relay CHRYSLER TOWN AND COUNTRY 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2002Pages: 2399, PDF Size: 57.96 MB

Page 362 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P2008 Short Runner Valve Solenoid Circuit An open or shorted condition detected in the short runner

tuning valve control circuit.

P2302 Ignition Coil Secondary #1 Circuit

P2305 Ignition Coil Secondary #2 Circuit

P2308 Ignition Coil Secondary #3 Circuit

P2311 Ignition Coil Secondary #4 Circuit

P2314 Ignition Coil Secondary #5 Circuit

P2317 Ignition Coil Secondary #6 Circuit

P2320 Ignition Coil Secondary #7 Circuit

P2323 Ignition Coil Secondary #8 Circuit

P2503 Charging System Voltage Low Charging system voltage below minimum acceptable voltage.

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module (PCM).

OPERATION - SCI RECEIVE - PCM INPUT

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Control Module (PCM) receives data from the DRB

through the SCI Receive circuit.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as three different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side of any relay, solenoid, ignition coil or injector.

The signal ground is used for any input that uses

sensor return for ground, and the ground side of any

internal processing component.

The SBEC III case is shielded to prevent RFI and

EMI. The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the case is also

grounded separately from the ground pins.

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM OUTPUT

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Engine coolant temperature sensor

²Manifold absolute pressure sensor

²Throttle position sensor

²Linear EGR solenoid

²Battery temperature

²Knock sensor

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 8 seconds, lamp then

flashes if once per trip (readiness) monitors havenot

been completed until vehicle is started, then MIL is

extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

RSELECTRONIC CONTROL MODULES8E-25

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 365 of 2399

TRANSMISSION CONTROL

MODULE

DESCRIPTION

The Transmission Control Module (TCM) is located

behind the left fender and is fastened with three

screws to three clips in the left frame rail forward of

the suspension (Fig. 14).

OPERATION

The TCM is the controlling unit for all electronic

operations of the transaxle. The TCM receives infor-

mation regarding vehicle operation from both direct

and indirect inputs, and selects the operational mode

of the transaxle. Direct inputs are hardwired to, and

used specifically by the TCM. Indirect inputs origi-

nate from other components/modules, and are shared

with the TCM via the J1850 communication bus.Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor (CKP)

²Transmission Range Sensor (TRS)

²Pressure Switches (L/R, 2/4, OD)

²Transmission Temperature Sensor (Integral to

TRS)

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

Some examples ofindirect inputsto the TCM are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Speed Control ON/OFF Switch

²Engine Coolant Temperature

²Ambient/Battery Temperature

²Brake Switch Status

²DRB Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids (LR/CC, 2/4, OD and UD)

²Vehicle Speed (to PCM)

²Torque Reduction Request (to PCM)

An example of a TCMindirect outputis:

²Transmission Temperature (to PCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indices

(CVI)

²

Storing and selecting appropriate Shift Schedules

²System self-diagnostics

²Diagnostic capabilities (with DRB scan tool)

Fig. 14 Transmission Control Module (TCM)

Location

1 - TRANSMISSION CONTROL MODULE (TCM)

8E - 28 ELECTRONIC CONTROL MODULESRS

ProCarManuals.com

Page 372 of 2399

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ENGINE CONTROL MODULE

DESCRIPTION..........................1

OPERATION............................1

STANDARD PROCEDURE - PCM/ECM/SKIM

PROGRAMMING - DIESEL...............2REMOVAL.............................4

INSTALLATION..........................4

ENGINE CONTROL MODULE

DESCRIPTION

The ECM is located in the left front corner of the

engine compartment attached to the radiator support

(Fig. 1).

OPERATION

The ECM has been programmed to monitor differ-

ent circuits of the diesel fuel injection system. Thismonitoring is called on-board diagnostics. Certain cri-

teria must be met for a diagnostic trouble code to be

entered into the ECM memory. The criteria may be a

range of: engine rpm, engine temperature, time or

other input signals to the ECM. If all of the criteria

for monitoring a system or circuit are met, and a

problem is sensed, then a DTC will be stored in the

ECM memory. It is possible that a DTC for a moni-

tored circuit may not be entered into the ECM mem-

ory, even though a malfunction has occurred. This

may happen when the monitoring criteria have not

been met. The ECM compares input signal voltages

from each input device with specifications (the estab-

lished high and low limits of the input range) that

are programmed into it for that device. If the input

voltage is not within the specifications and other

trouble code criteria are met, a DTC will be stored in

the ECM memory.

ECM OPERATING MODES

As input signals to the ECM change, the ECM

adjusts its response to the output devices. For exam-

ple, the ECM must calculate a different fuel quantity

and fuel timing for engine idle condition than it

would for a wide open throttle condition. There are

several different modes of operation that determine

how the ECM responds to the various input signals.

Ignition Switch On (Engine Off)

When the ignition is turned on, the ECM activates

the glow plug relay for a time period that is deter-

mined by engine coolant temperature, atmospheric

temperature and battery voltage.

Engine Start-Up Mode

The ECM uses the engine temperature sensor and

the crankshaft position sensor (engine speed) inputs

to determine fuel injection quantity.

Normal Driving Modes

Engine idle, warm-up, acceleration, deceleration

and wide open throttle modes are controlled based on

all of the sensor inputs to the ECM. The ECM uses

Fig. 1 ENGINE CONTROL MODULE LOCATION-

TYPICAL

1 - BATTERY

2 - IPM (INTEGRATED POWER MODULE)

3 - ECM (ENGINE CONTROL MODULE)

4 - RETAINING BOLT

5 - RADIATOR SUPPORT

6 - CLUTCH CABLE BRACKET (LHD)

7 - CLUTCH CABLE BRACKET RETAINING BOLT (LHD)

RGELECTRONIC CONTROL MODULES8Ea-1

ProCarManuals.com

Page 373 of 2399

these sensor inputs to adjust fuel quantity and fuel

injector timing.

Limp-In Mode

If there is a fault detected with the accelerator

pedal position sensor, the ECM will set the engine

speed at 1100 RPM.

Overspeed Detection Mode

If the ECM detects engine RPM that exceeds 5200

RPM, the ECM will set a DTC in memory and illu-

minate the MIL until the DTC is cleared.

After-Run Mode

The ECM transfers RAM information to ROM and

performs an Input/Output state check.

MONITORED CIRCUITS

The ECM is able to monitor and identify most

driveability related trouble conditions. Some circuits

are directly monitored through ECM feedback cir-

cuitry. In addition, the ECM monitors the voltage

state of some circuits and compares those states with

expected values. Other systems are monitored indi-

rectly when the ECM conducts a rationality test to

identify problems. Although most subsytems of the

engine control module are either directly or indirectly

monitored, there may be occasions when diagnostic

trouble codes are not immediately identified. For a

trouble code to set, a specific set of conditions must

occur and unless these conditions occur, a DTC will

not set.

DIAGNOSTIC TROUBLE CODES

Each diagnostic trouble code (DTC) is diagnosed by

following a specific procedure. The diagnostic test

procedure contains step-by-step instruction for deter-

mining the cause of the DTC as well as no trouble

code problems. Refer to the appropriate Diesel Pow-

ertrain Diagnostic Manual for more information.

HARD CODE

A DTC that comes back within one cycle of the

ignition key is a hard code. This means that the

problem is current every time the ECM/SKIM checks

that circuit or function. Procedures in this manual

verify if the DTC is a hard code at the beginning of

each test. When the fault is not a hard code, an

intermittent test must be performed. NOTE: If the

DRBIIItdisplays faults for multiple components (i.e.

ECT, VSS, IAT sensors) identify and check the

shared circuits for possible problems before continu-

ing (i.e. sensor grounds or 5-volt supply circuits).

Refer to the appropriate schematic to identify shared

circuits. Refer to the appropriate Diesel Powertrain

Diagnostic Manual for more information.INTERMITTENT CODE

A DTC that is not current every time the ECM/

SKIM checks the circuit or function is an intermit-

tent code. Most intermittent DTCs are caused by

wiring or connector problems. Problems that come

and go like this are the most difficult to diagnose;

they must be looked for under specific conditions that

cause them.NOTE: Electromagnetic (radio)

interference can cause an intermittent system

malfunction.This interference can interrupt com-

munication between the ignition key transponder and

the SKIM. The following checks may assist you in

identifying a possible intermittent problem:

²Visually inspect the related wire harness connec-

tors. Look for broken, bent, pushed out or corroded

terminals.

²Visually inspect the related wire harness. Look

for chafed, pierced or partially broken wire.

²Refer to hotlines or technical service bulletins

that may apply. Refer to the appropriate Diesel Pow-

ertrain Diagnostic Manual for more information.

ECM DIAGNOSTIC TROUBLE CODES

IMPORTANT NOTE: Before replacing the ECM for

a failed driver, control circuit or ground circuit, be

sure to check the related component/circuit integrity

for failures not detected due to a double fault in the

circuit. Most ECM driver/control circuit failures are

caused by internal failures to components (i.e. relays

and solenoids) and shorted circuits (i.e. sensor pull-

ups, drivers and ground circuits). These faults are

difficult to detect when a double fault has occurred

and only one DTC has set. If the DRBIIItdisplays

faults for multiple components (i.e.VSS, ECT, Batt

Temp, etc.) identify and check the shared circuits for

possible problems before continuing (i.e. sensor

grounds or 5-volt supply circuits). Refer to the appro-

priate wiring diagrams to identify shared circuits.

Refer to the appropriate Diesel Powertrain Diagnos-

tic Manual for more information.

STANDARD PROCEDURE - PCM/ECM/SKIM

PROGRAMMING - DIESEL

NOTE: Before replacing the PCM/ECM for a failed

driver, control circuit or ground circuit, be sure to

check the related component/circuit integrity for

failures not detected due to a double fault in the cir-

cuit. Most PCM/ECM driver/control circuit failures

are caused by internal component failures (i.e. relay

and solenoids) and shorted circuits (i.e. pull-ups,

drivers and switched circuits). These failures are

difficult to detect when a double fault has occurred

and only one DTC has set.

8Ea - 2 ELECTRONIC CONTROL MODULESRG

ENGINE CONTROL MODULE (Continued)

ProCarManuals.com

Page 392 of 2399

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Intelligent Power Module (IPM), in the

engine compartment. See the fuse and relay layout

label affixed to the underside of the IPM cover for

ASD relay identification and location.

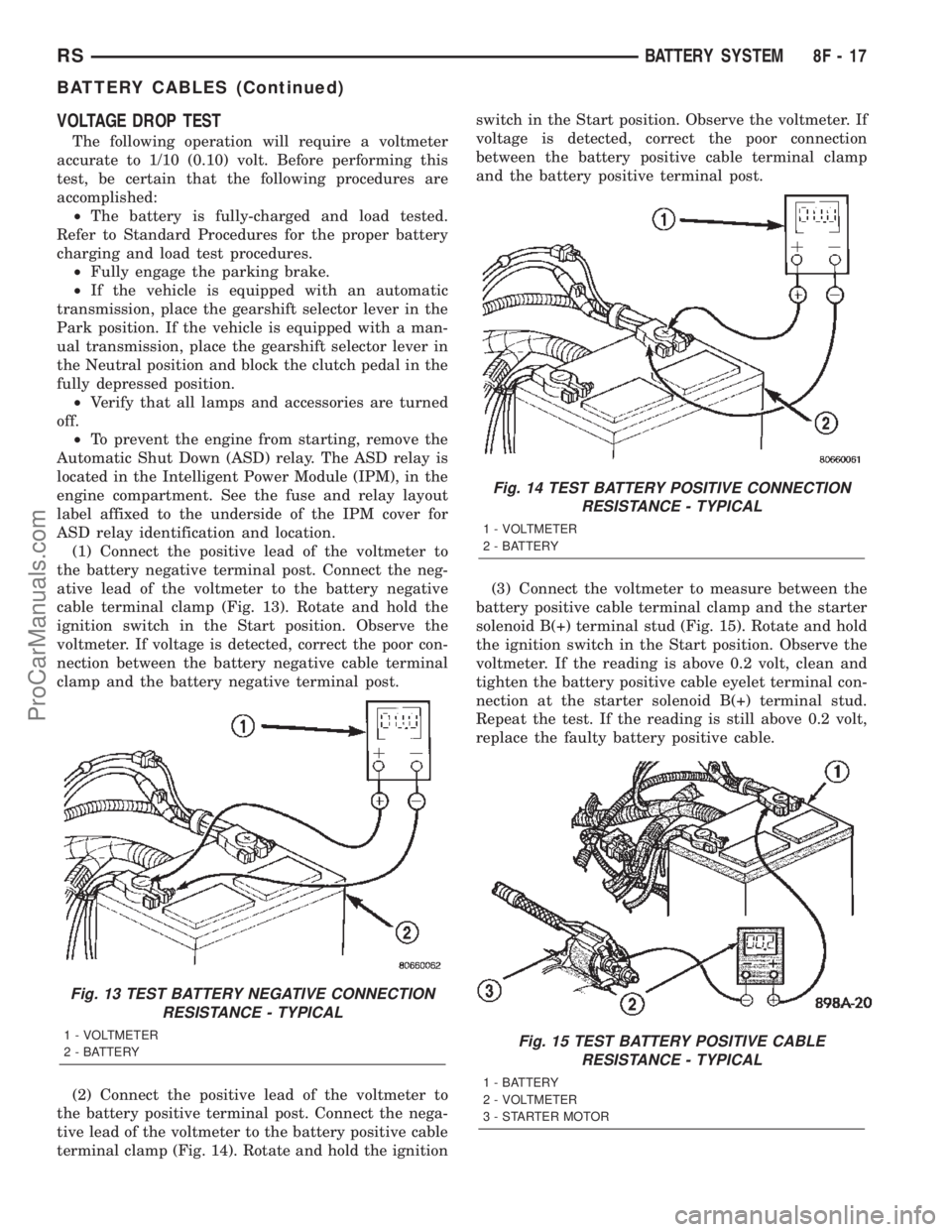

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 13). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

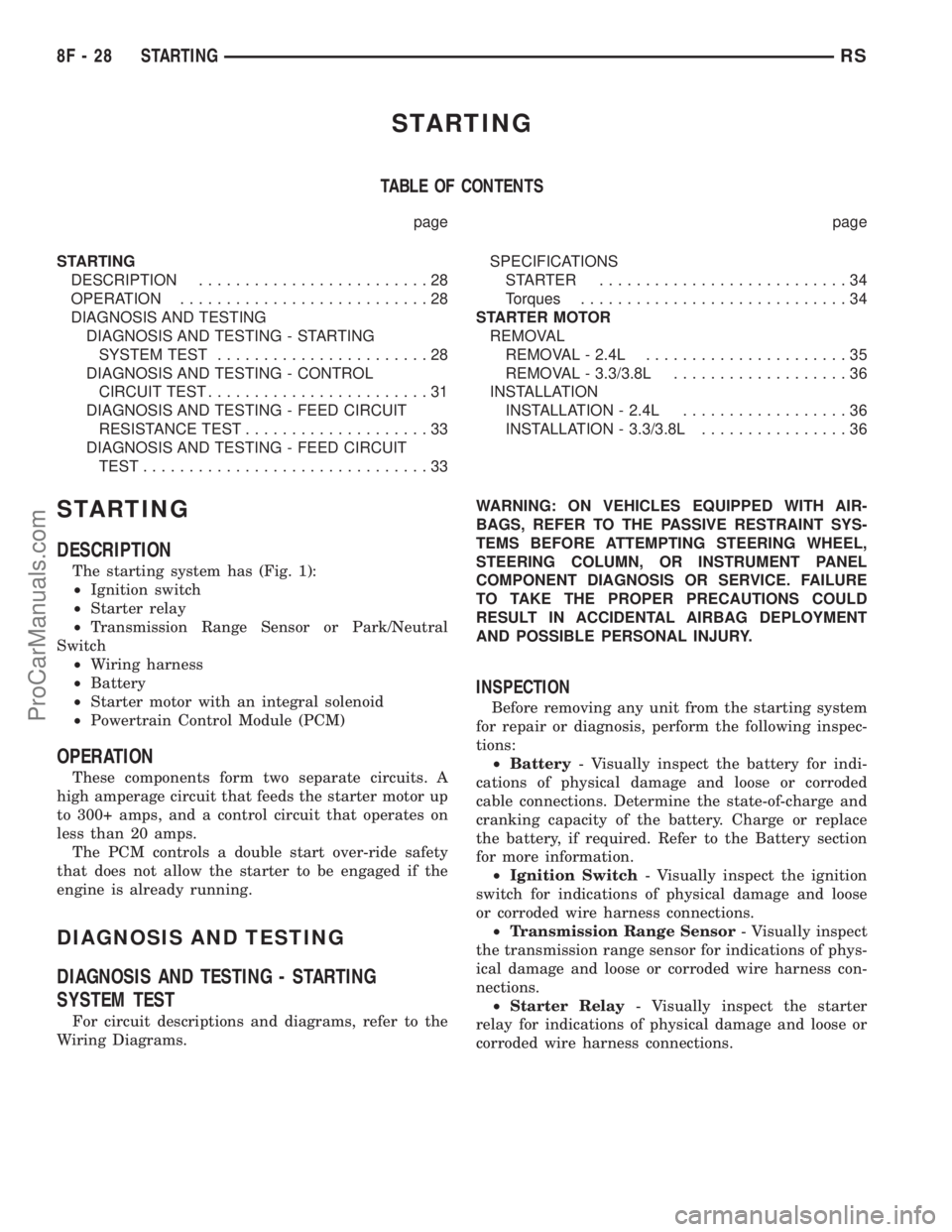

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 14). Rotate and hold the ignitionswitch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.

(3) Connect the voltmeter to measure between the

battery positive cable terminal clamp and the starter

solenoid B(+) terminal stud (Fig. 15). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery positive cable eyelet terminal con-

nection at the starter solenoid B(+) terminal stud.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery positive cable.

Fig. 13 TEST BATTERY NEGATIVE CONNECTION

RESISTANCE - TYPICAL

1 - VOLTMETER

2 - BATTERY

Fig. 14 TEST BATTERY POSITIVE CONNECTION

RESISTANCE - TYPICAL

1 - VOLTMETER

2 - BATTERY

Fig. 15 TEST BATTERY POSITIVE CABLE

RESISTANCE - TYPICAL

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

RSBATTERY SYSTEM8F-17

BATTERY CABLES (Continued)

ProCarManuals.com

Page 396 of 2399

CHARGING

TABLE OF CONTENTS

page page

CHARGING

DESCRIPTION - CHARGING SYSTEM.......21

OPERATION - CHARGING SYSTEM.........21

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM.................22

SPECIFICATIONS

GENERATOR........................23

TORQUE............................23

SPECIAL TOOLS.......................23

BATTERY TEMPERATURE SENSOR

DESCRIPTION.........................24

OPERATION...........................24

REMOVAL.............................24

GENERATOR

DESCRIPTION.........................24

OPERATION...........................24REMOVAL

REMOVAL - 2.4L......................24

REMOVAL - 3.3/3.8L...................24

INSTALLATION

INSTALLATION - 2.4L..................25

INSTALLATION - 3.3/3.8L................25

GENERATOR DECOUPLER PULLEY

DESCRIPTION.........................25

OPERATION...........................26

DIAGNOSIS AND TESTING - GENERATOR

DECOUPLER PULLEY..................26

REMOVAL.............................26

INSTALLATION.........................26

VOLTAGE REGULATOR

DESCRIPTION.........................27

OPERATION...........................27

CHARGING

DESCRIPTION - CHARGING SYSTEM

The charging system consists of:

²Generator

²Decoupler Pulley (If equipped)

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch (refer to the Ignition System sec-

tion for information)

²Battery (refer to the Battery section for informa-

tion)

²Inlet Air Temperature (calculated battery tem-

perature)

²Voltmeter (refer to the Instrument Cluster sec-

tion for information if equipped)

²Wiring harness and connections (refer to the

Wiring section for information)

²Accessory drive belt (refer to the Cooling section

for more information)

OPERATION - CHARGING SYSTEM

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. The ASD

relay is energized when the PCM grounds the ASD

control circuit. This voltage is connected through the

PCM or IPM (intelligent power module) (if equipped)

and supplied to one of the generator field terminals

(Gen. Source +) at the back of the generator.The generator is driven by the engine through a

serpentine belt and pulley or decoupler pulley

arrangement.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

An Inlet air temperature sensor is used to calcu-

late the temperature near the battery. This tempera-

ture data, along with data from monitored line

voltage (battery voltage sense circuit), is used by the

PCM to vary the battery charging rate. This is done

by cycling the ground path to control the strength of

the rotor magnetic field. The PCM then compensates

and regulates generator current output accordingly

to maintain system voltage at the targeted system

voltage based on battery temperature.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for certain failures it detects and

illuminate the (MIL) lamp. Refer to On-Board Diag-

nostics in the Electronic Control Modules(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) section for more DTC information.

RSCHARGING8F-21

ProCarManuals.com

Page 397 of 2399

The Check Gauges Lamp (if equipped) or Battery

Lamp monitors:charging system voltage,engine

coolant temperature and engine oil pressure. If an

extreme condition is indicated, the lamp will be illu-

minated. The signal to activate the lamp is sent via

the PCI bus circuits. The lamp is located on the

instrument panel. Refer to the Instrument Cluster

section for additional information.

The PCM uses the inlet air temperature sensor to

control the charge system voltage. This temperature,

along with data from monitored line voltage, is used

by the PCM to vary the battery charging rate. The

system voltage is higher at cold temperatures and is

gradually reduced as the calculated battery tempera-

ture increases.

The ambient temperature sensor is used to control

the battery voltage based upon ambient temperature

(approximation of battery temperature). The PCM

maintains the optimal output of the generator by

monitoring battery voltage and controlling it to a

range of 13.5 - 14.7 volts based on battery tempera-

ture.

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the OBD system. Some

circuits are checked continuously and some are

checked only under certain conditions.

If the OBD system senses that a monitored circuit

is bad, it will put a DTC into electronic memory. The

DTC will stay in electronic memory as long as the

circuit continues to be bad. The PCM is programmed

to clear the memory after 50 engine starts if the

problem does not occur again.

DIAGNOSTIC TROUBLE CODES

A DTC description can be read using the DRBIIIt

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for information.

A DTC does not identify which component in a cir-

cuit is bad. Thus, a DTC should be treated as a

symptom, not as the cause for the problem. In some

cases, because of the design of the diagnostic test

procedure, a DTC can be the reason for another DTC

to be set. Therefore, it is important that the test pro-

cedures be followed in sequence, to understand what

caused a DTC to be set.

ERASING DIAGNOSTIC TROUBLE CODES

The DRBIIItScan Tool must be used to erase a

DTC.The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp or battery lamp is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE)

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBIIItscan tool.

Perform the following inspections before attaching

the scan tool.

(1) Inspect the battery condition. Refer to the Bat-

tery section (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING) for proce-

dures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications (Refer to 8 - ELECTRICAL/

CHARGING - SPECIFICATIONS).

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications(Refer to 7 - COOLING/

ACCESSORY DRIVE - SPECIFICATIONS).

8F - 22 CHARGINGRS

CHARGING (Continued)

ProCarManuals.com

Page 403 of 2399

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST.......................28

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST........................31

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST....................33

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST...............................33SPECIFICATIONS

STARTER ...........................34

Torques.............................34

STARTER MOTOR

REMOVAL

REMOVAL - 2.4L......................35

REMOVAL - 3.3/3.8L...................36

INSTALLATION

INSTALLATION - 2.4L..................36

INSTALLATION - 3.3/3.8L................36

STARTING

DESCRIPTION

The starting system has (Fig. 1):

²Ignition switch

²Starter relay

²Transmission Range Sensor or Park/Neutral

Switch

²Wiring harness

²Battery

²Starter motor with an integral solenoid

²Powertrain Control Module (PCM)

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor- Visually inspect

the transmission range sensor for indications of phys-

ical damage and loose or corroded wire harness con-

nections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

8F - 28 STARTINGRS

ProCarManuals.com

Page 404 of 2399

²Starter- Visually inspect the starter for indica-

tions of physical damage and loose or corroded wire

harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

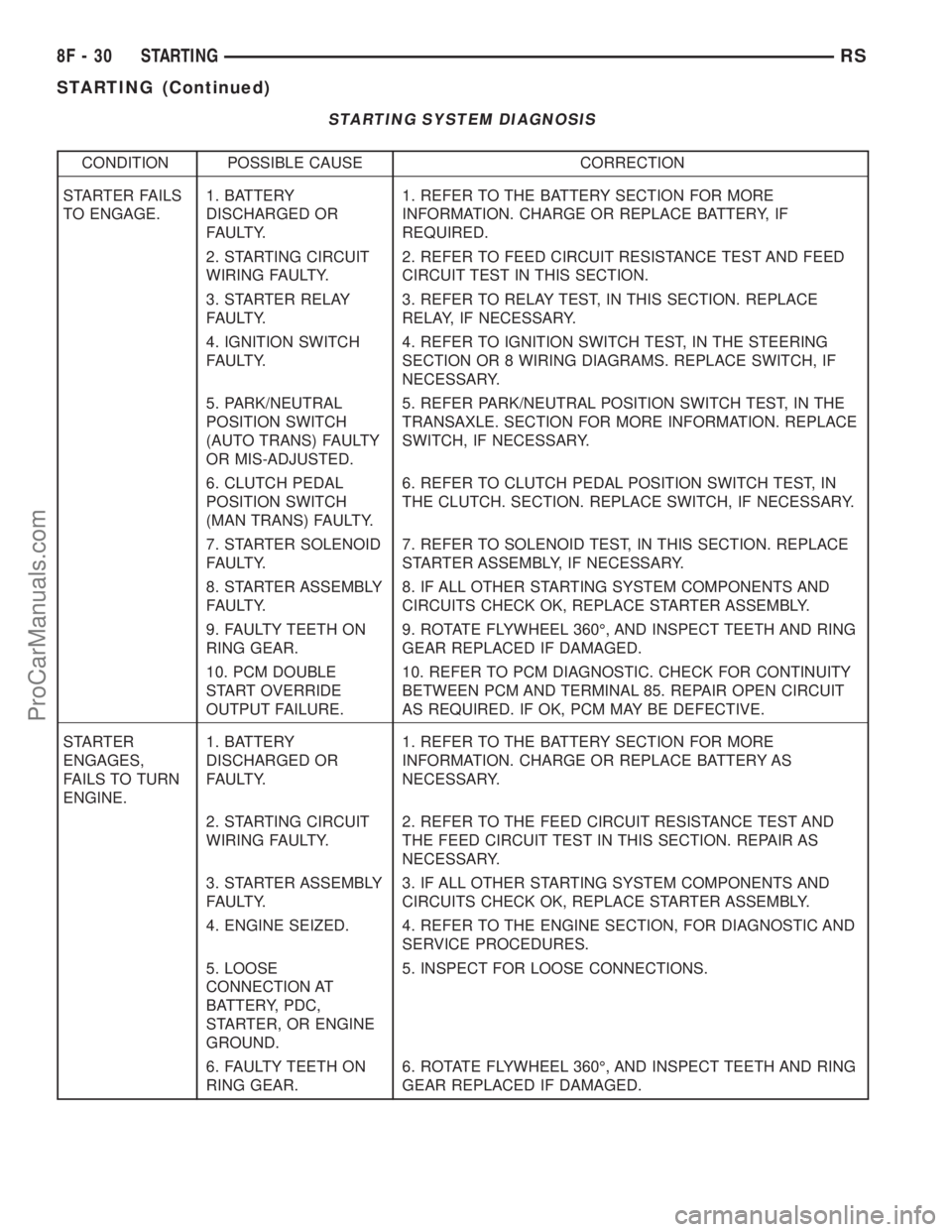

Fig. 1 STARTING SYSTEM SCHEMATIC

1 - SOLENOID TERMINAL

2 - STARTER SOLENOID

3 - STARTER MOTOR

4 - STARTER RELAY CONNECTOR

5 - PCM

6 - GROUND CIRCUIT

7 - TRANSMISSION RANGE SENSOR/PARK/NEUTRAL SENSE

8 - IGNITION SWITCH

9 - IGNITION FEED

10 - BATTERY

11 - BATTERY RELAY FEED

12 - POSITIVE CABLE

13 - NEGATIVE CABLE

14 - CLUTCH INTERLOCK SWITCH (MTX ONLY)

RSSTARTING8F-29

STARTING (Continued)

ProCarManuals.com

Page 405 of 2399

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH PEDAL

POSITION SWITCH

(MAN TRANS) FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE.10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO THE FEED CIRCUIT RESISTANCE TEST AND

THE FEED CIRCUIT TEST IN THIS SECTION. REPAIR AS

NECESSARY.

3. STARTER ASSEMBLY

FAULTY.3. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

4. ENGINE SEIZED. 4. REFER TO THE ENGINE SECTION, FOR DIAGNOSTIC AND

SERVICE PROCEDURES.

5. LOOSE

CONNECTION AT

BATTERY, PDC,

STARTER, OR ENGINE

GROUND.5. INSPECT FOR LOOSE CONNECTIONS.

6. FAULTY TEETH ON

RING GEAR.6. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

8F - 30 STARTINGRS

STARTING (Continued)

ProCarManuals.com