oil type CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1066 of 1938

sealing and a chrome plated taper faced intermediate

ring for additional cylinder pressure control. There

are also standard oil control rings.

CYLINDER HEAD:Features a Dual Over Head

Camshaft (DOHC) 4 valves per cylinder cross flow

design. The valves are arranged in two inline banks,

with the ports of the bank of two intake valves per

cylinder facing toward the radiator side of engine

and ports of the bank of two exhaust valves per cyl-

inder facing toward the dash panel. Incorporates

powder metal valve guides and seats. Integral oil gal-

leys within the cylinder head supplies oil to the

hydraulic lash adjusters, camshaft and valve mecha-

nisms.

CAMSHAFTS:The nodular iron camshafts have

six bearing journals and 2 cam lobes per cylinder.

Flanges at the rear journals control camshaft end

play. Provision for cam position sensor is located on

the intake camshaft at the rear of cylinder head. A

hydrodynamic oil seal is used for oil control at the

front of the camshaft.

VALVES:4 valves per cylinder are actuated by

roller cam followers which pivot on stationary

hydraulic lash adjusters. All valves have 6 mm diam-

eter chrome plated valve stems. The valve sizes are

34.8 mm (1.370 inch.) diameter intake valves and

30.5 mm (1.20 inch.) diameter exhaust valves. Viton

rubber valve stem seals are integral with the spring

seats. Valve springs, spring retainers, and locks are

conventional.

INTAKE MANIFOLD:The intake manifold is a

two piece aluminum casting, attached to the cylinder

head with ten screws. This long branch fan design

enhances low and midspeed torque, while minimizing

undesirable inlet noise.

EXHAUST MANIFOLD:The exhaust manifold is

made of cast iron for strength and high tempera-

tures.

ENGINE LUBRICATION:Refer to Group 0

Lubrication and Maintenance for recommended oil to

be used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted in the front engine cover and driven by the

crankshaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing. Pistons are lubricated from rod bearing

throw off and lubricating slots on the connecting rod

assemblies. Camshaft and valve mechanisms are

lubricated from a full length cylinder head oil gallery

supplied from the crankcase main oil gallery.DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit and install

gauge assembly C-3292.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170/550 kPa (25/80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open or a

clogged oil pickup screen.

SERVICE PROCEDURES

FITTING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 14 mm (9/16 inch.) from the bottom

of the skirt as shown in (Fig. 3). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 2). Refer to Cylinder Bore and Piston

Specification Chart.

Correct piston to bore clearance must be estab-

lished in order to assure quiet and economical oper-

ation.

Chrysler engines use pistons designed specifically

for each engine model. Clearance and sizing locations

vary with respect to engine model.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 70ÉF (21ÉC).

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 inch) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 4).

Refer to specification in Piston Ring Specification

Chart.

(2) Check piston ring to groove side clearance (Fig.

5). Refer to specification in Piston Ring Specification

Chart.

9 - 16 2.4L ENGINENS

DESCRIPTION AND OPERATION (Continued)

Page 1105 of 1938

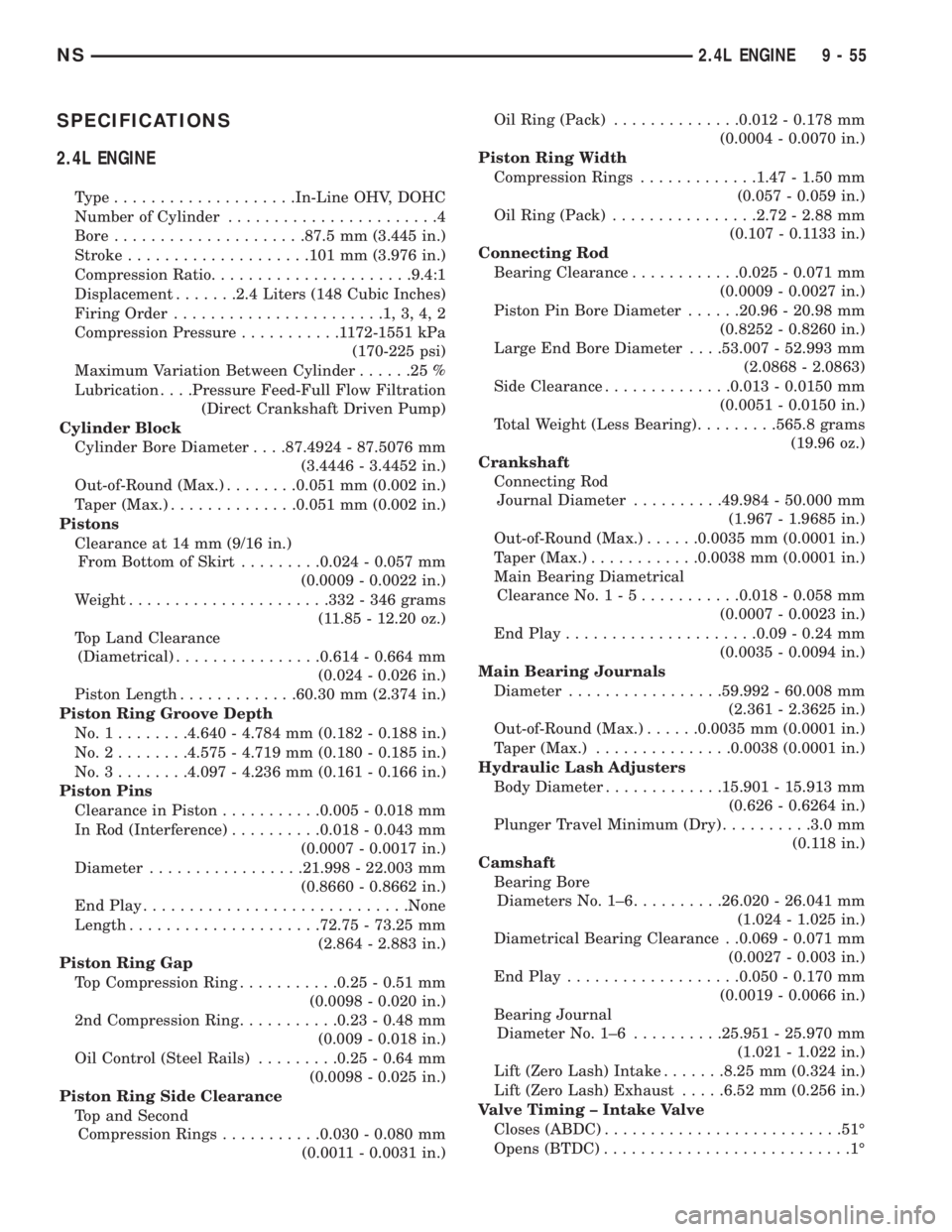

SPECIFICATIONS

2.4L ENGINE

Type....................In-Line OHV, DOHC

Number of Cylinder.......................4

Bore.....................87.5 mm (3.445 in.)

Stroke....................101 mm (3.976 in.)

Compression Ratio......................9.4:1

Displacement.......2.4 Liters (148 Cubic Inches)

Firing Order.......................1,3,4,2

Compression Pressure...........1172-1551 kPa

(170-225 psi)

Maximum Variation Between Cylinder......25%

Lubrication. . . .Pressure Feed-Full Flow Filtration

(Direct Crankshaft Driven Pump)

Cylinder Block

Cylinder Bore Diameter. . . .87.4924 - 87.5076 mm

(3.4446 - 3.4452 in.)

Out-of-Round (Max.)........0.051 mm (0.002 in.)

Taper (Max.)..............0.051 mm (0.002 in.)

Pistons

Clearance at 14 mm (9/16 in.)

From Bottom of Skirt.........0.024 - 0.057 mm

(0.0009 - 0.0022 in.)

Weight......................332 - 346 grams

(11.85 - 12.20 oz.)

Top Land Clearance

(Diametrical)................0.614 - 0.664 mm

(0.024 - 0.026 in.)

Piston Length.............60.30 mm (2.374 in.)

Piston Ring Groove Depth

No.1........4.640 - 4.784 mm (0.182 - 0.188 in.)

No.2........4.575 - 4.719 mm (0.180 - 0.185 in.)

No.3........4.097 - 4.236 mm (0.161 - 0.166 in.)

Piston Pins

Clearance in Piston...........0.005 - 0.018 mm

In Rod (Interference)..........0.018 - 0.043 mm

(0.0007 - 0.0017 in.)

Diameter.................21.998 - 22.003 mm

(0.8660 - 0.8662 in.)

End Play.............................None

Length.....................72.75 - 73.25 mm

(2.864 - 2.883 in.)

Piston Ring Gap

Top Compression Ring...........0.25 - 0.51 mm

(0.0098 - 0.020 in.)

2nd Compression Ring...........0.23 - 0.48 mm

(0.009 - 0.018 in.)

Oil Control (Steel Rails).........0.25 - 0.64 mm

(0.0098 - 0.025 in.)

Piston Ring Side Clearance

Top and Second

Compression Rings...........0.030 - 0.080 mm

(0.0011 - 0.0031 in.)Oil Ring (Pack)..............0.012 - 0.178 mm

(0.0004 - 0.0070 in.)

Piston Ring Width

Compression Rings.............1.47 - 1.50 mm

(0.057 - 0.059 in.)

Oil Ring (Pack)................2.72 - 2.88 mm

(0.107 - 0.1133 in.)

Connecting Rod

Bearing Clearance............0.025 - 0.071 mm

(0.0009 - 0.0027 in.)

Piston Pin Bore Diameter......20.96 - 20.98 mm

(0.8252 - 0.8260 in.)

Large End Bore Diameter. . . .53.007 - 52.993 mm

(2.0868 - 2.0863)

Side Clearance..............0.013 - 0.0150 mm

(0.0051 - 0.0150 in.)

Total Weight (Less Bearing).........565.8 grams

(19.96 oz.)

Crankshaft

Connecting Rod

Journal Diameter..........49.984 - 50.000 mm

(1.967 - 1.9685 in.)

Out-of-Round (Max.)......0.0035 mm (0.0001 in.)

Taper (Max.)............0.0038 mm (0.0001 in.)

Main Bearing Diametrical

Clearance No.1-5...........0.018 - 0.058 mm

(0.0007 - 0.0023 in.)

End Play.....................0.09 - 0.24 mm

(0.0035 - 0.0094 in.)

Main Bearing Journals

Diameter.................59.992 - 60.008 mm

(2.361 - 2.3625 in.)

Out-of-Round (Max.)......0.0035 mm (0.0001 in.)

Taper (Max.)...............0.0038 (0.0001 in.)

Hydraulic Lash Adjusters

Body Diameter.............15.901 - 15.913 mm

(0.626 - 0.6264 in.)

Plunger Travel Minimum (Dry)..........3.0 mm

(0.118 in.)

Camshaft

Bearing Bore

Diameters No. 1±6..........26.020 - 26.041 mm

(1.024 - 1.025 in.)

Diametrical Bearing Clearance . .0.069 - 0.071 mm

(0.0027 - 0.003 in.)

End Play...................0.050 - 0.170 mm

(0.0019 - 0.0066 in.)

Bearing Journal

Diameter No. 1±6..........25.951 - 25.970 mm

(1.021 - 1.022 in.)

Lift (Zero Lash) Intake.......8.25 mm (0.324 in.)

Lift (Zero Lash) Exhaust.....6.52 mm (0.256 in.)

Valve Timing ± Intake Valve

Closes (ABDC)..........................51É

Opens (BTDC)...........................1É

NS2.4L ENGINE 9 - 55

Page 1111 of 1938

3.0L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 61

ENGINE IDENTIFICATION NUMBER......... 61

ENGINE LUBRICATION................... 61

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 62

SERVICE PROCEDURES

AUTO LASH ADJUSTER................... 62

CHECKING CRANKSHAFT END PLAY........ 65

FITTING CONNECTING ROD BEARINGS...... 63

FITTING MAIN BEARING.................. 63

VALVE SERVICE RECONDITION............ 66

REMOVAL AND INSTALLATION

CAMSHAFT SEAL....................... 72

CAMSHAFT............................ 71

CRANKSHAFT.......................... 81

CYLINDER HEAD COVER................. 70

CYLINDER HEAD........................ 73

ENGINE ASSEMBLY...................... 69

ENGINE MOUNTS....................... 68

FRONT CRANKSHAFT OIL SEAL............ 83OIL FILTER AND ADAPTOR................ 84

OILPAN ............................... 77

OIL PUMP............................. 84

PISTON AND CONNECTING ROD........... 78

REAR CRANKSHAFT SEAL................ 83

ROCKER ARMS......................... 72

TIMING BELT........................... 75

DISASSEMBLY AND ASSEMBLY

ROCKER ARMS AND SHAFTS.............. 85

CLEANING AND INSPECTION

CYLINDER BORE........................ 87

CYLINDER HEAD........................ 86

OIL PUMP............................. 87

TIMING BELT........................... 86

ADJUSTMENTS

ENGINE MOUNTS....................... 88

SPECIFICATIONS

3.0L ENGINE........................... 89

TORQUE CHART 3.0L.................... 90

SPECIAL TOOLS

3.0L ENGINE........................... 91

DESCRIPTION AND OPERATION

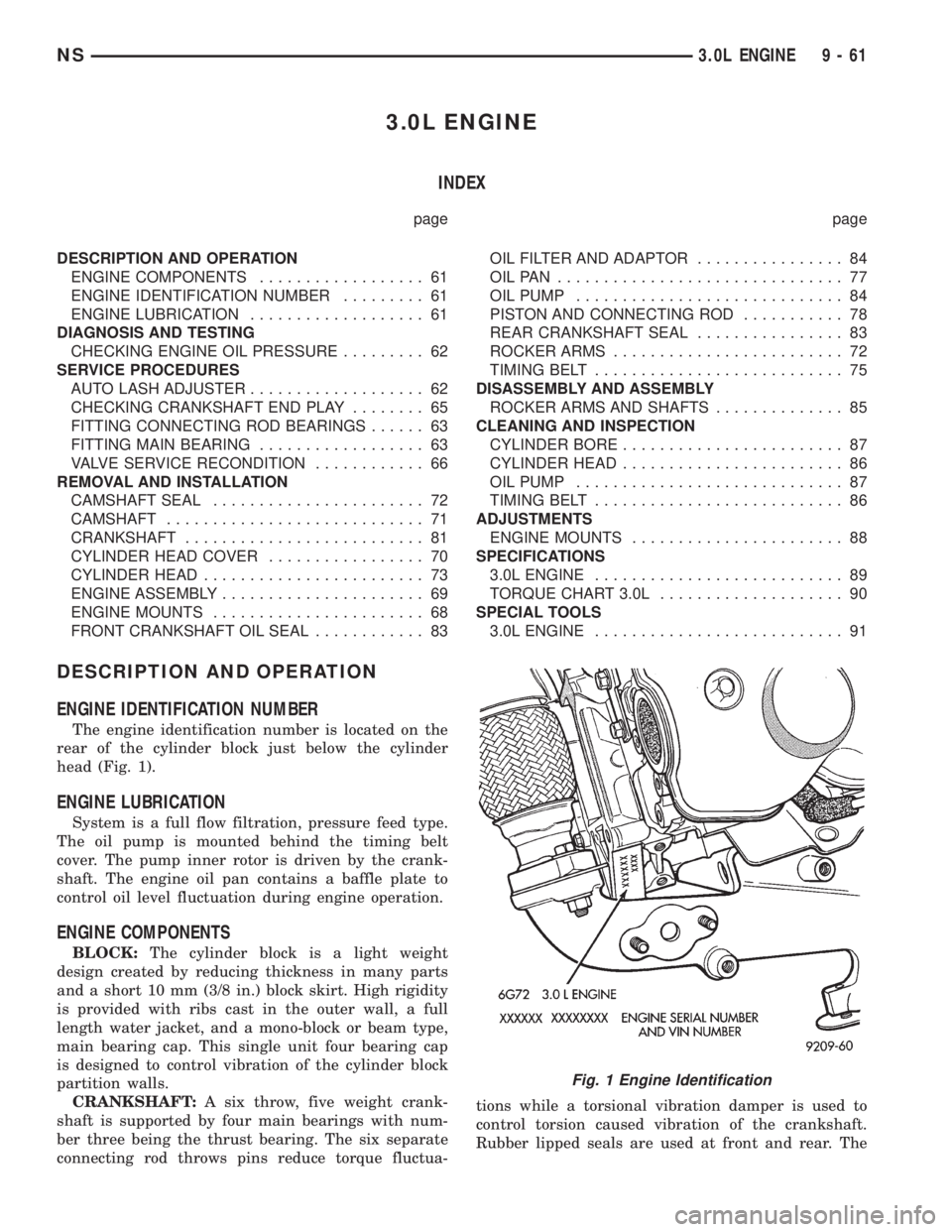

ENGINE IDENTIFICATION NUMBER

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 1).

ENGINE LUBRICATION

System is a full flow filtration, pressure feed type.

The oil pump is mounted behind the timing belt

cover. The pump inner rotor is driven by the crank-

shaft. The engine oil pan contains a baffle plate to

control oil level fluctuation during engine operation.

ENGINE COMPONENTS

BLOCK:The cylinder block is a light weight

design created by reducing thickness in many parts

and a short 10 mm (3/8 in.) block skirt. High rigidity

is provided with ribs cast in the outer wall, a full

length water jacket, and a mono-block or beam type,

main bearing cap. This single unit four bearing cap

is designed to control vibration of the cylinder block

partition walls.

CRANKSHAFT:A six throw, five weight crank-

shaft is supported by four main bearings with num-

ber three being the thrust bearing. The six separate

connecting rod throws pins reduce torque fluctua-tions while a torsional vibration damper is used to

control torsion caused vibration of the crankshaft.

Rubber lipped seals are used at front and rear. The

Fig. 1 Engine Identification

NS3.0L ENGINE 9 - 61

Page 1112 of 1938

front seal is retained in the oil pump case and the

rear is retained in a block-mounted housing.

PISTONS:Are aluminum alloy with a steel strut,

short height, and thin wall so as to be autothermic

and light weight. The piston head with valve

recesses, in combination with the cylinder head,

forms a compact spherical head with clearance for

total valve lift with pistons at top dead center. The

piston skirt, top and second ring lands are finished to

a tapered roughness for oil retention and high resis-

tance to scuffing. Piston pins, pressed into place, join

the pistons to the connecting rods.

CYLINDER HEAD:The alloy cylinder heads fea-

ture cross-flow type intake and exhaust ports. Valve

guides and inserts are hardened cast iron. Valves of

heat resistance steel are arranged in a V with each

camshaft on center. To improve combustion speed the

chambers are a compact spherical design with a

squish area of approximately 30 percent of the piston

top area. The cylinder heads are common to either

cylinder bank by reversing the direction of installa-

tion.

CAMSHAFTS:Two overhead camshafts provide

valve actuation, one front (radiator side of cylinder

bank) and one rear. The front camshaft is provided

with a distributor drive and is longer. Both cam-

shafts are supported by four bearing journals, thrust

for the front camshaft is taken at journal two and

the rear at journal three. Front and rear camshaft

driving sprockets are interchangeable. The sprockets

and the engine water pump are driven by a single

notched timing belt.

ROCKER ARM SHAFTS:The shafts are retained

by the camshaft bearing journal caps. Four shafts are

used, one for each intake and exhaust rocker arm

assembly on each cylinder head. The hollow shafts

provide a duct for lubricating oil flow from the cylin-

der head to the valve mechanisms.

ROCKER ARMS:Are of light weight die-cast with

roller type follower operating against the cam shaft.

The valve actuating end of the rocker arms are

machined to retain hydraulic lash adjusters, elimi-

nating valve lash adjustment.

VALVES:Are made of heat resistant steel, valve

springs are especially designed to be short. The valve

spring wire cross-section is oval shaped and provides

the same spring tension as longer springs. Valve

spring retainers, locks and seals are conventional.

INTAKE MANIFOLD:The aluminum alloy mani-

fold is a cross type with long runners to improve

inertia. The runners, attaching below at the cylinder

head, also attach above and support an air plenum.

The air plenum chamber absorbs air pulsations cre-

ated during the suction phase of each cylinder.

EXHAUST MANIFOLDS:Both manifolds are a

log style made of ductile cast iron. Exhaust gasses,collected from the front cylinder bank, leave the front

manifold through an end outlet and are fed through

an upper crossover tube to the rear manifold. The

collected exhaust from both manifolds are combined,

and exit to the exhaust pipe through an articulated

joint.

DIAGNOSIS AND TESTING

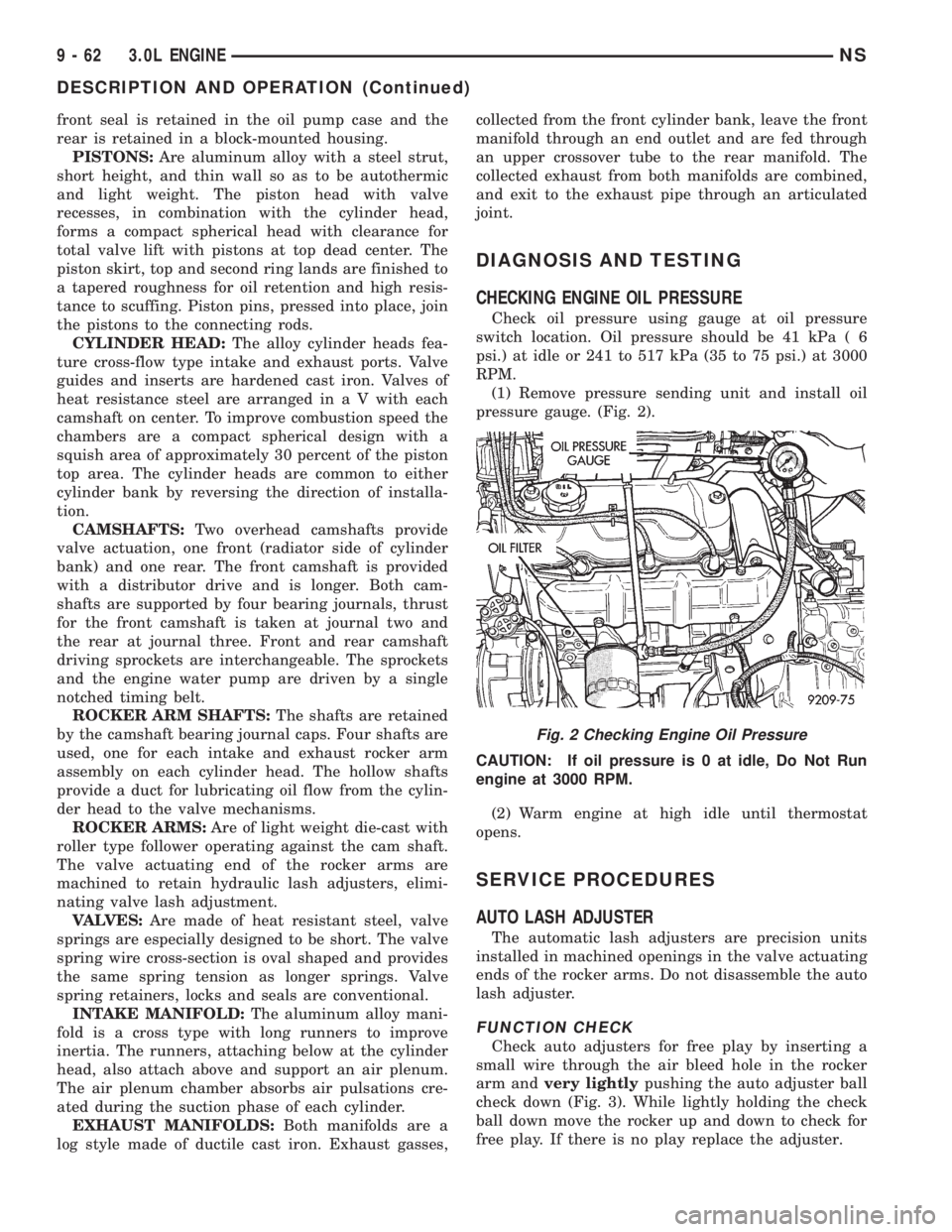

CHECKING ENGINE OIL PRESSURE

Check oil pressure using gauge at oil pressure

switch location. Oil pressure should be 41 kPa ( 6

psi.) at idle or 241 to 517 kPa (35 to 75 psi.) at 3000

RPM.

(1) Remove pressure sending unit and install oil

pressure gauge. (Fig. 2).

CAUTION: If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM.

(2) Warm engine at high idle until thermostat

opens.

SERVICE PROCEDURES

AUTO LASH ADJUSTER

The automatic lash adjusters are precision units

installed in machined openings in the valve actuating

ends of the rocker arms. Do not disassemble the auto

lash adjuster.

FUNCTION CHECK

Check auto adjusters for free play by inserting a

small wire through the air bleed hole in the rocker

arm andvery lightlypushing the auto adjuster ball

check down (Fig. 3). While lightly holding the check

ball down move the rocker up and down to check for

free play. If there is no play replace the adjuster.

Fig. 2 Checking Engine Oil Pressure

9 - 62 3.0L ENGINENS

DESCRIPTION AND OPERATION (Continued)

Page 1139 of 1938

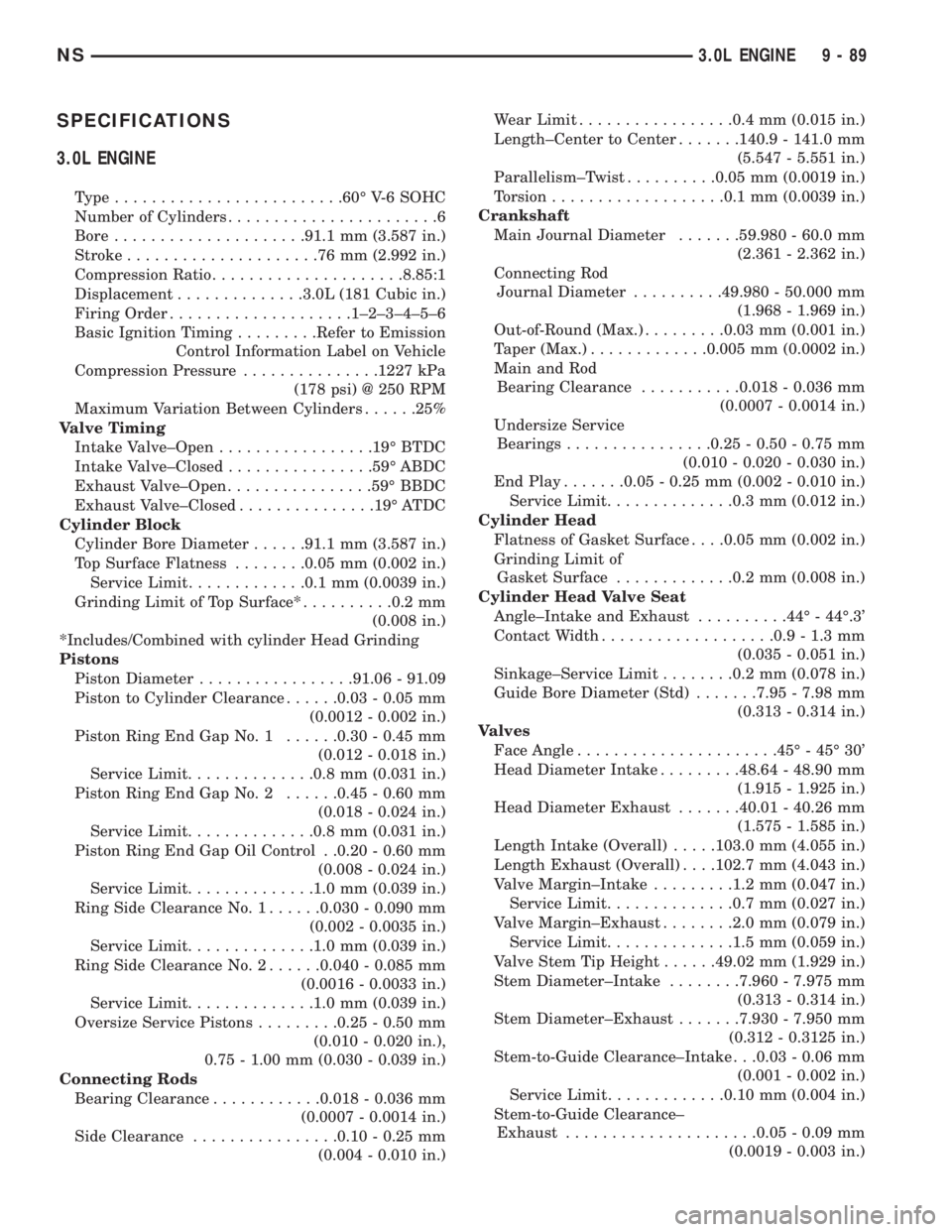

SPECIFICATIONS

3.0L ENGINE

Type.........................60É V-6 SOHC

Number of Cylinders.......................6

Bore.....................91.1 mm (3.587 in.)

Stroke.....................76mm(2.992 in.)

Compression Ratio.....................8.85:1

Displacement..............3.0L (181 Cubic in.)

Firing Order....................1±2±3±4±5±6

Basic Ignition Timing.........Refer to Emission

Control Information Label on Vehicle

Compression Pressure...............1227 kPa

(178 psi) @ 250 RPM

Maximum Variation Between Cylinders......25%

Valve Timing

Intake Valve±Open.................19É BTDC

Intake Valve±Closed................59É ABDC

Exhaust Valve±Open................59É BBDC

Exhaust Valve±Closed...............19É ATDC

Cylinder Block

Cylinder Bore Diameter......91.1 mm (3.587 in.)

Top Surface Flatness........0.05 mm (0.002 in.)

Service Limit.............0.1 mm (0.0039 in.)

Grinding Limit of Top Surface*..........0.2 mm

(0.008 in.)

*Includes/Combined with cylinder Head Grinding

Pistons

Piston Diameter.................91.06 - 91.09

Piston to Cylinder Clearance......0.03 - 0.05 mm

(0.0012 - 0.002 in.)

Piston Ring End Gap No. 1......0.30 - 0.45 mm

(0.012 - 0.018 in.)

Service Limit..............0.8 mm (0.031 in.)

Piston Ring End Gap No. 2......0.45 - 0.60 mm

(0.018 - 0.024 in.)

Service Limit..............0.8 mm (0.031 in.)

Piston Ring End Gap Oil Control . .0.20 - 0.60 mm

(0.008 - 0.024 in.)

Service Limit..............1.0 mm (0.039 in.)

Ring Side Clearance No. 1......0.030 - 0.090 mm

(0.002 - 0.0035 in.)

Service Limit..............1.0 mm (0.039 in.)

Ring Side Clearance No. 2......0.040 - 0.085 mm

(0.0016 - 0.0033 in.)

Service Limit..............1.0 mm (0.039 in.)

Oversize Service Pistons.........0.25 - 0.50 mm

(0.010 - 0.020 in.),

0.75 - 1.00 mm (0.030 - 0.039 in.)

Connecting Rods

Bearing Clearance............0.018 - 0.036 mm

(0.0007 - 0.0014 in.)

Side Clearance................0.10 - 0.25 mm

(0.004 - 0.010 in.)Wear Limit.................0.4 mm (0.015 in.)

Length±Center to Center.......140.9 - 141.0 mm

(5.547 - 5.551 in.)

Parallelism±Twist..........0.05 mm (0.0019 in.)

Torsion...................0.1 mm (0.0039 in.)

Crankshaft

Main Journal Diameter.......59.980 - 60.0 mm

(2.361 - 2.362 in.)

Connecting Rod

Journal Diameter..........49.980 - 50.000 mm

(1.968 - 1.969 in.)

Out-of-Round (Max.).........0.03 mm (0.001 in.)

Taper (Max.).............0.005 mm (0.0002 in.)

Main and Rod

Bearing Clearance...........0.018 - 0.036 mm

(0.0007 - 0.0014 in.)

Undersize Service

Bearings................0.25 - 0.50 - 0.75 mm

(0.010 - 0.020 - 0.030 in.)

End Play.......0.05 - 0.25 mm (0.002 - 0.010 in.)

Service Limit..............0.3 mm (0.012 in.)

Cylinder Head

Flatness of Gasket Surface. . . .0.05 mm (0.002 in.)

Grinding Limit of

Gasket Surface.............0.2 mm (0.008 in.)

Cylinder Head Valve Seat

Angle±Intake and Exhaust..........44É - 44É.3'

Contact Width...................0.9 - 1.3 mm

(0.035 - 0.051 in.)

Sinkage±Service Limit........0.2 mm (0.078 in.)

Guide Bore Diameter (Std).......7.95 - 7.98 mm

(0.313 - 0.314 in.)

Valves

Face Angle......................45É - 45É 30'

Head Diameter Intake.........48.64 - 48.90 mm

(1.915 - 1.925 in.)

Head Diameter Exhaust.......40.01 - 40.26 mm

(1.575 - 1.585 in.)

Length Intake (Overall).....103.0 mm (4.055 in.)

Length Exhaust (Overall). . . .102.7 mm (4.043 in.)

Valve Margin±Intake.........1.2 mm (0.047 in.)

Service Limit..............0.7 mm (0.027 in.)

Valve Margin±Exhaust........2.0 mm (0.079 in.)

Service Limit..............1.5 mm (0.059 in.)

Valve Stem Tip Height......49.02 mm (1.929 in.)

Stem Diameter±Intake........7.960 - 7.975 mm

(0.313 - 0.314 in.)

Stem Diameter±Exhaust.......7.930 - 7.950 mm

(0.312 - 0.3125 in.)

Stem-to-Guide Clearance±Intake . . .0.03 - 0.06 mm

(0.001 - 0.002 in.)

Service Limit.............0.10 mm (0.004 in.)

Stem-to-Guide Clearance±

Exhaust.....................0.05 - 0.09 mm

(0.0019 - 0.003 in.)

NS3.0L ENGINE 9 - 89

Page 1143 of 1938

3.3/3.8L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 93

ENGINE IDENTIFICATION................. 93

ENGINE LUBRICATION SYSTEM............ 93

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 96

HYDRAULIC TAPPETS.................... 94

SERVICE PROCEDURES

CRANKSHAFT END PLAY................. 99

FITTING CONNECTING ROD BEARINGS...... 97

FITTING MAIN BEARINGS................. 98

FITTING PISTONS AND RINGS............. 97

MEASURING TIMING CHAIN FOR STRETCH . . . 96

VALVE SERVICE RECONDITION........... 100

VALVE TIMING.......................... 96

REMOVAL AND INSTALLATION

CAMSHAFT BEARINGS.................. 114

CAMSHAFT........................... 113

CRANKSHAFT DAMPER................. 106

CRANKSHAFT OIL SEALÐFRONT.......... 117

CRANKSHAFT OIL SEALÐREAR........... 118

CRANKSHAFT......................... 116

CYLINDER HEAD COVER................ 107

CYLINDER HEAD....................... 108

ENGINE ASSEMBLY..................... 104

ENGINE MOUNTS...................... 102

ENGINE OIL GALLERY PLUGS............. 119OILFILTER ............................ 119

OILPAN .............................. 114

PISTON AND CONNECTING ROD.......... 115

ROCKER ARMS AND SHAFT ASSEMBLY..... 106

TAPPET REMOVAL...................... 110

TIMING CHAIN COVER................... 111

TIMING CHAIN......................... 112

VALVE STEM SEALS OR SPRINGS,

CYLINDER HEAD NOT REMOVED........ 106

VALVES AND VALVE SPRINGS............ 109

WIPER UNIT.......................... 102

DISASSEMBLY AND ASSEMBLY

HYDRAULIC TAPPETS................... 120

OIL PUMP............................ 119

CLEANING AND INSPECTION

CYLINDER HEAD....................... 120

ENGINE BLOCK AND BORE............... 121

OILPAN .............................. 121

OIL PUMP............................ 121

ADJUSTMENTS

ENGINE MOUNTS...................... 123

SPECIFICATIONS

3.3/3.8L ENGINE....................... 123

TORQUE CHART....................... 125

SPECIAL TOOLS

3.3/3.8L ENGINE....................... 127

DESCRIPTION AND OPERATION

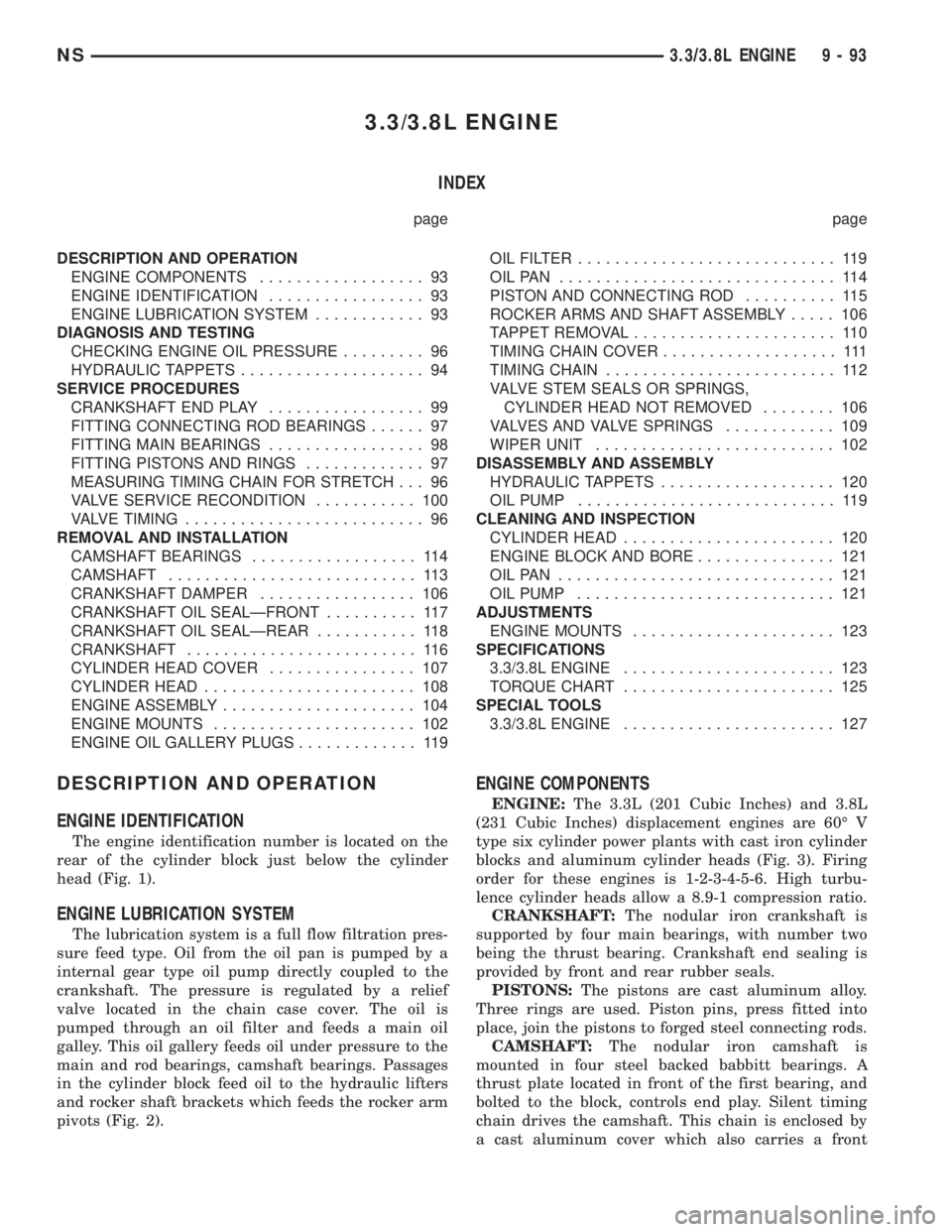

ENGINE IDENTIFICATION

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 1).

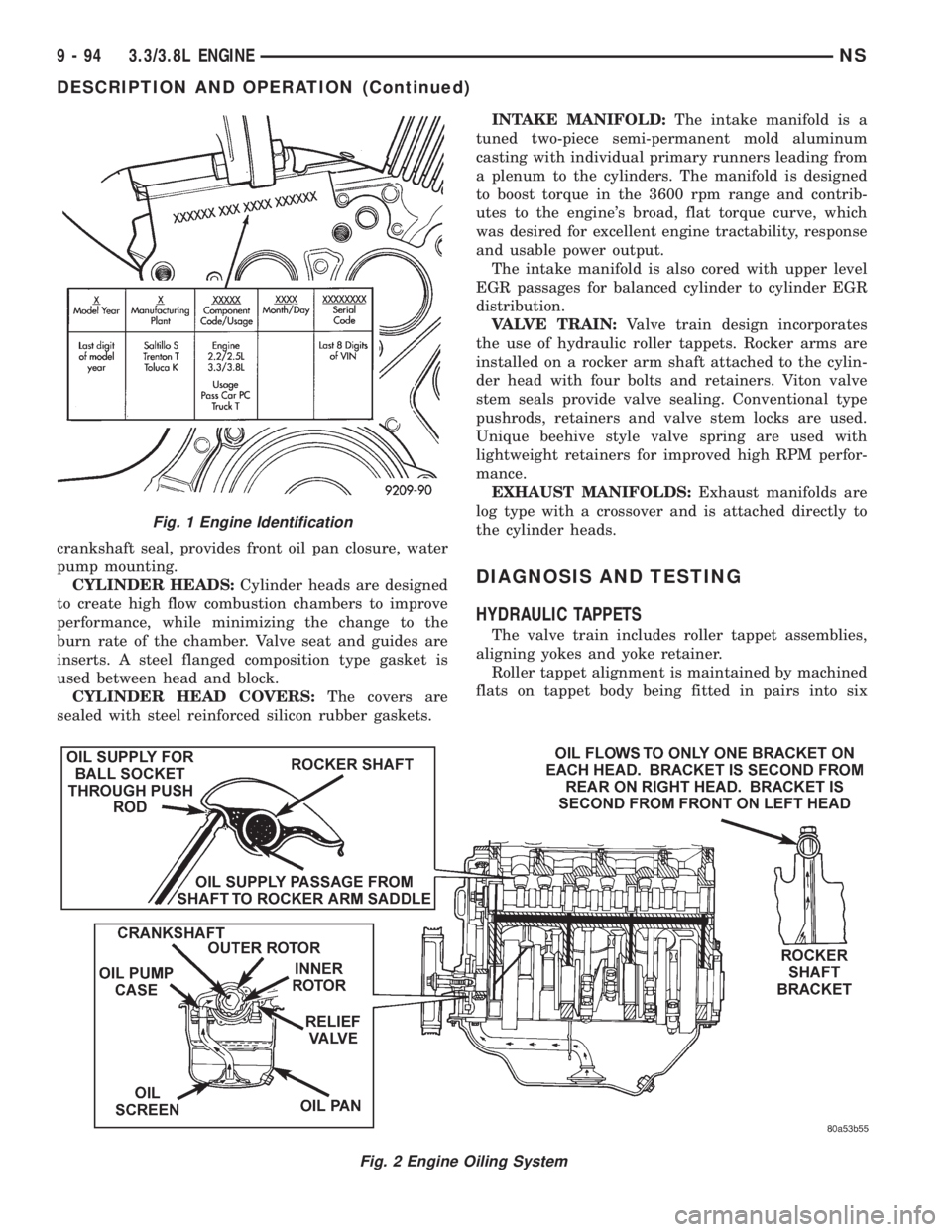

ENGINE LUBRICATION SYSTEM

The lubrication system is a full flow filtration pres-

sure feed type. Oil from the oil pan is pumped by a

internal gear type oil pump directly coupled to the

crankshaft. The pressure is regulated by a relief

valve located in the chain case cover. The oil is

pumped through an oil filter and feeds a main oil

galley. This oil gallery feeds oil under pressure to the

main and rod bearings, camshaft bearings. Passages

in the cylinder block feed oil to the hydraulic lifters

and rocker shaft brackets which feeds the rocker arm

pivots (Fig. 2).

ENGINE COMPONENTS

ENGINE:The 3.3L (201 Cubic Inches) and 3.8L

(231 Cubic Inches) displacement engines are 60É V

type six cylinder power plants with cast iron cylinder

blocks and aluminum cylinder heads (Fig. 3). Firing

order for these engines is 1-2-3-4-5-6. High turbu-

lence cylinder heads allow a 8.9-1 compression ratio.

CRANKSHAFT:The nodular iron crankshaft is

supported by four main bearings, with number two

being the thrust bearing. Crankshaft end sealing is

provided by front and rear rubber seals.

PISTONS:The pistons are cast aluminum alloy.

Three rings are used. Piston pins, press fitted into

place, join the pistons to forged steel connecting rods.

CAMSHAFT:The nodular iron camshaft is

mounted in four steel backed babbitt bearings. A

thrust plate located in front of the first bearing, and

bolted to the block, controls end play. Silent timing

chain drives the camshaft. This chain is enclosed by

a cast aluminum cover which also carries a front

NS3.3/3.8L ENGINE 9 - 93

Page 1144 of 1938

crankshaft seal, provides front oil pan closure, water

pump mounting.

CYLINDER HEADS:Cylinder heads are designed

to create high flow combustion chambers to improve

performance, while minimizing the change to the

burn rate of the chamber. Valve seat and guides are

inserts. A steel flanged composition type gasket is

used between head and block.

CYLINDER HEAD COVERS:The covers are

sealed with steel reinforced silicon rubber gaskets.INTAKE MANIFOLD:The intake manifold is a

tuned two-piece semi-permanent mold aluminum

casting with individual primary runners leading from

a plenum to the cylinders. The manifold is designed

to boost torque in the 3600 rpm range and contrib-

utes to the engine's broad, flat torque curve, which

was desired for excellent engine tractability, response

and usable power output.

The intake manifold is also cored with upper level

EGR passages for balanced cylinder to cylinder EGR

distribution.

VALVE TRAIN:Valve train design incorporates

the use of hydraulic roller tappets. Rocker arms are

installed on a rocker arm shaft attached to the cylin-

der head with four bolts and retainers. Viton valve

stem seals provide valve sealing. Conventional type

pushrods, retainers and valve stem locks are used.

Unique beehive style valve spring are used with

lightweight retainers for improved high RPM perfor-

mance.

EXHAUST MANIFOLDS:Exhaust manifolds are

log type with a crossover and is attached directly to

the cylinder heads.

DIAGNOSIS AND TESTING

HYDRAULIC TAPPETS

The valve train includes roller tappet assemblies,

aligning yokes and yoke retainer.

Roller tappet alignment is maintained by machined

flats on tappet body being fitted in pairs into six

Fig. 2 Engine Oiling System

Fig. 1 Engine Identification

9 - 94 3.3/3.8L ENGINENS

DESCRIPTION AND OPERATION (Continued)

Page 1157 of 1938

(4) Remove upper intake manifold. Refer to Group

11, Exhaust System and Intake Manifolds for proce-

dure.

(5) Remove cylinder head covers and spark plugs.

(6) Remove electrical connector from ignition coils.

(7) Using suitable socket and flex handle at crank-

shaft pulley retaining screw, turn engine so the num-

ber 1 piston is at Top Dead Center on the

compression stroke.

(8) Remove rocker arms with rocker shaft and

install a dummy shaft. The rocker arms should not

be disturbed and left on shaft.

(9) With air hose attached to spark plug adapter

installed in number 1 spark plug hole, apply 90 to

100 psi air pressure (620.5 to 689 kPa). This is to

hold valves in place while servicing components.

(10) Using Tool C-4682 or equivalent, compress

valve spring and remove retainer valve locks and

valve spring.

(11) The intake valve stem seals should be pushed

firmly and squarely over the valve guide using the

valve stem as guide.Do Not Forceseal against top

of guide. When installing the valve retainer locks,

compress the springonly enoughto install the

locks.

CAUTION: Do not pinch seal between retainer and

top of valve guide.

(12) Follow the same procedure on the remaining 5

cylinders using the firing sequence 1-2-3-4-5-6.Make

sure piston in cylinder is at TDC on the valve

spring that is being covered.

(13) Remove spark plug adapter tool.

(14) Remove dummy shaft and install rocker shaft

assembly and tighten screws to 28 N´m (250 in. lbs.).

(15) Install cylinder head covers tighten screws to

14 N´m (120 in. lbs.) and electrical connector to igni-

tion coils.

(16) Install Intake Manifold. Refer to Group 11,

Exhaust System and Intake Manifold for procedure.

(17) Connect negative cable to battery.

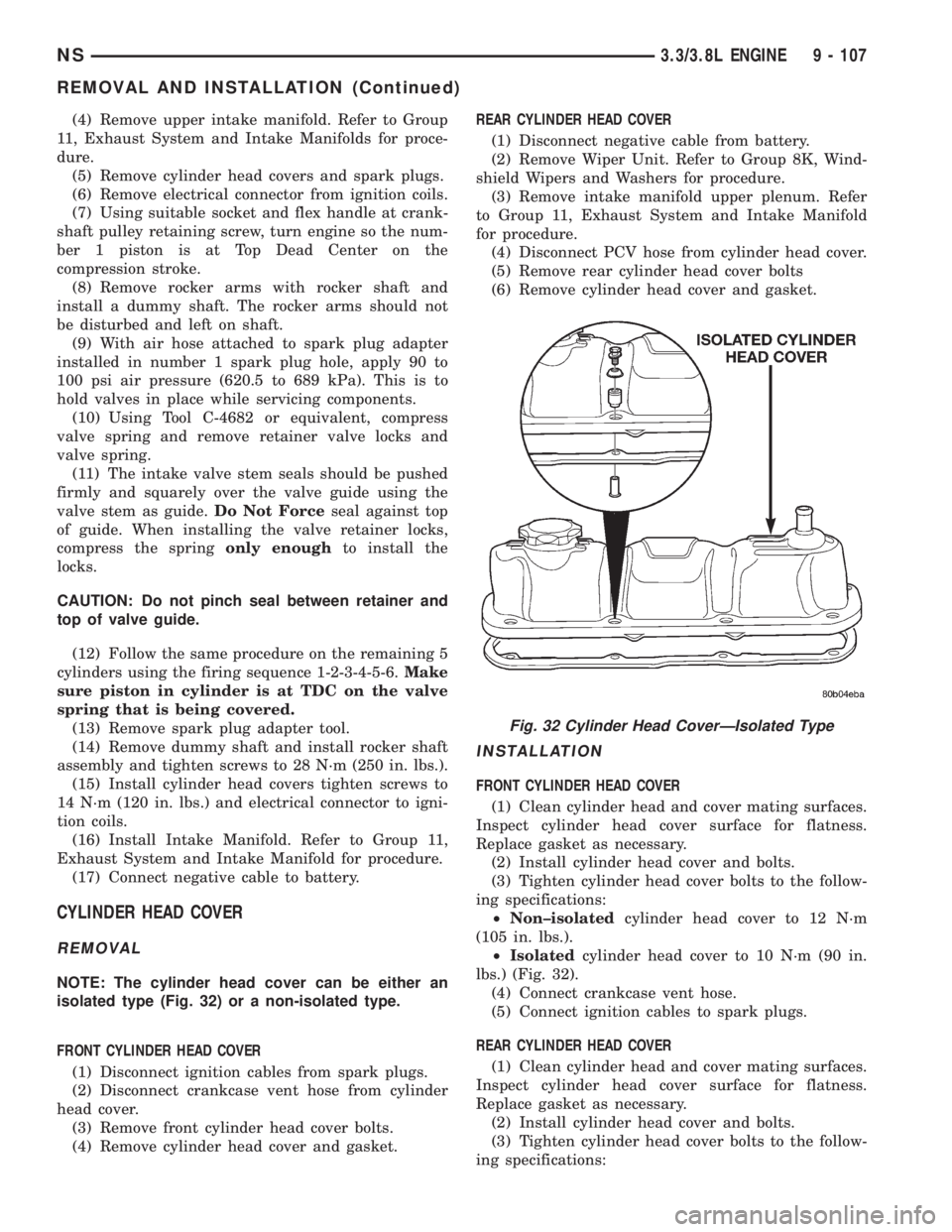

CYLINDER HEAD COVER

REMOVAL

NOTE: The cylinder head cover can be either an

isolated type (Fig. 32) or a non-isolated type.

FRONT CYLINDER HEAD COVER

(1) Disconnect ignition cables from spark plugs.

(2) Disconnect crankcase vent hose from cylinder

head cover.

(3) Remove front cylinder head cover bolts.

(4) Remove cylinder head cover and gasket.REAR CYLINDER HEAD COVER

(1) Disconnect negative cable from battery.

(2) Remove Wiper Unit. Refer to Group 8K, Wind-

shield Wipers and Washers for procedure.

(3) Remove intake manifold upper plenum. Refer

to Group 11, Exhaust System and Intake Manifold

for procedure.

(4) Disconnect PCV hose from cylinder head cover.

(5) Remove rear cylinder head cover bolts

(6) Remove cylinder head cover and gasket.

INSTALLATION

FRONT CYLINDER HEAD COVER

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Install cylinder head cover and bolts.

(3) Tighten cylinder head cover bolts to the follow-

ing specifications:

²Non±isolatedcylinder head cover to 12 N´m

(105 in. lbs.).

²Isolatedcylinder head cover to 10 N´m (90 in.

lbs.) (Fig. 32).

(4) Connect crankcase vent hose.

(5) Connect ignition cables to spark plugs.

REAR CYLINDER HEAD COVER

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Install cylinder head cover and bolts.

(3) Tighten cylinder head cover bolts to the follow-

ing specifications:

Fig. 32 Cylinder Head CoverÐIsolated Type

NS3.3/3.8L ENGINE 9 - 107

REMOVAL AND INSTALLATION (Continued)

Page 1174 of 1938

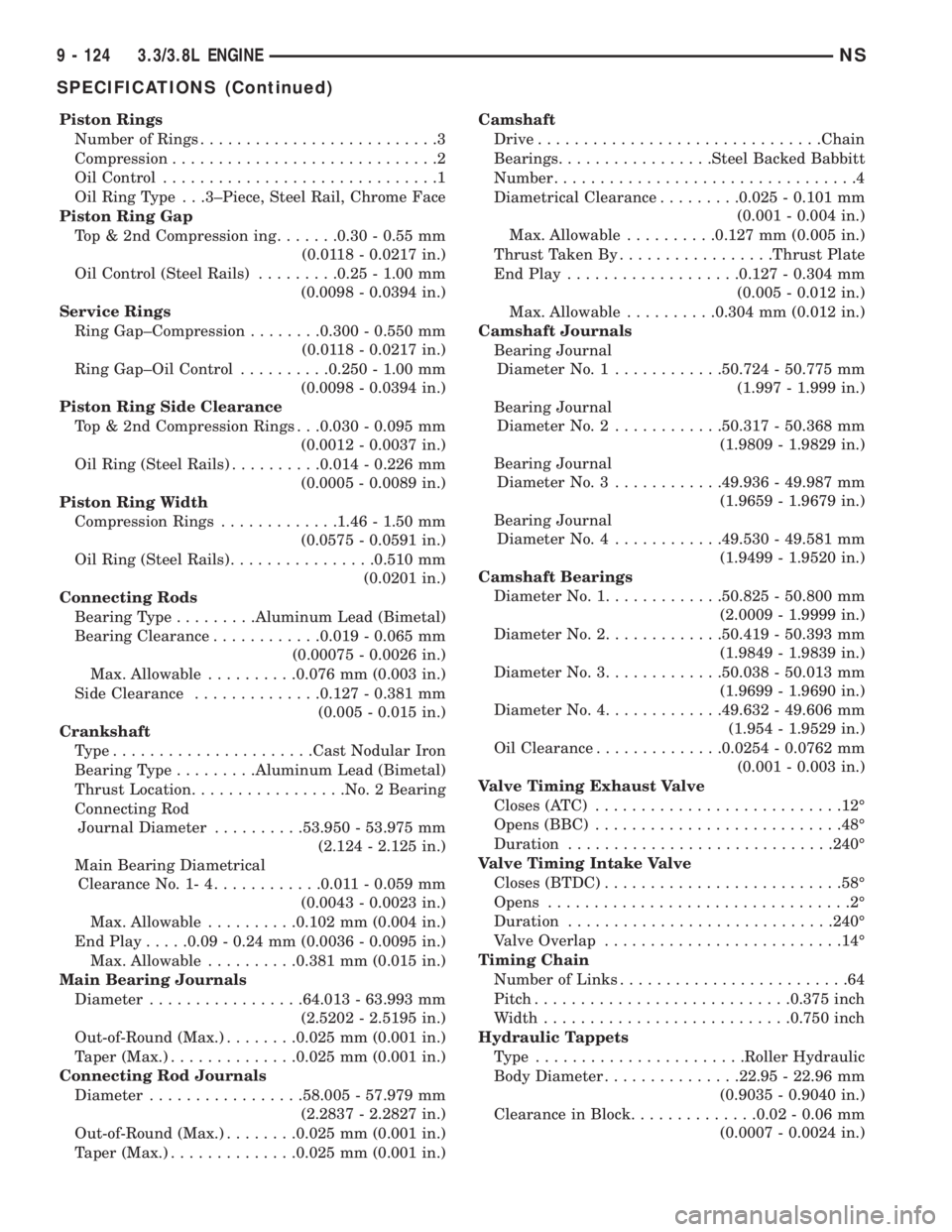

Piston Rings

Number of Rings..........................3

Compression.............................2

Oil Control..............................1

Oil Ring Type . . .3±Piece, Steel Rail, Chrome Face

Piston Ring Gap

Top & 2nd Compression ing.......0.30 - 0.55 mm

(0.0118 - 0.0217 in.)

Oil Control (Steel Rails).........0.25 - 1.00 mm

(0.0098 - 0.0394 in.)

Service Rings

Ring Gap±Compression........0.300 - 0.550 mm

(0.0118 - 0.0217 in.)

Ring Gap±Oil Control..........0.250 - 1.00 mm

(0.0098 - 0.0394 in.)

Piston Ring Side Clearance

Top & 2nd Compression Rings . . .0.030 - 0.095 mm

(0.0012 - 0.0037 in.)

Oil Ring (Steel Rails)..........0.014 - 0.226 mm

(0.0005 - 0.0089 in.)

Piston Ring Width

Compression Rings.............1.46 - 1.50 mm

(0.0575 - 0.0591 in.)

Oil Ring (Steel Rails)................0.510 mm

(0.0201 in.)

Connecting Rods

Bearing Type.........Aluminum Lead (Bimetal)

Bearing Clearance............0.019 - 0.065 mm

(0.00075 - 0.0026 in.)

Max. Allowable..........0.076 mm (0.003 in.)

Side Clearance..............0.127 - 0.381 mm

(0.005 - 0.015 in.)

Crankshaft

Type......................Cast Nodular Iron

Bearing Type.........Aluminum Lead (Bimetal)

Thrust Location.................No. 2 Bearing

Connecting Rod

Journal Diameter..........53.950 - 53.975 mm

(2.124 - 2.125 in.)

Main Bearing Diametrical

Clearance No. 1- 4............0.011 - 0.059 mm

(0.0043 - 0.0023 in.)

Max. Allowable..........0.102 mm (0.004 in.)

End Play.....0.09 - 0.24 mm (0.0036 - 0.0095 in.)

Max. Allowable..........0.381 mm (0.015 in.)

Main Bearing Journals

Diameter.................64.013 - 63.993 mm

(2.5202 - 2.5195 in.)

Out-of-Round (Max.)........0.025 mm (0.001 in.)

Taper (Max.)..............0.025 mm (0.001 in.)

Connecting Rod Journals

Diameter.................58.005 - 57.979 mm

(2.2837 - 2.2827 in.)

Out-of-Round (Max.)........0.025 mm (0.001 in.)

Taper (Max.)..............0.025 mm (0.001 in.)Camshaft

Drive...............................Chain

Bearings.................Steel Backed Babbitt

Number.................................4

Diametrical Clearance.........0.025 - 0.101 mm

(0.001 - 0.004 in.)

Max. Allowable..........0.127 mm (0.005 in.)

Thrust Taken By.................Thrust Plate

End Play...................0.127 - 0.304 mm

(0.005 - 0.012 in.)

Max. Allowable..........0.304 mm (0.012 in.)

Camshaft Journals

Bearing Journal

Diameter No. 1............50.724 - 50.775 mm

(1.997 - 1.999 in.)

Bearing Journal

Diameter No. 2............50.317 - 50.368 mm

(1.9809 - 1.9829 in.)

Bearing Journal

Diameter No. 3............49.936 - 49.987 mm

(1.9659 - 1.9679 in.)

Bearing Journal

Diameter No. 4............49.530 - 49.581 mm

(1.9499 - 1.9520 in.)

Camshaft Bearings

Diameter No. 1.............50.825 - 50.800 mm

(2.0009 - 1.9999 in.)

Diameter No. 2.............50.419 - 50.393 mm

(1.9849 - 1.9839 in.)

Diameter No. 3.............50.038 - 50.013 mm

(1.9699 - 1.9690 in.)

Diameter No. 4.............49.632 - 49.606 mm

(1.954 - 1.9529 in.)

Oil Clearance..............0.0254 - 0.0762 mm

(0.001 - 0.003 in.)

Valve Timing Exhaust Valve

Closes (ATC)...........................12É

Opens (BBC)...........................48É

Duration.............................240É

Valve Timing Intake Valve

Closes (BTDC)..........................58É

Opens.................................2É

Duration.............................240É

Valve Overlap..........................14É

Timing Chain

Number of Links.........................64

Pitch............................0.375 inch

Width...........................0.750 inch

Hydraulic Tappets

Type .......................Roller Hydraulic

Body Diameter...............22.95 - 22.96 mm

(0.9035 - 0.9040 in.)

Clearance in Block..............0.02 - 0.06 mm

(0.0007 - 0.0024 in.)

9 - 124 3.3/3.8L ENGINENS

SPECIFICATIONS (Continued)

Page 1175 of 1938

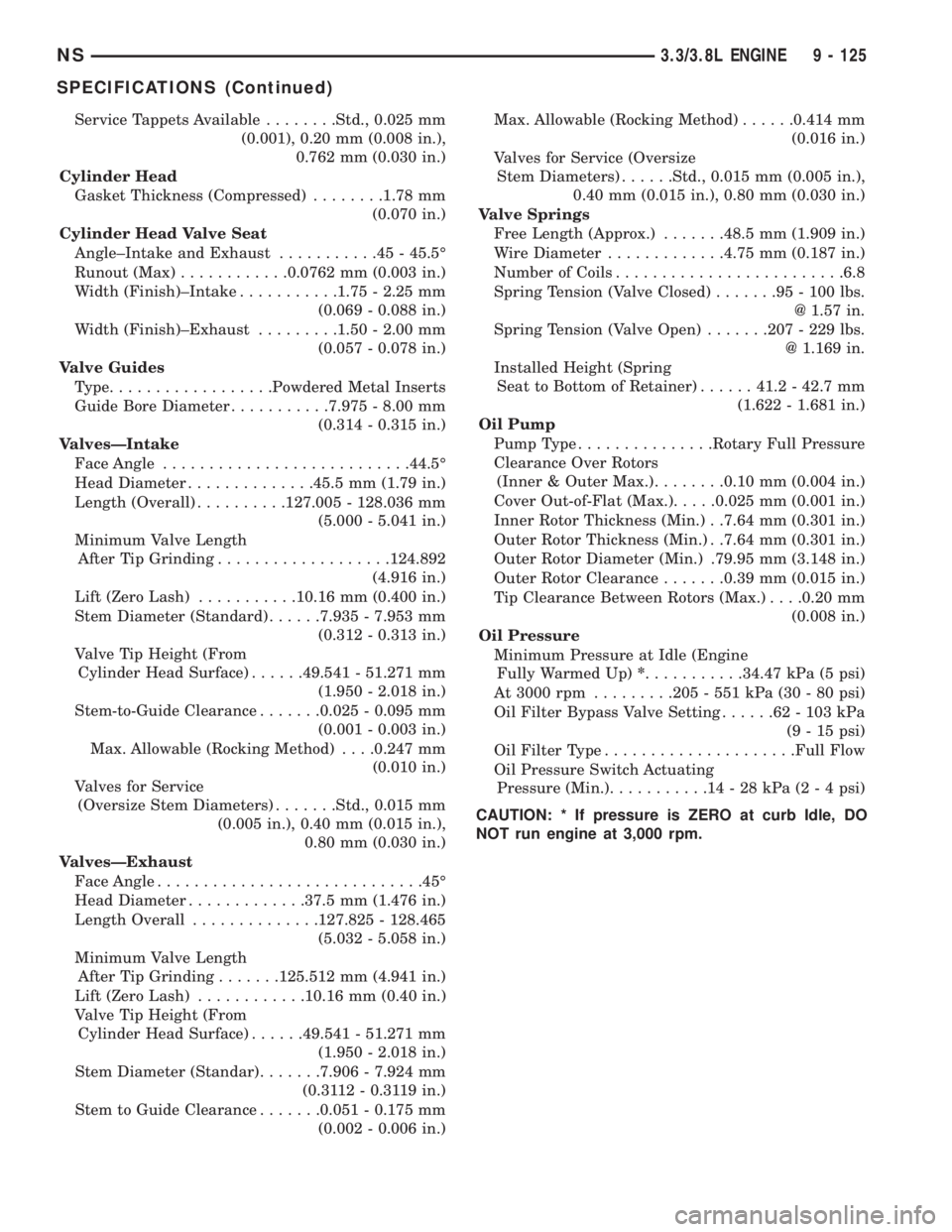

Service Tappets Available........Std., 0.025 mm

(0.001), 0.20 mm (0.008 in.),

0.762 mm (0.030 in.)

Cylinder Head

Gasket Thickness (Compressed)........1.78 mm

(0.070 in.)

Cylinder Head Valve Seat

Angle±Intake and Exhaust...........45-45.5É

Runout (Max)............0.0762 mm (0.003 in.)

Width (Finish)±Intake...........1.75 - 2.25 mm

(0.069 - 0.088 in.)

Width (Finish)±Exhaust.........1.50 - 2.00 mm

(0.057 - 0.078 in.)

Valve Guides

Type..................Powdered Metal Inserts

Guide Bore Diameter...........7.975 - 8.00 mm

(0.314 - 0.315 in.)

ValvesÐIntake

Face Angle...........................44.5É

Head Diameter..............45.5 mm (1.79 in.)

Length (Overall)..........127.005 - 128.036 mm

(5.000 - 5.041 in.)

Minimum Valve Length

After Tip Grinding...................124.892

(4.916 in.)

Lift (Zero Lash)...........10.16 mm (0.400 in.)

Stem Diameter (Standard)......7.935 - 7.953 mm

(0.312 - 0.313 in.)

Valve Tip Height (From

Cylinder Head Surface)......49.541 - 51.271 mm

(1.950 - 2.018 in.)

Stem-to-Guide Clearance.......0.025 - 0.095 mm

(0.001 - 0.003 in.)

Max. Allowable (Rocking Method). . . .0.247 mm

(0.010 in.)

Valves for Service

(Oversize Stem Diameters).......Std., 0.015 mm

(0.005 in.), 0.40 mm (0.015 in.),

0.80 mm (0.030 in.)

ValvesÐExhaust

Face Angle.............................45É

Head Diameter.............37.5 mm (1.476 in.)

Length Overall..............127.825 - 128.465

(5.032 - 5.058 in.)

Minimum Valve Length

After Tip Grinding.......125.512 mm (4.941 in.)

Lift (Zero Lash)............10.16 mm (0.40 in.)

Valve Tip Height (From

Cylinder Head Surface)......49.541 - 51.271 mm

(1.950 - 2.018 in.)

Stem Diameter (Standar).......7.906 - 7.924 mm

(0.3112 - 0.3119 in.)

Stem to Guide Clearance.......0.051 - 0.175 mm

(0.002 - 0.006 in.)Max. Allowable (Rocking Method)......0.414 mm

(0.016 in.)

Valves for Service (Oversize

Stem Diameters)......Std., 0.015 mm (0.005 in.),

0.40 mm (0.015 in.), 0.80 mm (0.030 in.)

Valve Springs

Free Length (Approx.).......48.5 mm (1.909 in.)

Wire Diameter.............4.75 mm (0.187 in.)

Number of Coils.........................6.8

Spring Tension (Valve Closed).......95-100lbs.

@ 1.57 in.

Spring Tension (Valve Open).......207 - 229 lbs.

@ 1.169 in.

Installed Height (Spring

Seat to Bottom of Retainer)......41.2 - 42.7 mm

(1.622 - 1.681 in.)

Oil Pump

Pump Type...............Rotary Full Pressure

Clearance Over Rotors

(Inner & Outer Max.)........0.10 mm (0.004 in.)

Cover Out-of-Flat (Max.).....0.025 mm (0.001 in.)

Inner Rotor Thickness (Min.) . .7.64 mm (0.301 in.)

Outer Rotor Thickness (Min.) . .7.64 mm (0.301 in.)

Outer Rotor Diameter (Min.) .79.95 mm (3.148 in.)

Outer Rotor Clearance.......0.39 mm (0.015 in.)

Tip Clearance Between Rotors (Max.). . . .0.20 mm

(0.008 in.)

Oil Pressure

Minimum Pressure at Idle (Engine

Fully Warmed Up)*...........34.47 kPa (5 psi)

At 3000 rpm.........205 - 551 kPa (30 - 80 psi)

Oil Filter Bypass Valve Setting......62-103kPa

(9 - 15 psi)

Oil Filter Type.....................Full Flow

Oil Pressure Switch Actuating

Pressure (Min.)...........14-28kPa(2 - 4 psi)

CAUTION: * If pressure is ZERO at curb Idle, DO

NOT run engine at 3,000 rpm.

NS3.3/3.8L ENGINE 9 - 125

SPECIFICATIONS (Continued)