battery replacement CHRYSLER VOYAGER 2001 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 356 of 4284

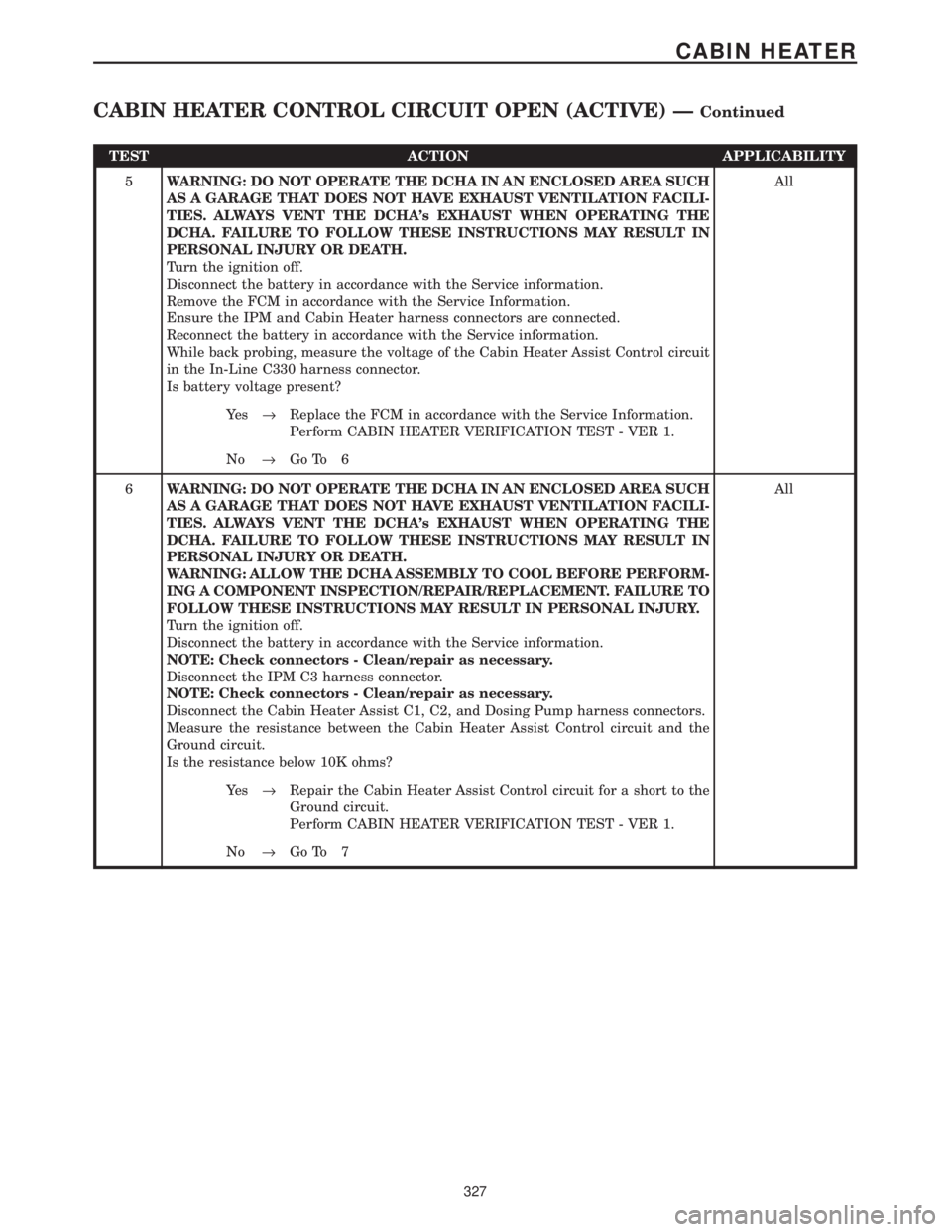

TEST ACTION APPLICABILITY

5WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

Turn the ignition off.

Disconnect the battery in accordance with the Service information.

Remove the FCM in accordance with the Service Information.

Ensure the IPM and Cabin Heater harness connectors are connected.

Reconnect the battery in accordance with the Service information.

While back probing, measure the voltage of the Cabin Heater Assist Control circuit

in the In-Line C330 harness connector.

Is battery voltage present?All

Ye s®Replace the FCM in accordance with the Service Information.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

No®Go To 6

6WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

Disconnect the battery in accordance with the Service information.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the IPM C3 harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Cabin Heater Assist C1, C2, and Dosing Pump harness connectors.

Measure the resistance between the Cabin Heater Assist Control circuit and the

Ground circuit.

Is the resistance below 10K ohms?All

Ye s®Repair the Cabin Heater Assist Control circuit for a short to the

Ground circuit.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

No®Go To 7

327

CABIN HEATER

CABIN HEATER CONTROL CIRCUIT OPEN (ACTIVE) ÐContinued

Page 357 of 4284

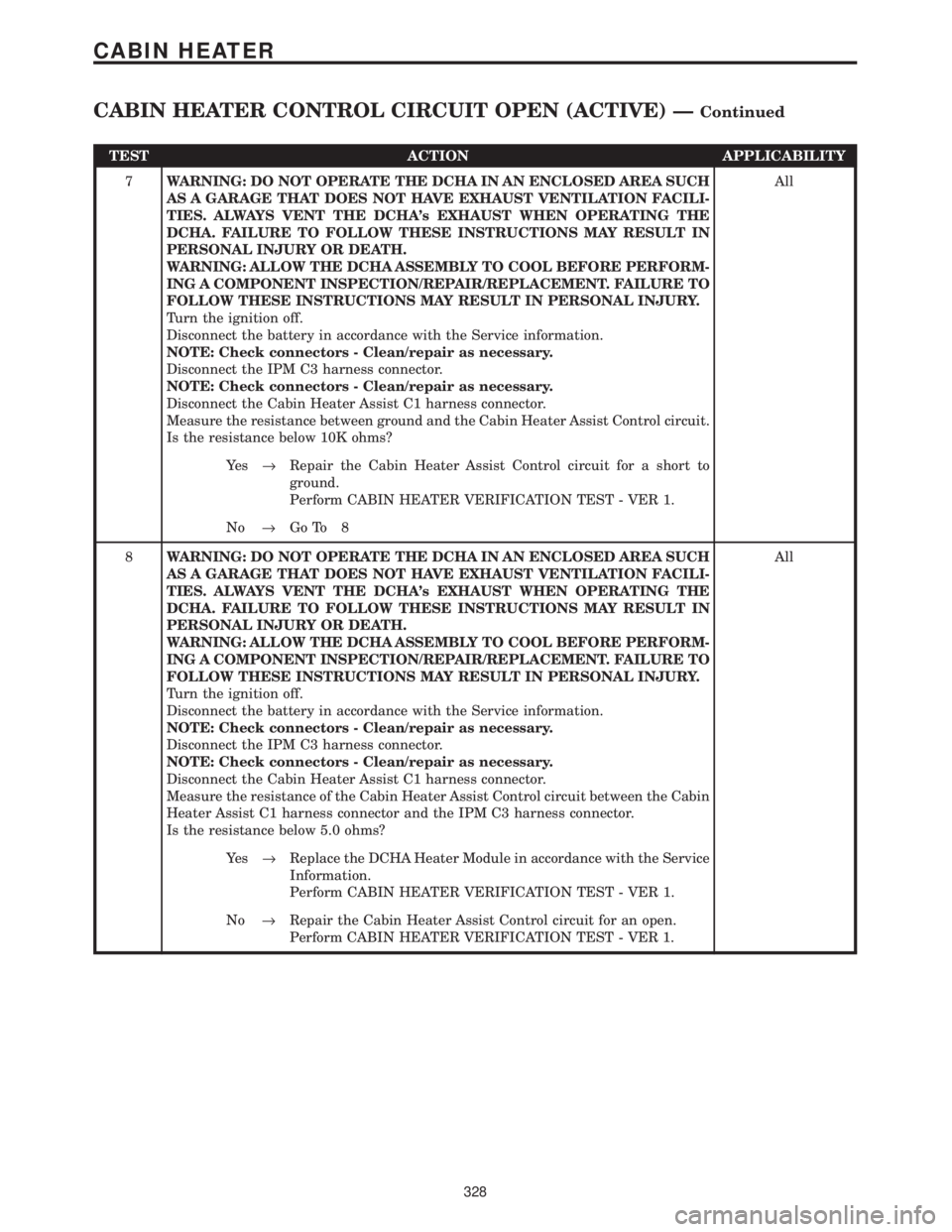

TEST ACTION APPLICABILITY

7WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

Disconnect the battery in accordance with the Service information.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the IPM C3 harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Cabin Heater Assist C1 harness connector.

Measure the resistance between ground and the Cabin Heater Assist Control circuit.

Is the resistance below 10K ohms?All

Ye s®Repair the Cabin Heater Assist Control circuit for a short to

ground.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

No®Go To 8

8WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

Disconnect the battery in accordance with the Service information.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the IPM C3 harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Cabin Heater Assist C1 harness connector.

Measure the resistance of the Cabin Heater Assist Control circuit between the Cabin

Heater Assist C1 harness connector and the IPM C3 harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Replace the DCHA Heater Module in accordance with the Service

Information.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

No®Repair the Cabin Heater Assist Control circuit for an open.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

328

CABIN HEATER

CABIN HEATER CONTROL CIRCUIT OPEN (ACTIVE) ÐContinued

Page 358 of 4284

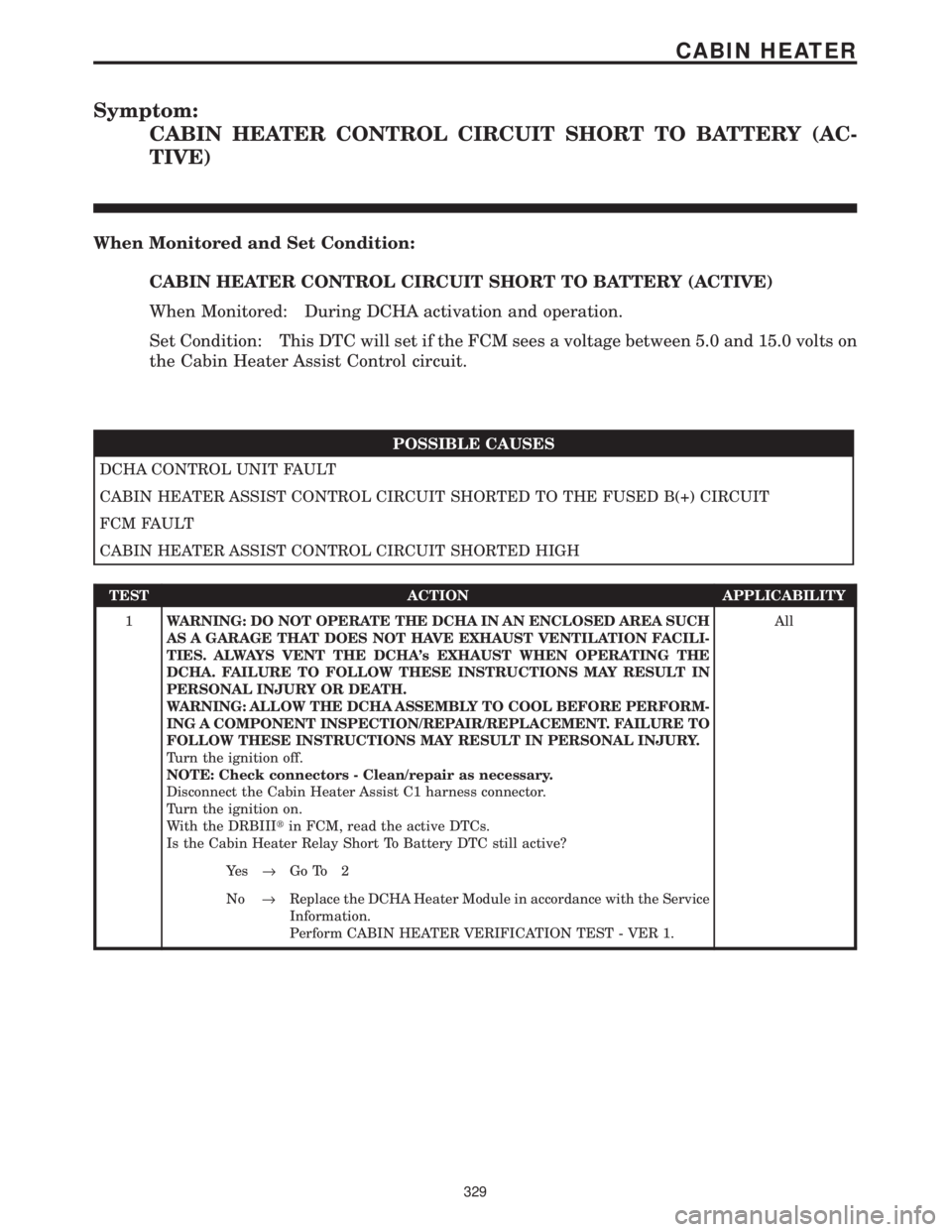

Symptom:

CABIN HEATER CONTROL CIRCUIT SHORT TO BATTERY (AC-

TIVE)

When Monitored and Set Condition:

CABIN HEATER CONTROL CIRCUIT SHORT TO BATTERY (ACTIVE)

When Monitored: During DCHA activation and operation.

Set Condition: This DTC will set if the FCM sees a voltage between 5.0 and 15.0 volts on

the Cabin Heater Assist Control circuit.

POSSIBLE CAUSES

DCHA CONTROL UNIT FAULT

CABIN HEATER ASSIST CONTROL CIRCUIT SHORTED TO THE FUSED B(+) CIRCUIT

FCM FAULT

CABIN HEATER ASSIST CONTROL CIRCUIT SHORTED HIGH

TEST ACTION APPLICABILITY

1WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Cabin Heater Assist C1 harness connector.

Turn the ignition on.

With the DRBIIItin FCM, read the active DTCs.

Is the Cabin Heater Relay Short To Battery DTC still active?All

Ye s®Go To 2

No®Replace the DCHA Heater Module in accordance with the Service

Information.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

329

CABIN HEATER

Page 359 of 4284

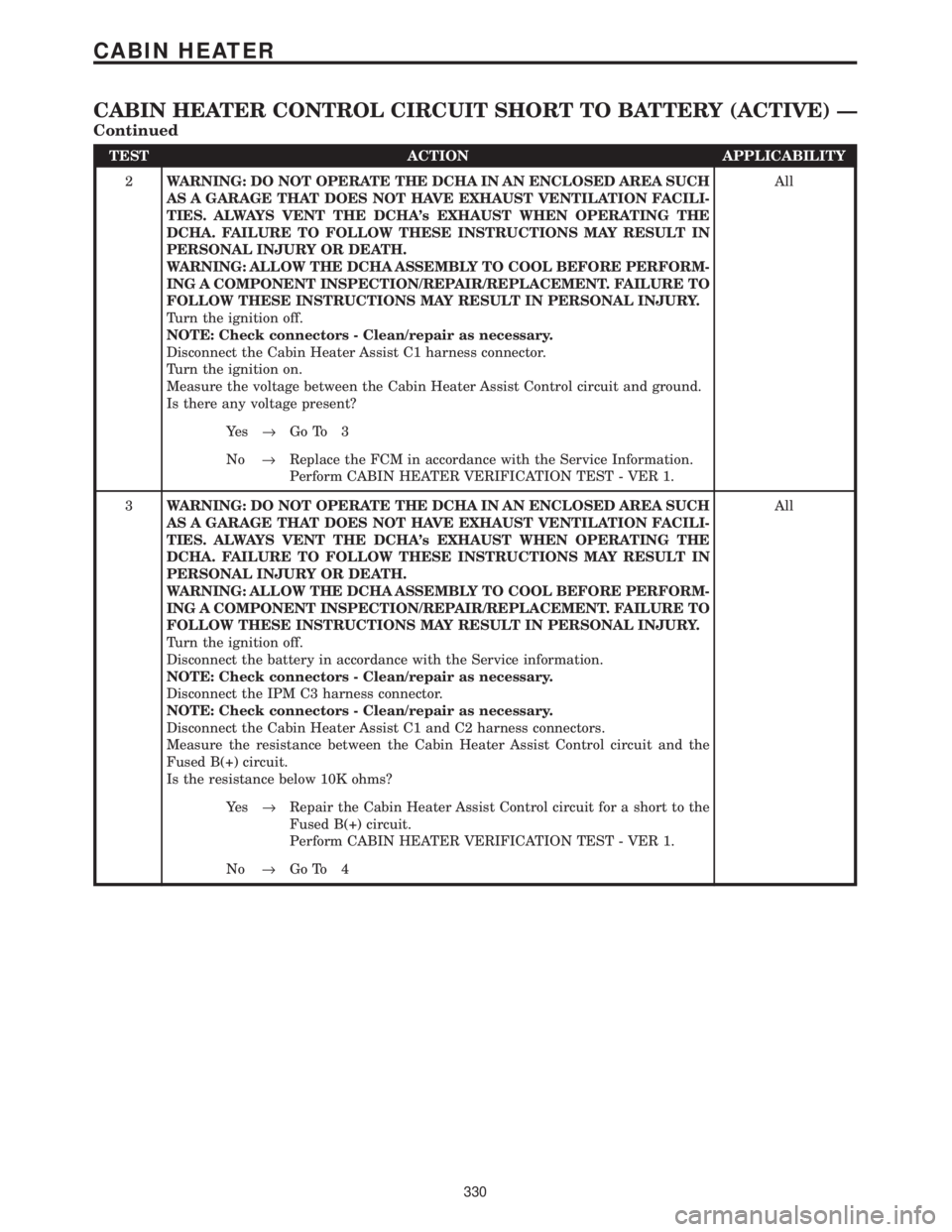

TEST ACTION APPLICABILITY

2WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Cabin Heater Assist C1 harness connector.

Turn the ignition on.

Measure the voltage between the Cabin Heater Assist Control circuit and ground.

Is there any voltage present?All

Ye s®Go To 3

No®Replace the FCM in accordance with the Service Information.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

3WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

Disconnect the battery in accordance with the Service information.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the IPM C3 harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Cabin Heater Assist C1 and C2 harness connectors.

Measure the resistance between the Cabin Heater Assist Control circuit and the

Fused B(+) circuit.

Is the resistance below 10K ohms?All

Ye s®Repair the Cabin Heater Assist Control circuit for a short to the

Fused B(+) circuit.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

No®Go To 4

330

CABIN HEATER

CABIN HEATER CONTROL CIRCUIT SHORT TO BATTERY (ACTIVE) Ð

Continued

Page 360 of 4284

TEST ACTION APPLICABILITY

4WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

Disconnect the battery in accordance with the Service Information.

Remove the FCM in accordance with the Service Information.

Reconnect the IPM C3 harness connector.

Reconnect the battery in accordance with the Service Information.

Turn the ignition on.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Cabin Heater Assist C1 harness connector.

Measure the voltage between the Cabin Heater Assist Control circuit and ground.

Is there any voltage present?All

Ye s®Repair the Cabin Heater Assist Control circuit for a short to

voltage.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

No®Replace the FCM in accordance with the Service Information.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

331

CABIN HEATER

CABIN HEATER CONTROL CIRCUIT SHORT TO BATTERY (ACTIVE) Ð

Continued

Page 1020 of 4284

CABIN HEATER VERIFICATION TEST - VER 1 APPLICABILITY

1. WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH AS A

GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE DCHA's EXHAUST WHEN OPERATING THE DCHA. FAILURE TO FOL-

LOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY OR DEATH.

2. WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORMING A

COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

3. NOTE: The DCHA Control will store up to three DTCs in its memory.

4. NOTE: If the DCHA Control detects a new fault in the DCHA system, one that is not

already stored in its memory, the DCHA Control will clear the oldest of the three

stored DTCs, and it will store the new fault's DTC.

5. NOTE: If the DCHA control detects a reoccurrence of a stored fault, the DCHA

control will overwrite that fault's DTC with the most recent occurrence.

6. Verify that the vehicle's battery is fully charged.

7. Verify that there is more than 1/8 of a tank of fuel in the vehicle's fuel tank. Add fuel, if

necessary.

8. Verify that all DCHA coolant hoses and fuel lines are securely fastened to their respective

components.

9. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

10. If a heater installation/cooling system service was performed, purge the coolant circuit of

air in accordance with the Service Information.

11. Turn the ignition on.

12. Set the Blend Control to the max cool position.

13. Ensure that all accessories are turned off.

14. If a fuel system service requiring fuel to drain out of the DCHA fuel line was performed,

prime the DCHA Dosing Pump in accordance with the Service Information.

15. With the DRBIIIt, record and erase all DTCs from the Diesel Cabin Heater Assist (DCHA)

Control and the Front Control Module (FCM). Cycle the ignition off then on.

16. Start the engine.

17. Allow the engine to idle.

18. Turn the A/C - Heater Control Module's Power switch on.

19. Turn the Blower switch to the high speed position.

20. CAUTION: Do not activate the Diesel Cabin Heater Test with the engine off.

Failure to follow these instructions may result in internal damage to the DCHA

Heater Module.

21. NOTE: Do not disconnect the vehicle's battery or the DCHA's main power supply

while the DCHA is in operation or in run-down mode. Failure to follow these

instructions may result in excess emissions from the DCHA during heater operation.

22. NOTE: While performing the Diesel Cabin Heater Test, inspect the coolant and

fuel connections for leakage.

23. With the DRBIIItin HVAC, Systems Tests, select Diesel Cabin Heater Test and press #1.

24. Set the Blend Control to the max heat position. Allow the Diesel Cabin Heater Test to run

for five minutes. Upon completion of the test, proceed as follows:

25. Set the Blend Control to the max cool position.

26. Press #2 on the DRBIIItkeyboard.

27. Turn the Blower switch off.

28. Turn the A/C - Heater Control Module's Power switch off.

29. Turn the ignition off, wait 5 seconds, then turn the ignition on.

30. Using the DRBIIIt, read the Cabin Heater and Active FCM DTCs.

Are any DTC's present or is the original condition still present?All

Ye s®Repair is not complete, refer to the appropriate symptom.

No®Repair is complete.

991

VERIFICATION TESTS

Verification Tests ÐContinued

Page 1695 of 4284

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes. This back-and-forth pro-

cess will continue until the required slip difference is

obtained. At the end of EBD braking (brakes

released) the fluid in the LPA drains back to the

master cylinder by switching on the outlet valve and

draining through the inlet valve check valve. At the

same time the inlet valve is switched on in case of

another brake application.

The EBD will remain functional during many ABS

fault modes. If both the red BRAKE, and amber ABS

warning indicators are illuminated, the EBD may not

be functioning.

OPERATION - TRACTION CONTROL SYSTEM

The traction control module monitors wheel speed.

During acceleration, if the module detects front

(drive) wheel slip and the brakes are not applied, the

module enters traction control mode. Traction control

operation proceeds in the following order:

(1) Close the normally open isolation valves.

(2) Start the pump/motor and supply volume and

pressure to the front (drive) hydraulic circuit. (The

pump/motor runs continuously during traction con-

trol operation.)

(3) Open and close the build and decay valves to

maintain minimum wheel slip and maximum trac-

tion.

The cycling of the build and decay valves during

traction control is similar to that during antilock

braking, except the valves work to control wheel spin

by applying the brakes, whereas the ABS function is

to control wheel skid by releasing the brakes.

If the brakes are applied at anytime during a trac-

tion control cycle, the brake lamp switch triggers the

controller to switch off traction control.

HYDRAULIC SHUTTLE VALVES

Two pressure relief hydraulic shuttle valves allow

pressure and volume to return to the master cylinder

reservoir when not consumed by the build and decay

valves. These valves are necessary because the

pump/motor supplies more volume than the system

requires.

TRACTION CONTROL LAMP

The traction control system is enabled at each igni-

tion cycle. It may be turned off by depressing the

Traction Control Off switch button when the ignition

is in the ON position. The traction control function

lamp (TRAC OFF) illuminates immediately upon

depressing the button.

The traction control function lamp illuminates dur-

ing a traction control cycle, displaying TRAC.If the CAB calculates that the brake temperatures

are high, the traction control system becomes inoper-

ative until a time-out period has elapsed. During this

ªthermo-protection mode,º the traction control func-

tion lamp illuminates TRAC OFF; note that no trou-

ble code is registered.

CAUTION

The ABS uses an electronic control module, the

CAB. This module is designed to withstand normal

current draws associated with vehicle operation.

Care must be taken to avoid overloading the CAB

circuits.

CAUTION: In testing for open or short circuits, do

not ground or apply voltage to any of the circuits

unless instructed to do so for a diagnostic proce-

dure.

CAUTION: These circuits should only be tested

using a high impedance multi-meter or the DRBIIIT

scan tool as described in this section. Power

should never be removed or applied to any control

module with the ignition in the ON position. Before

removing or connecting battery cables, fuses, or

connectors, always turn the ignition to the OFF

position.

CAUTION: The CAB 24-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

CAUTION: Use only factory wiring harnesses. Do

not cut or splice wiring to the brake circuits. The

addition of aftermarket electrical equipment (car

phone, radar detector, citizen band radio, trailer

lighting, trailer brakes, etc.) on a vehicle equipped

with antilock brakes may affect the function of the

antilock brake system.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS, do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.

CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.

RSBRAKES - ABS5-69

BRAKES - ABS (Continued)

Page 1717 of 4284

INSTALLATION - RHD

(1) Install the ICU on the mounting bracket (Fig.

5). Install the 3 bolts (Fig. 5) attaching the ICU to

the mounting bracket. Tighten the 3 mounting bolts

to a torque of 11 N´m (97 in. lbs.).

CAUTION: The ICU mounting bracket to front sus-

pension cradle mounting bolts have a unique corro-

sion protection coating and a special aluminum

washer. For this reason, only the original, or origi-

nal equipment Mopar replacement bolts can be

used to mount the ICU bracket to the front suspen-

sion crossmember.

(2) Install the ICU and its mounting bracket as an

assembly on the front suspension crossmember.

Install the 3 bolts attaching the ICU bracket to the

crossmember (Fig. 4). Tighten the 3 mounting bolts

to a torque of 28 N´m (250 in. lbs.).

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, and the brake

tubes between the HCU and the proportioning

valve, the brake tubes must be held in proper ori-

entation when tightened and torqued. These tubes

must not contact each other or other vehicle com-

ponents when installed. Also, after the brake tubes

are installed on the HCU, ensure all spacer clips are

reinstalled on the brake tubes.

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation. Refer to (Fig. 3) for the correct chassis brake

tube locations.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the ICU

mounting bracket.

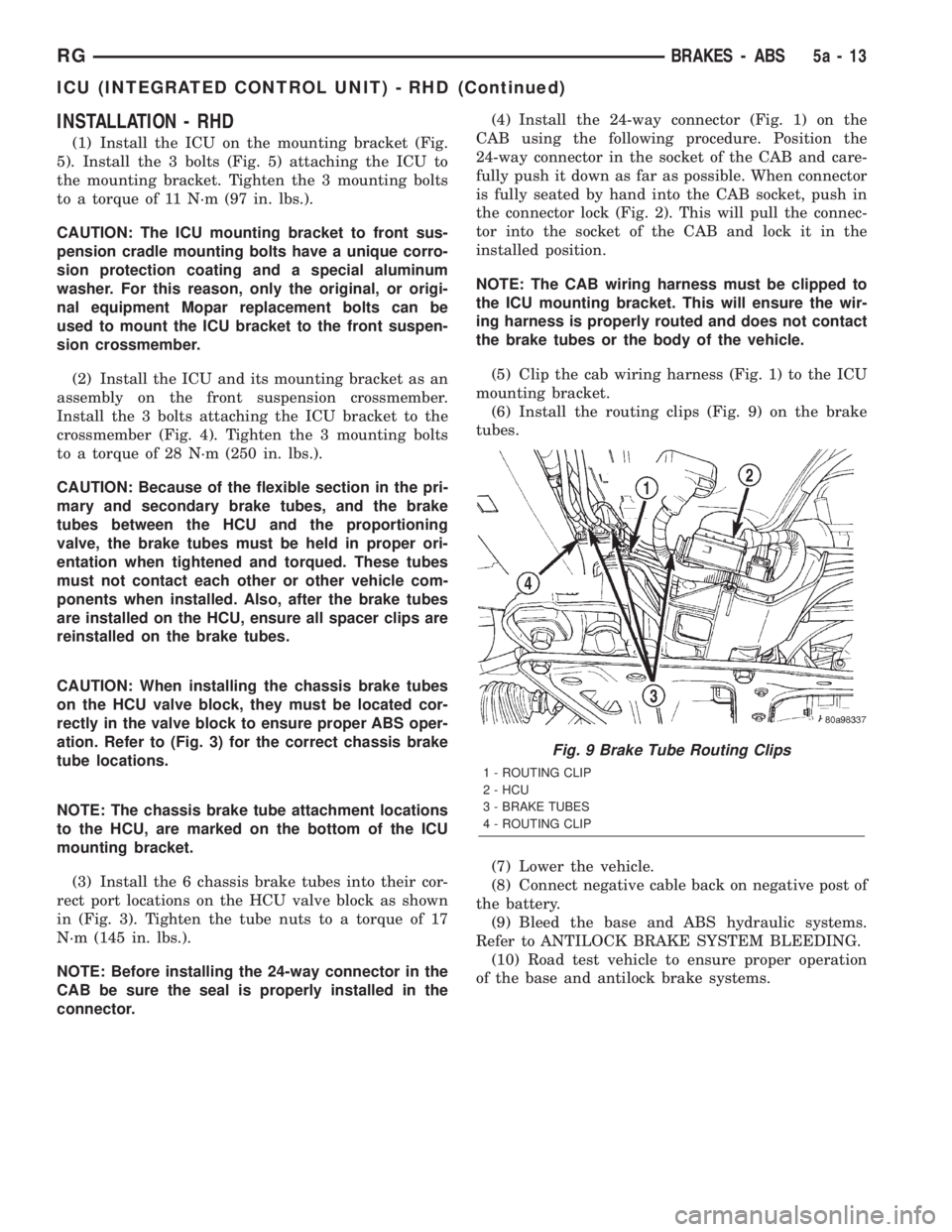

(3) Install the 6 chassis brake tubes into their cor-

rect port locations on the HCU valve block as shown

in (Fig. 3). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: Before installing the 24-way connector in the

CAB be sure the seal is properly installed in the

connector.(4) Install the 24-way connector (Fig. 1) on the

CAB using the following procedure. Position the

24-way connector in the socket of the CAB and care-

fully push it down as far as possible. When connector

is fully seated by hand into the CAB socket, push in

the connector lock (Fig. 2). This will pull the connec-

tor into the socket of the CAB and lock it in the

installed position.

NOTE: The CAB wiring harness must be clipped to

the ICU mounting bracket. This will ensure the wir-

ing harness is properly routed and does not contact

the brake tubes or the body of the vehicle.

(5) Clip the cab wiring harness (Fig. 1) to the ICU

mounting bracket.

(6) Install the routing clips (Fig. 9) on the brake

tubes.

(7) Lower the vehicle.

(8) Connect negative cable back on negative post of

the battery.

(9) Bleed the base and ABS hydraulic systems.

Refer to ANTILOCK BRAKE SYSTEM BLEEDING.

(10) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

Fig. 9 Brake Tube Routing Clips

1 - ROUTING CLIP

2 - HCU

3 - BRAKE TUBES

4 - ROUTING CLIP

RGBRAKES - ABS5a-13

ICU (INTEGRATED CONTROL UNIT) - RHD (Continued)

Page 1847 of 4284

SKIM is properly installed on the steering column,

the antenna ring fits snugly around the circumfer-

ence of the ignition lock cylinder housing. If this ring

is not mounted properly, communication problems

may arise in the form of transponder-related faults.

For added system security, each SKIM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKIM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKIM for service. The SKIM also stores in its mem-

ory the Vehicle Identification Number (VIN), which it

learns through a bus message from the assembly

plant tester. The SKIS scrambles the information

that is communicated between its components in

order to reduce the possibility of unauthorized SKIM

access and/or disabling.

OPERATION

When the ignition switch is moved to the RUN

position, the SKIM transmits an RF signal to the

transponder in the ignition key. The SKIM then

waits for a response RF signal from the transponder

in the key. If the response received identifies the key

as valid, the SKIM sends a9valid key9message to

the PCM over the PCI bus. If the response received

identifies the key as invalid or no response is

received from the transponder in the ignition key, the

SKIM sends an9invalid key9message to the PCM.

The PCM will enable or disable engine operation

based upon the status of the SKIM messages. It is

important to note that the default condition in the

PCM is9invalid key.9Therefore, if no response is

received by the PCM, the engine will be immobilized

after two (2) seconds of running.

The SKIM also sends indicator light status mes-

sages to the BCM to operate the light. This is the

method used to turn the light ON solid or to flash it

after the indicator light test is complete to signify a

fault in the SKIS. If the light comes ON and stays

ON solid after the indicator light test, this signifies

that the SKIM has detected a system malfunction

and/or that the SKIS has become inoperative. If theSKIM detects an invalid keyORa key-related fault

exists, the indicator light will flash following the

indicator light test. The SKIM may also request an

audible chime if the customer key programming fea-

ture is available and the procedure is being utilized.

Refer to Electrical, Vehicle Theft Security, Transpon-

der Key, Standard Procedure - Transponder Program-

ming.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Lower Instrument Panel Cover. Refer

to Body, Instrument Panel, Lower Instrument Panel

Cover, Removal.

(3) Remove the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Removal.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the one screws securing the SKIM to

the steering column.

(6) Rotate the SKIM upwards and then to the side

away from the steering column to slide the SKIM

antenna ring from around the ignition switch lock

cylinder housing.

(7) Remove the SKIM from the vehicle.

INSTALLATION

(1) Slip the SKIM antenna ring around the igni-

tion switch lock cylinder housing. Rotate the SKIM

downwards and then towards the steering column.

(2) Install the one screws securing the SKIM to

the steering column.

(3) Engage the steering column wire harness from

the Sentry Key Immobilizer Module (SKIM).

(4) Install the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Installation.

(5) Install the Lower Instrument Panel Cover.

Refer to Body, Instrument Panel, Lower Instrument

Panel Cover, Installation.

(6) Connect the battery negative cable.

SLIDING DOOR CONTROL

MODULE

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a sliding door control module. The sliding door con-

trol module is located behind the sliding door trim

panel in the center of the door, just above the sliding

door motor. This module controls the operation of the

door through the Programmable Communication

Interface (PCI) J1850 data bus circuit and the Body

RSELECTRONIC CONTROL MODULES8E-23

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 1852 of 4284

STANDARD PROCEDURE - TCC BREAK-IN

VIEW/RESTART PROCEDURE

The Transmission Control Module (TCM) employs

a strategy which modifies torque converter clutch

(TCC) operation. This strategy conditions the torque

converter clutch disc for optimum converter clutch

engagement and feel throughout the life of the trans-

axle. The cycle inhibits FEMCC until six hours of

PEMCC operation have taken place, or the vehicle

has been driven 6,035 km (3750 miles). The cycle

automatically terminates when either the time or

mileage has been achieved, however, the mileage

may vary slightly from vehicle to vehicle.

The TCC break-in cycle must be restarted using

the DRB Scan Tool, and upon:

²Replacement of TCM on vehicle with less than

6,035 km (3750 miles) or less than 6 hours of

PEMCC operation

²Replacement of torque converter assembly at

any vehicle mileage

NOTE: Failure to restart the TCC Break-In Cycle

upon TCM replacement in vehicles with less than

six hours of PEMCC or less than 6,035 km (3750

miles), or upon torque converter replacement at any

mileage, may result in vehicle shudder during cer-

tain operating conditions.

Procedure

The DRB Scan Tool is required to view and/or

restart the TCC Break-In cycle.

(1) Connect the DRB Scan Tool to the vehicle diag-

nostic connector.

(2) Navigate to ªTCC Break-Inº via Transmission/

Transmission Control Module/Miscellaneous.

(3) View or Start TCC Break-In as prompted by

DRB menu.

REMOVAL

NOTE: If transmission control module is being

replaced with a new or replacement unit, the Pinion

Factor and Quick Learn procedures must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE) (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE) If vehicle has less than 6,035 km

(3750 miles), the Torque Converter Clutch (TCC)

Break-In Strategy reset procedure must also be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Remove left front tire/wheel assembly.

(4) Pull back splash shield to gain access to TCM

location.

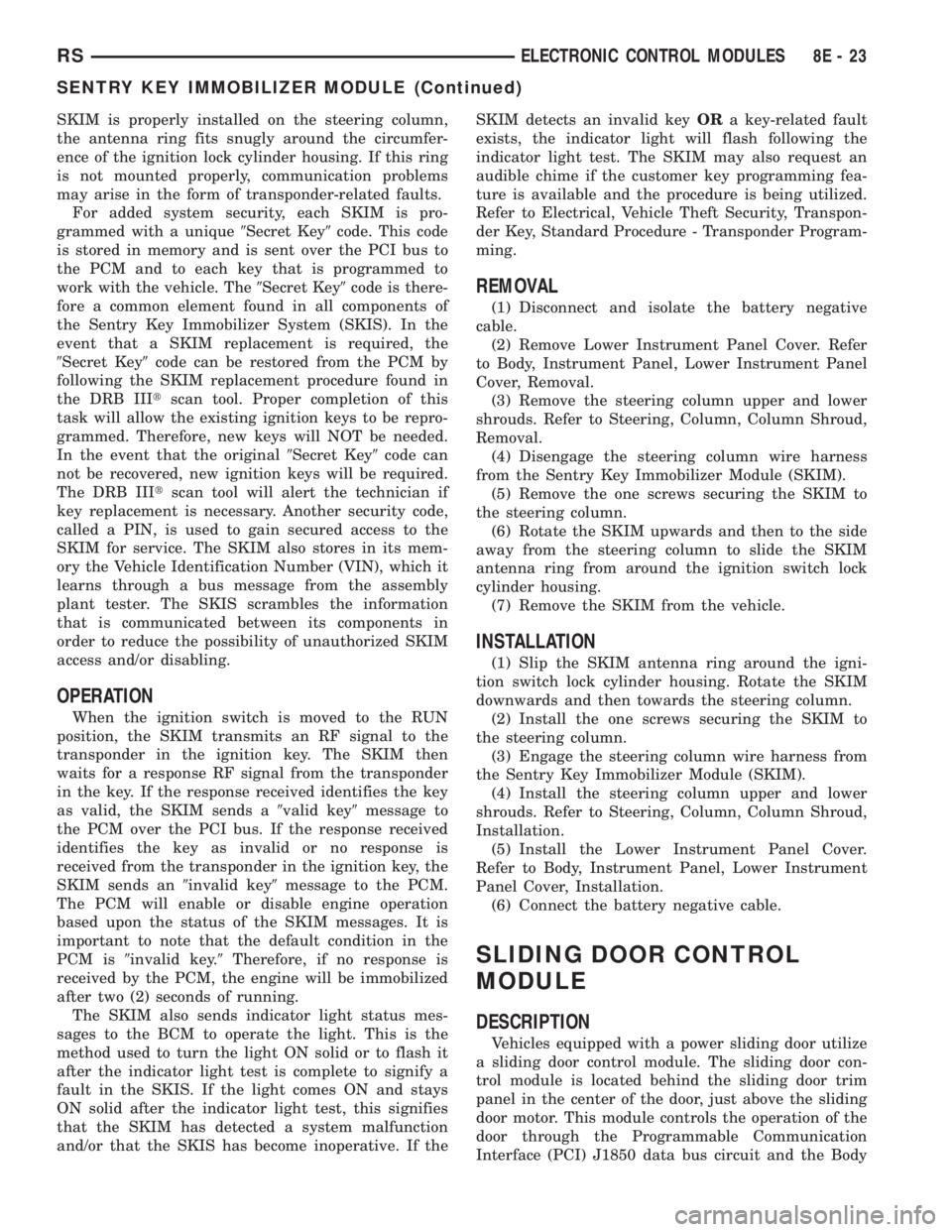

(5) Disconnect TCM 60-way connector (Fig. 15).

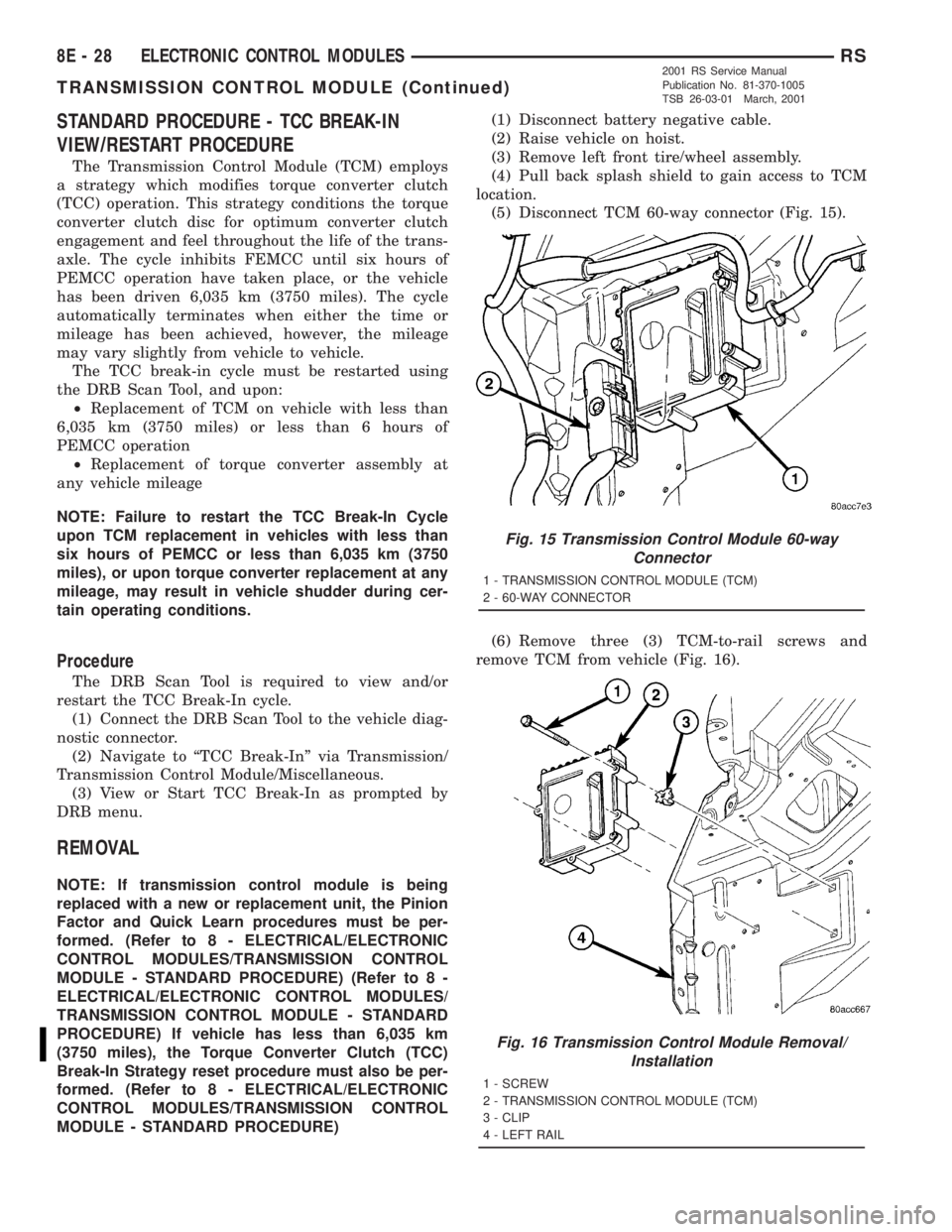

(6) Remove three (3) TCM-to-rail screws and

remove TCM from vehicle (Fig. 16).

Fig. 15 Transmission Control Module 60-way

Connector

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60-WAY CONNECTOR

Fig. 16 Transmission Control Module Removal/

Installation

1 - SCREW

2 - TRANSMISSION CONTROL MODULE (TCM)

3 - CLIP

4 - LEFT RAIL

8E - 28 ELECTRONIC CONTROL MODULESRS

TRANSMISSION CONTROL MODULE (Continued)

2001 RS Service Manual

Publication No. 81-370-1005

TSB 26-03-01 March, 2001