service schedule CHRYSLER SEBRING CONVERTIBLE 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: SEBRING CONVERTIBLE, Model: CHRYSLER SEBRING CONVERTIBLE 2008 3.GPages: 454, PDF Size: 5.8 MB

Page 179 of 454

The two trip odometers show individual trip mileage. To

switch from odometer to trip odometers, press and

release the Trip Odometer button. To reset a trip odom-

eter, display the desired trip odometer to be reset then

push and hold the button until the display resets (ap-

proximately 2 seconds). Refer to ªTrip Odometer Buttonº

for additional information.

Vehicle Warning Messages

When the appropriate conditions exist, ªDOOR AJAR,º

ªTRUNK AJAR,º or ªgASCAPº will display in the odom-

eter.

NOTE:If the instrument cluster is equipped with the

optional Electronic Vehicle Information Center (EVIC),

then all warnings including ªDOOR AJARº and

ªTRUNK AJARº will only display in the EVIC. (Refer to

ªElectronic Vehicle Information Center (EVIC)º in this

section for specific messages).gASCAP

If the vehicle diagnostic system detects a leak or change

in the evaporative system, or the fuel filler cap is loose,

improperly installed, or damaged, the words ªgASCAPº

will display in the odometer. If this occurs, tighten the

fuel filler cap properly and press the odometer reset

button to turn off the ªgASCAPº message. (Refer to

ªOnboard Diagnostic System Ð OBDIIº in Section 7 of

this manual for more information). If the problem con-

tinues, the message will appear the next time the vehicle

is started. See your authorized dealer service center as

soon as possible.

Change Oil

Your vehicle is equipped with an engine oil change

indicator system. The ªChange Oilº message will flash in

the instrument cluster odometer for approximately 12

seconds after a single chime has sounded to indicate the

next scheduled oil change interval. The engine oil change

UNDERSTANDING YOUR INSTRUMENT PANEL 179

4

Page 244 of 454

Window Fogging

Interior fogging on the windshield can be quickly re-

moved by turning the mode selector to Defrost. The

Defrost/Floor mode can be used to maintain a clear

windshield and provide sufficient heating. If side win-

dow fogging becomes a problem, increase blower speed.

Vehicle windows tend to fog on the inside in mild but

rainy or humid weather.

NOTE:Recirculate without A/C should not be used for

long periods as fogging may occur.

Side Window Demisters

A side window demister outlet is located at each end of

the instrument panel. These non-adjustable outlets direct

air toward the side windows when the system is in the

FLOOR, MIX, or DEFROST mode. The air is directed at

the area of the windows through which you view the

outside mirrors.

Outside Air Intake

Make sure the air intake, located directly in front of the

windshield, is free of obstructions such as leaves. Leaves

collected in the air intake may reduce airflow, and if they

enter the plenum, they could plug the water drains. In

winter months, make sure the air intake is clear of ice,

slush, and snow.

A/C Air Filter Ð If Equipped

The A/C Air Filter will reduce, but not eliminate, diesel

and agricultural smells. The filter acts on air coming from

outside the vehicle and recirculated air within the pas-

senger compartment. Refer to ªMaintenance Proceduresº

in Section 7 of this manual for A/C Air Filter service

information or see your authorized dealer for service.

Refer to the ªMaintenance Schedulesº in Section 8 of this

manual for filter service intervals.

244 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 360 of 454

vehicle serviced before going to the I/M station. The I/M

station can fail your vehicle because the MIL symbol is on

with the engine running.

REPLACEMENT PARTS

Use of genuine Mopartparts for normal/scheduled

maintenance and repairs is highly recommended to en-

sure the designed performance. Damage or failures

caused by the use of non-Mopartparts for maintenance

and repairs will not be covered by the manufacturer's

warranty.

DEALER SERVICE

Your authorized dealer has the qualified service person-

nel, special tools, and equipment to perform all service

operations in an expert manner. Service Manuals are

available which include detailed service information for

your vehicle. Refer to these manuals before attempting

any procedure yourself.NOTE:Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent

mechanic.

360 MAINTAINING YOUR VEHICLE

Page 365 of 454

Engine Oil Filter

The engine oil filter should be replaced at every engine

oil change.

Engine Oil Filter Selection

All of this manufacturer's engines have a full-flow type

disposable oil filter. Use a filter of this type for replace-

ment. The quality of replacement filters varies consider-

ably. Only high quality filters should be used to assure

most efficient service. MopartEngine Oil Filters are high

quality oil filters and are recommended.

Drive Belt

At the mileage indicated in section 8: ªMaintenance

Scheduleº, replace the drive belt with a new drive belt.

NOTE:The belt must be routed correctly to ensure

proper drive function.

Spark Plugs

Spark plugs must fire properly to assure engine perfor-

mance and emission control. New plugs should be in-

stalled at the specified mileage. The entire set should be

replaced if there is any malfunction due to a faulty spark

plug. Refer to ªFluids, Lubricants, and Genuine Partsº in

this section for the proper type of spark plug for use in

your vehicle.

Engine Air Cleaner Filter

Refer to the ªMaintenance Scheduleº in Section 8 of this

manual for engine air cleaner filter maintenance inter-

vals.

NOTE:Be sure to follow the ªdusty or off-road condi-

tionsº maintenance interval if applicable.

MAINTAINING YOUR VEHICLE 365

7

Page 370 of 454

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C System

Sealers, Stop Leak Products, Seal Conditioners, Compres-

sor Oil, and Refrigerants.

A/C Air Filter Ð If Equipped

Refer to the ªMaintenance Scheduleº in Section 8 of this

manual for A/C Air Filter service intervals.

WARNING!

Do not remove the A/C Air Filter while the blower is

operating or personal injury may result.The A/C Air Filter is located in the fresh air inlet behind

the glove box. Perform the following procedure to re-

place the filter:

1. Open the glove box and remove all contents.

2. Push in on the sides of the glove box and lower the

door.

3. Disconnect the glove box door dampener from the slot

on the side of the box. This is done by grasping the

dampener connector (on the outside of the box) and the

end of the connector pin (on the inside of the box) with

your thumb and forefinger and pulling outward while

lightly lifting upward on the door with your other hand.

Once disconnected, the dampener will retract under-

neath the instrument panel if you release it.

4. Pivot the glove box downward.

370 MAINTAINING YOUR VEHICLE

Page 381 of 454

Hoses and Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber

Pay particular attention to the hoses nearest to high heat

sources such as the exhaust manifold. Inspect hose rout-

ing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could cause failure.

Fuel System

Electronic Fuel Injection high-pressure fuel systems are

designed with tubes and special connects, connections,

and clamps which have unique material characteristics to

provide adequate sealing and resist attack by deterio-

rated gasoline.

You are urged to use only the manufactures-specified

tubes, connections and clamps, or their equivalent in

material and specification, in any fuel system servicing.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the ªMainte-

nance Scheduleº in this manual.

MAINTAINING YOUR VEHICLE 381

7

Page 382 of 454

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering Hoses

When servicing the vehicle for scheduled maintenance,

inspect the surface of the hoses and nylon tubing for

evidence of heat and mechanical damage. Hard and brittle

rubber, cracking, tears, cuts, abrasions, and excessive swell-

ing suggest deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.

Insure nylon tubing in these areas has not melted or

collapsed.Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:

²Often, fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations

to ease the assembly of hoses to couplings. Therefore,

oil wetness at the hose-coupling area is not necessarily

an indication of leakage. Actual dripping of hot fluid

when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

²Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replaced

immediately! Eventual deterioration of the hose can

take place resulting in a possibility of a burst failure.

382 MAINTAINING YOUR VEHICLE

Page 414 of 454

EMISSION CONTROL SYSTEM MAINTENANCE

The ªScheduledº maintenance services, listed inbold

typemust be done at the times or mileages specified to

assure the continued proper functioning of the emission

control system. These, and all other maintenance services

included in this manual, should be done to provide best

vehicle performance and reliability. More frequent main-

tenance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

Inspection and service also should be done anytime a

malfunction is suspected.

NOTE:Maintenance, replacement, or repair of the emis-

sion control devices and systems on your vehicle may be

performed by any automotive repair establishment or

individual using any automotive part, which has been

certified pursuant to U.S. EPA or, in the State of Califor-

nia, California Air Resources Board regulations.

MAINTENANCE SCHEDULE

The oil change indicator system will remind you that it is

time to take your vehicle in for scheduled maintenance.

On Electronic Vehicle Information Center (EVIC)

equipped vehicles ªOil Change Requiredº will be dis-

played in the EVIC and a single chime will sound,

indicating that an oil change is necessary.

On Non-EVIC equipped vehicles ªChange Oilº will flash

in the instrument cluster odometer and a single chime

will sound, indicating that an oil change is necessary.

Based on engine operation conditions the oil change

indicator message will illuminate, this means that service

is required for your vehicle. Have your vehicle serviced

as soon as possible, within the next 500 miles (805 km).

414 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 416 of 454

Once a Month

²Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering, and automatic trans-

axle, and add fluid as needed.

NOTE:Six speed AutoSticktTransaxle Ð if equipped is

sealed, therefore checking the fluid level can only be

done by a certified dealership service center.

²Check all lights and other electrical items for correct

operation.At Each Oil Change

²Change the engine oil filter.

²Inspect the brake hoses and lines.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

416 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 419 of 454

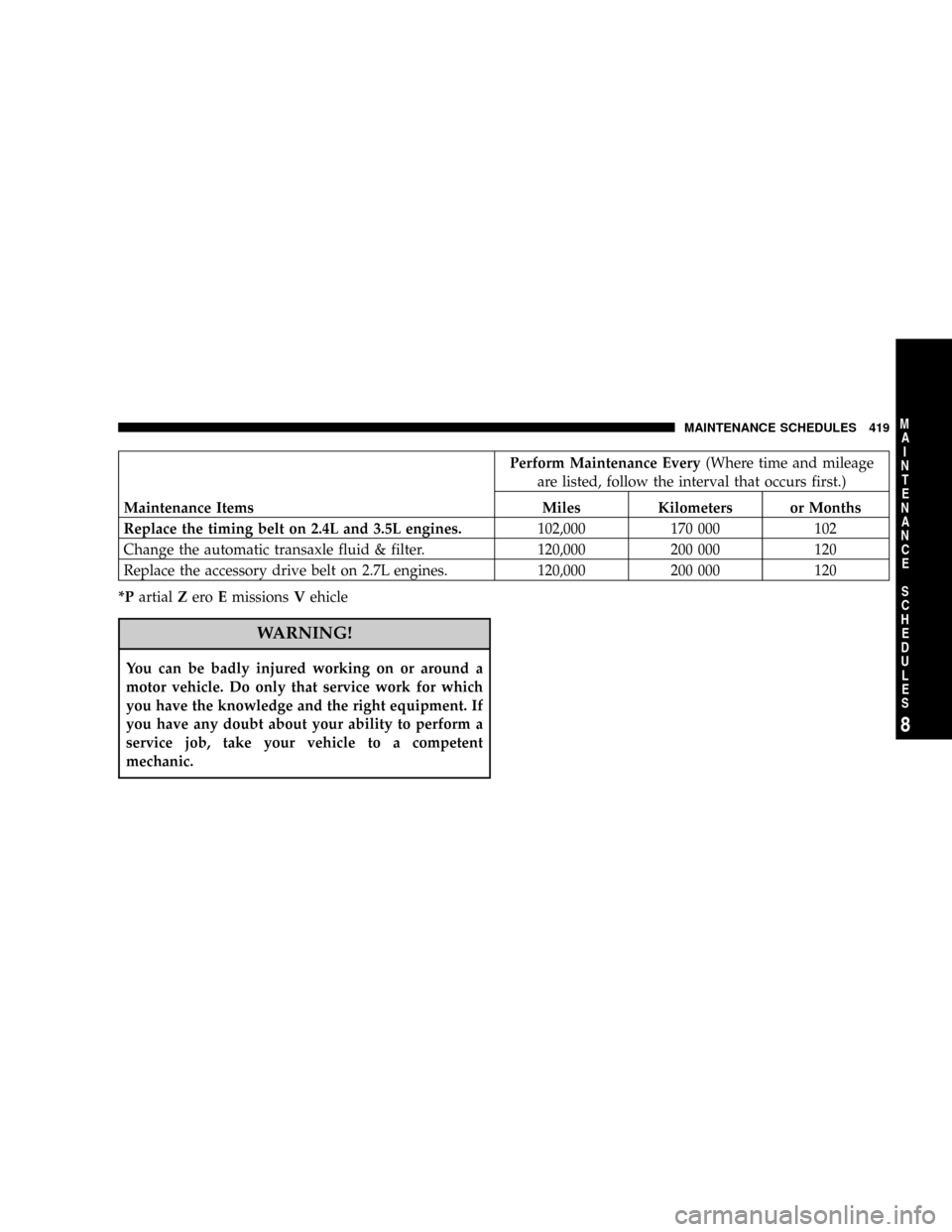

Perform Maintenance Every(Where time and mileage

are listed, follow the interval that occurs first.)

Maintenance Items Miles Kilometers or Months

Replace the timing belt on 2.4L and 3.5L engines.102,000 170 000 102

Change the automatic transaxle fluid & filter. 120,000 200 000 120

Replace the accessory drive belt on 2.7L engines. 120,000 200 000 120

*PartialZeroEmissionsVehicle

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which

you have the knowledge and the right equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent

mechanic.

MAINTENANCE SCHEDULES 419

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S