CHRYSLER TOWN AND COUNTRY 2011 5.G Repair Manual

Manufacturer: CHRYSLER, Model Year: 2011, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2011 5.GPages: 100, PDF Size: 3.24 MB

Page 61 of 100

• When the malfunction indicator is illuminated, the system may not be able to detect or signallow tire pressure as intended. TPMS malfunctions may occur for a variety of reasons, including

the installation of replacement or alternate tires or wheels on the vehicle that prevent the TPMS

from functioning properly. Always check the TPMS malfunction telltale after replacing one or

more tires or wheels on your vehicle, to ensure that the replacement or alternate tires and

wheels allow the TPMS to continue to function properly.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or balance beads if your vehicle is

equipped with a TPMS, as damage to the sensors may result.

- Engine Temperature Warning Light

• This light warns of an overheated engine condition.

• If the light turns on or flashes continuously while driving, safely pull over and stop the vehicle. Ifthe A/C system is on, turn it off. Also, shift the transmission into NEUTRAL and idle the

vehicle. If the temperature reading does not return to normal, turn the engine off immediately

and call for service.

• We recommend that you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

WARNING!

A hot engine cooling system is dangerous. You or others could be badly burned by steam

or boiling coolant. You may want to call an authorized service center for service if your

vehicle overheats.

BRAKE- Brake Warning Light

• The Brake Warning light illuminates when there is either a system malfunction or the parkingbrake is applied. If the light is on and the parking brake is not applied, it indicates a possible

brake hydraulic malfunction, brake booster problem or an Anti-Lock Brake System problem.

• We recommend you drive to the nearest service center and have the vehicle serviced immediately.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system may

have failed. It will take longer to stop the vehicle. You could have a collision. Have the

vehicle checked immediately.

WHAT TO DO IN EMERGENCIES

59

Page 62 of 100

- Malfunction Indicator Light (MIL)

• Certain conditions, such as a loose or missing gas cap, poor fuel quality, etc., may illuminate theMIL after engine start. The vehicle should be serviced if the light stays on through several

typical driving cycles. In most situations, the vehicle will drive normally and not require towing.

• If the MIL flashes when the engine is running, serious conditions may exist that could lead to immediate loss of power or severe catalytic converter damage. We recommend you do not

operate the vehicle. Have the vehicle serviced immediately.

- Electronic Stability Control (ESC) Indicator Light/Brake Assist System (BAS) Warning

Light

• If the ESC/BAS warning light comes on continuously with the engine running, a malfunction has been detected.

• If this light remains on after several ignition cy cles, and the vehicle has been driven several miles

(kilometers) at speeds greater than 30 mph (48 km/h), we recommend you drive to the nearest

service center and have the vehicle serviced immediately.

- Charging System Light

• This light shows the status of the electrical charging system. If the charging system light remains on, it means that the vehicle is experiencing a problem with the charging system.

• We recommend you do not continue driving if the charging system light is on. Have the vehicle serviced immediately.

- Oil Pressure Warning Light

• This light indicates low engine oil pressure. If the light turns on while driving, stop the vehicleand shut off the engine as soon as possible. A chime will sound for four minutes when this light

turns on.

• We recommend you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

- Anti-Lock Brake (ABS) Light

• This light monitors the Anti-Lock Brake System (ABS).

• If the light is not on during starting, stays on, or turns on while driving, we recommend you driveto the nearest service center and have the vehicle serviced immediately.

- Electronic Throttle Control (ETC) Light

• This light informs you of a problem with the Electronic Throttle Control (ETC) system.

• If a problem is detected, the light will come on while the engine is running. Cycle the ignitionwhen the vehicle has completely stopped and the shift lever is placed in the PARK position; the

light should turn off.

• If the light remains lit with the engine running, your vehicle will usually be drivable; however, see an authorized service center immediately. If the light is flashing when the engine is running,

immediate service is required and you may experience reduced performance, an

elevated/rough idle or engine stall and your vehicle may require towing. WHAT TO DO IN EMERGENCIES

60

Page 63 of 100

- Air Bag Warning Light

• If the light is not on during starting, stays on, or turns on while driving, have the vehicle servicedby an authorized service center immediately.

Fuel Cap/Loose Gas Cap Message

• If a “gas cap” message (shown as gASCAP) appears, tighten the gas cap until a “clicking” soundis heard.

• Press the odometer reset button to turn the message off.

• If the message continues to appear for more than three days after tightening the gas cap, see your authorized service center.

Oil Change Indicator

Message

• If an “oil change” message (shown as CHAngE OIL) appears and a single chime sounds, it is time for your next required oil change.

Resetting The Light After Servicing

• Turn the ignition switch to the ON/RUN position (do not start engine).

• Fully depress the accelerator pedal three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

IF YOUR ENGINE OVERHEATS • In any of the following situations, you can reduce the potential for overheating by taking theappropriate action.

• On the highways — slow down.

• In city traffic — while stopped, place the transmission in NEUTRAL, but do not increase engine idle speed.

NOTE: There are steps that you can take to slow down an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The A/C system adds heat to the engine cooling system and turning the A/C off can help remove this heat.

• You can also turn the temperature control to maximum heat, the mode control to floor and the blower control to high. This allows the heater core to act as a supplement to the radiator and aids

in removing heat from the engine cooling system.

CAUTION!

Driving with a hot cooling system could damage your vehicle. If the temperature gauge

reads 240°F (116 °C) or greater pull over and stop the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops back into the normal range 200–230°F

(93–110°C). If the pointer remains at 240°F (116°C) or greater and you hear a chime, turn

the engine off immediately and call for service.

WHAT TO DO IN EMERGENCIES

61

Page 64 of 100

WARNING!

You or others can be badly burned by hot engine coolant (antifreeze) or steam from your

radiator. If you see or hear steam coming from under the hood, do not open the hood until

the radiator has had time to cool. Never try to open a cooling system pressure cap when

the radiator or coolant bottle is hot.

JACKING AND TIRE CHANGING

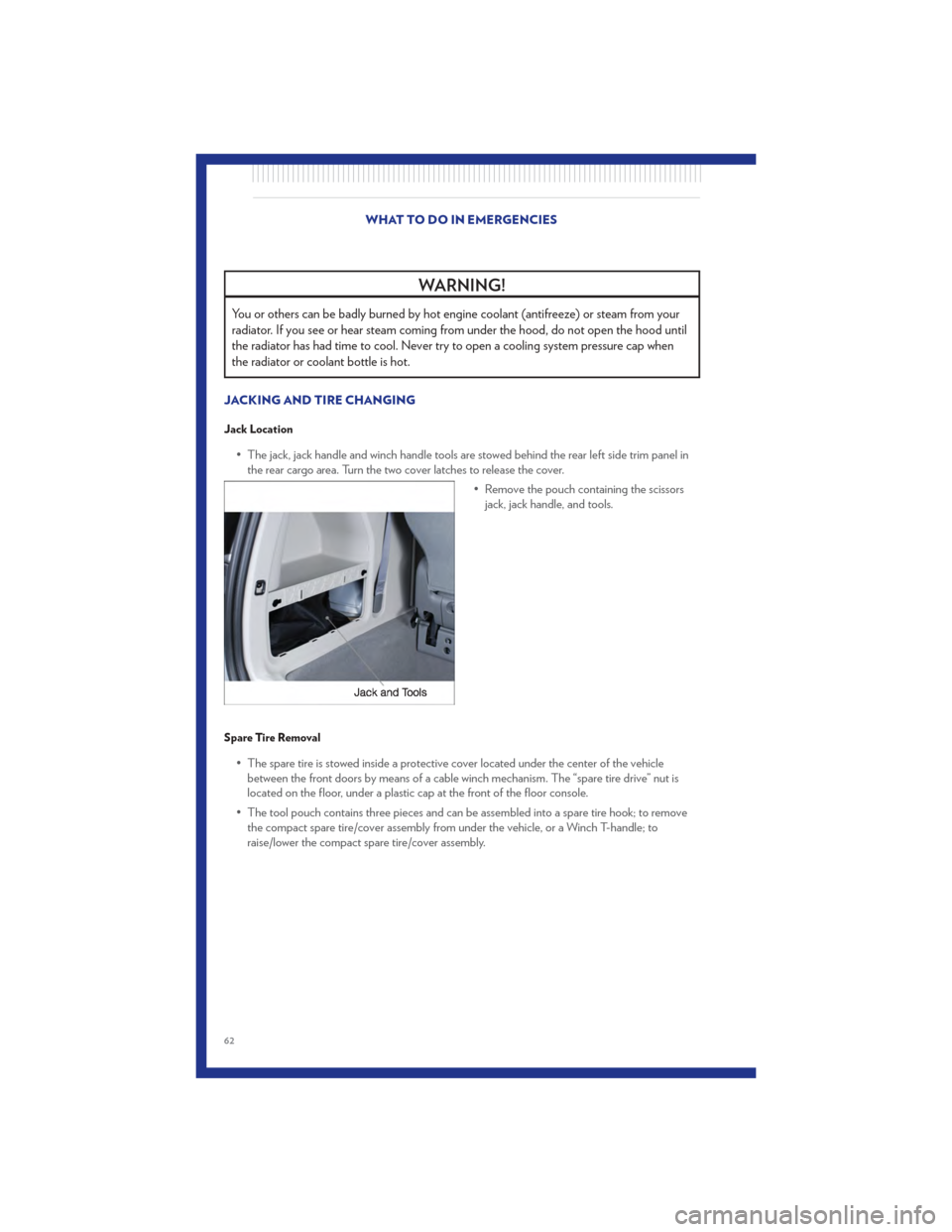

Jack Location

• The jack, jack handle and winch handle tools are stowed behind the rear left side trim panel inthe rear cargo area. Turn the two cover latches to release the cover.

• Remove the pouch containing the scissorsjack, jack handle, and tools.

Spare Tire Removal

• The spare tire is stowed inside a protective cover located under the center of the vehiclebetween the front doors by means of a cable winch mechanism. The “spare tire drive” nut is

located on the floor, under a plastic cap at the front of the floor console.

• The tool pouch contains three pieces and can be assembled into a spare tire hook; to remove the compact spare tire/cover assembly from under the vehicle, or a Winch T-handle; to

raise/lower the compact spare tire/cover assembly.

WHAT TO DO IN EMERGENCIES

62

Page 65 of 100

To Access Spare Tire Winch Drive Nut

• To access the spare tire winch drive nut and lower the spare tire, you will need to refer to one ofthe following center console configurations.

Super Console • For vehicles equipped with the Super Console, the spare tire winch assembly drive nut is located beneath the console.

1. Pull the lower drawer out from the rear ofthe floor console.

2. Open the front drawer to expose the storage compartment.

3. Remove the liner from the console's storage compartment to access the spare tire winch

drive nut.

Premium/Base/Cargo Center Console • Pull the Winch Cover assembly plug (if equipped) to access the winch drive nut.

WHAT TO DO IN EMERGENCIES

63

Page 66 of 100

Spare Tire Tools

• The spare tire pouch contains three pieces and can be assembled into a Winch T-handle orSpare Tire Hook.

A — Spare Tire Hook/T-handle

B — Extension 1

C — Extension 2

Assembled T-handle

A — Spare Tire Hook/T-handle

B — Extension 1

C — Extension 2

Assembling The Spare Tire Hook

WHAT TO DO IN EMERGENCIES

64

Page 67 of 100

Spare Tire Removal Instructions

• The spare tire is located under the vehicle beneath the center console area.

1. Assemble the spare tire tools into a T-handle and place the square end over the spare tirewinch drive nut.

2. Rotate the nut to the left until the winch mechanism stops turning freely. This will allow enough slack in the cable to allow you to pull the spare tire out from underneath the vehicle.

3. To remove the compact spare tire/cover assembly, assemble the winch T-handle extensions to form a “T” and fit the winch T-handle over the drive nut, refer to “Assembling The Spare Tire

Hook” graphic in “Spare Tire Tools”. Rotate the nut to the left until the winch mechanism stops

turning freely. This will allow enough slack in the cable to allow you to pull the spare tire out

from under the vehicle.

NOTE:If either front tire is flat it may be

necessary to jack up the vehicle to remove the

compact spare tire/cover assembly from under

the vehicle.

4. Stand the tire/cover assembly upright and remove the wheel spacer by squeezing the

winch retaining tabs together. Push the

retainer through the spare tire to release it

from the wheel.

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn OFF the ignition.

WHAT TO DO IN EMERGENCIES

65

Page 68 of 100

• Block both the front and rear of the wheeldiagonally opposite the jacking position. For

example, if changing the right front tire,

block the left rear wheel.

NOTE: Passengers should not remain in the

vehicle when the vehicle is being jacked.

Jacking Instructions

NOTE: Refer to the “Compact Spare Tire” section of “Tires – General Information” for

information about the spare tire, its use, and operation.

1. Loosen (but do not remove) the wheel lug nuts by turning them to the left one turn while the wheel is still on the ground.

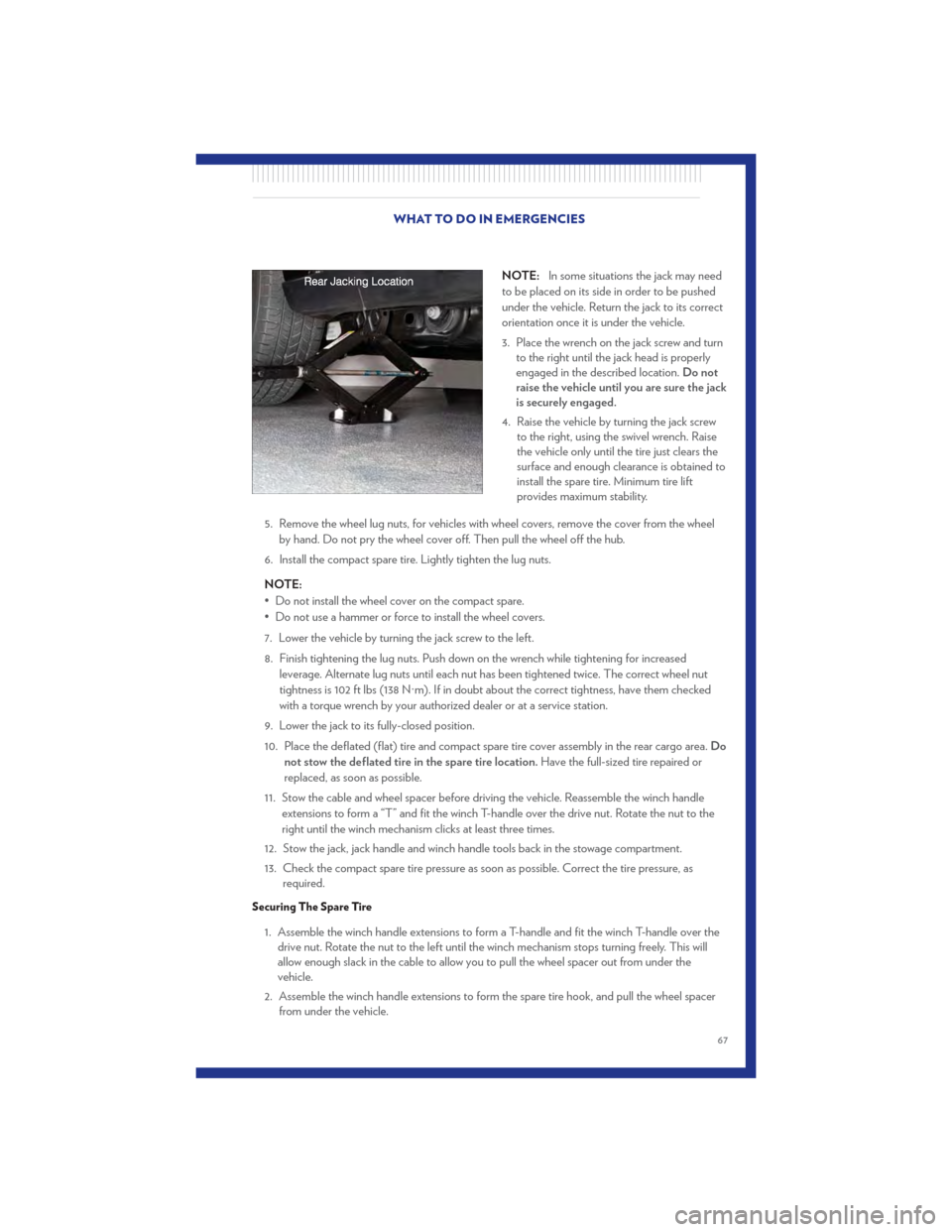

2. There are two jack engagement locations on each side of the vehicle body. These locations are on the sill flange of the vehicle body.

Rear jack locations are between a pair of down-facing tabs on the sill flange of the vehicle side

body.

Front jack location is on the sill flange of the

vehicle body and is located 6 in (150 mm) from

door edge.

WHAT TO DO IN EMERGENCIES

66

Page 69 of 100

NOTE:In some situations the jack may need

to be placed on its side in order to be pushed

under the vehicle. Return the jack to its correct

orientation once it is under the vehicle.

3. Place the wrench on the jack screw and turn to the right until the jack head is properly

engaged in the described location. Do not

raise the vehicle until you are sure the jack

is securely engaged.

4. Raise the vehicle by turning the jack screw to the right, using the swivel wrench. Raise

the vehicle only until the tire just clears the

surface and enough clearance is obtained to

install the spare tire. Minimum tire lift

provides maximum stability.

5. Remove the wheel lug nuts, for vehicles with wheel covers, remove the cover from the wheel by hand. Do not pry the wheel cover off. Then pull the wheel off the hub.

6. Install the compact spare tire. Lightly tighten the lug nuts.

NOTE:

• Do not install the wheel cover on the compact spare.

• Do not use a hammer or force to install the wheel covers.

7. Lower the vehicle by turning the jack screw to the left.

8. Finish tightening the lug nuts. Push down on the wrench while tightening for increased leverage. Alternate lug nuts until each nut has been tightened twice. The correct wheel nut

tightness is 102 ft lbs (138 N·m). If in doubt about the correct tightness, have them checked

with a torque wrench by your authorized dealer or at a service station.

9. Lower the jack to its fully-closed position.

10. Place the deflated (flat) tire and compact spare tire cover assembly in the rear cargo area. Do

not stow the deflated tire in the spare tire location. Have the full-sized tire repaired or

replaced, as soon as possible.

11. Stow the cable and wheel spacer before driving the vehicle. Reassemble the winch handle extensions to form a “T” and fit the winch T-handle over the drive nut. Rotate the nut to the

right until the winch mechanism clicks at least three times.

12. Stow the jack, jack handle and winch handle tools back in the stowage compartment.

13. Check the compact spare tire pressure as soon as possible. Correct the tire pressure, as required.

Securing The Spare Tire

1. Assemble the winch handle extensions to form a T-handle and fit the winch T-handle over thedrive nut. Rotate the nut to the left until the winch mechanism stops turning freely. This will

allow enough slack in the cable to allow you to pull the wheel spacer out from under the

vehicle.

2. Assemble the winch handle extensions to form the spare tire hook, and pull the wheel spacer from under the vehicle.

WHAT TO DO IN EMERGENCIES

67

Page 70 of 100

3. Turn the compact spare tire so that the valve stem is down, and place the tire into the sparetire/cover assembly. Slide the wheel spacer through the center of the wheel and spare

tire/cover assembly, so that the two retainer tabs snap out and engage the spare tire cover on

the opposite side.

4. Using the winch T-handle, rotate the drive nut to the right until the compact spare tire/cover assembly is drawn into place against the underside of the vehicle.

5. Continue to rotate the nut to the right until you hear the winch mechanism click three times. It cannot be overtightened. Check under the vehicle to ensure the compact spare tire/cover

assembly is positioned correctly against the underside of the vehicle.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts on the mounting studs which are on each side of the valve stem. Install the lug nuts with the cone

shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover by hand, snapping the cover over the two lug nuts. Do not use a hammer or excessive force to

install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts. To avoid the risk of forcing the vehicle off the jack, do not tighten the lug

nuts fully until the vehicle is lowered to the ground.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut has been tightened

twice. The correct tightness of each lug nut is 102 ft/lbs (138 N·m). If in doubt about the

correct tightness, have them checked with a torque wrench by your authorized dealer or

service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

Vehicles Without Wheel Covers 1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tightening the lug nuts in a star pattern until each nut has been tightened

twice. The correct tightness of each lug nut is 102 ft/lbs (138 N·m). If in doubt about the

correct tightness, have them checked with a torque wrench by your authorized dealer or

service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel. WHAT TO DO IN EMERGENCIES

68