torque CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2766 of 4284

DESCRIPTION TORQUE*

STRIP-OUT REPAIR SCREWS ONLY

MAP Sensor Repair

Screw4 N´m (35 in. lbs.)

Power Steering Reservoir

Repair Screw9 N´m (80 in. lbs.)

EGR Tube Attaching

Repair Screw9 N´m (80 in. lbs.)

Throttle Cable Bracket

Repair Screw9 N´m (80 in. lbs.)

*Install Slowly Using Hand Tools Only

STANDARD PROCEDURE - INTAKE MANIFOLD

VACUUM PORT REPAIR

The composite intake manifold vacuum ports can

be repaired. Although, if the manifold plenum cham-ber is damaged or cracked, the manifold must be

replaced.

To repair a broken or damaged vacuum nipple

(port) on the composite intake manifold, perform the

following procedure:

PARTS REQUIRED TOOLS REQUIRED

Brass Nipple ± 1/49O.D.

x 1/89pipe thread

(LDP/Speed Control Port)Pipe Tap ± 1/49-18NPT

& 1/89-18NPT

Brass Nipple ± 1/29O.D.

x 1/49pipe thread (Brake

Booster Port)Drill Bit ± 7/169& 11/329

File/Sand Paper

NOTE: While performing this procedure, avoid get-

ting the manifold material residue into the plenum

chamber.

(1) File or sand the remaining port back until a

flat surface is obtained (plane normal to nipple (port)

axis).

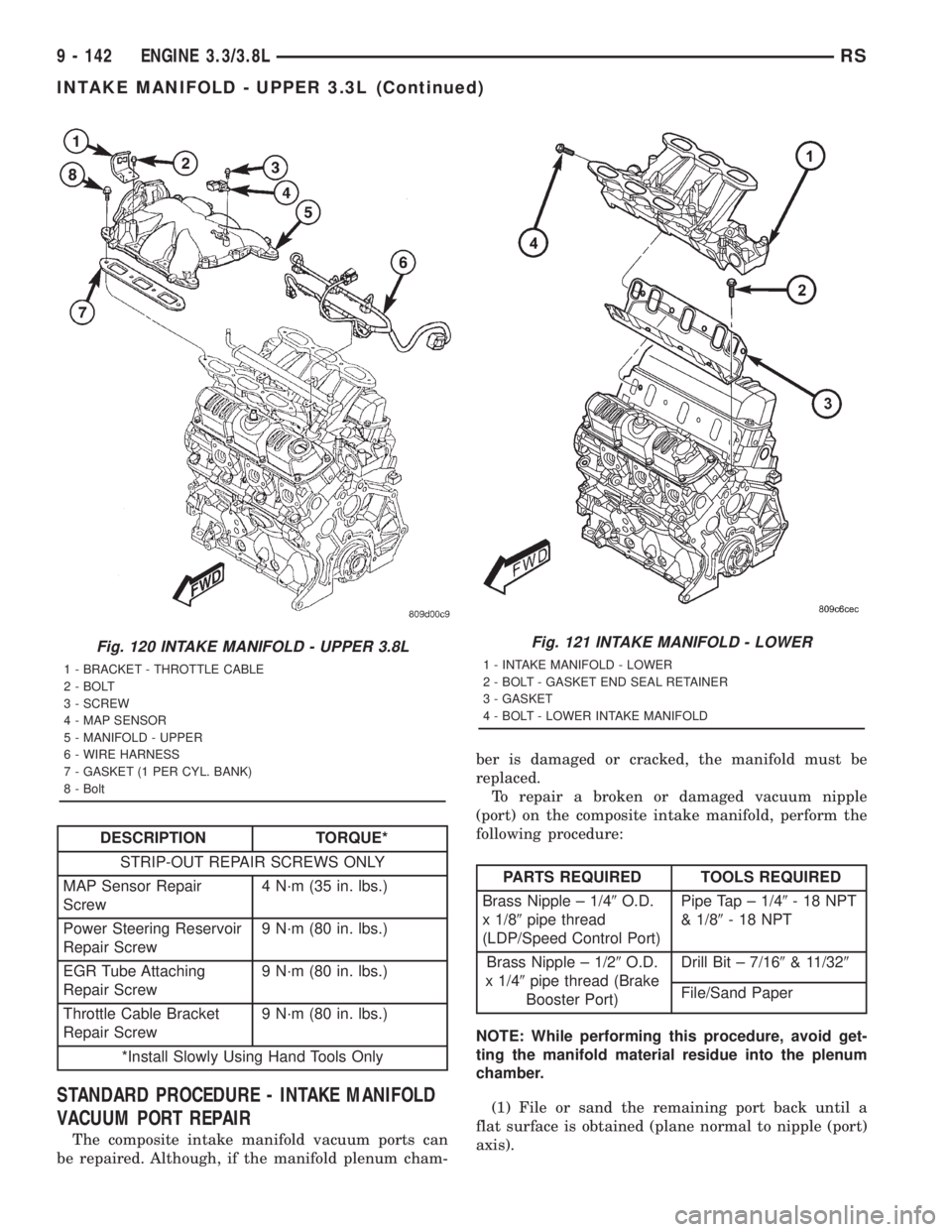

Fig. 120 INTAKE MANIFOLD - UPPER 3.8L

1 - BRACKET - THROTTLE CABLE

2 - BOLT

3 - SCREW

4 - MAP SENSOR

5 - MANIFOLD - UPPER

6 - WIRE HARNESS

7 - GASKET (1 PER CYL. BANK)

8 - Bolt

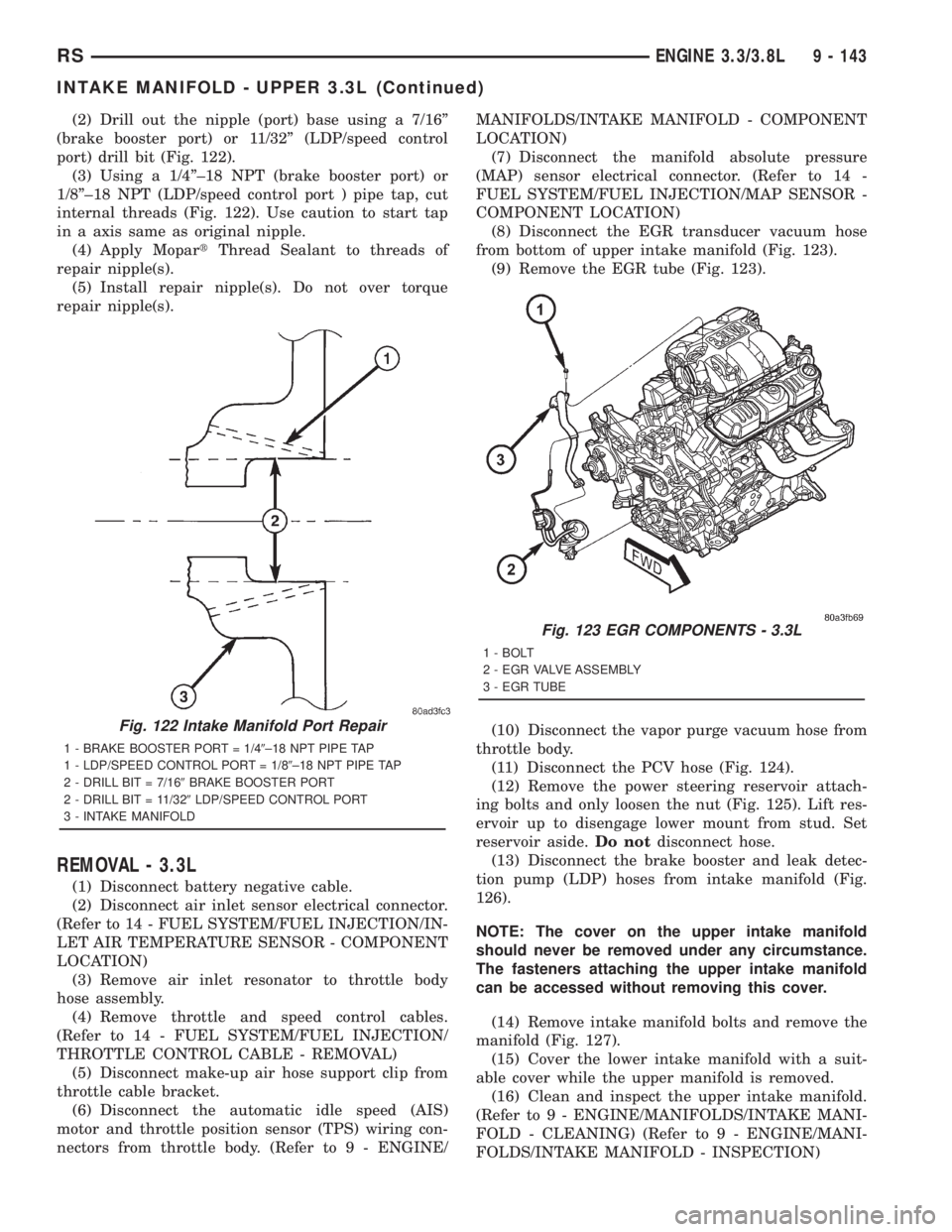

Fig. 121 INTAKE MANIFOLD - LOWER

1 - INTAKE MANIFOLD - LOWER

2 - BOLT - GASKET END SEAL RETAINER

3 - GASKET

4 - BOLT - LOWER INTAKE MANIFOLD

9 - 142 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - UPPER 3.3L (Continued)

Page 2767 of 4284

(2) Drill out the nipple (port) base using a 7/16º

(brake booster port) or 11/32º (LDP/speed control

port) drill bit (Fig. 122).

(3) Using a 1/4º±18 NPT (brake booster port) or

1/8º±18 NPT (LDP/speed control port ) pipe tap, cut

internal threads (Fig. 122). Use caution to start tap

in a axis same as original nipple.

(4) Apply MopartThread Sealant to threads of

repair nipple(s).

(5) Install repair nipple(s). Do not over torque

repair nipple(s).

REMOVAL - 3.3L

(1) Disconnect battery negative cable.

(2) Disconnect air inlet sensor electrical connector.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/IN-

LET AIR TEMPERATURE SENSOR - COMPONENT

LOCATION)

(3) Remove air inlet resonator to throttle body

hose assembly.

(4) Remove throttle and speed control cables.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL)

(5) Disconnect make-up air hose support clip from

throttle cable bracket.

(6) Disconnect the automatic idle speed (AIS)

motor and throttle position sensor (TPS) wiring con-

nectors from throttle body. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - COMPONENT

LOCATION)

(7) Disconnect the manifold absolute pressure

(MAP) sensor electrical connector. (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/MAP SENSOR -

COMPONENT LOCATION)

(8) Disconnect the EGR transducer vacuum hose

from bottom of upper intake manifold (Fig. 123).

(9) Remove the EGR tube (Fig. 123).

(10) Disconnect the vapor purge vacuum hose from

throttle body.

(11) Disconnect the PCV hose (Fig. 124).

(12) Remove the power steering reservoir attach-

ing bolts and only loosen the nut (Fig. 125). Lift res-

ervoir up to disengage lower mount from stud. Set

reservoir aside.Do notdisconnect hose.

(13) Disconnect the brake booster and leak detec-

tion pump (LDP) hoses from intake manifold (Fig.

126).

NOTE: The cover on the upper intake manifold

should never be removed under any circumstance.

The fasteners attaching the upper intake manifold

can be accessed without removing this cover.

(14) Remove intake manifold bolts and remove the

manifold (Fig. 127).

(15) Cover the lower intake manifold with a suit-

able cover while the upper manifold is removed.

(16) Clean and inspect the upper intake manifold.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - CLEANING) (Refer to 9 - ENGINE/MANI-

FOLDS/INTAKE MANIFOLD - INSPECTION)

Fig. 122 Intake Manifold Port Repair

1 - BRAKE BOOSTER PORT = 1/49±18 NPT PIPE TAP

1 - LDP/SPEED CONTROL PORT = 1/89±18 NPT PIPE TAP

2 - DRILL BIT = 7/169BRAKE BOOSTER PORT

2 - DRILL BIT = 11/329LDP/SPEED CONTROL PORT

3 - INTAKE MANIFOLD

Fig. 123 EGR COMPONENTS - 3.3L

1 - BOLT

2 - EGR VALVE ASSEMBLY

3 - EGR TUBE

RSENGINE 3.3/3.8L9 - 143

INTAKE MANIFOLD - UPPER 3.3L (Continued)

Page 2769 of 4284

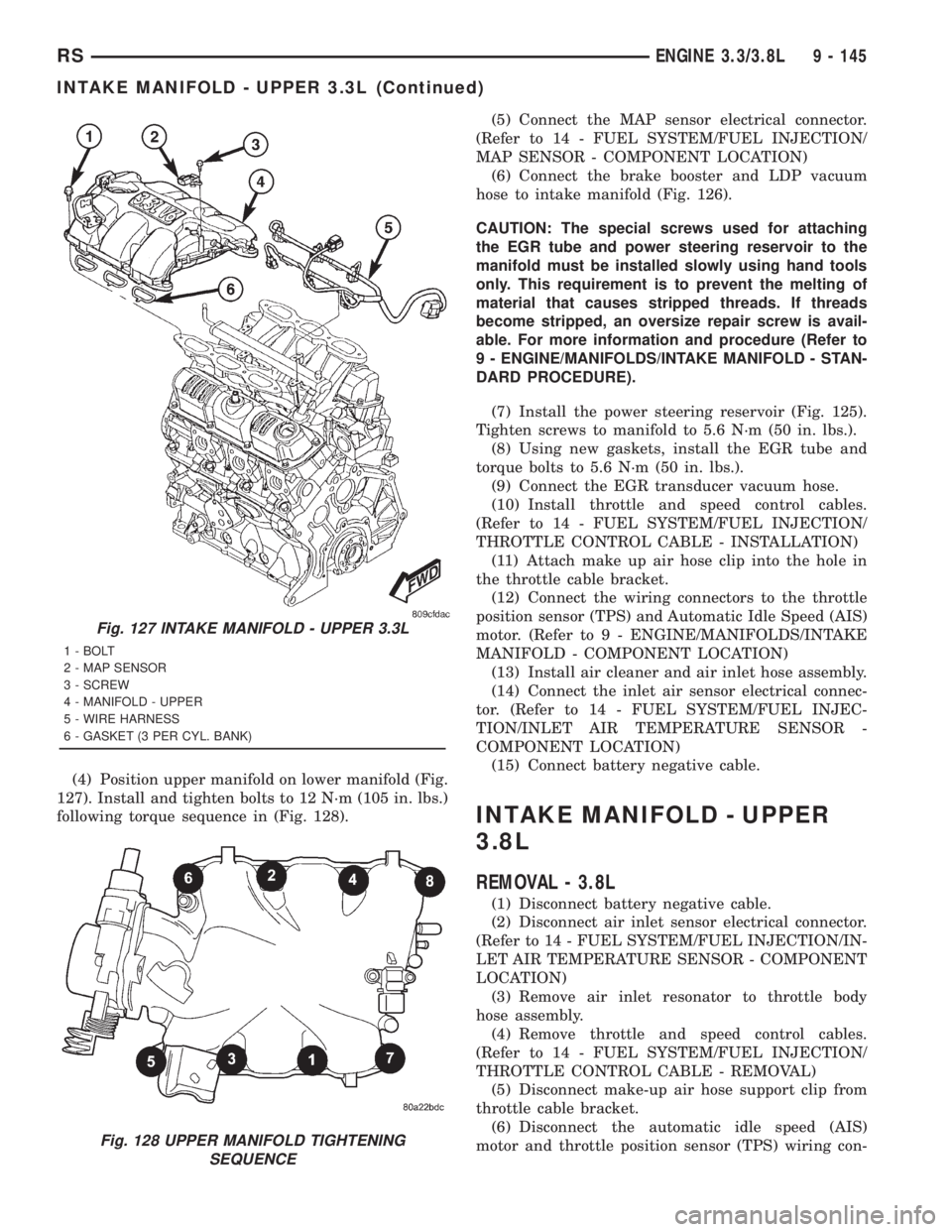

(4) Position upper manifold on lower manifold (Fig.

127). Install and tighten bolts to 12 N´m (105 in. lbs.)

following torque sequence in (Fig. 128).(5) Connect the MAP sensor electrical connector.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

MAP SENSOR - COMPONENT LOCATION)

(6) Connect the brake booster and LDP vacuum

hose to intake manifold (Fig. 126).

CAUTION: The special screws used for attaching

the EGR tube and power steering reservoir to the

manifold must be installed slowly using hand tools

only. This requirement is to prevent the melting of

material that causes stripped threads. If threads

become stripped, an oversize repair screw is avail-

able. For more information and procedure (Refer to

9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - STAN-

DARD PROCEDURE).

(7) Install the power steering reservoir (Fig. 125).

Tighten screws to manifold to 5.6 N´m (50 in. lbs.).

(8) Using new gaskets, install the EGR tube and

torque bolts to 5.6 N´m (50 in. lbs.).

(9) Connect the EGR transducer vacuum hose.

(10) Install throttle and speed control cables.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - INSTALLATION)

(11) Attach make up air hose clip into the hole in

the throttle cable bracket.

(12) Connect the wiring connectors to the throttle

position sensor (TPS) and Automatic Idle Speed (AIS)

motor. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - COMPONENT LOCATION)

(13) Install air cleaner and air inlet hose assembly.

(14) Connect the inlet air sensor electrical connec-

tor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/INLET AIR TEMPERATURE SENSOR -

COMPONENT LOCATION)

(15) Connect battery negative cable.

INTAKE MANIFOLD - UPPER

3.8L

REMOVAL - 3.8L

(1) Disconnect battery negative cable.

(2) Disconnect air inlet sensor electrical connector.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/IN-

LET AIR TEMPERATURE SENSOR - COMPONENT

LOCATION)

(3) Remove air inlet resonator to throttle body

hose assembly.

(4) Remove throttle and speed control cables.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL)

(5) Disconnect make-up air hose support clip from

throttle cable bracket.

(6) Disconnect the automatic idle speed (AIS)

motor and throttle position sensor (TPS) wiring con-

Fig. 127 INTAKE MANIFOLD - UPPER 3.3L

1 - BOLT

2 - MAP SENSOR

3 - SCREW

4 - MANIFOLD - UPPER

5 - WIRE HARNESS

6 - GASKET (3 PER CYL. BANK)

Fig. 128 UPPER MANIFOLD TIGHTENING

SEQUENCE

RSENGINE 3.3/3.8L9 - 145

INTAKE MANIFOLD - UPPER 3.3L (Continued)

Page 2771 of 4284

INSPECTION

Check manifold for:

²Damage and cracks.

²Mounting surface distortion by using a straight-

edge and thickness gauge.

INSTALLATION - 3.8L

(1) If the following components were removed from

manifold, install and tighten to specifications:

²MAP sensor - 3.4 N´m (30 in. lbs.)

²Throttle cable bracket - 12 N´m (105 in. lbs.)

(2) Remove covering on lower intake manifold and

clean surfaces.

(3) Position the new intake manifold gasket on

lower manifold.

(4) Position upper manifold on lower manifold (Fig.

133). Install and tighten bolts to 12 N´m (105 in. lbs.)

following torque sequence in (Fig. 134).

(5) Connect the MAP sensor electrical connector.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

MAP SENSOR - COMPONENT LOCATION)

(6) Connect the brake booster and LDP vacuum

hose to intake manifold (Fig. 132).

(7) Connect the PCV hose (Fig. 130).

(8) Install the power steering reservoir (Fig. 131)

and torque fasteners to 12 N´m (105 in. lbs.).

(9) Connect the EGR transducer vacuum hose.

(10) Using new gaskets, install the EGR tube (Fig.

129) and torque bolts to 12 N´m (105 in. lbs.).

Fig. 132 BRAKE BOOSTER & LDP VACUUM HOSES

1 - LDP & SPEED CONTROL VACUUM HOSE

2 - BRAKE BOOSTER VACUUM HOSE

3 - MAP SENSOR

Fig. 133 INTAKE MANIFOLD - UPPER 3.8L

1 - BRACKET - THROTTLE CABLE

2 - BOLT

3 - SCREW

4 - MAP SENSOR

5 - MANIFOLD - UPPER

6 - WIRE HARNESS

7 - GASKET (1 PER CYL. BANK)

8 - BOLT

Fig. 134 UPPER MANIFOLD TIGHTENING

SEQUENCE

RSENGINE 3.3/3.8L9 - 147

INTAKE MANIFOLD - UPPER 3.8L (Continued)

Page 2773 of 4284

INSTALLATION

(1) Place a bead (approximately 1/4 in. diameter)

of MopartEngine RTV GEN II onto each of thefour

manifold to cylinder head gasket corners (Fig. 138).

(2) Carefully install the new intake manifold gas-

ket (Fig. 139). Tighten end seal retainer screws to 12

N´m (105 in. lbs.).

(3) Install lower intake manifold (Fig. 139). Install

the bolts and torque to 1 N´m (10 in. lbs.). Then

torque bolts to 22 N´m (200 in. lbs.) in sequence

shown in (Fig. 140). Then torque again to 22 N´m

(200 in. lbs.). After intake manifold is in place,

inspect to make sure seals are in place.

(4) Install the fuel injectors and rail assembly.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL RAIL - INSTALLATION)

(5) Connect fuel injector electrical harness.

(6) Connect the engine coolant temperature sensor

(Fig. 136).

(7) Connect the heater supply (Fig. 136) and radi-

ator upper hoses to manifold.

(8) Connect the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(9) Install the upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

(10) Connect negative battery cable.(11) Fill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

Fig. 136 ECT SENSOR & HEATER SUPPLY

1 - ENGINE COOLANT TEMPERATURE SENSOR

2 - CONNECTOR - ENGINE COOLANT SENSOR

3 - FITTING - HEATER SUPPLY

Fig. 137 INTAKE MANIFOLD - LOWER

1 - INTAKE MANIFOLD - LOWER

2 - BOLT - GASKET END SEAL RETAINER

3 - GASKET

4 - BOLT - LOWER INTAKE MANIFOLD

Fig. 138 Intake Manifold Gasket Sealing

1 - SEALER LOCATIONS

RSENGINE 3.3/3.8L9 - 149

INTAKE MANIFOLD - LOWER (Continued)

Page 2780 of 4284

TIMING CHAIN AND

SPROCKETS

REMOVAL - TIMING CHAIN AND CAMSHAFT

SPROCKET

(1) Disconnect negative cable from battery.

(2) Remove the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(3) Rotate engine by turning crankshaft until the

timing marks are aligned as shown in (Fig. 156).

(4) Remove camshaft sprocket attaching bolt.

(5) Remove the timing chain with camshaft

sprocket.

(6) Remove the crankshaft sprocket. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL)

REMOVAL - CRANKSHAFT SPROCKET

(1) Remove the timing chain. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL)

(2) Using Special Tools 8539, 5048-6, and 5048-1,

remove the crankshaft sprocket while holding the

crankshaft from turning (Fig. 157). Be careful not to

damage the crankshaft surfaces.

INSPECTION

(1) Position a scale next to timing chain so that

any movement of chain may be measured.

(2) Position a torque wrench and socket on the

camshaft sprocket attaching bolt. Apply force in the

direction of crankshaft rotation to take up slack to

the following torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removed

Fig. 155 TIMING CHAIN COVER BOLT LOCATIONS

1 - BOLT - M8 x 1.25 x 95 4 - BOLT - M8 x 1.25 x 80

2 - BOLT - M10 x 1.5 x 100 5 - BOLT - M8 x 1.25 x 45

3 - BOLT - M10 x 1.5 x 85

9 - 156 ENGINE 3.3/3.8LRS

TIMING CHAIN COVER (Continued)

Page 2781 of 4284

NOTE: With torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block crankshaft to

prevent rotation.

(3) Holding a measuring scale along edge of chain

links (Fig. 158).

(4) Apply force in the reverse direction to the fol-

lowing torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removed

(5) Measure amount of sprocket/chain movement.

(6) Install a new timing chain and sprockets if

movement exceeds 3.175 mm (1/8 in.). (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL)

INSTALLATION - TIMING CHAIN AND

CAMSHAFT SPROCKET

(1) Rotate crankshaft so the timing arrow is to the

12 o'clock position (Fig. 156).

NOTE: Lubricate timing chain and sprockets with

clean engine oil before installation.

(2) While holding camshaft sprocket and chain in

hand, place timing chain around the sprocket, align-

ing the plated link with the dot on the sprocket. Posi-

tion the timing arrow to the 6 o'clock position (Fig.

156).

(3) Place timing chain around crankshaft sprocket

with the plated link lined up with the dot on the

sprocket. Install camshaft sprocket into position.

(4) Use a straight edge to check alignment of tim-

ing marks.

(5) Install camshaft sprocket bolt and washer.

Tighten bolt to 54 N´m (40 ft. lbs.).

Fig. 156 Timing Mark Alignment

1 - CAMSHAFT SPROCKET TIMING MARK (DOT)

2 - PLATED LINK

3 - CRANKSHAFT SPROCKET TIMING MARK (DOT)

4 - ARROWS

Fig. 157 CRANKSHAFT SPROCKET - REMOVAL

1 - SPECIAL TOOL 5048-6

2 - SPECIAL TOOL 5048-1

3 - SPECIAL TOOL 8450

4 - CRANKSHAFT SPROCKET

5 - SPECIAL TOOL 8539

Fig. 158 Measuring Timing Chain Wear

1 - TORQUE WRENCH

RSENGINE 3.3/3.8L9 - 157

TIMING CHAIN AND SPROCKETS (Continued)

Page 2788 of 4284

(47) Remove left engine mount through bolt.

(48) Raise vehicle, leaving engine and transmis-

sion on engine cradle.

(49) Lift engine from engine cradle and diassemble

as necessary.

REMOVAL - ENGINE COVER

(1) Remove the engine cover retaining bolts.

(2) Remove the engine cover from the engine.

INSTALLATION - 2.5L TURBO DIESEL ENGINE

(1) Reassembly engine and transmission assembly

and install on engine cradle.

(2) Position engine and cradle assembly under

vehicle.

(3) Slowly lower the vehicle down over the engine

and cradle assembly.

(4) Install right engine mount bolts. Torque to

54N´m (40 ft. lbs.)

(5) Install left engine mount through bolt. Torque

to 75N´m (55 ft. lbs.)

(6) Raise vehicle and engine from engine cradle.

Fig. 9 ENGINE COMPONENT LOCATIONS

1 - FUEL INJECTOR RETURN LINE

2 - FUEL INJECTOR SUPPLY LINE

3 - OIL SEPARATOR

4 - FUEL INJECTOR

5 - CAMSHAFT POSITION SENSOR

6 - BOOST PRESSURE/INTAKE AIR TEMPERATURE SENSOR

7 - EGR SOLENOID

8 - FUEL PRESSURE SENSOR

9 - CYLINDER HEAD COVER/INTAKE MANIFOL

10 - FUEL RAIL

11 - WIRING HARNESS RETAINING CLIPS

Fig. 10 REAR ENGINE VIEW

1 - SUSPENSION CRADLE

2 - ENGINE BLOCK

3 - OIL PRESSURE SWITCH

4 - OIL TEMPERATURE SENSOR

5 - VEHICLE SPEED SENSOR

6 - TRANSMISSION

Fig. 11 Figure Caption Here

1 - ENGINE COVER MOUNTING BOLTS

2 - ENGINE COVER

9a - 6 ENGINE 2.5L TURBO DIESELRG

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2789 of 4284

(7) Attach front engine mount bracket to lower

radiator support. Torque to 54N´m (40 ft. lbs.)

(8) Connect cabin heater coolant hose.

(9) Connect exhaust pipe to the turbocharger

downpipe flange. Torque to 28 N´m (250 in. lbs.)

(10) Connect reverse lamp electrical connector at

transmission.

(11) Connect both shifter cables (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/GEAR

SHIFT CABLE - INSTALLATION).

(12) Connect the clutch slave cylinder quick dis-

connect connector (RHD only)(Refer to 6 - CLUTCH/

SLAVE CYLINDER - INSTALLATION).

(13) Install engine harness into bracket on trans-

mission.

(14) Lower vehicle.

(15) Connect fuel supply and return lines.

(16) Connect A/C lines to A/C compressor. Torque

to 23N´m (17 ft. lbs.)

(17) Route engine wiring harnes to proper location.

(18) Connect engine harness ground cables to

engine block

(19) Connect starter solenoid electrical connector

and battery feed wire to starter. Torque to 10N´m (90

in. lbs.)

(20) Connect A/C compressor, injection pump, glow

plugs, and coolant temperature sensor electrical con-

nectors.

(21) Connect generator electrical connector. Torque

to 9N´m (75 in. lbs.)

(22) Connect the fuel injector, fuel pressure sensor,

boost pressure/intake air temp sensor, cam sensor,

and egr solenoid electrical connectors (Fig. 9).

(23) Connect egr solenoid vacuum supply line to

brake boost vacuum supply line.

(24) Connect brake booster vacuum supply line.

(25) Connect heater core return hose to coolant

pipe.

(26) Connect lower radiator hose to engine (Fig. 8).

(27) Install charger air cooler inlet hose (Fig. 7).

(28) Install charge air cooler outlet hose (Fig. 7).

(29) Connect upper radiator hose to engine (Fig.

8).

(30) Install battery shield.

(31) Install coolant reserve pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

(32) Install power steering reservoir and bracket

(Fig. 5).

(33) Raise vehicle

(34) Connect oil pressure sensor, oil temperature

sensor, engine speed sensor, and vehicle speed sensor

electrical connector (Fig. 10).(35) Install suspension cradle in vehicle (Refer to

13 - FRAME & BUMPERS/FRAME/ENGINE CRA-

DLE CROSSMEMBER - INSTALLATION).

(36) Install both axle shaft assemblies (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

INSTALLATION).

(37) Connect the power steering supply, pressure,

and return lines to power steering pump (Fig. 5).

(38) Install the power steering line brackets on oil

pan (Fig. 5).

(39) Install lower splash shield and side panels.

(40) Install both front wheel and tire assemblies.

(41) Lower vehicle.

(42) Install air cleaner housing, MAF sensor, and

air intake tube assembly (Fig. 4).

(43) Refill transmission to proper level (Refer to 21

- TRANSMISSION/TRANSAXLE/MANUAL/FLUID -

STANDARD PROCEDURE).

(44) Refill engine coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(45) Recharge A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-

ANT - STANDARD PROCEDURE) .

(46) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION) (Fig. 3).

(47) Connect negative battery cable.

INSTALLATION - ENGINE COVER

(1) Install engine cover on engine.

(2) Install the engine cover mounting bolts (Fig.

11).

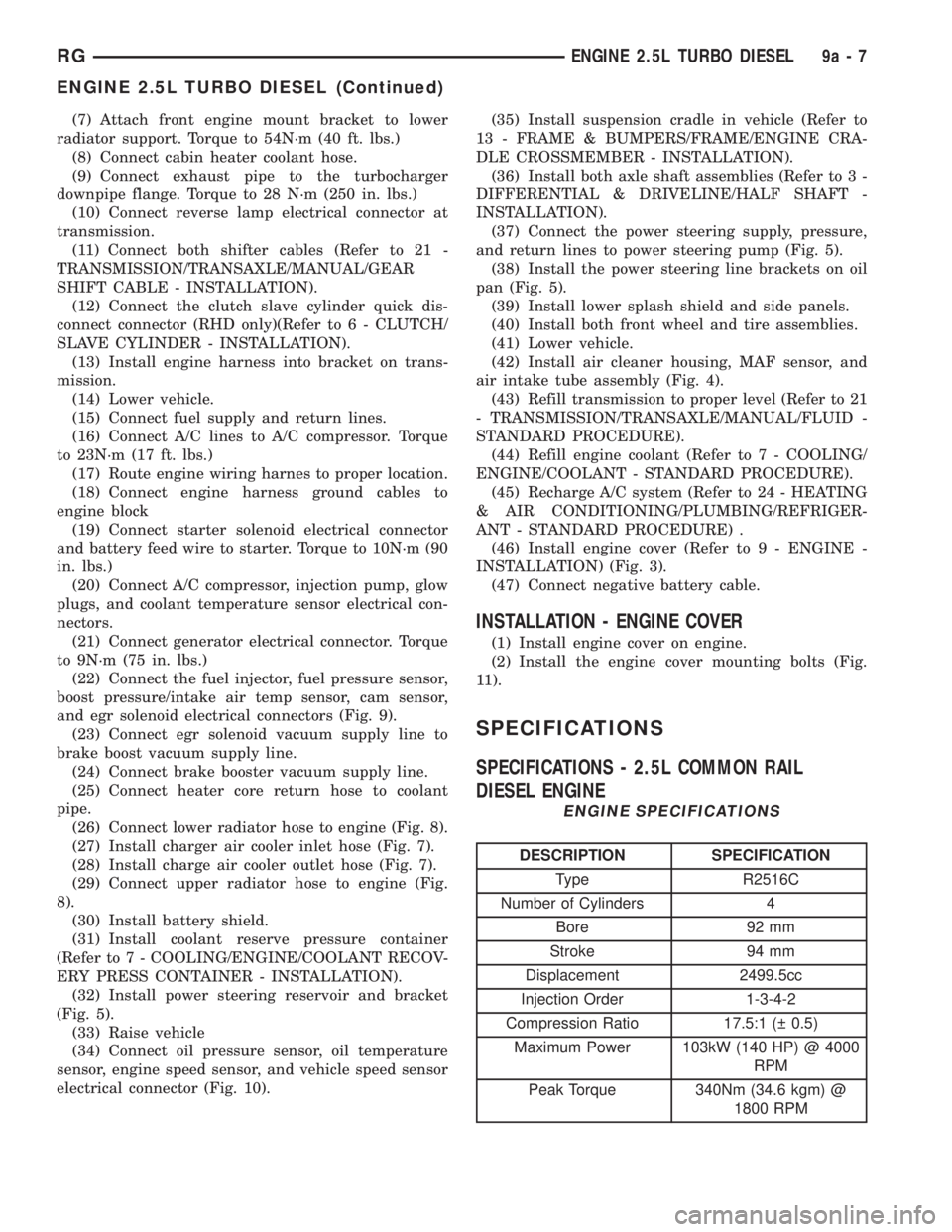

SPECIFICATIONS

SPECIFICATIONS - 2.5L COMMON RAIL

DIESEL ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Type R2516C

Number of Cylinders 4

Bore 92 mm

Stroke 94 mm

Displacement 2499.5cc

Injection Order 1-3-4-2

Compression Ratio 17.5:1 ( 0.5)

Maximum Power 103kW (140 HP) @ 4000

RPM

Peak Torque 340Nm (34.6 kgm) @

1800 RPM

RGENGINE 2.5L TURBO DIESEL9a-7

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2792 of 4284

SPECIFICATIONS - TORQUE

2.5L DIESEL TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Oil Pump Bolts 10.8 8 96

Vacuum Pump Bolts 10.8 8 96

Crankshaft Gear Bolts 10.8 8 96

Crankshaft Position

Sensor Bolts10.8 8 96

Flywheel Bolts - Refer to the Service Procedure

Cylinder Head Bolts - Refer to the Service Procedure

Reluctor Wheel Bolts 14.6 11 130

Rear Main Bearing

Support Bolts27.5 21 240

Oil Cooler to Engine Block

Bolt47.1 35 Ð

Oil Cooler Mounting Stud 50 37 Ð

Water Pump Housing Nuts 24.4 18 212

Connecting Rod Bolts - Refer to the Service Procedure

Balance Shaft Bolts 32.4 24 Ð

Oil Jet Bolts 10.8 8 96

Oil Pan Bolts 11.8 8 96

Crankshaft Hub Bolt 304 225 Ð

Front Engine Cover Bolts 11.8 8 96

Transmission to Engine

Bolts83.4 62 Ð

Cylinder Head Cover /

Intake Manifold Bolts27.5 20 Ð

Camshaft Access Plugs 80 59 Ð

Oil Separator Bolts 10.8 8 96

Camshaft Position Sensor

Bolt10.8 8 96

Boost Pressure / Intake

Air Temp. Sensor Bolts5.4 Ð 48

Accessory Drive Bracket

Bolts47.1 35 Ð

Vacuum Line Fitting Bolt 56.9 42 Ð

Fuel Pump Nuts 27.5 21 Ð

Fuel Line Fittings at Pump 27.5 21 Ð

Inner Timing Belt Cover Bolts

8mm 10.8 8 96

10mm 47.1 35 Ð

Outer Timing Belt Cover Bolts

3mm 6 Ð 54

8mm 10.8 8 96

9a - 10 ENGINE 2.5L TURBO DIESELRG

ENGINE 2.5L TURBO DIESEL (Continued)