engine CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 85 of 364

Symptom

P0172 -1/1 FUEL SYSTEM RICH

When Monitored and Set Condition:

P0172 -1/1 FUEL SYSTEM RICH

When Monitored: With the engine in closed loop mode, the ambient/battery temperature

above þ5 deg. C (20 deg. F) and altitude below 8000 ft.

Set Condition: If the PCM multiplies short term compensation by long term adaptive and

the result is below a certain value for two trips, a freeze frame is stored, the MIL

illuminates and a trouble code is stored.

POSSIBLE CAUSES

FUEL PUMP MODULE DEFECTIVE

TPS VOLTAGE CHANGE NOT SMOOTH

TPS VOLTAGE <0.92V

FUEL INLET STRAINER PLUGGED

ECT SENSOR DEFECTIVE (OUT OF CALIBRATION)

MAP SENSOR DEFECTIVE (OUT OF CALIBRATION)

ENGINE MECHANICAL PROBLEM

FUEL FILTER/PRESSURE REGULATOR DEFECTIVE (HIGH)

FUEL FILTER/PRESSURE REGULATOR DEFECTIVE (LOW)

TEST ACTION APPLICABILITY

1 Turn ignition on.

With the DRB, read the DTC's.

Is the DTC Specific Good Trip Counter displayed and equal to zero?All

Ye s®Go To 2

No®Go To 14

2 Ignition On, Engine Not Running

With the DRB, read the TPS voltage.

While monitoring the DRB, slowly open and close the Throttle.

Is the voltage change smooth?All

Ye s®Go To 3

No®Replace the Throttle Position Sensor.

Perform Powertrain Verification Test VER-5A.

79

ProCarManuals.com

Page 86 of 364

TEST ACTION APPLICABILITY

3 Ignition On, Engine Not Running.

With the DRB, read TP Sensor voltage. Throttle must be against stop.

Is the voltage 0.92 or less with the Throttle closed?All

Ye s®Go To 4

No®Replace the Throttle Position Sensor.

Perform Powertrain Verification Test VER-5A.

4 Turn ignition on.

With the DRB in sensors, read the ªEng Coolant Tmp Degº value.

Note: If engine coolant temperature is above 82ÉC (180ÉF), allow the engine

to cool until 62ÉC (150ÉF) is reached.

Start the Engine.

While monitoring the DRB, allow the engine to reach normal operating temperature

above 82ÉC (180ÉF).

Did the engine coolant temperature value reach 180ÉF or above?All

Ye s®Go To 5

No®Replace the Engine Coolant Temperature Sensor.

Perform Powertrain Verification Test VER-5A.

5 Turn ignition On.

With the DRB in sensors, read the ªEng Coolant Tmp Deg'' value

Note: If engine coolant temperature is above 82ÉC (180ÉF), allow the engine

to cool until 62ÉC (150ÉF) is reached.

Start the Engine.

While monitoring the DRB, allow the engine to reach normal operating temperature

above 82ÉC (180ÉF).

Was the coolant temperature value increase a smooth transition?All

Ye s®Go To 6

No®Replace the Engine Coolant Temperature Sensor.

Perform Verification Test VER-5A.

6 Turn ignition off.

Connect a Vacuum Gauge to a Manifold Vacuum source.

Start the engine.

Allow the engine to idle.

Note: If engine will not idle, maintain a constant RPM above idle.

Using the DRB in Sensors, read the MAP Sensor vacuum value.

Is the DRB reading within 19of the Vacuum Gauge reading?All

Ye s®Go To 7

No®Replace the MAP Sensor.

Perform Powertrain Verification Test VER-5A.

7Note: Engine must be at operating temp and in closed loop to perform this

test.

Start engine and run until operating temp and closed loop mode is reached.

With the DRB under System Tests, go to ªPurge Vapors Test''. Observe the Short

Term Adaptive value and press 3 to flow.

Note: Short Term Adaptive should change.

Did the Short Term Adaptive value change?All

Ye s®Go To 8

No®Refer to symptom *CHECKING EVAPORATIVE EMISSION

SYSTEM in the DRIVEABILITY category.

80

P0172 -1/1 FUEL SYSTEM RICH ÐContinued

ProCarManuals.com

Page 87 of 364

TEST ACTION APPLICABILITY

8 Turn ignition off.

Warning: The fuel system is under a constant pressure (even with the engine

off). Before testing or servicing any fuel system hose, fitting or line, the fuel

system pressure must be released.

Remove the pressure test port cap at the fuel rail test port. Connect a fuel pressure

gauge to the test port pressure fitting on the fuel rail.

Ignition on. With the DRB, actuate the ASD Fuel System test and observe the fuel

pressure gauge.

Note: Fuel pressure specification is 49.2 psi +/þ 5 psi.

Choose a conclusion that best matches your fuel pressure reading.All

Below Specification

Go To 9

Within Specification

Go To 13

Above Specification

Replace the fuel filter/pressure regulator.

Caution: Stop ALL Actuations.

9 Check for any of the following conditions/mechanical problems.

ENGINE VACUUM Ð must be at least 13 inches in neutral

ENGINE VALVE TIMING Ð must be within specifications

ENGINE COMPRESSION Ð must be within specifications

ENGINE EXHAUST SYSTEM Ð must be free of any restrictions or leaks.

ENGINE PVC SYSTEM Ð must flow freely

TORQUE CONVERTER STALL SPEED Ð must be within specifications

POWER BRAKE BOOSTER Ð no internal vacuum leaks

FUEL - must be free of contamination

FUEL INJECTOR Ð plugged or restricted injector; control wire not connected to

correct injector

Are there any engine mechanical problems?All

Ye s®Repair as necessary.

Perform FUEL SYSTEM/MISFIRE MONITOR VERIFICATION

TEST

No®Go To 10

10 Turn ignition off.

Warning: The fuel system is under a constant pressure (even with the engine

off). Before testing or servicing any fuel system hose, fitting or line, the fuel

system pressure must be released.

Raise vehicle on hoist, and disconnect the fuel pressure line at the fuel pump module.

Install special 5/169fuel line adapter tool #6539 between disconnected fuel line and

the fuel pump module.

Attach a fuel pressure test gauge to the ªT'' fitting on tool #6539.

Ignition on. With the DRB, actuate the ASD Fuel System test and observe the fuel

pressure gauge.

Note: Fuel pressure specification is 49.2 psi +/- 5 psi.

Is the fuel pressure within specification now?All

Ye s®Repair the restriction in the chassis fuel supply line between the

fuel tank and fuel rail.

No®Go to 11

Caution: Stop ALL Actuations.

81

P0172 -1/1 FUEL SYSTEM RICH ÐContinued

ProCarManuals.com

Page 88 of 364

TEST ACTION APPLICABILITY

11Warning: The fuel system is under a constant pressure (even with the engine

off). Before testing or servicing any fuel system hose, fitting or line, the fuel

system pressure must be released.

Remove the Fuel Pump Module and inspect the Fuel Inlet Strainer.

Is the Fuel Inlet Strainer plugged?All

Ye s®Replace the Fuel Inlet Strainer.

No®Go To 12

12 If there are no potential causes remaining, the Fuel Pump Module is assumed to be

defective.

View repair options.All

Repair

Replace the Fuel Pump Module

13 Check for any of the following conditions/mechanical problems.

ENGINE VACUUM Ð must be at least 13 inches in neutral

ENGINE VALVE TIMING Ð must be within specifications

ENGINE COMPRESSION Ð must be within specifications

ENGINE EXHAUST SYSTEM Ð must be free of any restrictions or leaks.

ENGINE PVC SYSTEM Ð must flow freely

TORQUE CONVERTER STALL SPEED Ð must be within specifications

POWER BRAKE BOOSTER Ð no internal vacuum leaks

FUEL - must be free of contamination

FUEL INJECTOR Ð plugged or restricted injector; control wire not connected to

correct injector

Are there any engine mechanical problems?All

Ye s®Repair as necessary.

Perform FUEL SYSTEM/MISFIRE MONITOR VERIFICATION

TEST

No®Test Complete.

14 The conditions required to set the DTC are no longer present.

With the DRB read and record the freeze frame data and the ªFuel System Similar

Conditions Window'' data.

Utilize the data and try to duplicate the operating conditions at which the DTC was

set. Pay particular attention to the ECT and RPM for added diagnostics.

Note: Refer to any TSB's that may apply to the symptom.

Test Complete

Repair

Test Complete.

82

P0172 -1/1 FUEL SYSTEM RICH ÐContinued

ProCarManuals.com

Page 89 of 364

Symptom:start here

P-0201 INJECTOR #1 CONTROL CIRCUIT

When Monitored and Set Condition:

P-0201 INJECTOR #1 CONTROL CIRCUIT

When Monitored: With battery voltage greater than 12 volts, the auto shutdown relay

energized, injector pulse width less than 10ms, and engine speed less than 3000 rpm.

Set Condition: This trouble code takes .64 to 10.0 seconds to set when no inductive kick

is sensed .18ms after injector turn off, and with no other injectors on.

POSSIBLE CAUSES

ASD RELAY OUTPUT CIRCUIT OPEN

INJECTOR DEFECTIVE

INJECTOR #1 DRIVER CIRCUIT OPEN

INJECTOR #1 DRIVER CIRCUIT SHORTED TO GROUND

POWERTRAIN CONTROL MODULE DEFECTIVE

INJECTOR #1 DRIVER CIRCUIT SHORT TO GROUND

INJECTOR #1 DRIVER CIRCUIT SHORT TO GROUND (PCM)

TEST ACTION APPLICABILITY

1 Ignition Off

Start engine, let idle for at least 20 seconds.

Key on, engine off.

With the DRB, read Trouble Codes.

Is the Global Good Trip counter displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Ignition Off

Disconnect the Injector #1 Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure resistance of Injector #1.

Is the resistance between 10.0 and 16.0 ohms?All

Ye s®Go To 3

No®Replace the Fuel Injector.

Perform Powertrain Verification Test VER-5A.

83

DRIVEABILITY

ProCarManuals.com

Page 91 of 364

TEST ACTION APPLICABILITY

8 Engine Running

Wiggle Wiring Harness from the Injector to the PCM.

Does the engine miss or stall?All

Ye s®Repair as necessary where wiggling caused the problem to

appear.

Perform Powertrain Verification Test VER-5A.

No®Test Complete.

85

DRIVEABILITY

P-0201 INJECTOR #1 CONTROL CIRCUIT ÐContinued

ProCarManuals.com

Page 92 of 364

Symptom:

P-0202 INJECTOR #2 CONTROL CIRCUIT

When Monitored and Set Condition:

P-0202 INJECTOR #2 CONTROL CIRCUIT

When Monitored: With battery voltage greater than 12 volts, the auto shutdown relay

energized, injector pulse width less than 10ms, and engine speed less than 3000 rpm.

Set Condition: This trouble code takes .64 to 10.0 seconds to set when no inductive kick

is sensed .18ms after injector turn off, and with no other injectors on.

POSSIBLE CAUSES

ASD RELAY OUTPUT CIRCUIT OPEN

INJECTOR DEFECTIVE

INJECTOR #2 DRIVER CIRCUIT OPEN

INJECTOR #2 DRIVER CIRCUIT SHORTED TO GROUND

PCM DEFECTIVE

TEST ACTION APPLICABILITY

1 Ignition Off

Start engine, let idle for at least 20 seconds.

Key on, engine off.

With the DRB, read Trouble Codes.

Is the Global Good Trip counter displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Ignition Off

Note: It may be necessary to remove the Intake Plenum in the following

steps.

Disconnect the Injector #2 Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure resistance of Injector #2.

Is the resistance between 10.0 and 16.0 ohms?All

Ye s®Go To 3

No®Replace the Fuel Injector.

Perform Powertrain Verification Test VER-5A.

86

DRIVEABILITY

ProCarManuals.com

Page 93 of 364

TEST ACTION APPLICABILITY

3Note: It may be necessary to remove the Intake Plenum in the following

steps.

Ignition Off

Disconnect the Injector #2 Connector.

Note: Check connectors - Clean/repair as necessary.

Turn ignition on.

With the DRB, actuate the Auto Shutdown Relay.

Using a Voltmeter, measure the ASD Relay Output Circuit voltage.

Does the voltage cycle high and low?All

Ye s®Go To 4

No®Repair the open ASD Relay Output Circuit.

Perform Powertrain Verification Test VER-5A.

4 Ignition Off

Disconnect the Injector #2 Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module Connector.

Note: Check connectors - Clean/repair as necessary.

Use an Ohmmeter in the following step.

Measure the Injector #2 Driver Circuit from the PCM to the Injector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the open Injector #2 Driver Circuit.

Perform Powertrain Verification Test VER-5A.

5 Ignition Off

Disconnect the Injector #2 Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module Connector.

Note: Check Connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the Injector #2 Driver Circuit to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Injector #2 Driver Circuit for a short to ground.

Perform Powertrain Verification Test VER-5A.

No®Go To 6

6 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.All

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

7 Engine Running

Wiggle Wiring Harness from the Injector to the PCM.

Does the engine miss or stall?All

Ye s®Repair as necessary where wiggling caused the problem to

appear.

Perform Powertrain Verification Test VER-5A.

No®Go To 8

87

DRIVEABILITY

P-0202 INJECTOR #2 CONTROL CIRCUIT ÐContinued

ProCarManuals.com

Page 95 of 364

Symptom:

P-0203 INJECTOR #3 CONTROL CIRCUIT

When Monitored and Set Condition:

P-0203 INJECTOR #3 CONTROL CIRCUIT

When Monitored: With battery voltage greater than 12 volts, the auto shutdown relay

energized, injector pulse width less than 10ms, and engine speed less than 3000 rpm.

Set Condition: This trouble code takes .64 to 10.0 seconds to set when no inductive kick

is sensed .18ms after injector turn off, and with no other injectors on.

POSSIBLE CAUSES

ASD RELAY OUTPUT CIRCUIT OPEN

FUEL INJECTOR #3 DEFECTIVE

INJECTOR #3 DRIVER CIRCUIT OPEN

INJECTOR #3 DRIVER CIRCUIT SHORTED TO GROUND

PCM DEFECTIVE

TEST ACTION APPLICABILITY

1 Ignition Off

Start engine, let idle for at least 20 seconds.

Key on, engine off.

With the DRB, read Trouble Codes.

Is the Global Good Trip counter displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Ignition Off

Note: It may be necessary to remove the Intake Plenum in the following

steps.

Disconnect the Injector #3 Connector.

Note: Check connectors - Clear/repair as necessary.

Using an Ohmmeter, measure the resistance of Injector #3.

Is the resistance between 10.0 and 16.0 ohms?All

Ye s®Go To 3

No®Replace the Fuel Injector.

Perform Powertrain Verification Test VER-5A.

89

DRIVEABILITY

ProCarManuals.com

Page 96 of 364

TEST ACTION APPLICABILITY

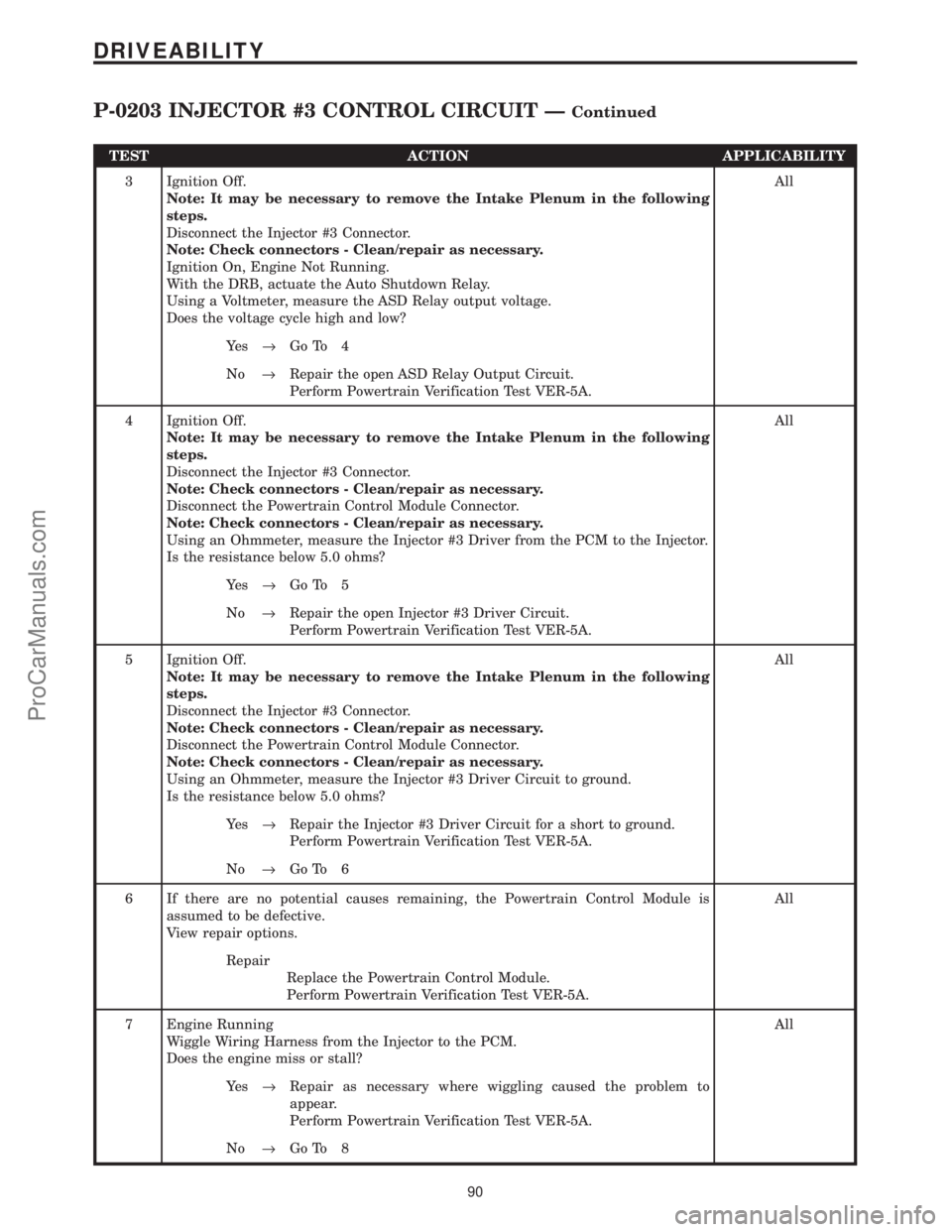

3 Ignition Off.

Note: It may be necessary to remove the Intake Plenum in the following

steps.

Disconnect the Injector #3 Connector.

Note: Check connectors - Clean/repair as necessary.

Ignition On, Engine Not Running.

With the DRB, actuate the Auto Shutdown Relay.

Using a Voltmeter, measure the ASD Relay output voltage.

Does the voltage cycle high and low?All

Ye s®Go To 4

No®Repair the open ASD Relay Output Circuit.

Perform Powertrain Verification Test VER-5A.

4 Ignition Off.

Note: It may be necessary to remove the Intake Plenum in the following

steps.

Disconnect the Injector #3 Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the Injector #3 Driver from the PCM to the Injector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the open Injector #3 Driver Circuit.

Perform Powertrain Verification Test VER-5A.

5 Ignition Off.

Note: It may be necessary to remove the Intake Plenum in the following

steps.

Disconnect the Injector #3 Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the Injector #3 Driver Circuit to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Injector #3 Driver Circuit for a short to ground.

Perform Powertrain Verification Test VER-5A.

No®Go To 6

6 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.All

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

7 Engine Running

Wiggle Wiring Harness from the Injector to the PCM.

Does the engine miss or stall?All

Ye s®Repair as necessary where wiggling caused the problem to

appear.

Perform Powertrain Verification Test VER-5A.

No®Go To 8

90

DRIVEABILITY

P-0203 INJECTOR #3 CONTROL CIRCUIT ÐContinued

ProCarManuals.com