chain CHRYSLER TOWN AND COUNTRY 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2002Pages: 2399, PDF Size: 57.96 MB

Page 21 of 2399

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

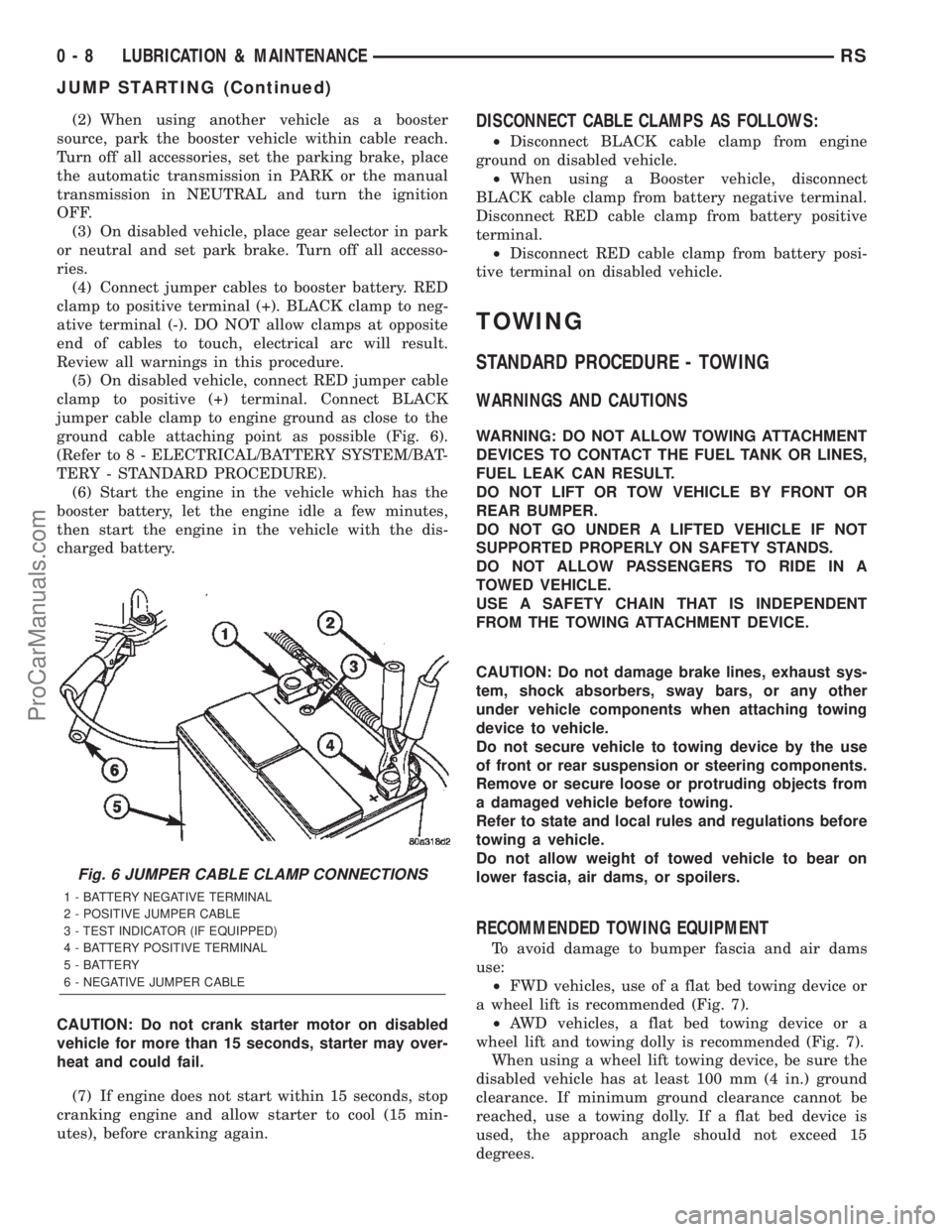

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 6).

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter may over-

heat and could fail.

(7) If engine does not start within 15 seconds, stop

cranking engine and allow starter to cool (15 min-

utes), before cranking again.DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

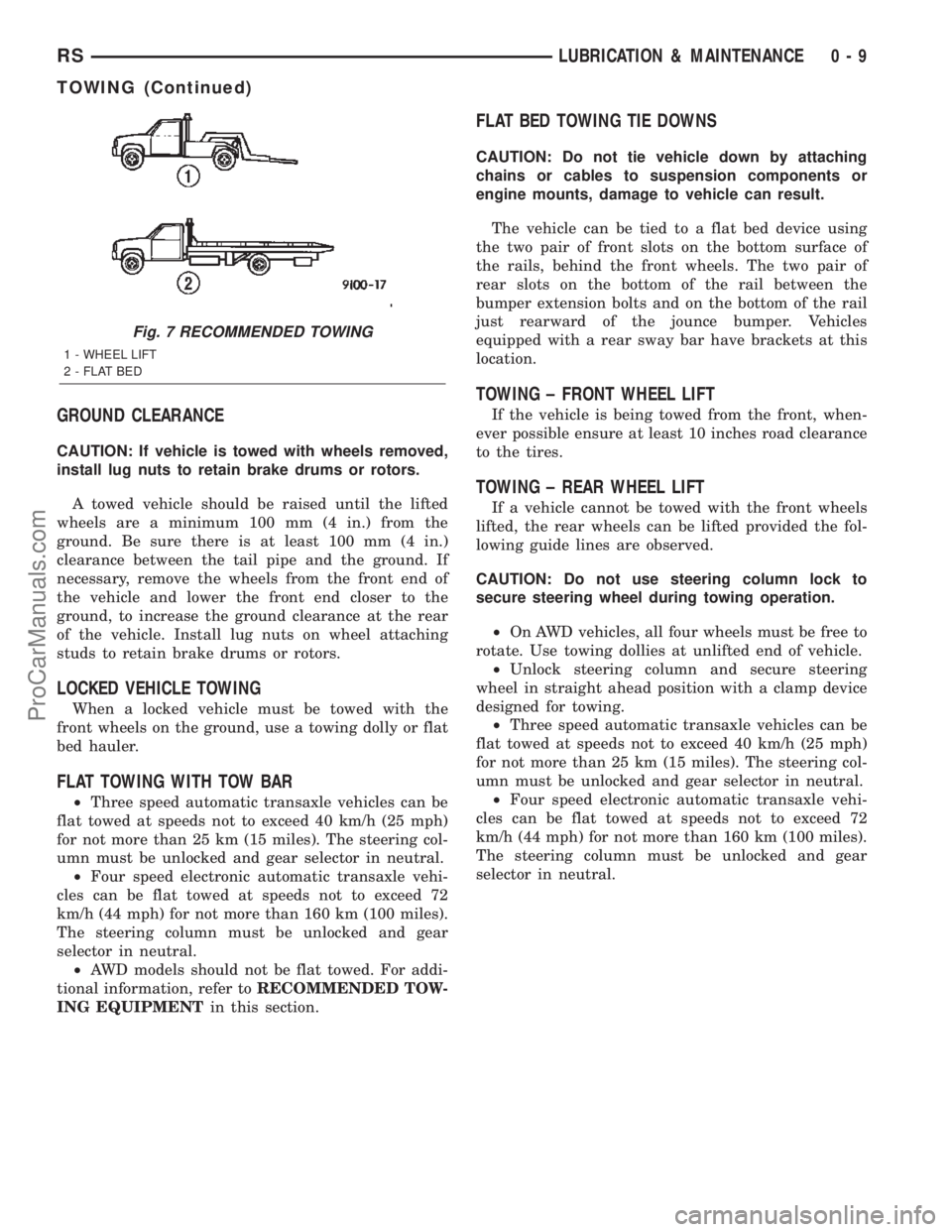

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

Fig. 6 JUMPER CABLE CLAMP CONNECTIONS

1 - BATTERY NEGATIVE TERMINAL

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR (IF EQUIPPED)

4 - BATTERY POSITIVE TERMINAL

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

0 - 8 LUBRICATION & MAINTENANCERS

JUMP STARTING (Continued)

ProCarManuals.com

Page 22 of 2399

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the front end of

the vehicle and lower the front end closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

TOWING ± FRONT WHEEL LIFT

If the vehicle is being towed from the front, when-

ever possible ensure at least 10 inches road clearance

to the tires.

TOWING ± REAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

Fig. 7 RECOMMENDED TOWING

1 - WHEEL LIFT

2 - FLAT BED

RSLUBRICATION & MAINTENANCE0-9

TOWING (Continued)

ProCarManuals.com

Page 283 of 2399

(7) Install the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- INSTALLATION).

(8) Install the generator mount bracket. (Fig. 24)

(9) Install the generator.

(10) Install right engine mount bracket and engine

mount (Refer to 9 - ENGINE/ENGINE MOUNTING/

RIGHT MOUNT - INSTALLATION).

(11) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(12) Install the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Lower vehicle and connect battery cable.

WATER PUMP - 3.3/3.8L

DESCRIPTION

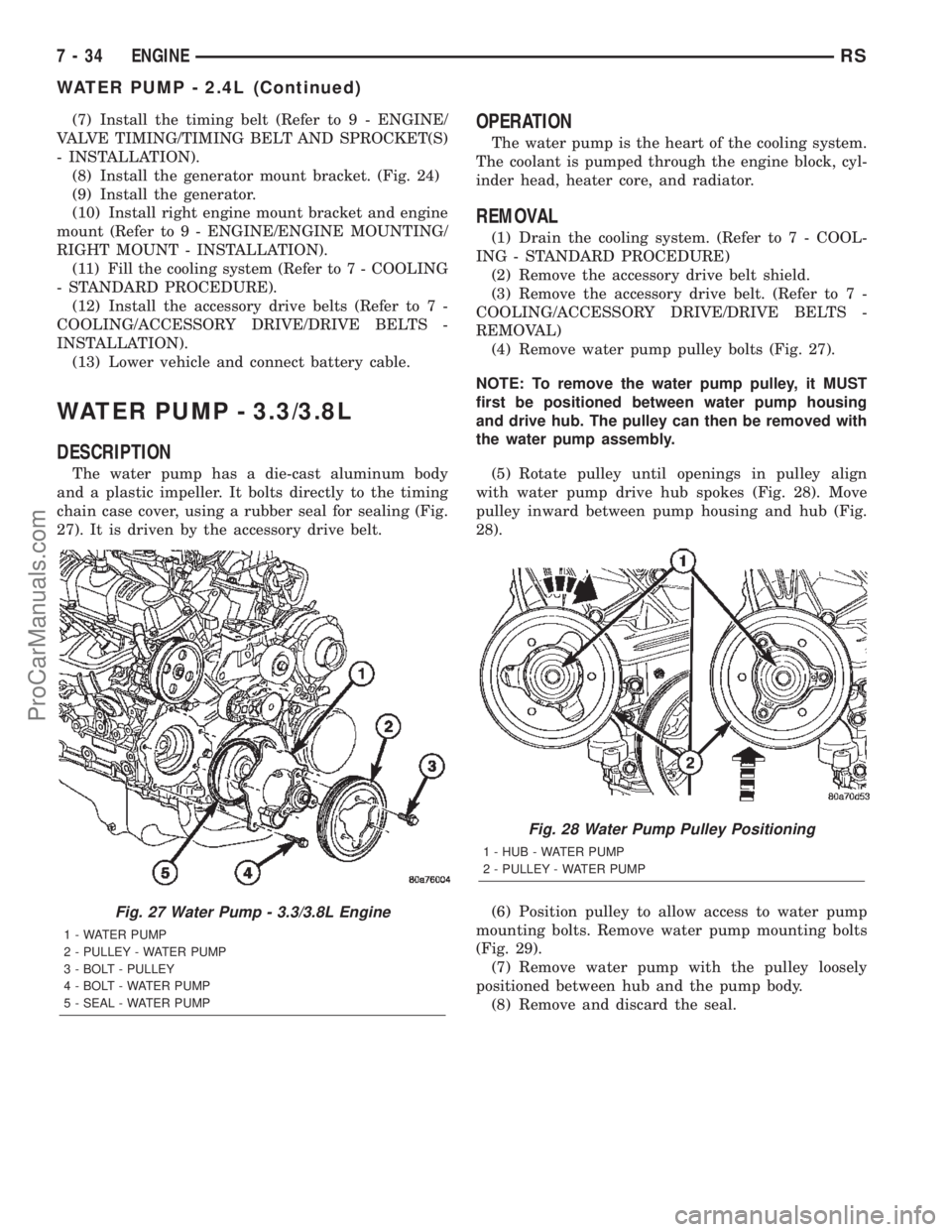

The water pump has a die-cast aluminum body

and a plastic impeller. It bolts directly to the timing

chain case cover, using a rubber seal for sealing (Fig.

27). It is driven by the accessory drive belt.

OPERATION

The water pump is the heart of the cooling system.

The coolant is pumped through the engine block, cyl-

inder head, heater core, and radiator.

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Remove the accessory drive belt shield.

(3) Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove water pump pulley bolts (Fig. 27).

NOTE: To remove the water pump pulley, it MUST

first be positioned between water pump housing

and drive hub. The pulley can then be removed with

the water pump assembly.

(5) Rotate pulley until openings in pulley align

with water pump drive hub spokes (Fig. 28). Move

pulley inward between pump housing and hub (Fig.

28).

(6) Position pulley to allow access to water pump

mounting bolts. Remove water pump mounting bolts

(Fig. 29).

(7) Remove water pump with the pulley loosely

positioned between hub and the pump body.

(8) Remove and discard the seal.

Fig. 27 Water Pump - 3.3/3.8L Engine

1 - WATER PUMP

2 - PULLEY - WATER PUMP

3 - BOLT - PULLEY

4 - BOLT - WATER PUMP

5 - SEAL - WATER PUMP

Fig. 28 Water Pump Pulley Positioning

1 - HUB - WATER PUMP

2 - PULLEY - WATER PUMP

7 - 34 ENGINERS

WATER PUMP - 2.4L (Continued)

ProCarManuals.com

Page 284 of 2399

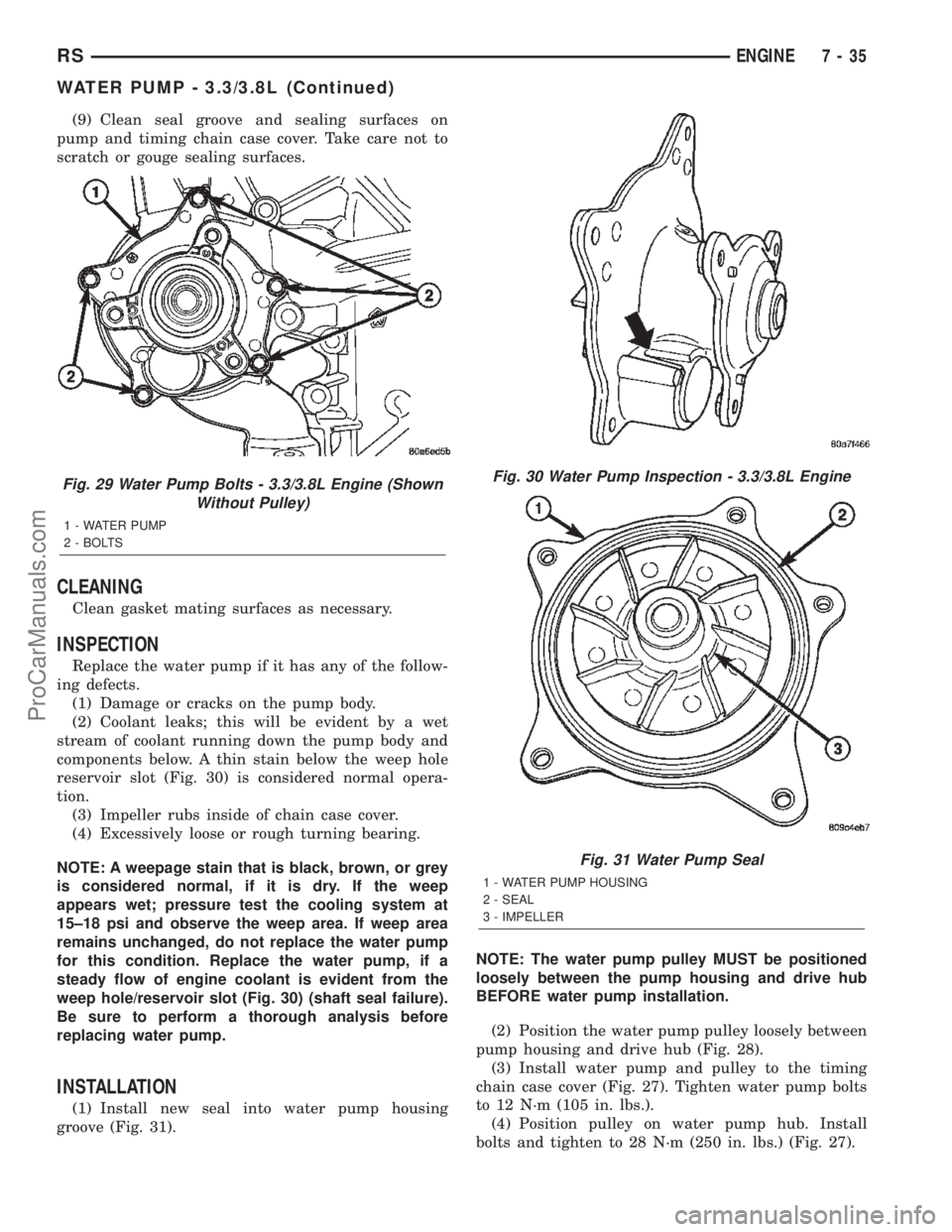

(9) Clean seal groove and sealing surfaces on

pump and timing chain case cover. Take care not to

scratch or gouge sealing surfaces.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Replace the water pump if it has any of the follow-

ing defects.

(1) Damage or cracks on the pump body.

(2) Coolant leaks; this will be evident by a wet

stream of coolant running down the pump body and

components below. A thin stain below the weep hole

reservoir slot (Fig. 30) is considered normal opera-

tion.

(3) Impeller rubs inside of chain case cover.

(4) Excessively loose or rough turning bearing.

NOTE: A weepage stain that is black, brown, or grey

is considered normal, if it is dry. If the weep

appears wet; pressure test the cooling system at

15±18 psi and observe the weep area. If weep area

remains unchanged, do not replace the water pump

for this condition. Replace the water pump, if a

steady flow of engine coolant is evident from the

weep hole/reservoir slot (Fig. 30) (shaft seal failure).

Be sure to perform a thorough analysis before

replacing water pump.

INSTALLATION

(1) Install new seal into water pump housing

groove (Fig. 31).NOTE: The water pump pulley MUST be positioned

loosely between the pump housing and drive hub

BEFORE water pump installation.

(2) Position the water pump pulley loosely between

pump housing and drive hub (Fig. 28).

(3) Install water pump and pulley to the timing

chain case cover (Fig. 27). Tighten water pump bolts

to 12 N´m (105 in. lbs.).

(4) Position pulley on water pump hub. Install

bolts and tighten to 28 N´m (250 in. lbs.) (Fig. 27).

Fig. 29 Water Pump Bolts - 3.3/3.8L Engine (Shown

Without Pulley)

1 - WATER PUMP

2 - BOLTS

Fig. 30 Water Pump Inspection - 3.3/3.8L Engine

Fig. 31 Water Pump Seal

1 - WATER PUMP HOUSING

2 - SEAL

3 - IMPELLER

RSENGINE7-35

WATER PUMP - 3.3/3.8L (Continued)

ProCarManuals.com

Page 286 of 2399

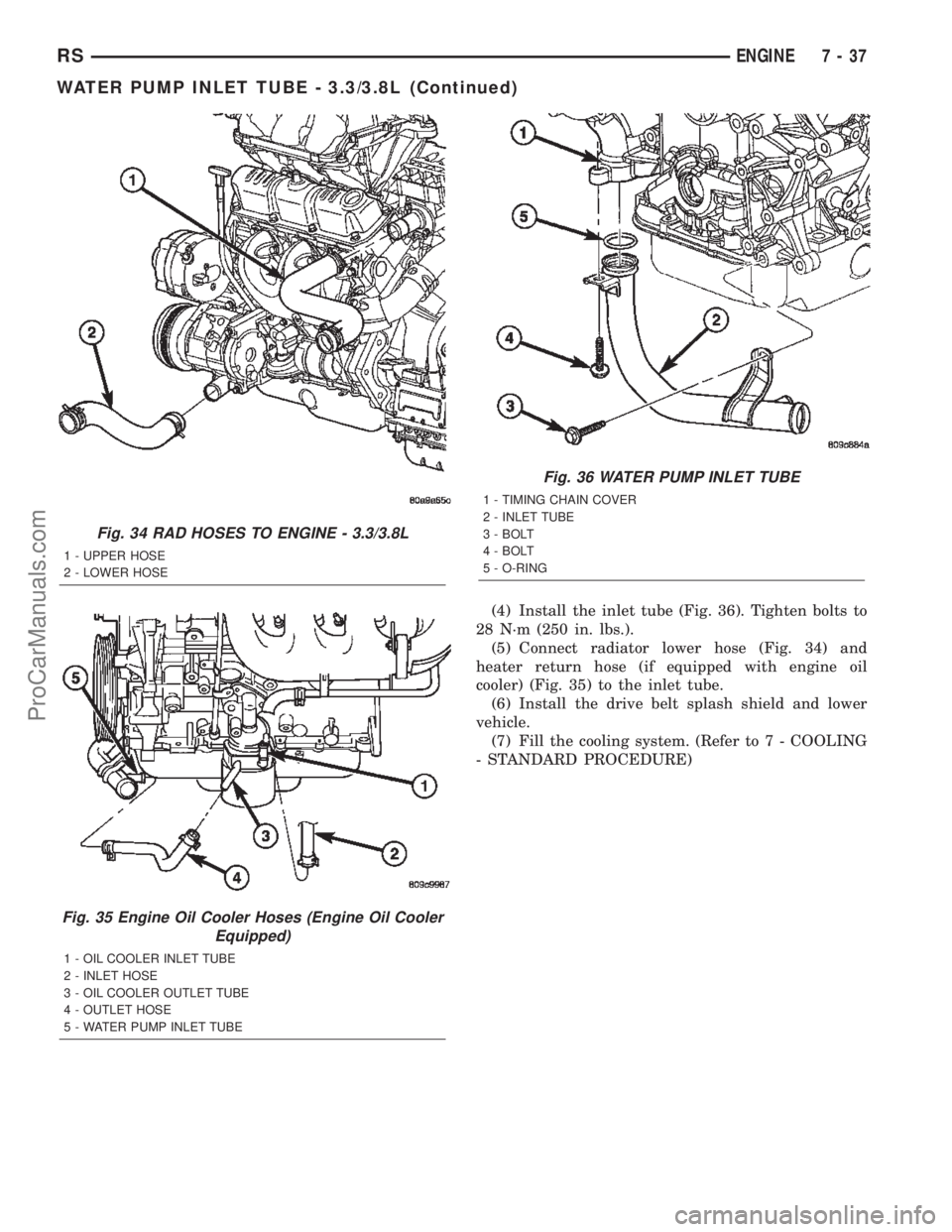

(4) Install the inlet tube (Fig. 36). Tighten bolts to

28 N´m (250 in. lbs.).

(5) Connect radiator lower hose (Fig. 34) and

heater return hose (if equipped with engine oil

cooler) (Fig. 35) to the inlet tube.

(6) Install the drive belt splash shield and lower

vehicle.

(7) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

Fig. 34 RAD HOSES TO ENGINE - 3.3/3.8L

1 - UPPER HOSE

2 - LOWER HOSE

Fig. 35 Engine Oil Cooler Hoses (Engine Oil Cooler

Equipped)

1 - OIL COOLER INLET TUBE

2 - INLET HOSE

3 - OIL COOLER OUTLET TUBE

4 - OUTLET HOSE

5 - WATER PUMP INLET TUBE

Fig. 36 WATER PUMP INLET TUBE

1 - TIMING CHAIN COVER

2 - INLET TUBE

3 - BOLT

4 - BOLT

5 - O-RING

RSENGINE7-37

WATER PUMP INLET TUBE - 3.3/3.8L (Continued)

ProCarManuals.com

Page 312 of 2399

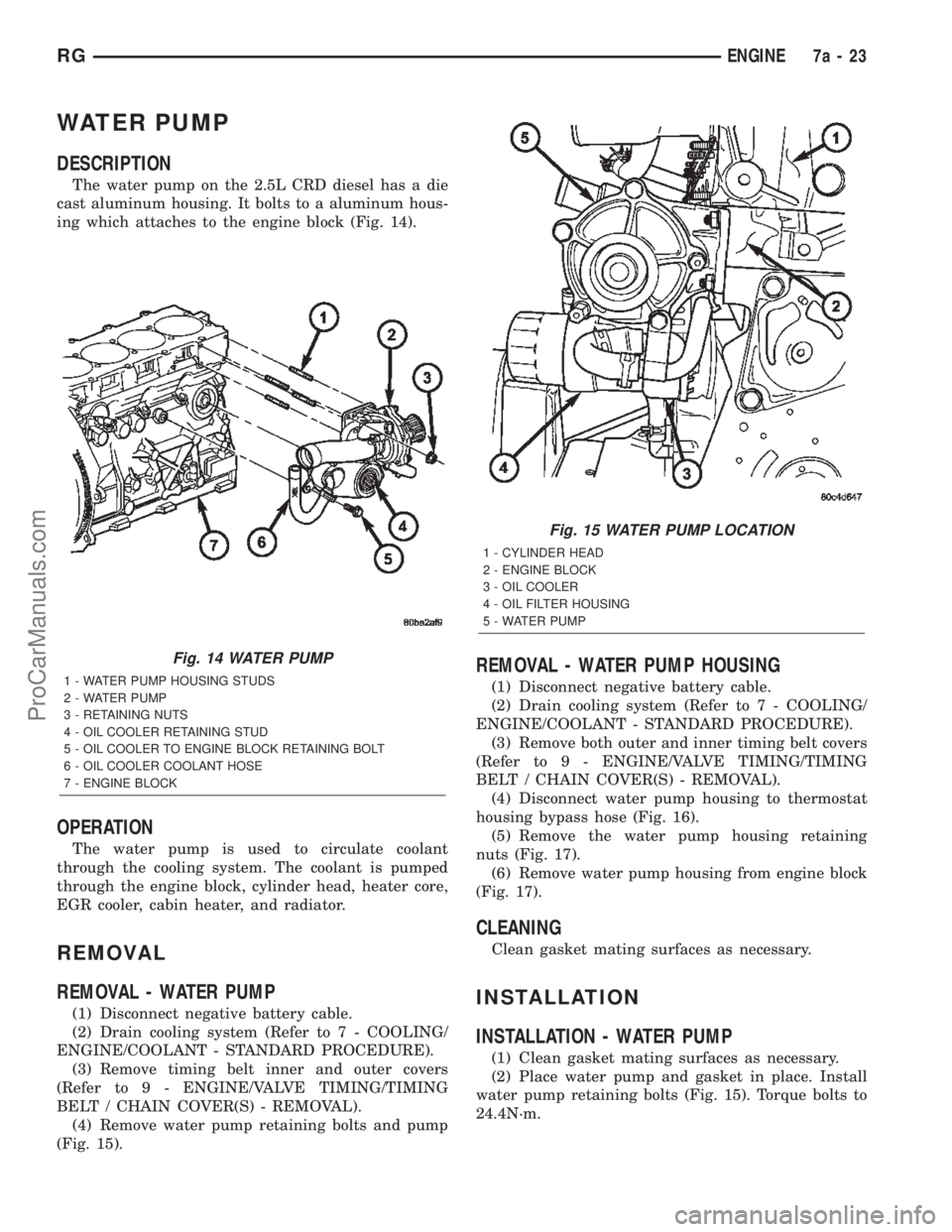

WATER PUMP

DESCRIPTION

The water pump on the 2.5L CRD diesel has a die

cast aluminum housing. It bolts to a aluminum hous-

ing which attaches to the engine block (Fig. 14).

OPERATION

The water pump is used to circulate coolant

through the cooling system. The coolant is pumped

through the engine block, cylinder head, heater core,

EGR cooler, cabin heater, and radiator.

REMOVAL

REMOVAL - WATER PUMP

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove timing belt inner and outer covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Remove water pump retaining bolts and pump

(Fig. 15).

REMOVAL - WATER PUMP HOUSING

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove both outer and inner timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Disconnect water pump housing to thermostat

housing bypass hose (Fig. 16).

(5) Remove the water pump housing retaining

nuts (Fig. 17).

(6) Remove water pump housing from engine block

(Fig. 17).

CLEANING

Clean gasket mating surfaces as necessary.

INSTALLATION

INSTALLATION - WATER PUMP

(1) Clean gasket mating surfaces as necessary.

(2) Place water pump and gasket in place. Install

water pump retaining bolts (Fig. 15). Torque bolts to

24.4N´m.

Fig. 14 WATER PUMP

1 - WATER PUMP HOUSING STUDS

2 - WATER PUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

Fig. 15 WATER PUMP LOCATION

1 - CYLINDER HEAD

2 - ENGINE BLOCK

3 - OIL COOLER

4 - OIL FILTER HOUSING

5 - WATER PUMP

RGENGINE7a-23

ProCarManuals.com

Page 313 of 2399

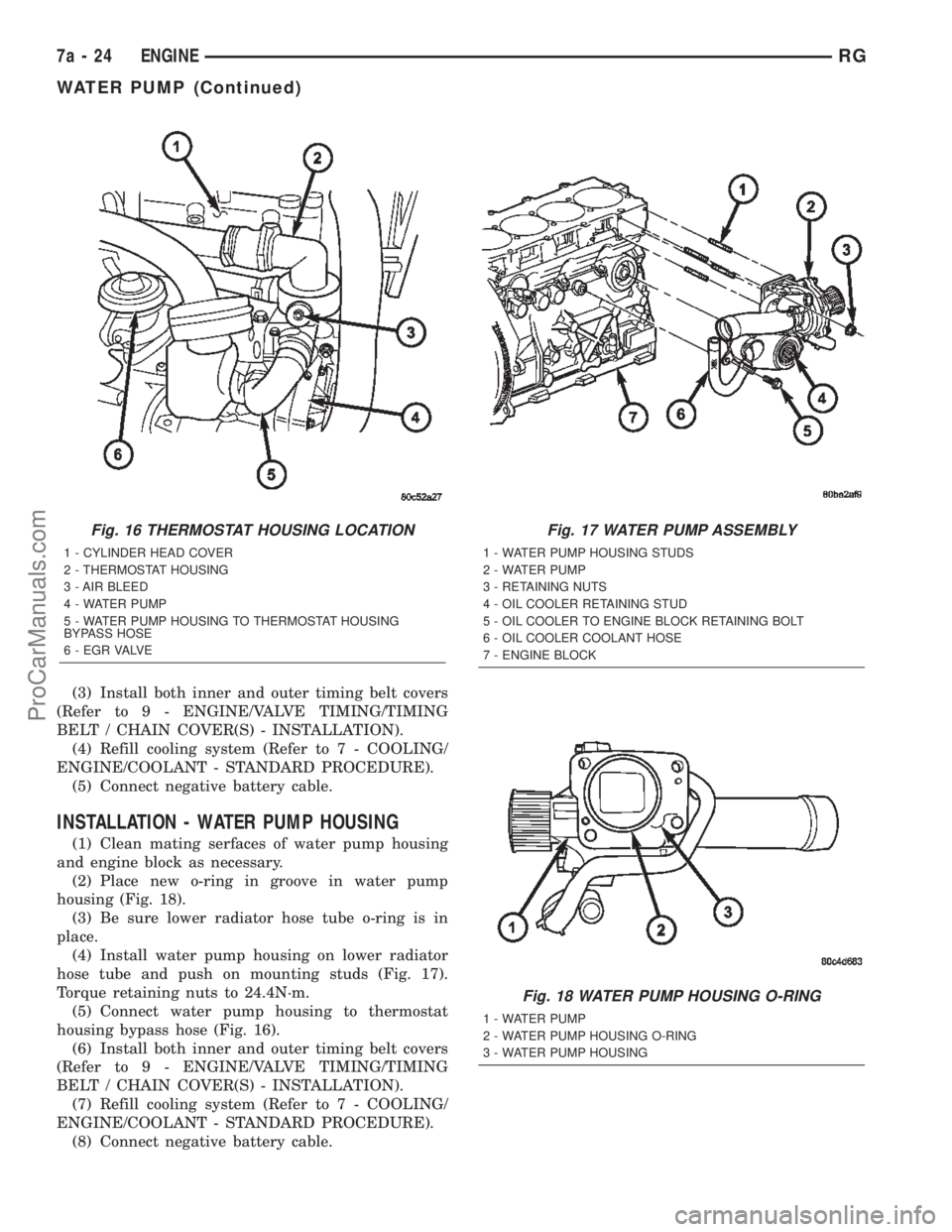

(3) Install both inner and outer timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION).

(4) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Connect negative battery cable.

INSTALLATION - WATER PUMP HOUSING

(1) Clean mating serfaces of water pump housing

and engine block as necessary.

(2) Place new o-ring in groove in water pump

housing (Fig. 18).

(3) Be sure lower radiator hose tube o-ring is in

place.

(4) Install water pump housing on lower radiator

hose tube and push on mounting studs (Fig. 17).

Torque retaining nuts to 24.4N´m.

(5) Connect water pump housing to thermostat

housing bypass hose (Fig. 16).

(6) Install both inner and outer timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION).

(7) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(8) Connect negative battery cable.

Fig. 16 THERMOSTAT HOUSING LOCATION

1 - CYLINDER HEAD COVER

2 - THERMOSTAT HOUSING

3 - AIR BLEED

4 - WATER PUMP

5 - WATER PUMP HOUSING TO THERMOSTAT HOUSING

BYPASS HOSE

6 - E G R VA LV E

Fig. 17 WATER PUMP ASSEMBLY

1 - WATER PUMP HOUSING STUDS

2 - WATER PUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

Fig. 18 WATER PUMP HOUSING O-RING

1 - WATER PUMP

2 - WATER PUMP HOUSING O-RING

3 - WATER PUMP HOUSING

7a - 24 ENGINERG

WATER PUMP (Continued)

ProCarManuals.com

Page 480 of 2399

(6) Pull sensor up out of the chain case cover.Do

not pull on the sensor wiring.There is an O-ring

on the body of the sensor. The O-ring may make

removal difficult. A light tap to top of sensor prior to

removal may reduce force needed for removal.

Fig. 3 EGR/CAM SENSOR 2.4L

Fig. 4 Target Magnet Removal/Installation

1 - TARGET MAGNET

2 - MOUNTING BOLT

3 - REAR OF CYLINDER HEAD

Fig. 5 AIR BOX COVER

Fig. 6 CAMSHAFT POSITION SENSOR

RSIGNITION CONTROL8I-5

CAMSHAFT POSITION SENSOR (Continued)

ProCarManuals.com

Page 481 of 2399

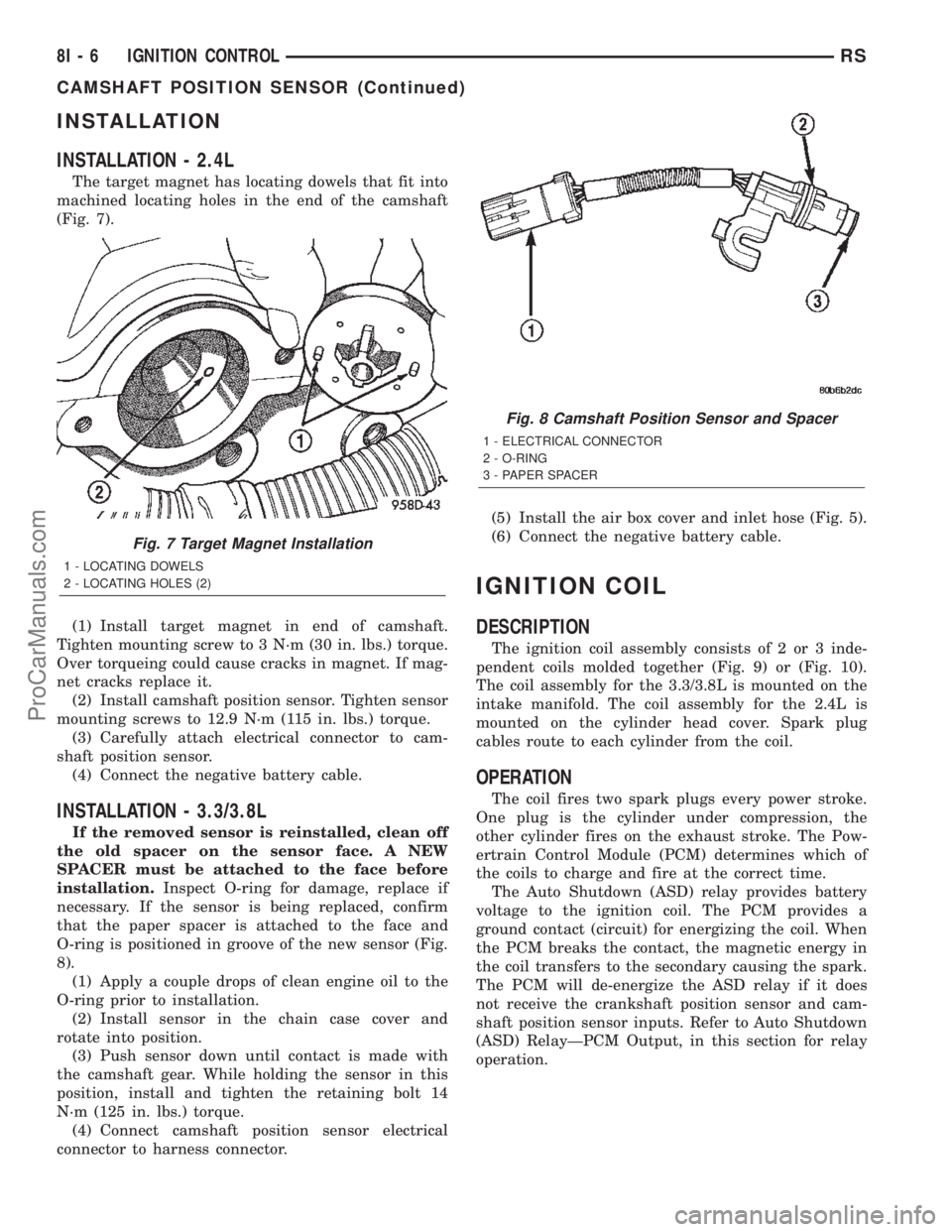

INSTALLATION

INSTALLATION - 2.4L

The target magnet has locating dowels that fit into

machined locating holes in the end of the camshaft

(Fig. 7).

(1) Install target magnet in end of camshaft.

Tighten mounting screw to 3 N´m (30 in. lbs.) torque.

Over torqueing could cause cracks in magnet. If mag-

net cracks replace it.

(2) Install camshaft position sensor. Tighten sensor

mounting screws to 12.9 N´m (115 in. lbs.) torque.

(3) Carefully attach electrical connector to cam-

shaft position sensor.

(4) Connect the negative battery cable.

INSTALLATION - 3.3/3.8L

If the removed sensor is reinstalled, clean off

the old spacer on the sensor face. A NEW

SPACER must be attached to the face before

installation.Inspect O-ring for damage, replace if

necessary. If the sensor is being replaced, confirm

that the paper spacer is attached to the face and

O-ring is positioned in groove of the new sensor (Fig.

8).

(1) Apply a couple drops of clean engine oil to the

O-ring prior to installation.

(2) Install sensor in the chain case cover and

rotate into position.

(3) Push sensor down until contact is made with

the camshaft gear. While holding the sensor in this

position, install and tighten the retaining bolt 14

N´m (125 in. lbs.) torque.

(4) Connect camshaft position sensor electrical

connector to harness connector.(5) Install the air box cover and inlet hose (Fig. 5).

(6) Connect the negative battery cable.

IGNITION COIL

DESCRIPTION

The ignition coil assembly consists of 2 or 3 inde-

pendent coils molded together (Fig. 9) or (Fig. 10).

The coil assembly for the 3.3/3.8L is mounted on the

intake manifold. The coil assembly for the 2.4L is

mounted on the cylinder head cover. Spark plug

cables route to each cylinder from the coil.

OPERATION

The coil fires two spark plugs every power stroke.

One plug is the cylinder under compression, the

other cylinder fires on the exhaust stroke. The Pow-

ertrain Control Module (PCM) determines which of

the coils to charge and fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the magnetic energy in

the coil transfers to the secondary causing the spark.

The PCM will de-energize the ASD relay if it does

not receive the crankshaft position sensor and cam-

shaft position sensor inputs. Refer to Auto Shutdown

(ASD) RelayÐPCM Output, in this section for relay

operation.

Fig. 7 Target Magnet Installation

1 - LOCATING DOWELS

2 - LOCATING HOLES (2)

Fig. 8 Camshaft Position Sensor and Spacer

1 - ELECTRICAL CONNECTOR

2 - O-RING

3 - PAPER SPACER

8I - 6 IGNITION CONTROLRS

CAMSHAFT POSITION SENSOR (Continued)

ProCarManuals.com

Page 575 of 2399

NOTE: Take care to locate the lower hinge assem-

bly on the door in its original position (ie. match

screw washer with rings left on hinge). Adjust door

fit if required.

(4) Remove the floor jack (Fig. 14).

(5) Install the hold-open striker. Refer to the Body

section for the procedure.

(6) Install the side door sill plate on the lower of

the door opening. Refer to the Body section for the

procedure.

(7) Connect the negative battery cable.

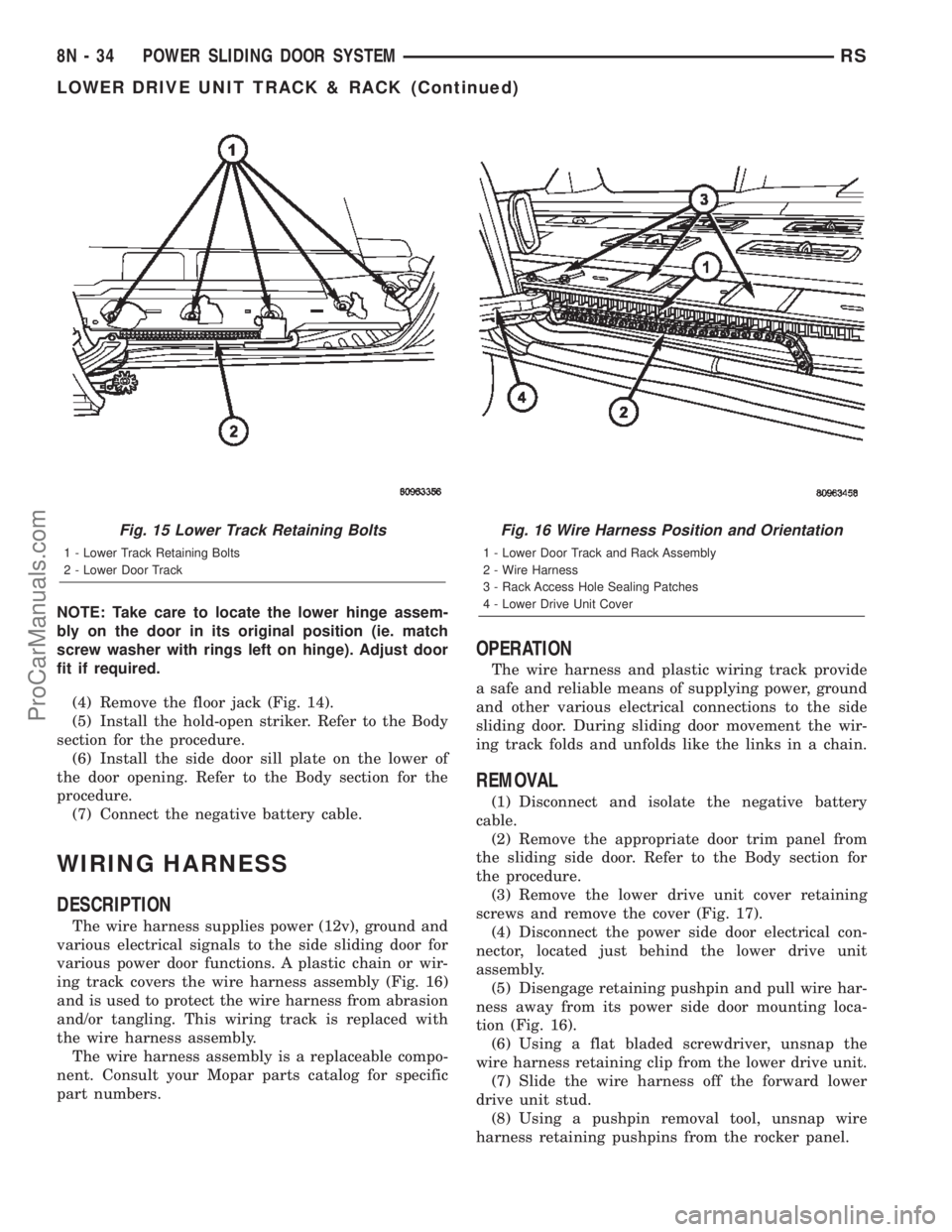

WIRING HARNESS

DESCRIPTION

The wire harness supplies power (12v), ground and

various electrical signals to the side sliding door for

various power door functions. A plastic chain or wir-

ing track covers the wire harness assembly (Fig. 16)

and is used to protect the wire harness from abrasion

and/or tangling. This wiring track is replaced with

the wire harness assembly.

The wire harness assembly is a replaceable compo-

nent. Consult your Mopar parts catalog for specific

part numbers.

OPERATION

The wire harness and plastic wiring track provide

a safe and reliable means of supplying power, ground

and other various electrical connections to the side

sliding door. During sliding door movement the wir-

ing track folds and unfolds like the links in a chain.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate door trim panel from

the sliding side door. Refer to the Body section for

the procedure.

(3) Remove the lower drive unit cover retaining

screws and remove the cover (Fig. 17).

(4) Disconnect the power side door electrical con-

nector, located just behind the lower drive unit

assembly.

(5) Disengage retaining pushpin and pull wire har-

ness away from its power side door mounting loca-

tion (Fig. 16).

(6) Using a flat bladed screwdriver, unsnap the

wire harness retaining clip from the lower drive unit.

(7) Slide the wire harness off the forward lower

drive unit stud.

(8) Using a pushpin removal tool, unsnap wire

harness retaining pushpins from the rocker panel.

Fig. 15 Lower Track Retaining Bolts

1 - Lower Track Retaining Bolts

2 - Lower Door Track

Fig. 16 Wire Harness Position and Orientation

1 - Lower Door Track and Rack Assembly

2 - Wire Harness

3 - Rack Access Hole Sealing Patches

4 - Lower Drive Unit Cover

8N - 34 POWER SLIDING DOOR SYSTEMRS

LOWER DRIVE UNIT TRACK & RACK (Continued)

ProCarManuals.com