Evap CHRYSLER TOWN AND COUNTRY 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2002Pages: 2399, PDF Size: 57.96 MB

Page 243 of 2399

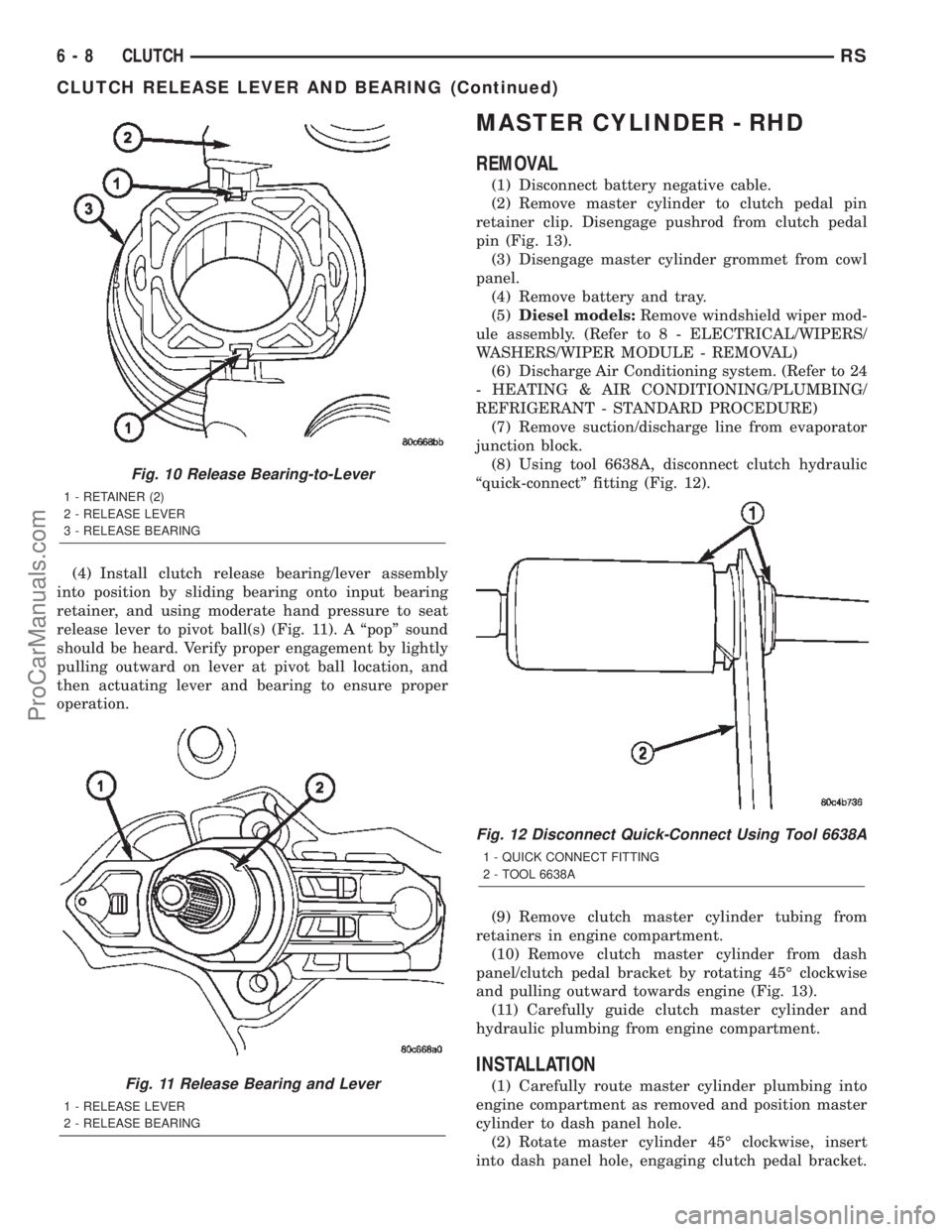

(4) Install clutch release bearing/lever assembly

into position by sliding bearing onto input bearing

retainer, and using moderate hand pressure to seat

release lever to pivot ball(s) (Fig. 11). A ªpopº sound

should be heard. Verify proper engagement by lightly

pulling outward on lever at pivot ball location, and

then actuating lever and bearing to ensure proper

operation.

MASTER CYLINDER - RHD

REMOVAL

(1) Disconnect battery negative cable.

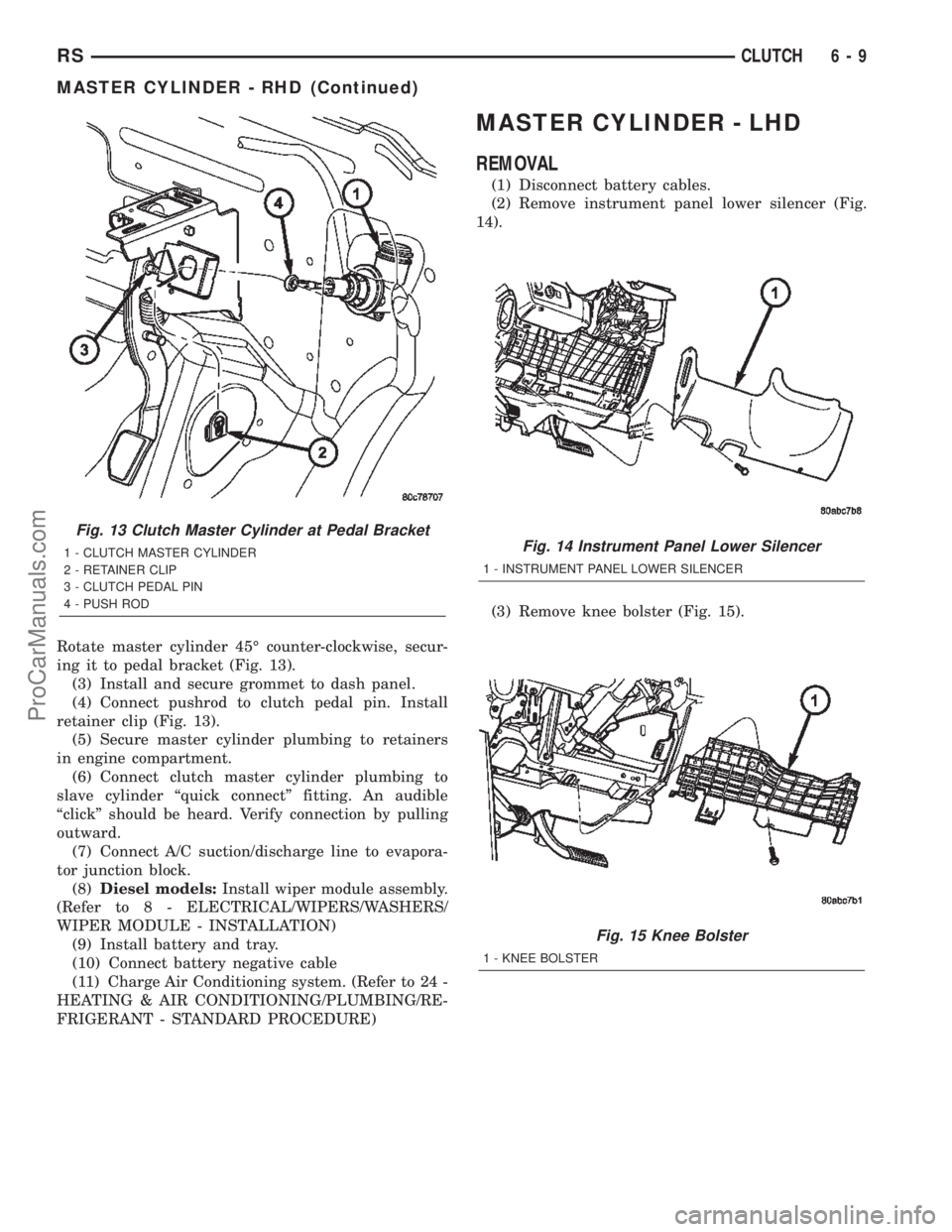

(2) Remove master cylinder to clutch pedal pin

retainer clip. Disengage pushrod from clutch pedal

pin (Fig. 13).

(3) Disengage master cylinder grommet from cowl

panel.

(4) Remove battery and tray.

(5)Diesel models:Remove windshield wiper mod-

ule assembly. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL)

(6) Discharge Air Conditioning system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

REFRIGERANT - STANDARD PROCEDURE)

(7) Remove suction/discharge line from evaporator

junction block.

(8) Using tool 6638A, disconnect clutch hydraulic

ªquick-connectº fitting (Fig. 12).

(9) Remove clutch master cylinder tubing from

retainers in engine compartment.

(10) Remove clutch master cylinder from dash

panel/clutch pedal bracket by rotating 45É clockwise

and pulling outward towards engine (Fig. 13).

(11) Carefully guide clutch master cylinder and

hydraulic plumbing from engine compartment.

INSTALLATION

(1) Carefully route master cylinder plumbing into

engine compartment as removed and position master

cylinder to dash panel hole.

(2) Rotate master cylinder 45É clockwise, insert

into dash panel hole, engaging clutch pedal bracket.

Fig. 10 Release Bearing-to-Lever

1 - RETAINER (2)

2 - RELEASE LEVER

3 - RELEASE BEARING

Fig. 11 Release Bearing and Lever

1 - RELEASE LEVER

2 - RELEASE BEARING

Fig. 12 Disconnect Quick-Connect Using Tool 6638A

1 - QUICK CONNECT FITTING

2 - TOOL 6638A

6 - 8 CLUTCHRS

CLUTCH RELEASE LEVER AND BEARING (Continued)

ProCarManuals.com

Page 244 of 2399

Rotate master cylinder 45É counter-clockwise, secur-

ing it to pedal bracket (Fig. 13).

(3) Install and secure grommet to dash panel.

(4) Connect pushrod to clutch pedal pin. Install

retainer clip (Fig. 13).

(5) Secure master cylinder plumbing to retainers

in engine compartment.

(6) Connect clutch master cylinder plumbing to

slave cylinder ªquick connectº fitting. An audible

ªclickº should be heard. Verify connection by pulling

outward.

(7) Connect A/C suction/discharge line to evapora-

tor junction block.

(8)Diesel models:Install wiper module assembly.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION)

(9) Install battery and tray.

(10) Connect battery negative cable

(11) Charge Air Conditioning system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/RE-

FRIGERANT - STANDARD PROCEDURE)

MASTER CYLINDER - LHD

REMOVAL

(1) Disconnect battery cables.

(2) Remove instrument panel lower silencer (Fig.

14).

(3) Remove knee bolster (Fig. 15).

Fig. 13 Clutch Master Cylinder at Pedal Bracket

1 - CLUTCH MASTER CYLINDER

2 - RETAINER CLIP

3 - CLUTCH PEDAL PIN

4 - PUSH RODFig. 14 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 15 Knee Bolster

1 - KNEE BOLSTER

RSCLUTCH6-9

MASTER CYLINDER - RHD (Continued)

ProCarManuals.com

Page 266 of 2399

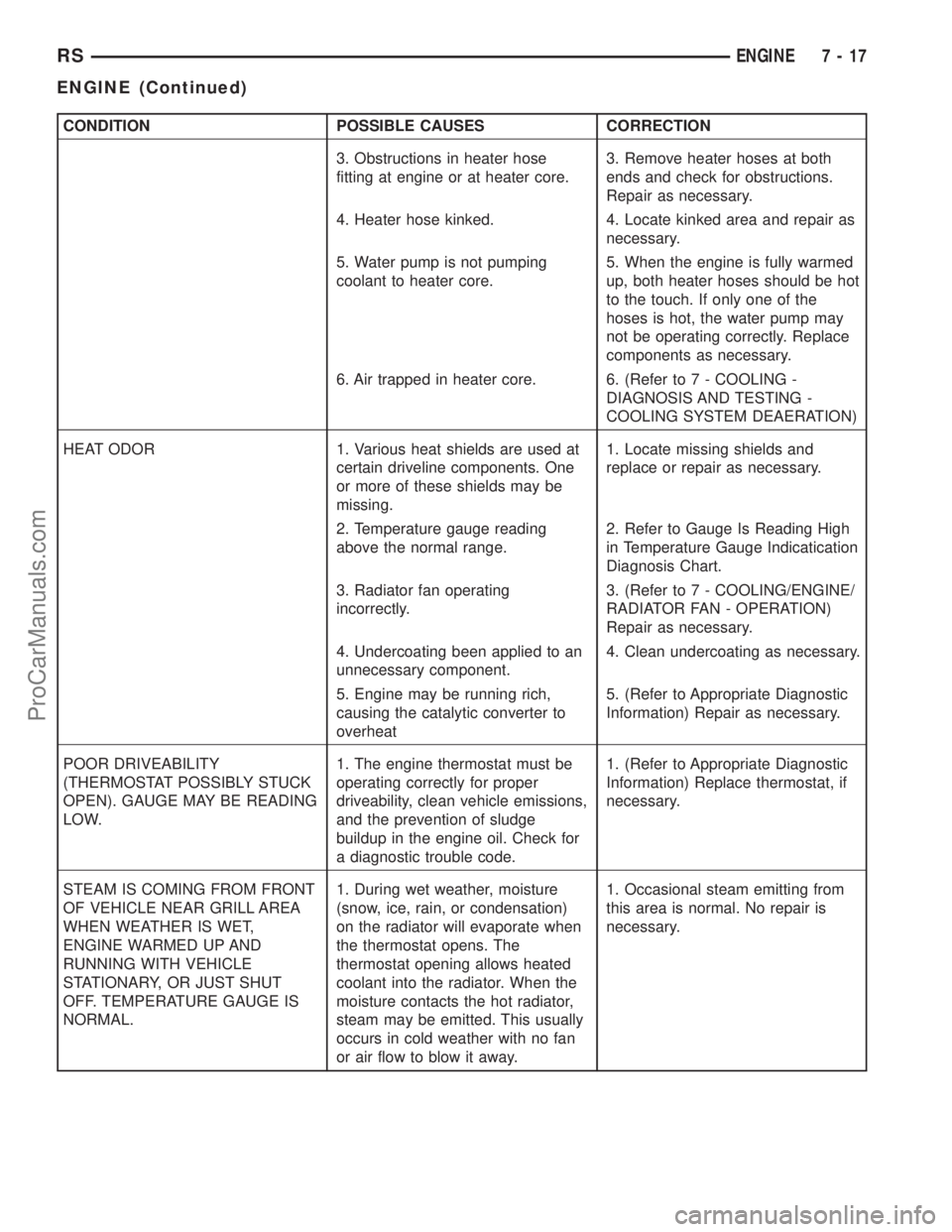

CONDITION POSSIBLE CAUSES CORRECTION

3. Obstructions in heater hose

fitting at engine or at heater core.3. Remove heater hoses at both

ends and check for obstructions.

Repair as necessary.

4. Heater hose kinked. 4. Locate kinked area and repair as

necessary.

5. Water pump is not pumping

coolant to heater core.5. When the engine is fully warmed

up, both heater hoses should be hot

to the touch. If only one of the

hoses is hot, the water pump may

not be operating correctly. Replace

components as necessary.

6. Air trapped in heater core. 6. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING -

COOLING SYSTEM DEAERATION)

HEAT ODOR 1. Various heat shields are used at

certain driveline components. One

or more of these shields may be

missing.1. Locate missing shields and

replace or repair as necessary.

2. Temperature gauge reading

above the normal range.2. Refer to Gauge Is Reading High

in Temperature Gauge Indicatication

Diagnosis Chart.

3. Radiator fan operating

incorrectly.3. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - OPERATION)

Repair as necessary.

4. Undercoating been applied to an

unnecessary component.4. Clean undercoating as necessary.

5. Engine may be running rich,

causing the catalytic converter to

overheat5. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

POOR DRIVEABILITY

(THERMOSTAT POSSIBLY STUCK

OPEN). GAUGE MAY BE READING

LOW.1. The engine thermostat must be

operating correctly for proper

driveability, clean vehicle emissions,

and the prevention of sludge

buildup in the engine oil. Check for

a diagnostic trouble code.1. (Refer to Appropriate Diagnostic

Information) Replace thermostat, if

necessary.

STEAM IS COMING FROM FRONT

OF VEHICLE NEAR GRILL AREA

WHEN WEATHER IS WET,

ENGINE WARMED UP AND

RUNNING WITH VEHICLE

STATIONARY, OR JUST SHUT

OFF. TEMPERATURE GAUGE IS

NORMAL.1. During wet weather, moisture

(snow, ice, rain, or condensation)

on the radiator will evaporate when

the thermostat opens. The

thermostat opening allows heated

coolant into the radiator. When the

moisture contacts the hot radiator,

steam may be emitted. This usually

occurs in cold weather with no fan

or air flow to blow it away.1. Occasional steam emitting from

this area is normal. No repair is

necessary.

RSENGINE7-17

ENGINE (Continued)

ProCarManuals.com

Page 269 of 2399

higher the freeze protection (up to a maximum of

60% by volume glycol).

A refractometer (Special Tool 8286)(Refer to 7 -

COOLING - SPECIAL TOOLS) will test the amount

of glycol in a coolant mixture by measuring the

amount a beam of light bends as it passes through

the fluid.

Some coolant manufactures use other types of gly-

cols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freez-

ing protection and corrosion protection and is not rec-

ommended.

CAUTION: Do not mix types of coolantÐcorrosion

protection will be severely reduced.

STANDARD PROCEDURE - COOLANT SERVICE

For engine coolant recommended service schedule,

(Refer to LUBRICATION & MAINTENANCE/MAIN-

TENANCE SCHEDULES - DESCRIPTION).

COOLANT RECOVERY

CONTAINER

DESCRIPTION

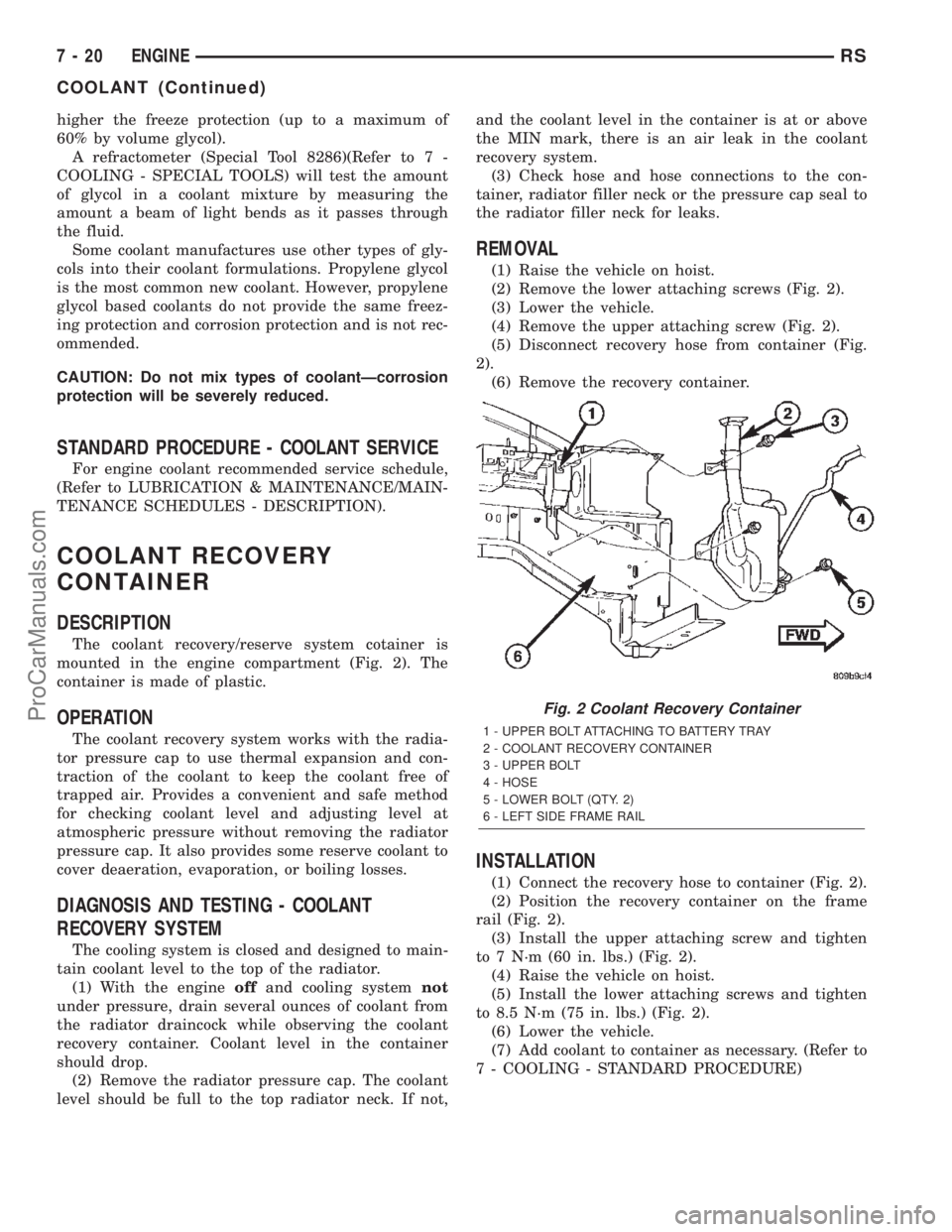

The coolant recovery/reserve system cotainer is

mounted in the engine compartment (Fig. 2). The

container is made of plastic.

OPERATION

The coolant recovery system works with the radia-

tor pressure cap to use thermal expansion and con-

traction of the coolant to keep the coolant free of

trapped air. Provides a convenient and safe method

for checking coolant level and adjusting level at

atmospheric pressure without removing the radiator

pressure cap. It also provides some reserve coolant to

cover deaeration, evaporation, or boiling losses.

DIAGNOSIS AND TESTING - COOLANT

RECOVERY SYSTEM

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator.

(1) With the engineoffand cooling systemnot

under pressure, drain several ounces of coolant from

the radiator draincock while observing the coolant

recovery container. Coolant level in the container

should drop.

(2) Remove the radiator pressure cap. The coolant

level should be full to the top radiator neck. If not,and the coolant level in the container is at or above

the MIN mark, there is an air leak in the coolant

recovery system.

(3) Check hose and hose connections to the con-

tainer, radiator filler neck or the pressure cap seal to

the radiator filler neck for leaks.

REMOVAL

(1) Raise the vehicle on hoist.

(2) Remove the lower attaching screws (Fig. 2).

(3) Lower the vehicle.

(4) Remove the upper attaching screw (Fig. 2).

(5) Disconnect recovery hose from container (Fig.

2).

(6) Remove the recovery container.

INSTALLATION

(1) Connect the recovery hose to container (Fig. 2).

(2) Position the recovery container on the frame

rail (Fig. 2).

(3) Install the upper attaching screw and tighten

to 7 N´m (60 in. lbs.) (Fig. 2).

(4) Raise the vehicle on hoist.

(5) Install the lower attaching screws and tighten

to 8.5 N´m (75 in. lbs.) (Fig. 2).

(6) Lower the vehicle.

(7) Add coolant to container as necessary. (Refer to

7 - COOLING - STANDARD PROCEDURE)

Fig. 2 Coolant Recovery Container

1 - UPPER BOLT ATTACHING TO BATTERY TRAY

2 - COOLANT RECOVERY CONTAINER

3 - UPPER BOLT

4 - HOSE

5 - LOWER BOLT (QTY. 2)

6 - LEFT SIDE FRAME RAIL

7 - 20 ENGINERS

COOLANT (Continued)

ProCarManuals.com

Page 295 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

4. Has undercoating been applied to

any unnecessary components?4. Clean undercoating as

necessary.

STEAM IS COMING FROM

FRONT OF VEHICLE

NEAR GRILL AREA WHEN

WEATHER IS WET,

ENGINE IS WARMED UP

AND RUNNING, AND

VEHICLE IS STATIONARY.

TEMPERATURE GAUGE

IS IN NORMAL RANGE1. During wet weather, moisture

(snow, ice, or rain condensation) on

the radiator will evaporate when the

thermostat opens. This opening

allows heated water into the radiator.

When the moisture contacts the hot

radiator, steam may be emitted. This

usually occurs in cold weather with

no fan or airflow to blow it away.1. Occasional steam emitting

from this area is normal. No

repair is necessary.

COOLANT ODOR 1. Coolant color is not necessarily an

indication of adequate corrosion or

temperature protection. Do not rely

on coolant color for determining

condition of coolant.1. Refer to Coolant in this group

for antifreeze tests. Adjust

antifreeze-to-water ratio as

necessary.

COOLANT LEVEL

CHANGES IN COOLANT

TANK. TEMPERATURE

GAUGE IS IN NORMAL

RANGE1. Level changes are to be expected

as coolant volume fluctuates with

engine temperature. If the level in

the tank was between the HOT and

COLD marks at normal engine

operating temperature, the level

should return to within that range

after operation at elevated

temperatures.1. This a normal condition. No

repair necessary.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAK TEST

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

With engine not running, remove pressure/vent cap

from the coolant recovery pressure container and

wipe the filler neck sealing seat clean. The coolant

recovery pressure container should be full.

Attach the Cooling System Tester 7700 or equiva-

lent to the radiator, as shown in (Fig. 1) and apply

104 kPa (15 psi) pressure. If the pressure drops more

than 13.8 kPa (2 psi) in 2 minutes, inspect all points

for external leaks.

All radiator and heater hoses should be shaken

while at 104 kPa (15 psi), since some leaks occur only

while driving due to engine movement.

If there are no external leaks, after the gauge dial

shows a drop in pressure, detach the tester. Startengine and run until the thermostat opens, allowing

the coolant to expand. Reattach the cooling system

tester. If the needle on the dial fluctuates it indicates

a combustion leak, usually a head gasket leak.

WARNING: WITH TOOL IN PLACE, PRESSURE WILL

BUILD UP FAST. EXCESSIVE PRESSURE BUILT UP,

BY CONTINUOUS ENGINE OPERATION, MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, raise

the engine rpm a few times. If an abnormal amount

of coolant or steam emits from the tailpipe, it may

indicate a coolant leak caused by a faulty head gas-

ket, cracked engine block, or cracked cylinder head.

There may be internal leaks that can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil it will indicate an

internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

7a - 6 COOLING 2.5L TURBO DIESELRG

COOLING 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 306 of 2399

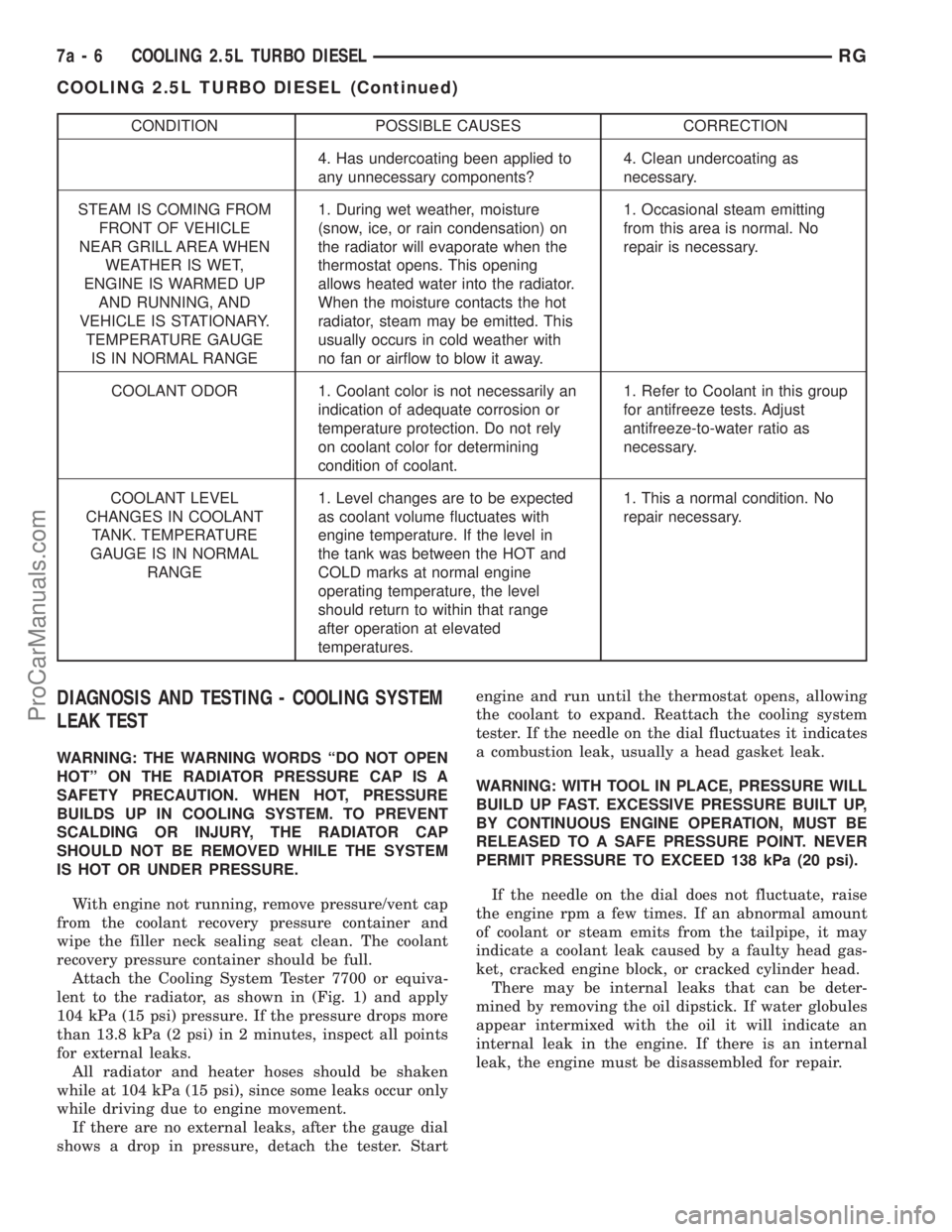

(5) Continue filling coolant recovery pressure con-

tainer until level reaches the full line.

(6) Without installing the pressure/vent cap, start

and run engine at idle for a couple minutes.

(7) Recheck coolant level and fill as necessary.

(8) Install pressure/vent cap and drive vehicle for

approx. 10 km to reach normal operating tempera-

tures.

(9) Allow vehicle to cool. Check and fill coolant as

needed.

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE/VENT CAP, CYLINDER

BLOCK DRAIN PLUGS, OR THE DRAINCOCK WHEN

THE SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

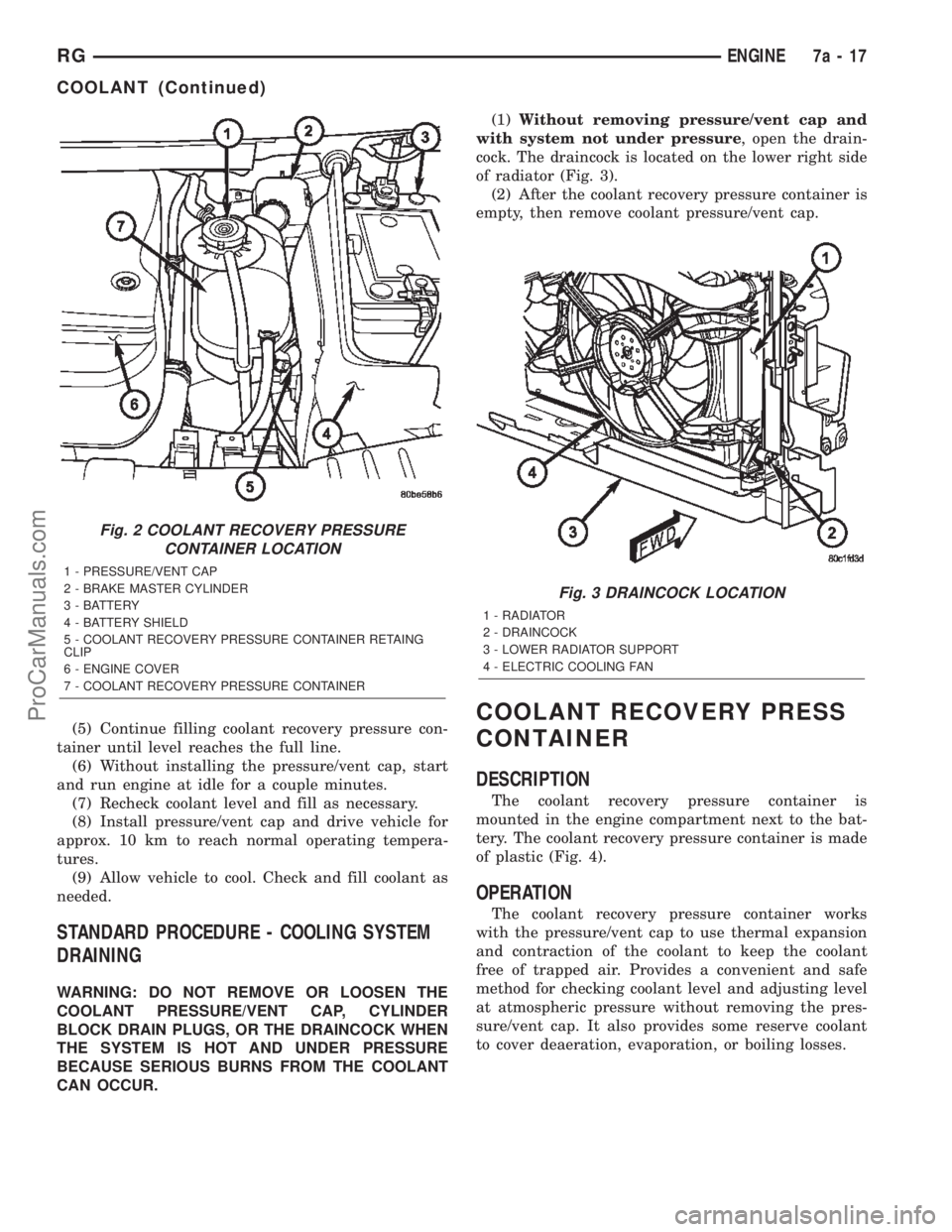

CAN OCCUR.(1)Without removing pressure/vent cap and

with system not under pressure, open the drain-

cock. The draincock is located on the lower right side

of radiator (Fig. 3).

(2) After the coolant recovery pressure container is

empty, then remove coolant pressure/vent cap.

COOLANT RECOVERY PRESS

CONTAINER

DESCRIPTION

The coolant recovery pressure container is

mounted in the engine compartment next to the bat-

tery. The coolant recovery pressure container is made

of plastic (Fig. 4).

OPERATION

The coolant recovery pressure container works

with the pressure/vent cap to use thermal expansion

and contraction of the coolant to keep the coolant

free of trapped air. Provides a convenient and safe

method for checking coolant level and adjusting level

at atmospheric pressure without removing the pres-

sure/vent cap. It also provides some reserve coolant

to cover deaeration, evaporation, or boiling losses.

Fig. 2 COOLANT RECOVERY PRESSURE

CONTAINER LOCATION

1 - PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - BATTERY

4 - BATTERY SHIELD

5 - COOLANT RECOVERY PRESSURE CONTAINER RETAING

CLIP

6 - ENGINE COVER

7 - COOLANT RECOVERY PRESSURE CONTAINER

Fig. 3 DRAINCOCK LOCATION

1 - RADIATOR

2 - DRAINCOCK

3 - LOWER RADIATOR SUPPORT

4 - ELECTRIC COOLING FAN

RGENGINE7a-17

COOLANT (Continued)

ProCarManuals.com

Page 354 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0330 Knock Sensor #2 Circuit Knock sensor (#2) signal above or below minimum

acceptable threshold voltage at particular engine speeds.

P0335 Crankshaft Position Sensor Circuit A rationality error has been detected for loss of crankshaft

position sensor.

P0339 Crankshaft Position Sensor Circuit

IntermittentA rationality error has been detected for intermittent loss of

crankshaft position sensor.

P0340 (M) Camshaft Position Sensor Circuit A rationality error has been detected for loss of camshaft

position sensor.

P0344 Camshaft Position Sensor Circuit

IntermittentA rationality error has been detected for intermittent loss of

camshaft position sensor.

P0350 Ignition Coil Draws Too Much Current A coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil Primary # 1 Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil Primary # 2 Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil Primary # 3 Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil Primary# 4 Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil Primary # 5 Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil Primary # 6 Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 Ignition Coil Primary # 7 Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 Ignition Coil Primary # 8 Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0400 Diesel EGR System Failure

P0401 (M) EGR System Failure Required change in air/fuel ration not detected during

diagnostic test.

P0403 (M) EGR Solenoid Circuit An open or shorted condition detected in the EGR solenoid

control circuit.

P0404 (M) EGR Position Sensor Rationality EGR position sensor signal does not correlate to EGR duty

cycle.

P0405 (M) EGR Position Sensor Volts Too Low EGR position sensor input below the acceptable voltage

range.

P0406 (M) EGR Position Sensor Volts Too High EGR position sensor input above the acceptable voltage

range.

P0412 Secondary Air Solenoid Circuit An open or shorted condition detected in the secondary air

(air switching/aspirator) solenoid control circuit.

P0420 (M) 1/1 Catalytic Converter Efficiency Catalyst 1/1 efficiency below required level.

P0432 (M) 1/2 Catalytic Converter Efficiency Catalyst 2/1 efficiency below required level.

P0440 General EVAP System Failure General system failure.

RSELECTRONIC CONTROL MODULES8E-17

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 355 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0441 (M) Evap Purge Flow Monitor Insufficient or excessive vapor flow detected during

evaporative emission system operation.

P0442 (M) Evap Leak Monitor 0.040 Leak

DetectedA 0.040 leak has been detected in the evaporative system.

P0443 (M) Evap Purge Solenoid Circuit An open or shorted condition detected in the EVAP purge

solenoid control circuit.

P0452 NVLD Pressure Switch Stuck Closed NVLD pressure switch stuck closed.

P0453 NVLD Pressure Switch Stuck Open NVLD pressure switch stuck open.

P0455 (M) Evap Leak Monitor Large Leak

DetectedA large leak has been detected in the evaporative system.

P0456 (M) Evap Leak Monitor 0.020 Leak

DetectedA 0.020 leak has been detected in the evaporative system.

P0460 Fuel Level Unit No Change Over Miles No movement of fuel level sender detected.

P0461 Fuel Level Unit No Changeover Time No level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too Low Fuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0480 Low Speed Fan Relay Control Circuit An open or shorted condition detected in the low speed rad.

fan relay control circuit.

P0481 High Speed Fan Relay Control Circuit An open or shorted condition detected in the high speed rad.

fan relay control circuit.

P0498 NVLD Canister Vent Valve Solenoid

Circuit LowA shorted low condition detected in NVLD solenoid circuit.

P0499 NVLD Canister Vent Valve Solenoid

Circuit HighA shorted high condition detected in NVLD solenoid circuit.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road load

conditions.

P0501 Vehicle Speed Sensor #1 Performance A rationality error has been detected for no vehicle speed

sensor signal detected during road load conditions.

P0505 (M) Idle Air Control Motor Circuits Replace idle air control motor.

P0508 (M) Idle Air Control Motor Circuit Low Idle Air Control Motor Circuit input below acceptable current

P0509 (M) Idle Air Control Motor Circuit High Idle Air Control Motor Circuit input above acceptable current

P0511 Idle Air Control Valve Solenoid Circuit An open or shorted condition detected in the IAC control

circuit.

P0513 Invalid SKIM Key The engine controller has received an invalid key from the

Smart Key Immobilizer Module.

P0516 Battery Temperature Sensor Low Battery Temp. sensor input below minimum acceptable

voltage.

P0517 Battery Temperature Sensor High Battery Temp. sensor input above maximum acceptable

voltage.

P0519 Idle Speed Performance A rationality error has been detected for target RPM not met

during drive idle condition. Possible Vacuum leak or IAC lost

steps.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 359 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P1298 Lean Operation at Wide Open Throttle A prolonged lean condition is detected during Wide Open

Throttle.

P1299 (M) Vacuum Leak Found (IAC Fully

Seated)MAP Sensor signal does not correlate to Throttle Position

Sensor signal. Possible vacuum leak.

P1388 Auto Shutdown Relay Control Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P1389 No ASD Relay Output Voltage At PCM No Z1 or Z2 voltage sensed when the auto shutdown relay is

energized.

P1390 (M) Timing Belt Skipped 1 Tooth or More Relationship between Cam and Crank signals not correct.

P1391 (M) Intermittent Loss of CMP or CKP Loss of the Cam Position Sensor or Crank Position sensor

has occurred. For PL 2.0L

P1398 (M) Mis-Fire Adaptive Numerator at Limit PCM is unable to learn the Crank Sensor's signal in

preparation for Misfire Diagnostics. Probable defective Crank

Sensor.

P1399 Wait To Start Lamp Circuit An open or shorted condition detected in the Wait to Start

Lamp circuit.

P1403 No 5 Volts to EGR Sensor Loss of 5v feed to the EGR position sensor.

P1476 Too Little Secondary Air Insufficient flow of secondary air injection detected during

aspirator test.(was P0411)

P1477 Too Much Secondary Air Excessive flow of secondary air injection detected during

aspirator test (was P0411).

P1478 (M) Battery Temp Sensor Volts Out of Limit Internal temperature sensor input voltage out of an

acceptable range.

P1479 Transmission Fan Relay Circuit An open or shorted condition detected in the transmission

fan relay circuit.

P1480 PCV Solenoid Circuit An open or shorted condition detected in the PCV solenoid

circuit.

P1481 EATX RPM Pulse Performance ETAX RPM pulse generator signal for misfire detection does

not correlate with expected value.

P1482 Catalyst Temperature Sensor Circuit

Shorted LowCatalyst temperature sensor circuit shorted low.

P1483 Catalyst Temperature Sensor Circuit

Shorted High.Catalyst temperature sensor circuit shorted high.

P1484 Catalytic Converter Overheat Detected A catalyst overheat condition has been detected by the

catalyst temperature sensor.

P1485 Air Injection Solenoid Circuit An open or shorted condition detected in the air assist

solenoid circuit.

P1486 (M) Evap Leak Monitor Pinched Hose

FoundLDP has detected a pinched hose in the evaporative hose

system.

P1487 Hi Speed Rad Fan CTRL Relay Circuit An open or shorted condition detected in the control circuit of

the #2 high speed radiator fan control relay.

P1488 Auxiliary 5 Volt Supply Output Too Low Auxiliary 5 volt sensor feed is sensed to be below an

acceptable limit.

8E - 22 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 399 of 2399

BATTERY TEMPERATURE

SENSOR

DESCRIPTION

The PCM incorporates a Battery Temperature Sen-

sor (BTS) on its circuit board.

OPERATION

The PCM uses the temperature of the battery area

to control the charge system voltage. This tempera-

ture, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

The system voltage is higher at cold temperatures

and is gradually reduced as temperature around the

battery increases.

The ambient temperature sensor is used to control

the battery voltage based upon ambient temperature

(approximation of battery temperature). The PCM

maintains the optimal output of the generator by

monitoring battery voltage and controlling it to a

range of 13.5 - 14.7 volts based on battery tempera-

ture.

The battery temperature sensor is also used for

OBD II diagnostics. Certain faults and OBD II mon-

itors are either enabled or disabled depending upon

the battery temperature sensor input (example: dis-

able purge and EGR, enable LDP). Most OBD II

monitors are disabled below 20ÉF.

REMOVAL

The battery temperature sensor is not serviced sep-

arately. If replacement is necessary, the PCM must

be replaced.

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine. It is

serviced only as a complete assembly. The generator

produces DC voltage at the B+ terminal. If the gen-

erator is failed, the generator assembly subcompo-

nents (generator and decoupler pulley) must be

inspected for individual failure and replaced accord-

ingly.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DCcurrent is delivered to the vehicles electrical system

through the generator, battery, and ground terminals.

Excessive or abnormal noise emitting from the gen-

erator may be caused by:

²Worn, loose or defective bearings

²Loose or defective drive pulley (2.4L) or decou-

pler (3.3/3.8L)

²Incorrect, worn, damaged or misadjusted drive

belt

²Loose mounting bolts

²Misaligned drive pulley

²Defective stator or diode

²Damaged internal fins

REMOVAL

REMOVAL - 2.4L

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable.

(3) Disconnect the Inlet Air Temperature sensor.

(4) Remove the Air Box, refer to the Engine/Air

Cleaner for more information.

(5) Remove the EVAP Purge solenoid from its

bracket and reposition.

(6) Disconnect the push-in field wire connector

from back of generator.

(7) Remove nut holding B+ wire terminal to back

of generator.

(8) Separate B+ terminal from generator.

(9) Remove accessory drive belt, refer to the Cool-

ing System section for proper procedures.

(10) Remove the generator.

REMOVAL - 3.3/3.8L

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable.

(3) Disconnect the push-in field wire connector

from back of generator.

(4) Remove nut holding B+ wire terminal to back

of generator.

(5) Separate B+ terminal from generator.

(6) Raise vehicle and support.

(7) Remove the right front lower splash shield.

(8) Remove accessory drive belt, refer to the Cool-

ing System section for proper procedures.

(9) Remove the lower oil dip stick tube bolt (Fig.

2).

(10) Remove wiring harness from the oil dip stick

tube

(11) Remove the 3 mounting bolts.

(12) Lower vehicle.

(13) Remove oil dip stick tube from vehicle.

(14) Roll and remove the generator from vehicle

(Fig. 3).

8F - 24 CHARGINGRS

ProCarManuals.com