air filter housing removal CHRYSLER TOWN AND COUNTRY 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2002Pages: 2399, PDF Size: 57.96 MB

Page 1225 of 2399

AIR CLEANER ELEMENT

REMOVAL

(1) Unsnap 2 clips.

(2) Lift cover and pull toward the engine and

remove cover tabs from air box.

(3) Lift cover and remove the element (Fig. 11).

INSTALLATION

(1) Install the air filter element into air box (Fig.

11).

(2) Move cover so that the tabs insert into the air

box.

(3) Push cover down and snap the 2 clips.

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the inlet air temperature sensor

(Fig. 12).

(3) Remove the inlet hose to throttle body (Fig. 11).

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

12).

(5) Connect the negative battery cable.

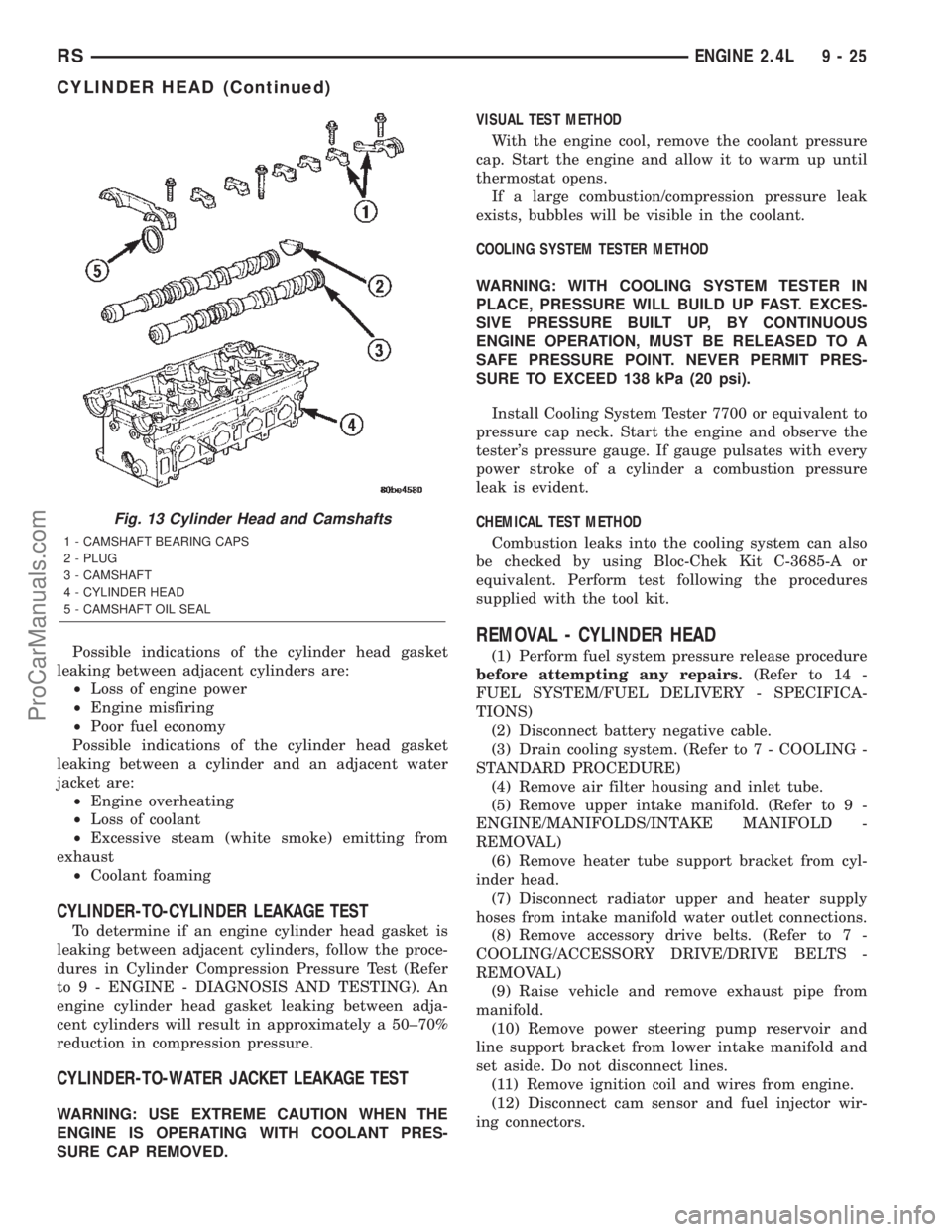

CYLINDER HEAD

DESCRIPTION

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 13). The valves are arranged in two

in-line banks. The intake valves face toward the

front of the vehicle. The exhaust valves face the dash

panel. The cylinder head incorporates powdered

metal valve guides and seats. The cylinder head is

sealed to the block using a multi-layer steel head

gasket and retaining bolts.

Integral oil galleries provide lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

OPERATION

The cylinder head closes the combustion chamber,

allowing the pistons to compress the fuel/air mixture

for ignition. The valves are actuated by the lobe pro-

files on the camshaft to open and close at specified

duration to either allow clean air in the combustion

chamber or the exhaust gases out; depending on the

stroke of the engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Fig. 11 AIR BOX COVER

Fig. 12 IAT SENSOR 2.4L

9 - 24 ENGINE 2.4LRS

ProCarManuals.com

Page 1226 of 2399

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL - CYLINDER HEAD

(1) Perform fuel system pressure release procedure

before attempting any repairs.(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - SPECIFICA-

TIONS)

(2) Disconnect battery negative cable.

(3) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(4) Remove air filter housing and inlet tube.

(5) Remove upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)

(6) Remove heater tube support bracket from cyl-

inder head.

(7) Disconnect radiator upper and heater supply

hoses from intake manifold water outlet connections.

(8) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Raise vehicle and remove exhaust pipe from

manifold.

(10) Remove power steering pump reservoir and

line support bracket from lower intake manifold and

set aside. Do not disconnect lines.

(11) Remove ignition coil and wires from engine.

(12) Disconnect cam sensor and fuel injector wir-

ing connectors.

Fig. 13 Cylinder Head and Camshafts

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

RSENGINE 2.4L9-25

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1300 of 2399

AIR CLEANER ELEMENT

REMOVAL

(1) Unsnap 2 clips.

(2) Lift cover and pull toward the engine and

remove cover tabs from air box.

(3) Lift cover and remove the element (Fig. 15).

INSTALLATION

(1) Install the air filter element into air box (Fig.

15).

(2) Move cover so that the tabs insert into the air

box.

(3) Push cover down and snap the 2 clips.

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the inlet air temperature sensor

(Fig. 16).

(3) Remove the inlet hose to throttle body.

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

Pressure Transducer CH7059

Compression Test Adapter 8116

DRB IIITwith PEP Module OT-CH6010A

Fig. 15 AIR BOX COVER

Fig. 16 Inlet Air Temperature Sensor

RSENGINE 3.3/3.8L9-99

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1338 of 2399

RIGHT MOUNT

REMOVAL

(1) Remove air cleaner housing lid and clean air

hose from throttle body.

(2) Remove air cleaner element and housing.

(3) Disconnect make-up air hose from cylinder

head cover.

(4) Remove the load on the right engine mount by

carefully supporting the engine assembly with a floor

jack.

(5) Disconnect electrical harness support clips from

engine mount bracket.

(6) Remove the bolts attaching the engine mount

to the frame rail (Fig. 99).

(7) Remove the three bolts attaching the engine

mount to the engine bracket (Fig. 99).

(8) Remove the right engine mount (Fig. 99).

INSTALLATION

(1) Install engine bracket (if removed). Tighten

bolts to 33 N´m (24 ft. lbs.).

(2) Position right engine mount and install frame

rail to mount bolts (Fig. 99). Tighten bolts to 68 N´m

(50 ft. lbs.).

(3) Install the mount to engine bracket bolts and

tighten to 54 N´m (40 ft. lbs.). (Fig. 99)

(4) Connect electrical harness support clips to

engine mount bracket.

(5) Remove jack from under engine.

(6) Connect make-up air hose to cylinder head

cover.

(7) Install air cleaner housing and element.

(8) Install air cleaner housing lid and clean air

tube to throttle body.

LUBRICATION

DESCRIPTION

The lubrication system is a full flow filtration pres-

sure feed type. The oil pump is mounted in the tim-

ing chain cover and is driven by the crankshaft

OPERATION

Oil from the oil pan is pumped by a internal gear

type oil pump directly coupled to the crankshaft. The

pressure is regulated by a relief valve located in the

timing chain cover. The oil is pumped through an oil

filter and feeds a main oil gallery. This oil gallery

feeds oil under pressure to the main and rod bear-

ings, camshaft bearings. Passages in the cylinder

block feed oil to the hydraulic lifters and rocker shaft

brackets which feeds the rocker arm pivots (Fig.

100).

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

(1) Disconnect and remove oil pressure switch

(Refer to 9 - ENGINE/LUBRICATION/OIL PRES-

SURE SENSOR/SWITCH - REMOVAL).

(2) Install Special Tools C-3292 Gauge with 8406

Adaptor. For Special Tool identification, (Refer to 9 -

ENGINE - SPECIAL TOOLS).

(3) Start engine and record oil pressure. Refer to

Oil Pressure in Engine Specifications for the correct

pressure (Refer to 9 - ENGINE - SPECIFICATIONS).

Fig. 99 Right Engine Mount

1 - RIGHT ENGINE MOUNT

2 - BOLT - MOUNT TO FRAME RAIL

3 - BOLT - MOUNT TO ENGINE

4 - ENGINE MOUNT BRACKET

5 - RIGHT FRAME RAIL

RSENGINE 3.3/3.8L9 - 137

ProCarManuals.com

Page 1493 of 2399

Refer to the maintenance schedules for the recom-

mended fuel filter replacement intervals.

For draining of water from canister, refer to Fuel

Filter/Water Separator Removal/Installation section.

A Water-In-Fuel (WIF) sensor is part of the fuel fil-

ter cap. Refer to Water-In-Fuel Sensor Description/

Operation.

The fuel heater is installed into the filter/separator

housing above the fuel filter. Refer to Fuel Heater

Description/Operation.

FUEL LINES

DESCRIPTION

DESCRIPTION

All fuel lines up to the fuel injection pump are con-

sidered low-pressure. This includes the fuel lines

from: the fuel tank to the fuel transfer pump, and

the fuel transfer pump to the fuel injection pump.

The fuel return lines and the fuel drain lines are also

considered low-pressure lines. High-pressure lines

are used between the fuel injection pump and the

fuel injectors. Also refer to High-Pressure Fuel Lines

Description/Operation.

DESCRIPTION - HIGH PRESSURE FUEL LINES

The high-pressure fuel lines are the 4 lines located

between the fuel injection pump and the fuel injec-

torsctor tubes. All other fuel lines are considered low-

pressure lines.

OPERATION - HIGH PRESSURE FUEL LINES

CAUTION: The high-pressure fuel lines cannot con-

tact each other or other components. Do not

attempt to weld high-pressure fuel lines or to repair

lines that are damaged. If lines are ever kinked or

bent, they must be replaced. Use only the recom-

mended lines when replacement of high-pressure

fuel line is necessary.

High-pressure fuel lines deliver fuel under

extremely high pressure from the injection pump to

the fuel injectors. The lines expand and contract from

the high-pressure fuel pulses generated during the

injection process. All high-pressure fuel lines are of

the same length and inside diameter. Correct high-

pressure fuel line usage and installation is critical to

smooth engine operation.

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH-PRESSURE FUEL LEAKS.

INSPECT FOR HIGH-PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTIONPRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

DIAGNOSIS AND TESTING - HIGH PRESSURE

FUEL LINES

High-pressure fuel line leaks can cause starting

problems and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES,

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. DO NOT GET YOUR

HAND NEAR A SUSPECTED LEAK. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

Start the engine. Move the cardboard over the

high-pressure fuel lines and check for fuel spray onto

the cardboard (Fig. 4). If a high-pressure line connec-

tion is leaking, bleed the system and tighten the con-

nection. Refer to the Air Bleed Procedure in this

group for procedures. Replace damaged, restricted or

leaking high-pressure fuel lines with the correct

replacement line.

Fig. 4 Typical Test for Leaks with Cardboard

1 - HIGH-PRESSURE LINE

2 - CARDBOARD

3 - FITTING

14a - 6 FUEL DELIVERYRG

FUEL FILTER / WATER SEPARATOR (Continued)

ProCarManuals.com

Page 1494 of 2399

CAUTION: The high-pressure fuel lines cannot con-

tact each other or other components. Do not

attempt to weld high-pressure fuel lines or to repair

lines that are damaged. Only use the recommended

lines when replacement of high-pressure fuel line is

necessary.

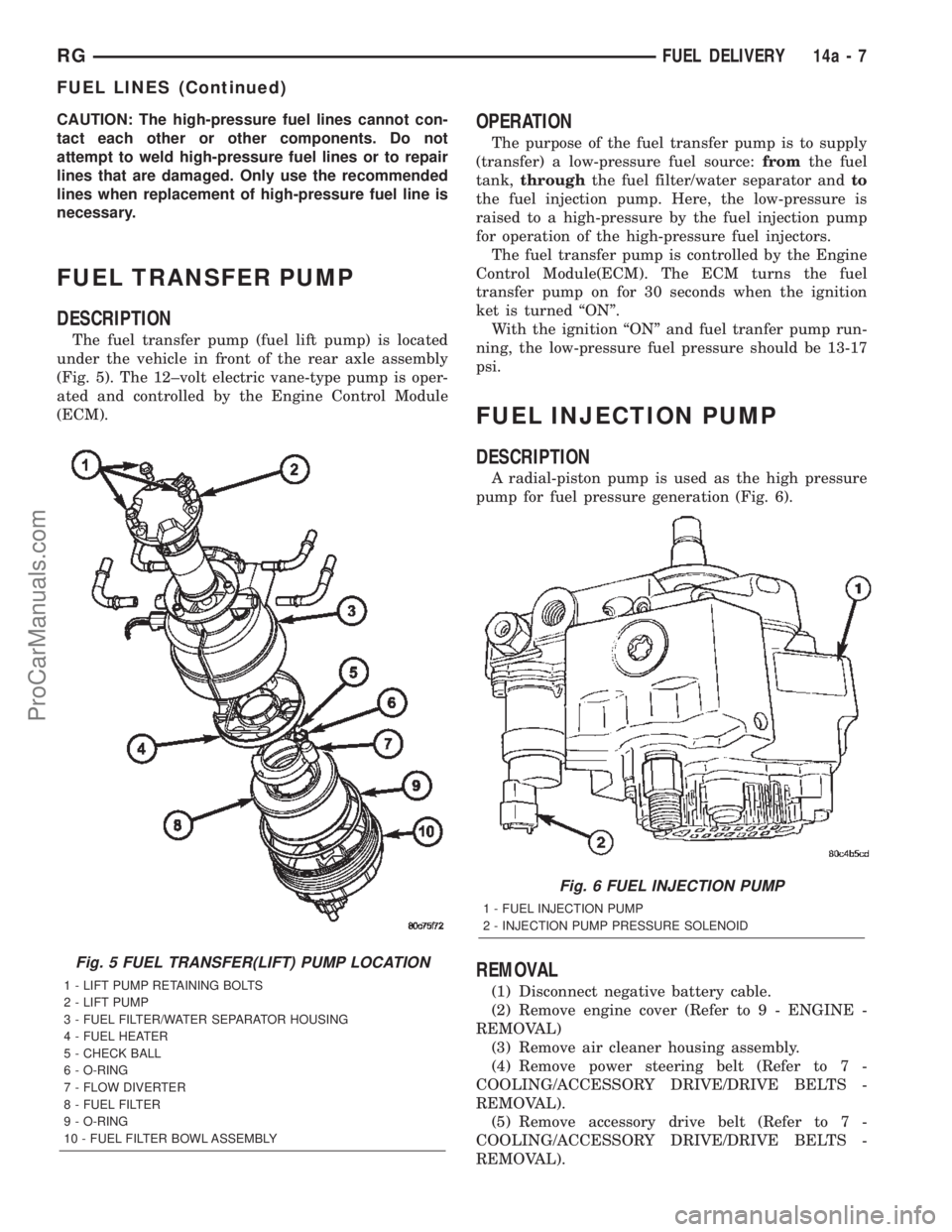

FUEL TRANSFER PUMP

DESCRIPTION

The fuel transfer pump (fuel lift pump) is located

under the vehicle in front of the rear axle assembly

(Fig. 5). The 12±volt electric vane-type pump is oper-

ated and controlled by the Engine Control Module

(ECM).

OPERATION

The purpose of the fuel transfer pump is to supply

(transfer) a low-pressure fuel source:fromthe fuel

tank,throughthe fuel filter/water separator andto

the fuel injection pump. Here, the low-pressure is

raised to a high-pressure by the fuel injection pump

for operation of the high-pressure fuel injectors.

The fuel transfer pump is controlled by the Engine

Control Module(ECM). The ECM turns the fuel

transfer pump on for 30 seconds when the ignition

ket is turned ªONº.

With the ignition ªONº and fuel tranfer pump run-

ning, the low-pressure fuel pressure should be 13-17

psi.

FUEL INJECTION PUMP

DESCRIPTION

A radial-piston pump is used as the high pressure

pump for fuel pressure generation (Fig. 6).

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL)

(3) Remove air cleaner housing assembly.

(4) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

Fig. 5 FUEL TRANSFER(LIFT) PUMP LOCATION

1 - LIFT PUMP RETAINING BOLTS

2 - LIFT PUMP

3 - FUEL FILTER/WATER SEPARATOR HOUSING

4 - FUEL HEATER

5 - CHECK BALL

6 - O-RING

7 - FLOW DIVERTER

8 - FUEL FILTER

9 - O-RING

10 - FUEL FILTER BOWL ASSEMBLY

Fig. 6 FUEL INJECTION PUMP

1 - FUEL INJECTION PUMP

2 - INJECTION PUMP PRESSURE SOLENOID

RGFUEL DELIVERY14a-7

FUEL LINES (Continued)

ProCarManuals.com

Page 1503 of 2399

MASS AIR FLOW (MAF)

SENSOR

DESCRIPTION

The Mass Air Flow (MAF) Sensor is mounted

inline in the air intake between the air filter and the

turbocharger (Fig. 8).

OPERATION

The ECM uses the mass air flow (MAF) sensor to

measure air density. The MAF sensor contains a

ceramic element. A signal voltage is provided to the

element. As engine speed increases, airflow across

the ceramic element increases. Changes in air flow

and air density cause the temperature of the ceramic

element to fluxuate. The ceramic element changes

resistance respectively to changes in temperature.

The change in resistance varies the signal voltage

output to the ECM. The diesel power relay supplies

battery power the to MAF sensor. Ground is providedby the ECM. The MAF sensor signal is provided by

the ECM.

REMOVAL

(1) Disconnect negative battery cable.

(2) Disconnect MAF sensor electrical connector

(Fig. 9).

(3) Loosen MAF sensor retaining clamps (Fig. 9).

(4) Remove MAF sensor from airduct (Fig. 9).

INSTALLATION

(1) Install MAF sensor in airduct (Fig. 9).

(2) Tighten retaining clamps (Fig. 9).

(3) Connect MAF sensor electrical connector (Fig.

9).

(4) Connect negative battery cable.

Fig. 8 MASS AIR FLOW (MAF) SENSOR

Fig. 9 MASS AIR FLOW (MAF) SENSOR LOCATION

1 - MAF SENSOR ELECTRICAL CONNECTOR

2 - RETAINING CLAMPS

3 - MASS AIR FLOW (MAF) SENSOR

4 - AIR CLEANER HOUSING

14a - 16 FUEL INJECTIONRG

ProCarManuals.com

Page 1578 of 2399

31TH AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

31TH AUTOMATIC TRANSAXLE

DESCRIPTION.........................22

OPERATION...........................24

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

DIAGNOSIS..........................24

DIAGNOSIS AND TESTING - ROAD TEST . . . 31

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS....................32

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE . . . 35

DIAGNOSIS AND TESTING - CLUTCH AND

SERVO AIR PRESSURE TESTS..........35

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR......................37

REMOVAL.............................37

DISASSEMBLY.........................40

ASSEMBLY............................51

INSTALLATION.........................61

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC

SCHEMATICS........................64

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE..........72

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE..........75

ACCUMULATOR

DESCRIPTION.........................79

OPERATION...........................79

BANDS

DESCRIPTION

KICKDOWN (FRONT) BAND.............80

OPERATION

LOW/REVERSE (REAR) BAND...........80

ADJUSTMENTS

ADJUSTMENT - FRONT BAND...........80

ADJUSTMENTS - REAR BAND...........80

CLUTCH - FRONT

DESCRIPTION.........................82

OPERATION...........................82

DISASSEMBLY.........................82

ASSEMBLY............................84

CLUTCH - REAR

DESCRIPTION.........................86

OPERATION...........................86

DISASSEMBLY.........................87

ASSEMBLY............................89

FINAL DRIVE

DISASSEMBLY.........................91

ASSEMBLY............................94ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING . . 97

FLUID

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

AND CONDITION CHECK...............99

STANDARD PROCEDURE - FLUID AND

FILTER CHANGE......................99

GEAR SHIFT CABLE

REMOVAL............................101

INSTALLATION........................102

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT.......104

GOVERNOR

DESCRIPTION........................104

OPERATION..........................104

CLEANING...........................104

INSPECTION.........................104

OIL PUMP

DESCRIPTION........................105

OPERATION..........................105

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................105

DISASSEMBLY........................106

CLEANING...........................106

INSPECTION.........................106

ASSEMBLY...........................107

PARK/NEUTRAL POSITION SWITCH

DIAGNOSIS AND TESTING - PARK/NEUTRAL

POSITION SWITCH...................107

REMOVAL............................107

INSTALLATION........................107

PLANETARY GEARTRAIN

DISASSEMBLY........................108

ASSEMBLY...........................109

SEAL - OIL PUMP

REMOVAL............................110

INSTALLATION........................110

SERVO - KICKDOWN

DESCRIPTION........................111

OPERATION..........................111

DISASSEMBLY........................111

CLEANING...........................112

INSPECTION..........................113

ASSEMBLY...........................113

SERVO - LOW/REVERSE

DESCRIPTION........................113

OPERATION..........................113

DISASSEMBLY........................114

CLEANING...........................114

RS31TH AUTOMATIC TRANSAXLE21-21

ProCarManuals.com

Page 1718 of 2399

41TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

41TE AUTOMATIC TRANSAXLE

DESCRIPTION........................162

OPERATION..........................164

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 41TE

TRANSAXLE GENERAL DIAGNOSIS......164

DIAGNOSIS AND TESTING - ROAD TEST . . 165

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS...................165

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS...................168

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE . . 168

REMOVAL............................169

DISASSEMBLY........................171

ASSEMBLY...........................190

INSTALLATION........................213

SCHEMATICS AND DIAGRAMS

41TE TRANSAXLE HYDRAULIC

SCHEMATICS.......................216

SPECIFICATIONS - 41TE TRANSAXLE......228

SPECIAL TOOLS

41TE AUTOMATIC TRANSAXLE.........230

ACCUMULATOR

DESCRIPTION........................236

OPERATION..........................236

AUTOSTICK SWITCH

DESCRIPTION........................237

OPERATION..........................237

DRIVING CLUTCHES

DESCRIPTION........................237

OPERATION..........................238

FINAL DRIVE

DISASSEMBLY........................238

ASSEMBLY...........................243

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING

PRELOAD..........................246

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK . . . 249

STANDARD PROCEDURE - FLUID AND

FILTER SERVICE.....................250

GEAR SHIFT CABLE

REMOVAL............................251

INSTALLATION........................253

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT.......254

HOLDING CLUTCHES

DESCRIPTION........................255OPERATION..........................255

INPUT CLUTCH ASSEMBLY

DISASSEMBLY........................255

ASSEMBLY...........................263

OIL PUMP

DESCRIPTION........................272

OPERATION..........................272

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................272

DISASSEMBLY........................273

ASSEMBLY...........................274

PLANETARY GEARTRAIN

DESCRIPTION........................274

OPERATION..........................274

SEAL - OIL PUMP

REMOVAL............................275

INSTALLATION........................275

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................275

OPERATION..........................276

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................277

REMOVAL............................277

INSTALLATION........................278

SOLENOID/PRESSURE SWITCH ASSY

DESCRIPTION........................279

OPERATION..........................280

REMOVAL............................280

INSTALLATION........................281

SPEED SENSOR - INPUT

DESCRIPTION........................281

OPERATION..........................282

REMOVAL............................282

INSTALLATION........................283

SPEED SENSOR - OUTPUT

DESCRIPTION........................283

OPERATION..........................283

REMOVAL............................284

INSTALLATION........................284

TORQUE CONVERTER

DESCRIPTION........................285

OPERATION..........................289

REMOVAL............................290

INSTALLATION........................290

TRANSMISSION CONTROL RELAY

DESCRIPTION........................291

OPERATION..........................291

TRANSMISSION RANGE SENSOR

DESCRIPTION........................291

RS41TE AUTOMATIC TRANSAXLE21 - 161

ProCarManuals.com

Page 2254 of 2399

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the headlamp and dash wire har-

ness connector for the A/C pressure transducer from

the transducer connector receptacle (Fig. 3).

(3) Using an open end wrench, unscrew the A/C

pressure transducer from the fitting on the liquid

line between the filter-drier and the expansion valve.

(4) Remove the seal from the A/C pressure trans-

ducer fitting and discard.

INSTALLATION

(1) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the A/C pressure

transducer fitting.

(2) Using an open end wrench, install and tighten

the A/C pressure transducer onto the fitting on the

liquid line between the filter-drier and the expansion

valve.

(3) Reconnect the headlamp and dash wire harness

connector for the A/C pressure transducer to the

transducer connector receptacle.

(4) Reconnect the battery negative cable.

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door actuators are reversible, 12-volt

Direct Current (DC), servo motors. Models with the

single zone heater and air conditioner system have a

single blend air door, which is controlled by a singleblend door actuator. Models with the optional dual

zone front heater and air conditioner system have

dual blend air doors, which are controlled by two

blend door actuators. The single zone blend door

actuator is located on the driver side end of the heat-

er-A/C housing unit, close to the dash panel. In the

dual zone system, the same blend door actuator used

for the single zone system becomes the passenger

blend door actuator, and is mechanically connected to

only the passenger side blend air door. In the dual

zone system, a second separate blend door actuator is

also located on the driver side end of the heater-A/C

housing unit close to the instrument panel, and is

mechanically connected to only the driver side blend

air door.

The blend door actuators are interchangeable with

each other, as well as with the actuators for the

mode door and the recirculation air door. Each actua-

tor is contained within an identical black molded

plastic housing with an integral wire connector

receptacle. Two integral mounting tabs allow the

actuator to be secured with two screws to the heater-

A/C unit housing. Each actuator also has an identical

output shaft with splines that connects it to the link-

age that drives the proper blend air door. The blend

door actuators do not require mechanical indexing to

the blend door linkage, as they are electronically cal-

ibrated by the heater-A/C control module. The blend

door actuators cannot be adjusted or repaired and, if

damaged or faulty, they must be replaced.

OPERATION

Each blend door actuator is connected to the heat-

er-A/C control module through the vehicle electrical

system by a dedicated two-wire take out and connec-

tor of the HVAC wire harness. The blend door actua-

tor can move the blend air door in two directions.

When the heater-A/C control module pulls the volt-

age on one side of the motor connection high and the

other connection low, the blend air door will move in

one direction. When the module reverses the polarity

of the voltage to the motor, the blend air door moves

in the opposite direction. When the module makes

the voltage to both connections high or both connec-

tions low, the blend air door stops and will not move.

These same motor connections also provide a feed-

back signal to the heater-A/C control module. This

feedback signal allows the module to monitor the

operation and relative positions of the blend door

actuator and the blend air door. The heater-A/C con-

trol module learns the blend air door stop positions

during the calibration procedure and will store a

Diagnostic Trouble Code (DTC) for any problems it

detects in the blend door actuator circuits. The blend

door actuator can be diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Fig. 3 A/C Pressure Transducer

1 - RIGHT FRONT STRUT TOWER

2 - CONNECTOR

3 - A/C PRESSURE TRANSDUCER

4 - RIGHT WIPER MODULE DRAIN TUBE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

RSCONTROLS - FRONT24-11

A/C PRESSURE TRANSDUCER (Continued)

ProCarManuals.com