDULE ªBº

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 247 of 271

![CHRYSLER SEBRING CONVERTIBLE 2004 2.G Owners Manual Miles 42,000 48,000 54,000 60,000 66,000 72,000

(Kilometers) (67 000) (77 000) (86 000) (96 000) (106 000) (115 000)

[Months] [42] [48] [54] [60] [66] [72]

Change engine oil and engine oil filter. X X CHRYSLER SEBRING CONVERTIBLE 2004 2.G Owners Manual Miles 42,000 48,000 54,000 60,000 66,000 72,000

(Kilometers) (67 000) (77 000) (86 000) (96 000) (106 000) (115 000)

[Months] [42] [48] [54] [60] [66] [72]

Change engine oil and engine oil filter. X X](/img/25/8538/w960_8538-246.png)

Miles 42,000 48,000 54,000 60,000 66,000 72,000

(Kilometers) (67 000) (77 000) (86 000) (96 000) (106 000) (115 000)

[Months] [42] [48] [54] [60] [66] [72]

Change engine oil and engine oil filter. X XXXXX

Inspect theair cleaner filterand replace if

required.*XXX XX

Replace theair cleaner filter.*X

Inspect and check tension for power steering

belt (2.4 Liter Engine). Adjust or replace if re-

quired.X

Inspect the front and rear brake pads, linings,

rotors, rear drums and shoes.XX

Replace thespark plugson 2.4 liter engine. X

Flush and replace engine coolant at 60 months

or 100,000 miles.X

Check and replace, if necessary, thePCV

valve.*³X

Replace theignition cableson 2.4 liter en-

gine.X

Replace the accessory drive belts in 2.7 liter

engine.X

SCHEDULE ªAº 247

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S