lock CHRYSLER SEBRING CONVERTIBLE 2004 2.G Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: SEBRING CONVERTIBLE, Model: CHRYSLER SEBRING CONVERTIBLE 2004 2.GPages: 271, PDF Size: 5.31 MB

Page 180 of 271

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

6. Remove lug nuts and tire.

7. Mount spare tire.

8. Tighten all lug nuts on mounting studs.

9. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

10. Fully tighten the lug nuts. Torque wheel lug nuts to

100 ft. lbs. (135 N´m).

11. Store the flat tire, jack, and tools.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

12. Wheel cover installation (if required). Do not attempt

to install a wheel cover on a compact spare. align valve

notch in wheel cover with valve stem on wheel. Snap

cover into place.

NOTE:When reinstalling the center cap it is necessary

to align the center cap notch with the first spoke, just

right of the valve stem.

13. Adjust the tire pressure as soon as possible. Correct

pressure is on the label located on the driver's door.

180 WHAT TO DO IN EMERGENCIES

Page 186 of 271

TOWING THIS VEHICLE BEHIND ANOTHER

VEHICLE (Flat towing with all four wheels on the

ground)

Automatic Transaxle

Your vehicle may be towed under the following condi-

tions: The gear selector must be in NEUTRAL, the

distance to be towed must not exceed 15 miles (25 km),

and the towing speed must not exceed 25 mph (40

km/h). If the transaxle is not operative, or if the vehicle

is to be towed more than 15 miles (25 km), the vehicle

must be towed with the front wheels off the ground.

Manual Transaxle

If your vehicle is equipped with a manual transaxle, it

may be towed at any legal highway speed, for any

distance, if the transaxle is in neutral.

All Transaxles

CAUTION!

If the vehicle being towed requires steering, the

ignition switch must be in the OFF position, not in

the LOCK or ACCESSORY positions.

If it is necessary to use the accessories while being towed

(wipers, defrosters, etc.), the key must be in the ON

position, not the ACCESSORY position. Make certain the

transaxle remains in NEUTRAL.

186 WHAT TO DO IN EMERGENCIES

Page 203 of 271

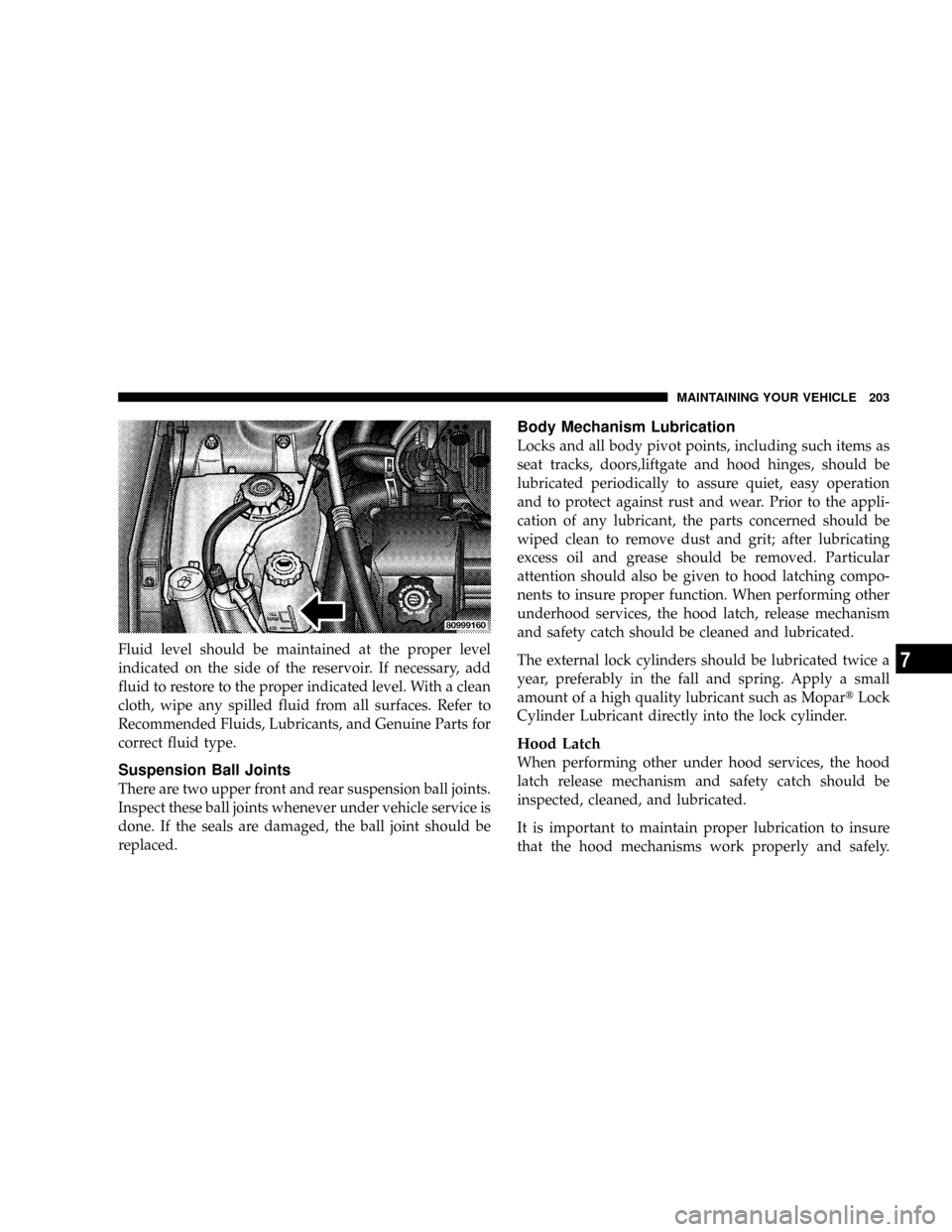

Fluid level should be maintained at the proper level

indicated on the side of the reservoir. If necessary, add

fluid to restore to the proper indicated level. With a clean

cloth, wipe any spilled fluid from all surfaces. Refer to

Recommended Fluids, Lubricants, and Genuine Parts for

correct fluid type.

Suspension Ball Joints

There are two upper front and rear suspension ball joints.

Inspect these ball joints whenever under vehicle service is

done. If the seals are damaged, the ball joint should be

replaced.

Body Mechanism Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors,liftgate and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

Hood Latch

When performing other under hood services, the hood

latch release mechanism and safety catch should be

inspected, cleaned, and lubricated.

It is important to maintain proper lubrication to insure

that the hood mechanisms work properly and safely.

MAINTAINING YOUR VEHICLE 203

7

Page 204 of 271

Multi-Purpose Lubricant, NLGI Grade 2, should be ap-

plied sparingly to all pivot and sliding contact areas.

External Lock Cylinders

Lubricate the external lock cylinders twice a year, prefer-

ably in the fall and spring. Apply a small amount of

lubricant, such as Mopar Lock Cylinder Lubricant di-

rectly into the lock cylinder (avoid excess lubricant).

Insert the key into the lock cylinder and rotate from the

unlocked to the locked position; without adding more

lubricant. Repeat this procedure three or four times. Wipe

all the lubricant off the key with a clean cloth, to avoid

soiling clothing.

If you use a lubricant that cannot be dispensed directly

into the lock cylinder, apply a small amount of the

lubricant to the key. Insert the key into the lock cylinder,

then proceed as described above, to distribute the lubri-

cant within the lock cylinder. Pay attention to trunk

hinges, especially during cold weather, to ensure ease of

trunk operation.

Other Body Mechanisms

The following body mechanisms should be inspected

and, if necessary, all pivot and sliding contact areas of

these components should be lubricated with the lubricant

specified as follows:

Engine Oil

²

Door hinges

²Hood hinges

²Trunk hinges

Smooth White Body Lubricant - Such as Mopar

Spray White Lube:

²

Hood hinge springs and links

²Lock cylinders

²Parking brake mechanism

²Trunk latches

²Ash tray

204 MAINTAINING YOUR VEHICLE

Page 205 of 271

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild non abrasive cleaner. This will remove accumula-

tions of salt or road film.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield. Avoid using the wiper blades to

remove frost or ice from the windshield. Keep the blade

rubber out of contact with petroleum products such as

engine oil, gasoline, etc.

Windshield Wiper Blade Replacement

²

Lift the wiper arm away from the glass.

²Push the release tab and slide the wiper blade assem-

bly away from the wiper arm. Gently place the wiper

arm on the windshield.

²Install the new blade assembly onto the wiper arm tip

until it locks in place.

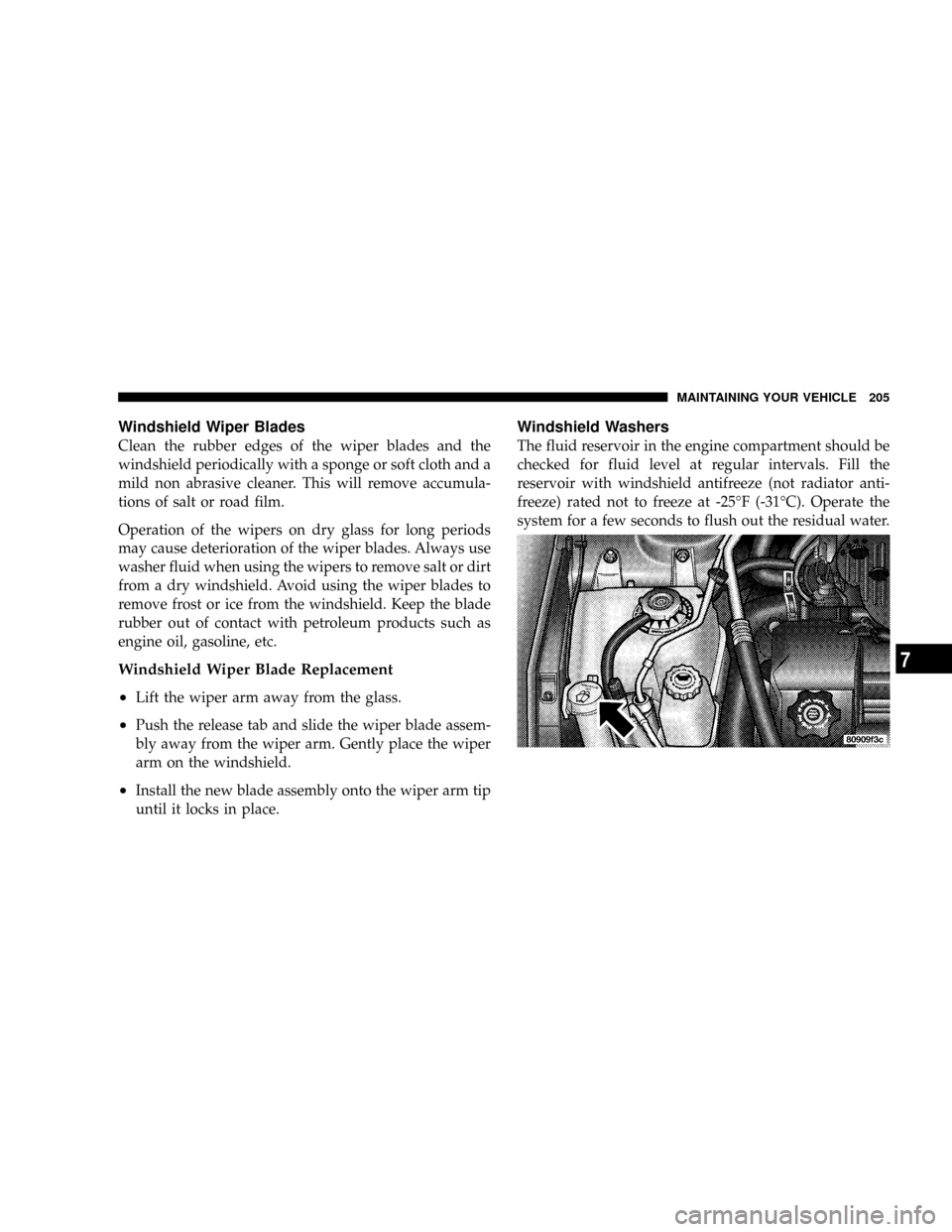

Windshield Washers

The fluid reservoir in the engine compartment should be

checked for fluid level at regular intervals. Fill the

reservoir with windshield antifreeze (not radiator anti-

freeze) rated not to freeze at -25ÉF (-31ÉC). Operate the

system for a few seconds to flush out the residual water.

MAINTAINING YOUR VEHICLE 205

7

Page 224 of 271

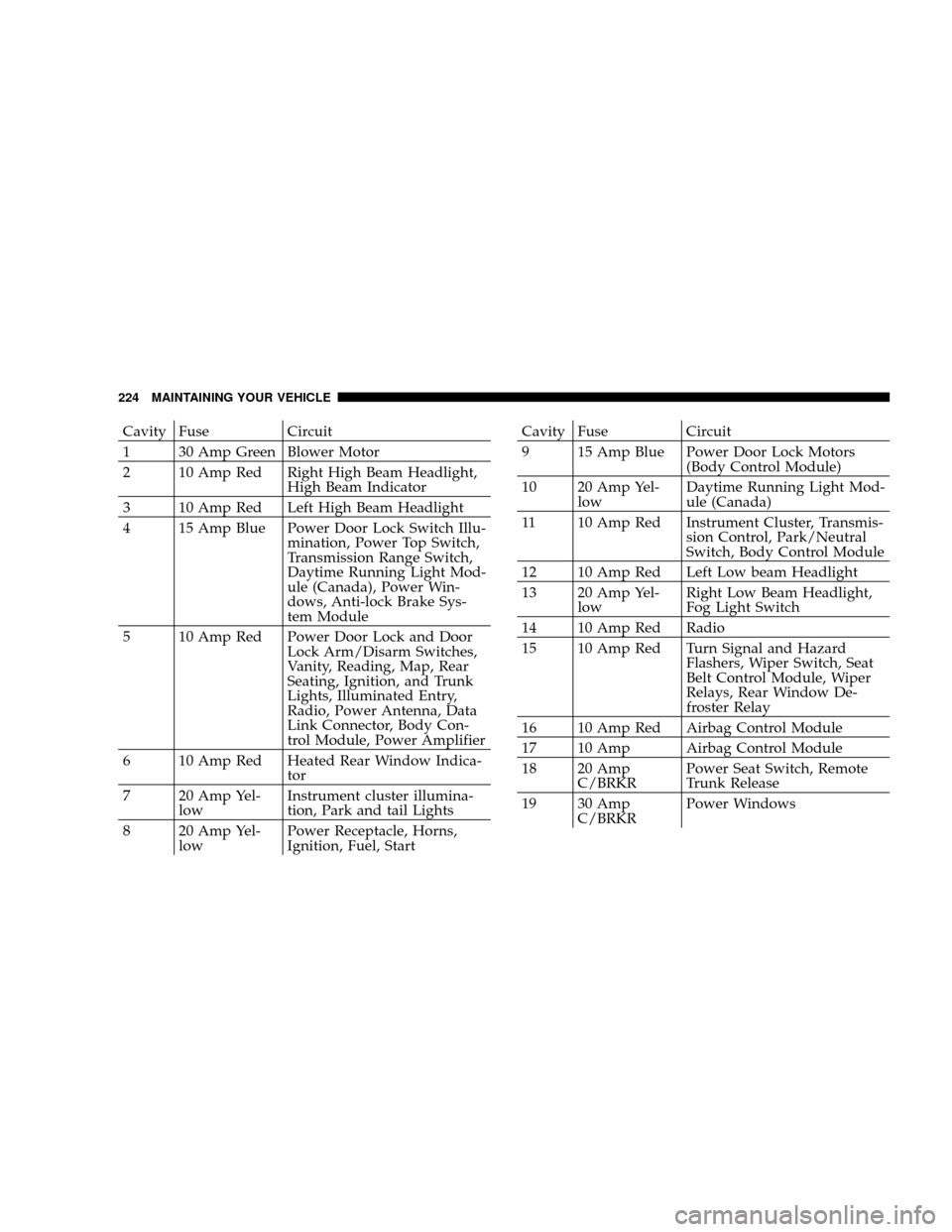

Cavity Fuse Circuit

1 30 Amp Green Blower Motor

2 10 Amp Red Right High Beam Headlight,

High Beam Indicator

3 10 Amp Red Left High Beam Headlight

4 15 Amp Blue Power Door Lock Switch Illu-

mination, Power Top Switch,

Transmission Range Switch,

Daytime Running Light Mod-

ule (Canada), Power Win-

dows, Anti-lock Brake Sys-

tem Module

5 10 Amp Red Power Door Lock and Door

Lock Arm/Disarm Switches,

Vanity, Reading, Map, Rear

Seating, Ignition, and Trunk

Lights, Illuminated Entry,

Radio, Power Antenna, Data

Link Connector, Body Con-

trol Module, Power Amplifier

6 10 Amp Red Heated Rear Window Indica-

tor

7 20 Amp Yel-

lowInstrument cluster illumina-

tion, Park and tail Lights

8 20 Amp Yel-

lowPower Receptacle, Horns,

Ignition, Fuel, StartCavity Fuse Circuit

9 15 Amp Blue Power Door Lock Motors

(Body Control Module)

10 20 Amp Yel-

lowDaytime Running Light Mod-

ule (Canada)

11 10 Amp Red Instrument Cluster, Transmis-

sion Control, Park/Neutral

Switch, Body Control Module

12 10 Amp Red Left Low beam Headlight

13 20 Amp Yel-

lowRight Low Beam Headlight,

Fog Light Switch

14 10 Amp Red Radio

15 10 Amp Red Turn Signal and Hazard

Flashers, Wiper Switch, Seat

Belt Control Module, Wiper

Relays, Rear Window De-

froster Relay

16 10 Amp Red Airbag Control Module

17 10 Amp Airbag Control Module

18 20 Amp

C/BRKRPower Seat Switch, Remote

Trunk Release

19 30 Amp

C/BRKRPower Windows

224 MAINTAINING YOUR VEHICLE

Page 227 of 271

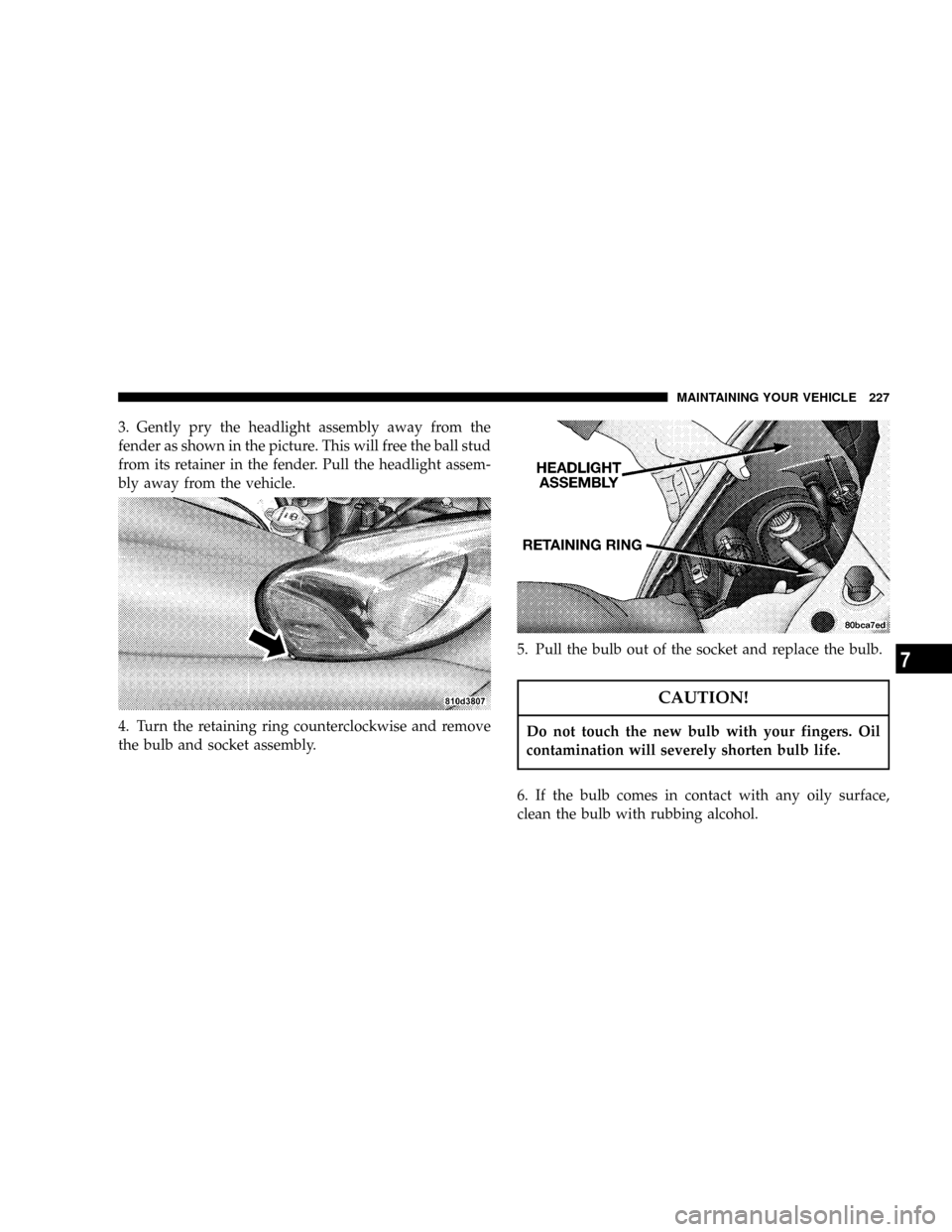

3. Gently pry the headlight assembly away from the

fender as shown in the picture. This will free the ball stud

from its retainer in the fender. Pull the headlight assem-

bly away from the vehicle.

4. Turn the retaining ring counterclockwise and remove

the bulb and socket assembly.5. Pull the bulb out of the socket and replace the bulb.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life.

6. If the bulb comes in contact with any oily surface,

clean the bulb with rubbing alcohol.

MAINTAINING YOUR VEHICLE 227

7

Page 228 of 271

7. Reinsert the bulb and socket assembly and turn the

retaining ring clockwise to secure the bulb.

8. Reinstall the headlight assembly.

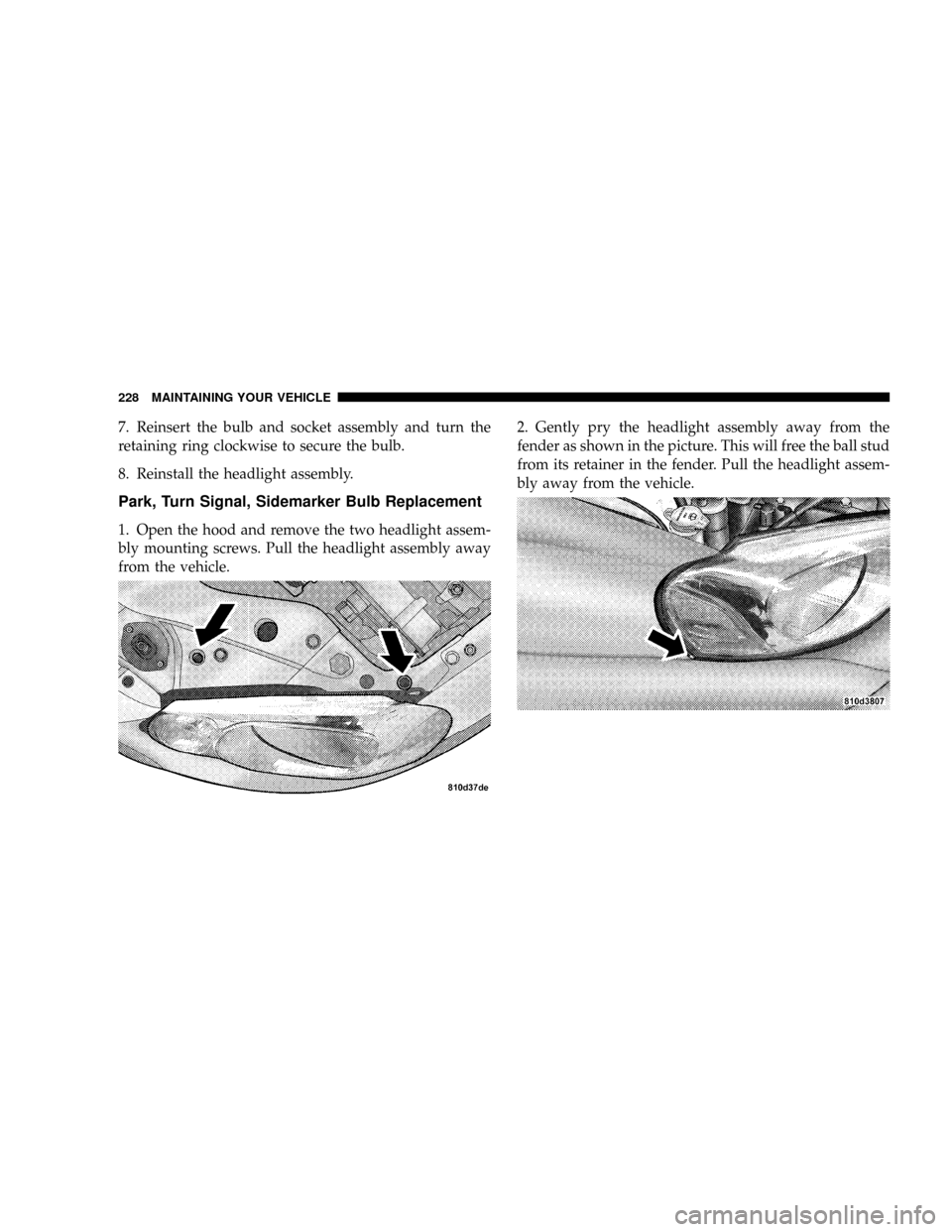

Park, Turn Signal, Sidemarker Bulb Replacement

1. Open the hood and remove the two headlight assem-

bly mounting screws. Pull the headlight assembly away

from the vehicle.2. Gently pry the headlight assembly away from the

fender as shown in the picture. This will free the ball stud

from its retainer in the fender. Pull the headlight assem-

bly away from the vehicle.

228 MAINTAINING YOUR VEHICLE

Page 229 of 271

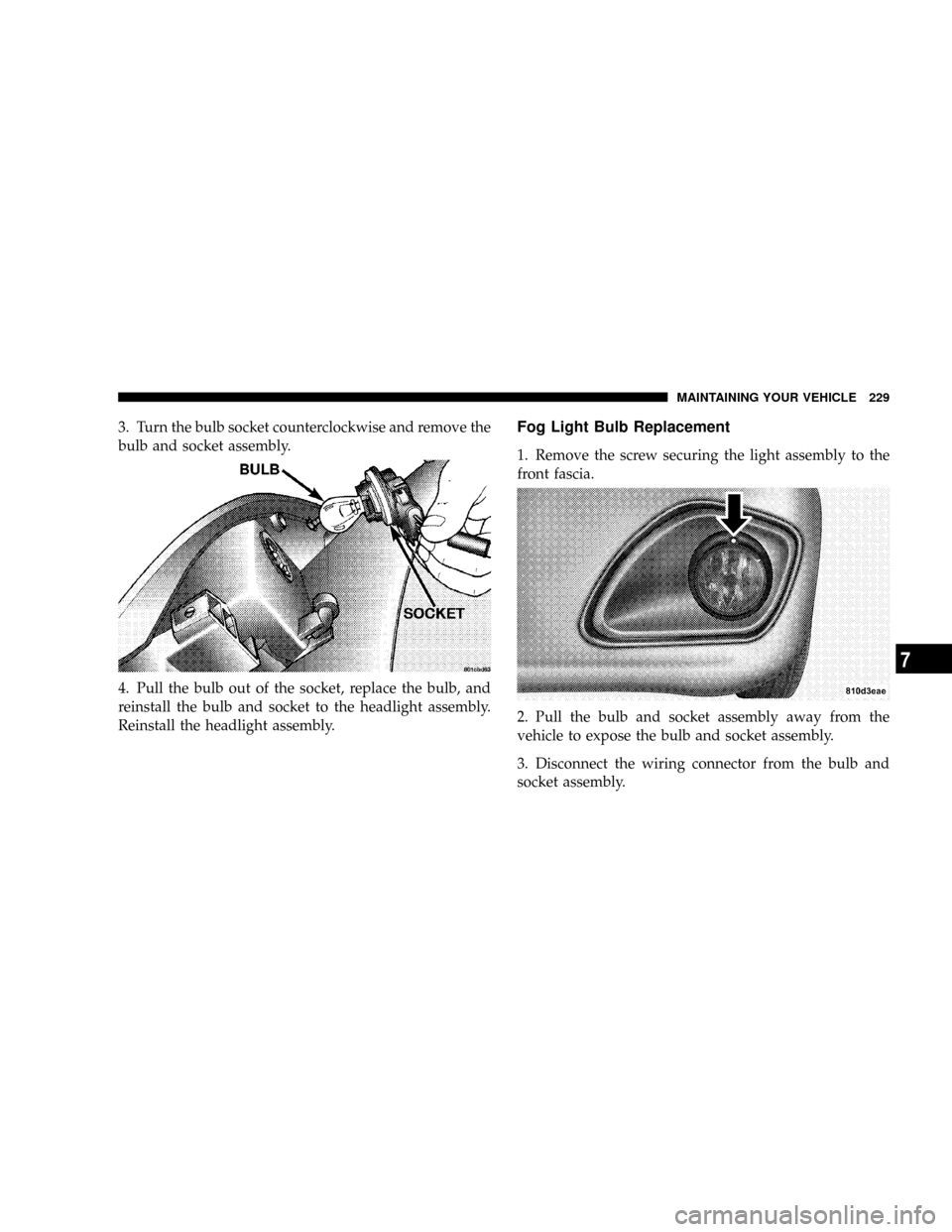

3. Turn the bulb socket counterclockwise and remove the

bulb and socket assembly.

4. Pull the bulb out of the socket, replace the bulb, and

reinstall the bulb and socket to the headlight assembly.

Reinstall the headlight assembly.Fog Light Bulb Replacement

1. Remove the screw securing the light assembly to the

front fascia.

2. Pull the bulb and socket assembly away from the

vehicle to expose the bulb and socket assembly.

3. Disconnect the wiring connector from the bulb and

socket assembly.

MAINTAINING YOUR VEHICLE 229

7

Page 230 of 271

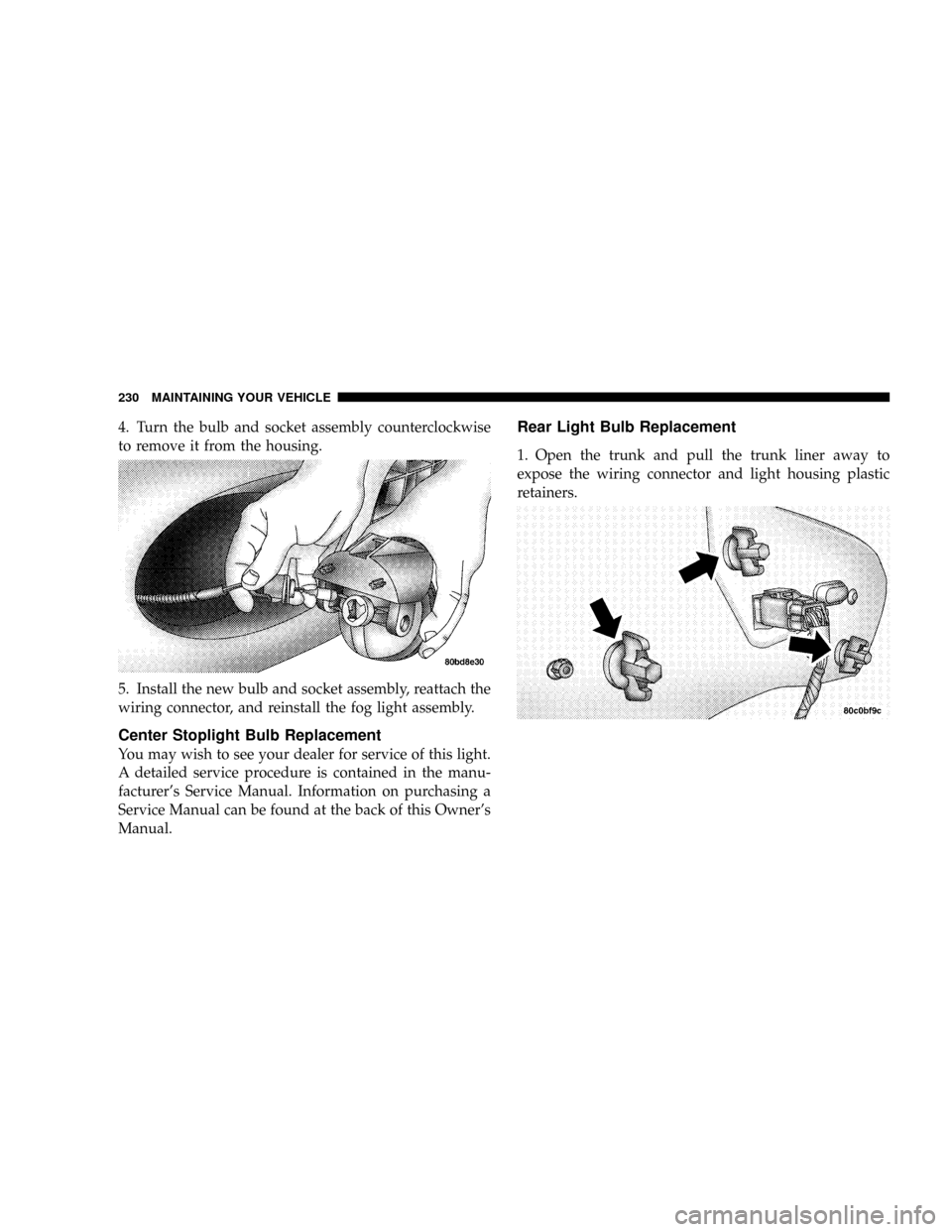

4. Turn the bulb and socket assembly counterclockwise

to remove it from the housing.

5. Install the new bulb and socket assembly, reattach the

wiring connector, and reinstall the fog light assembly.

Center Stoplight Bulb Replacement

You may wish to see your dealer for service of this light.

A detailed service procedure is contained in the manu-

facturer's Service Manual. Information on purchasing a

Service Manual can be found at the back of this Owner's

Manual.

Rear Light Bulb Replacement

1. Open the trunk and pull the trunk liner away to

expose the wiring connector and light housing plastic

retainers.

230 MAINTAINING YOUR VEHICLE