check engine CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 50 of 364

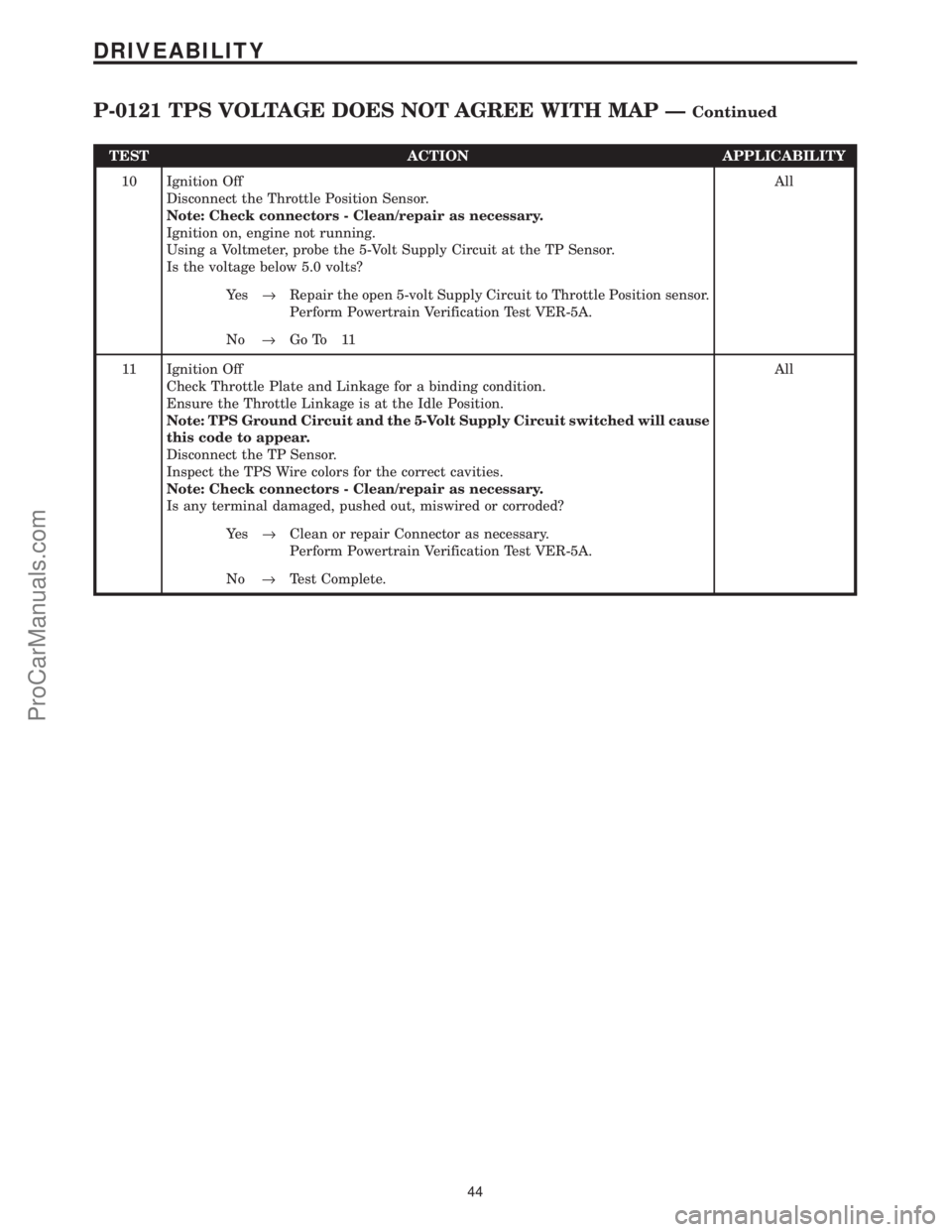

TEST ACTION APPLICABILITY

10 Ignition Off

Disconnect the Throttle Position Sensor.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a Voltmeter, probe the 5-Volt Supply Circuit at the TP Sensor.

Is the voltage below 5.0 volts?All

Ye s®Repair the open 5-volt Supply Circuit to Throttle Position sensor.

Perform Powertrain Verification Test VER-5A.

No®Go To 11

11 Ignition Off

Check Throttle Plate and Linkage for a binding condition.

Ensure the Throttle Linkage is at the Idle Position.

Note: TPS Ground Circuit and the 5-Volt Supply Circuit switched will cause

this code to appear.

Disconnect the TP Sensor.

Inspect the TPS Wire colors for the correct cavities.

Note: Check connectors - Clean/repair as necessary.

Is any terminal damaged, pushed out, miswired or corroded?All

Ye s®Clean or repair Connector as necessary.

Perform Powertrain Verification Test VER-5A.

No®Test Complete.

44

DRIVEABILITY

P-0121 TPS VOLTAGE DOES NOT AGREE WITH MAP ÐContinued

ProCarManuals.com

Page 51 of 364

Symptom:

P-0122 THROTTLE POSITION SENSOR VOLTAGE LOW

When Monitored and Set Condition:

P-0122 THROTTLE POSITION SENSOR VOLTAGE LOW

When Monitored: With the ignition on.

Set Condition: The TP sensor signal voltage goes below 0.16 volt.

POSSIBLE CAUSES

TPS 5-VOLT SUPPLY CIRCUIT OPEN

TPS SIGNAL CIRCUIT SHORT TO GROUND

TPS SIGNAL CIRCUIT SHORT TO SENSOR GROUND CIRCUIT

TPS WIRING HARNESS INTERMITTENT DEFECT

TPS WIRING HARNESS OBSERVABLE DEFECT

PCM DEFECTIVE (TPS)

THROTTLE POSITION SENSOR DEFECTIVE

THROTTLE POSITION SENSOR VOLTAGE CHANGE NOT SMOOTH

TRANSMISSION CONTROL MODULE DEFECTIVE (TPS)

TEST ACTION APPLICABILITY

1 Turn key on, engine off.

With the DRB, read the Throttle Position Sensor (TP Sensor) voltage.

Is the Throttle Position Sensor voltage below 0.16 volt?All

Ye s®Go To 2

No®Go To 8

2 Ignition Off

Disconnect the Throttle Position Sensor.

Note: Check connectors - Clean/repair as necessary.

Ignition On, Engine Not Running.

Measure the voltage at the 5-Volt Supply Circuit at TPS Connector.

Is the voltage below 4.0 volts?All

Ye s®Repair the open TP Sensor 5-Volt Supply Circuit.

Perform Powertrain Verification Test VER-5A.

No®Go To 3

45

DRIVEABILITY

ProCarManuals.com

Page 52 of 364

TEST ACTION APPLICABILITY

3 Ignition Off

Disconnect the Throttle Position Sensor.

Note: Check connectors - Clean repair as necessary.

Ignition On, Engine Not Running.

With the DRB, read the Throttle Position Sensor voltage.

Is the voltage above 1.0 volt?All

Ye s®Replace the Throttle Position Sensor.

Perform Powertrain Verification Test VER-5A.

No®Go To 4

4 Ignition Off

Disconnect the Throttle Position Sensor.

Disconnect the Transmission Control Module.

Disconnect the PCM.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between the TP Sensor Signal Circuit and ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Throttle Position Sensor Signal Circuit for a short to

ground.

Perform Powertrain Verification Test VER-5A.

No®Go To 5

5 Ignition Off

Disconnect the Throttle Position Sensor.

Disconnect the Transmission Control Module.

Disconnect the PCM.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between the TP Sensor Signal Circuit and the Sensor Ground

Circuit.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Sensor Signal Circuit shorted to Sensor Ground

Circuit.

Perform Powertrain Verification Test VER-5A.

No®Go To 6

6 Ignition Off

Disconnect the Throttle Position Sensor.

Disconnect the Transmission Control Module if equipped..

Note: Check connectors - Clean/repair as necessary.

Key On

With the DRB, read the Throttle Position Sensor voltage.

Is the voltage above 1.0 volt?All

Ye s®Replace the Transmission Control Module.

Perform Powertrain Verification Test VER-5A.

No®Go To 7

7 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.All

Repair

Replace the PCM.

Perform Powertrain Verification Test VER-5A.

46

DRIVEABILITY

P-0122 THROTTLE POSITION SENSOR VOLTAGE LOW ÐContinued

ProCarManuals.com

Page 54 of 364

Symptom:

P-0123 THROTTLE POSITION SENSOR VOLTAGE HIGH

When Monitored and Set Condition:

P-0123 THROTTLE POSITION SENSOR VOLTAGE HIGH

When Monitored: With the ignition on.

Set Condition: TP sensor signal voltage goes above 4.5 volts for .704 seconds.

POSSIBLE CAUSES

THROTTLE POSITION SENSOR GROUND CIRCUIT OPEN

THROTTLE POSITION SENSOR SIGNAL CIRCUIT OPEN

TPS SIGNAL CKT TO TPS 5 VOLT SUPPLY CKT SHORTED

TPS WIRING HARNESS INTERMITTENT DEFECT

TPS WIRING HARNESS OBSERVABLE DEFECT

POWERTRAIN CONTROL MODULE DEFECTIVE (TPS)

THROTTLE POSITION SENSOR VOLTAGE BELOW 1.0 VOLT

THROTTLE POSITION SENSOR VOLTAGE CHANGE NOT SMOOTH

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

Using the DRB, read the Throttle Position Sensor voltage.

Is the Throttle Position Sensor voltage above 4.5 volts?All

Ye s®Go To 2

No®Go To 8

2 Ignition Off

Disconnect the Throttle Position Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Ignition On.

With the DRB actuate the ASD relay.

Measure the voltage of the TP sensor signal circuit.

Is the voltage above 4.9 volts?All

Ye s®Repair the short voltage in the Throttle Position Sensor Signal

Circuit.

Perform Powertrain Verification Test VER-5A.

No®Go To 3

48

DRIVEABILITY

ProCarManuals.com

Page 55 of 364

TEST ACTION APPLICABILITY

3 Ignition Off

Disconnect the Throttle Position Sensor Connector.

Disconnect the Powertrain Control Module Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure between the 5-volt Supply Circuit and the Throttle

Position Sensor Signal Circuit at the Throttle Position Sensor Connector.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Throttle Position Sensor Signal Circuit shorted to the

5-volt Supply Circuit.

Perform Powertrain Verification Test VER-5A.

No®Go To 4

4 Turn the Ignition Off

Disconnect the TCM harness connector.

Turn the Ignition On.

Using the DRB, monitor the TP sensor voltage.

Is the voltage below 1.0 volt?All

Ye s®Replace the Transmission Control Module.

No®Go To 5

5 Ignition Off

Disconnect the Throttle Position Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the Throttle Position Sensor Signal Circuit and

Sensor Ground Circuit.

Ignition on, engine not running.

Using the DRB, read the Throttle Position Sensor voltage.

Is the voltage below 1.0 volt?All

Ye s®Replace the Throttle Position Sensor.

Perform Powertrain Verification Test VER-5A.

No®Go To 6

6 Ignition Off

Disconnect the TPS Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the TPS Signal Circuit and a good engine ground.

Ignition on, engine not running.

Using the DRB, read the Throttle Position Sensor voltage.

Is the voltage below 1.0 volt?All

Ye s®Repair the open Throttle Position Sensor Ground Circuit.

Perform Powertrain Verification Test VER-5A.

No®Go To 7

49

DRIVEABILITY

P-0123 THROTTLE POSITION SENSOR VOLTAGE HIGH ÐContinued

ProCarManuals.com

Page 56 of 364

TEST ACTION APPLICABILITY

7 Ignition Off

Disconnect the Throttle Position Sensor.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of the TPS Signal Circuit from the TPS

Connector to the PCM Connector.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

No®Repair the open Throttle Position Sensor Signal Circuit.

Perform Powertrain Verification Test VER-5A.

8 Ignition On, Engine Not Running

Wiggle Throttle Position Sensor Connectors and Harness.

Monitor the DRB display.

Was there any change in Throttle Position Sensor voltage when wiggled?All

Ye s®Repair the Harness or Connector that caused the voltage change.

Perform Powertrain Verification Test VER-5A.

No®Go To 9

9 Ignition Off

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 10

10 Ignition On, Engine Not Running

While monitoring the DRB, slowly open and close the Throttle.

Is the voltage change smooth?All

Ye s®Test Complete.

No®Replace the Throttle Position Sensor.

Perform Powertrain Verification Test VER-5A.

50

DRIVEABILITY

P-0123 THROTTLE POSITION SENSOR VOLTAGE HIGH ÐContinued

ProCarManuals.com

Page 57 of 364

Symptom:

P-0125 CLOSED LOOP TEMP NOT REACHED

When Monitored and Set Condition:

P-0125 CLOSED LOOP TEMP NOT REACHED

When Monitored: After engine is started, for ten minutes.

Set Condition: The engine temperature does not go above 10 degrees C (50 degrees F) by

13 minutes after the engine is started for 2 consecutive trips.

POSSIBLE CAUSES

PCM CONNECTOR AND TERM DAM, PSHD OUT, OR MISWIRED

ECT SENSOR CONN AND TERM DAM, PSHD OUT, MISWIRED

ECT SENSOR RESISTANCE >=11.00 K OHMS

PCM DEFECTIVE

THERMOSTAT DEFECTIVE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, read the FREEZE FRAME DATA.

Using the FREEZE FRAME DATA, attempt to duplicate the condition that has set

this fault.

Note that the DTC is a 2 trip failure.

Does P0121 reset?All

Ye s®Go To 3

No®Go To 2

2 The conditions required to set the DTC are no longer present.

Ensure the engine cooling system is operating properly, coolant level is at specifica-

tion, and no external or internal coolant leaks. Refer to the appropriate service

category for cooling system information.

Is the Cooling System operating correctly?All

Ye s®Test complete

No®Repair as necessary.

Perform Powertrain verification Test VER-5A

3 Ignition off.

Disconnect the ECT Sensor Connector.

Note: Check Connectors - clean/repair as necessary.

Is any Terminal damaged, pushed out, or miswired?All

Ye s®Clean or repair connector as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 4

51

DRIVEABILITY

ProCarManuals.com

Page 61 of 364

Symptom:

P-0132 1/1 O2 SENSOR SHORTED TO VOLTAGE

When Monitored and Set Condition:

P-0132 1/1 O2 SENSOR SHORTED TO VOLTAGE

When Monitored: With the engine running for more than 2 minutes and coolant

temperature above 76 degrees C (170 degrees F).

Set Condition: The Upstream Oxygen Sensor Signal voltage is above 1.2 volts.

POSSIBLE CAUSES

1/1 O2 SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

1/1 O2 SEN HARNESS INTERMITTENT SHORT TO VOLTAGE

1/1 O2 SENSOR CONNECTOR OBSERVABLE DEFECT (A)

1/1 O2 SENSOR CONNECTOR OBSERVABLE DEFECT (B)

1/1 O2 SENSOR HARNESS OBSERVABLE DEFECT

1/1 O2 SENSOR DEFECTIVE

TEST ACTION APPLICABILITY

1 Start the engine.

With the DRB, read the Upstream O2 Sensor voltage.

Is the Upstream O2 Sensor voltage above 1.2 volts?All

Ye s®Go To 2

No®Go To 5

2 Ignition Off

Disconnect the Upstream O2 Sensor.

Note: Check connectors - Clean/repair as necessary.

Start the engine.

With the DRB, read the Upstream O2 Sensor Voltage.

Is the Upstream O2 Sensor voltage above 1.2 volts?All

Ye s®Repair the Upstream O2 Sensor Signal Circuit for a short to

voltage. If ok, replace the PCM.

Perform Powertrain Verification Test VER-5A.

No®Go To 3

3 Ignition Off

Disconnect the Upstream O2 Sensor.

Note: Check connectors - Clean/repair as necessary.

Is any Terminal damaged, pushed out or miswired?All

Ye s®Repair or replace as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 4

55

DRIVEABILITY

ProCarManuals.com

Page 62 of 364

TEST ACTION APPLICABILITY

4 If there are no potential causes remaining, the Upstream O2 Sensor is assumed to be

defective.

View repair options.All

Repair

Replace the Upstream O2 Sensor.

Perform Powertrain Verification Test VER-5A.

5 Start the engine.

Wiggle Upstream O2 Sensor Connector and Harness.

While wiggling the Harness, watch the Upstream O2 Sensor voltage.

Did the O2 Sensor voltage go above 1.2 volts at any time?All

Ye s®Repair the Harness or Connector that has the intermittent short

to voltage.

Perform Powertrain Verification Test VER-5A.

No®Go To 6

6 Ignition Off

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 7

7 Ignition Off

Disconnect the Upstream O2 Sensor.

Note: Check connectors - Clean/repair as necessary.

Inspect connectors.

Is any Terminal damaged, pushed out or miswired?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Test Complete.

56

DRIVEABILITY

P-0132 1/1 O2 SENSOR SHORTED TO VOLTAGE ÐContinued

ProCarManuals.com

Page 64 of 364

TEST ACTION APPLICABILITY

3 Turn Ignition On (Engine Off).

During the following voltage drop measurement, wiggle wires between O2S Connec-

tor and PCM Connector.

Using a voltmeter, backprobe O2S (Signal) Circuit between O2S Connector (O2S

Signal) and PCM Connector (O2S Signal).

While wiggling wires, is the voltage drop reading below 0.10 VDC?All

Ye s®Go To 4

No®Repair poor connection (high resistance) on O2S Signal Circuit.

Perform VERIFICATION TEST VER-5A3.

4 At this time the 1/1 O2S SLOW RESPONSE does not exist or is an intermittent

problem.

With the DRB, read the FREEZE FRAME DATA.

With this screen, attempt to duplicate the condition that has set this fault.

While using FREEZE FRAME pay particular attention to the fault setting condi-

tions, such as speed, temp, load, and map vacuum.

Does the 1/1 O2S SLOW RESPONSE reoccur?All

Ye s®Go To 5

No®The 1/1 O2S SLOW RESPONSE no longer exists.

Perform VERIFICATION TEST VER-5A3.

5 The following are possible causes for O2 Sensor Slow Response: exhaust leak, fuel

contamination, O2 sensor failure, electrical wiring connectors, electrical mechanical,

and O2 heater failure.

Start the Engine.

NOTE: Check the exhaust for excessive smoke caused by oil or coolant

consumption.

Is there an oil or coolant consumption condition present?All

Ye s®Repair engine mechanical as necessary and replace O2 Sensor.

Perform VERIFICATION TEST VER-5A3.

No®Go To 6

6 The following are possible causes for O2 Sensor Slow Response: exhaust leak, fuel

contamination, O2 sensor failure, electrical wiring connectors, electrical mechanical,

and O2 heater failure.

Start the Engine.

Check the Exhaust System for leaks between the Engine and the catalyst.

Are there any leaks?All

Ye s®Repair or replace leaking Exhaust System as necessary.

Perform VERIFICATION TEST VER-5A3.

No®Go To 7

7 The following are possible causes for O2 Sensor Slow Response: exhaust leak, fuel

contamination, O2 sensor failure, electrical wiring connectors, electrical mechanical,

and O2 heater failure.

Turn Ignition On (Engine Off).

Using a voltmeter, backprobe O2S (Signal) Circuit between O2S Connector (O2S

Signal) and PCM Connector (O2S Signal).

Is the voltage drop reading below 0.10 VDC?All

Ye s®Go To 8

No®Repair poor connection (high resistance) on O2S Signal Circuit.

Perform VERIFICATION TEST VER-5A3.

58

DRIVEABILITY

P-0133 1/1 O2S SLOW RESPONSE ÐContinued

ProCarManuals.com