battery location CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1802 of 4284

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, use Special Tool 6094 or equivalent, con-

stant tension clamp pliers (Fig. 24) to compress the

hose clamp.

RADIATOR FAN RELAY

DESCRIPTION

The low and high speed fan relays are mounted to

the upper radiator support above the charge air

cooler (Fig. 25).

OPERATION

The cooling system uses two fans. Both fans oper-

ate at two different speeds, low and high. Depending

on engine coolant temperature and A/C system high

side pressure, the fans operate at either low or high.

The ignition switch supplies voltage to the coil side of

the relay. When the ECM grounds the coil side of the

relay, the contacts close and the battery supplies

power to the fans.

COOLANT SYSTEM HOSES

REMOVAL - UPPER RADIATOR HOSE

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.(1) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove upper radiator hose (Fig. 26).

REMOVAL - LOWER RADIATOR HOSE

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

(1) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(2) Remove lower radiator hose (Fig. 26).

REMOVAL - COOLANT BYPASS HOSE

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

(1) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(2) Remove the coolant bypass hose (Fig. 26).

Fig. 24 Hose Clamp Tool

1 - HOSE CLAMP TOOL 6094

2 - HOSE CLAMP

Fig. 25 RELAY LOCATIONS

1 - GLOW PLUG RELAY

2 - UPPER RADIATOR SUPPORT

3 - CHARGE AIR COOLER OUTLET HOSE

4 - RADIATOR FAN RELAYS

5 - UPPER RADIATOR HOSE

6 - EGR SOLENOID

7a - 28 ENGINERG

HOSE CLAMPS (Continued)

Page 1812 of 4284

(4) Connect battery negative cable.

QUARTER PANEL SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove speaker grill by prying away from trim

panel.

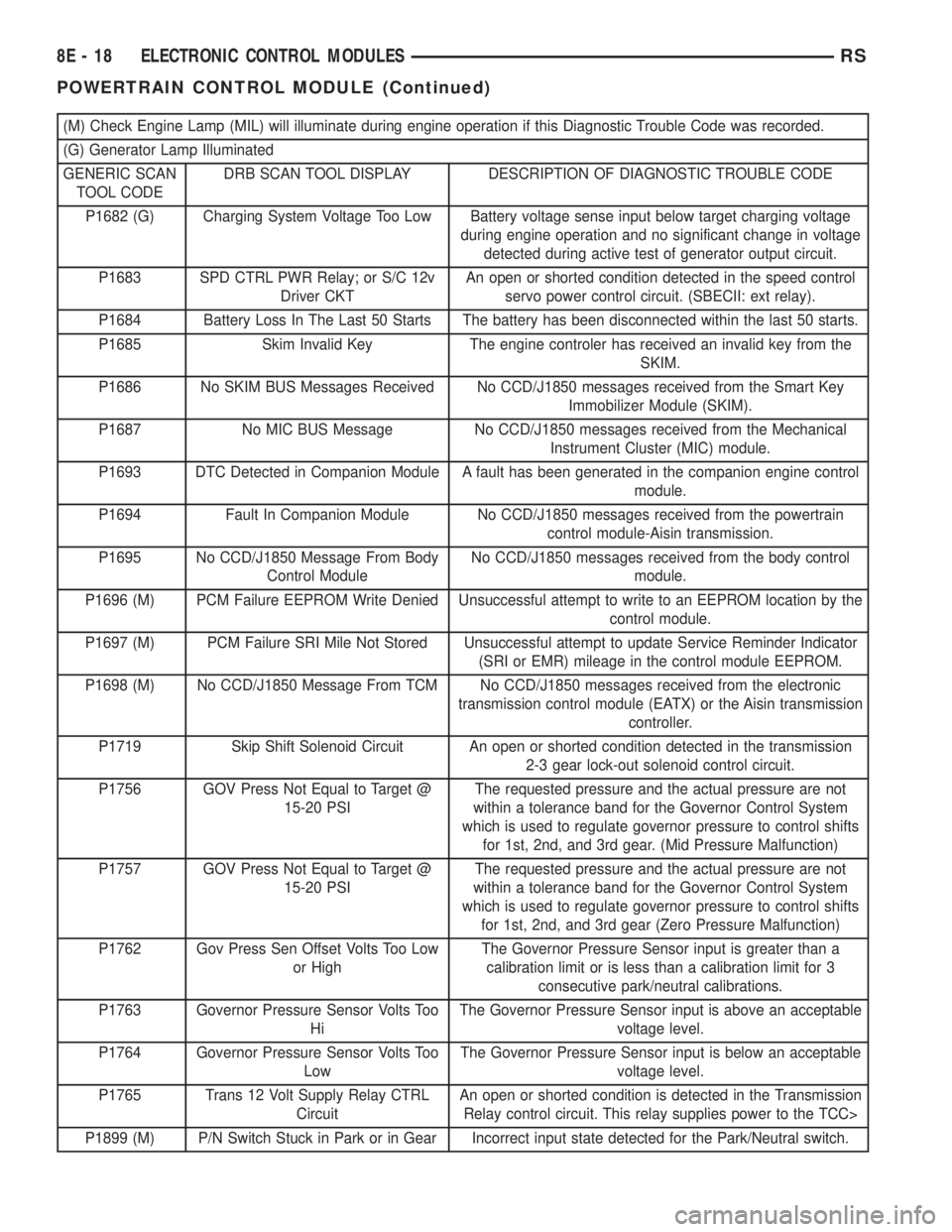

(3) Remove speaker retaining screws (Fig. 9).

(4) Disconnect wire harness connector from

speaker.

INSTALLATION

(1) Connect the wire harness to the speaker.

(2) Install the speaker retaining screws.

(3) Install speaker grill by pressing into the trim

panel.

(4) Connect the battery negative cable.

RADIO

DIAGNOSIS AND TESTING

If the vehicle is equipped with remote radio

switches located on the backs of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WARNING:

ON VEHICLES EQUIPPED WITH AIRBAGS, REFER

TO ELECTRICAL, RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION:

The speaker output of the radio is a ªfloating

groundº system. Do not allow any speaker lead to

short to ground, as damage to the radio may result.

(1) Check the fuse(s) in the junction block and the

Intelligent Power Module. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(2) Check for battery voltage at the fuse in the

Intelligent Power Module. If OK, go to Step 3. If not

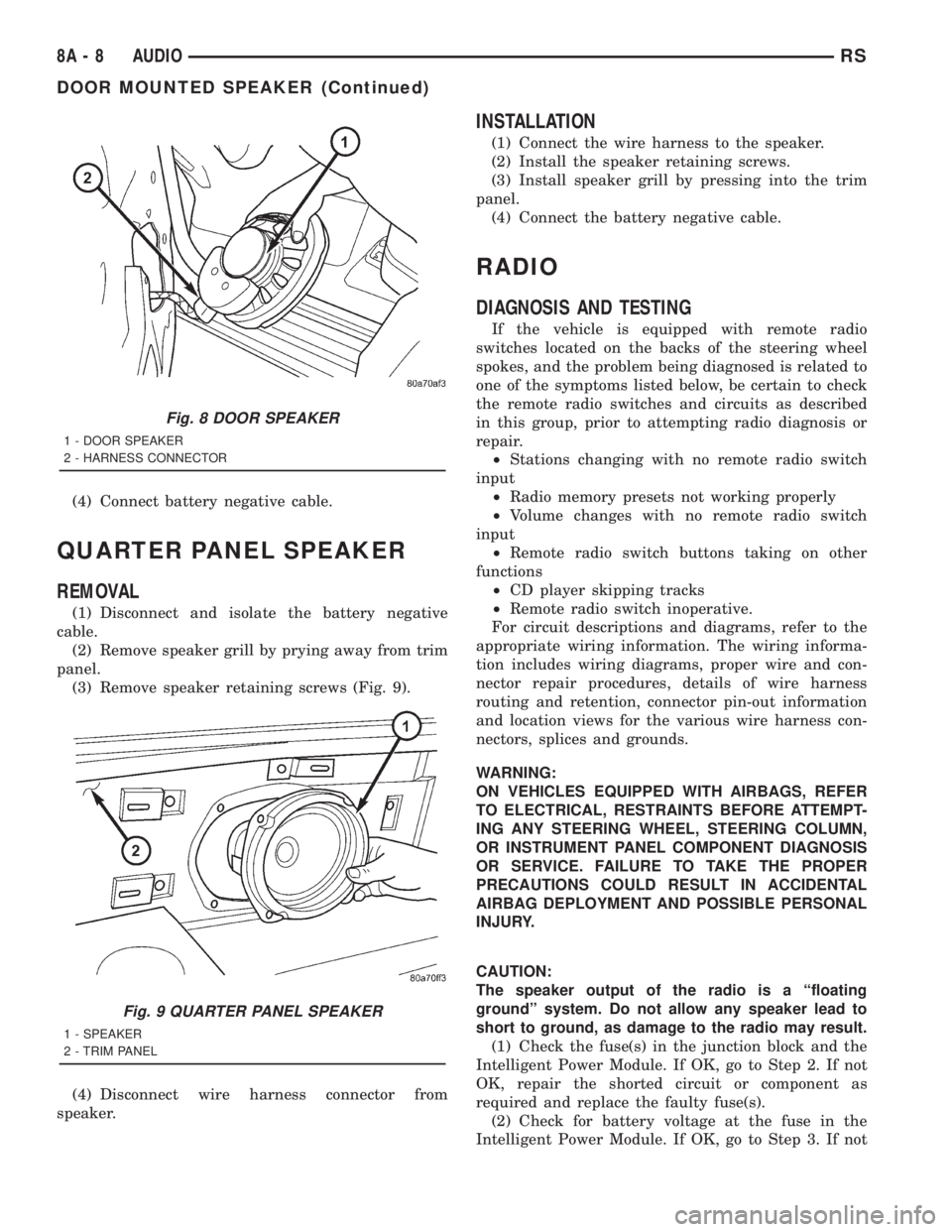

Fig. 8 DOOR SPEAKER

1 - DOOR SPEAKER

2 - HARNESS CONNECTOR

Fig. 9 QUARTER PANEL SPEAKER

1 - SPEAKER

2 - TRIM PANEL

8A - 8 AUDIORS

DOOR MOUNTED SPEAKER (Continued)

Page 1819 of 4284

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

CHIME SYSTEM.........................1

DOME LAMP ON CHIME..................2

ENGINE TEMPERATURE CRITICAL CHIME....2EXTERIOR LAMPS ON CHIME..............2

KEY-IN IGNITION CHIME..................2

LOW OIL PRESSURE CHIME...............2

SEAT BELT CHIME.......................3

SEAT BELT LAMP.......................3

TURN SIGNAL ON CHIME.................3

WARNING LAMP ANNOUNCEMENT CHIME....3

CHIME/BUZZER

DESCRIPTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The chime/buzzer system provides the driver with

warning chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Key-In Accessory

OPERATION

The Chime/Buzzer Warning System is diagnosed

using a DRBIIItscan tool. Refer to the proper Body

Diagnostic Procedures Manual.

DIAGNOSIS AND TESTING - CHIME SYSTEM

NO TONE WHEN IGNITION SWITCH IS TURNED ON

AND DRIVER'S SEAT BELT IS NOT BUCKLED.

(1) Using a DRBIIItscan tool, actuate chime

(BCM actuates).

(2) Using a voltmeter, check for voltage:

(a) BCM has two battery feeds at pin 1 and pin

5 of the 6±way connector.

(b) Pin 5 of the (BX2) 32 way connector of the

BCM for ignition feed.

(c) Check voltage (PX2) connector, pin 34 for 12v.

(d) If voltage OK, go to step Step 3

(e) If NO voltage repair as necessary. Refer to

the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

(3) Check driver's seat belt buckle switch input

(form ORC) for a closed circuit when not buckled. If

input not seen, look for open in wiring or switch. The

switch is grounded when belt is not buckled.

(4) Verify PCI data bus communication between

ORC and BCM.

NO FASTEN SEAT BELT LAMP WHEN IGNITION

SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage at the clus-

ter conncctor:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

RSCHIME/BUZZER8B-1

Page 1842 of 4284

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P1682 (G) Charging System Voltage Too Low Battery voltage sense input below target charging voltage

during engine operation and no significant change in voltage

detected during active test of generator output circuit.

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed control

servo power control circuit. (SBECII: ext relay).

P1684 Battery Loss In The Last 50 Starts The battery has been disconnected within the last 50 starts.

P1685 Skim Invalid Key The engine controler has received an invalid key from the

SKIM.

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

P1687 No MIC BUS Message No CCD/J1850 messages received from the Mechanical

Instrument Cluster (MIC) module.

P1693 DTC Detected in Companion Module A fault has been generated in the companion engine control

module.

P1694 Fault In Companion Module No CCD/J1850 messages received from the powertrain

control module-Aisin transmission.

P1695 No CCD/J1850 Message From Body

Control ModuleNo CCD/J1850 messages received from the body control

module.

P1696 (M) PCM Failure EEPROM Write Denied Unsuccessful attempt to write to an EEPROM location by the

control module.

P1697 (M) PCM Failure SRI Mile Not Stored Unsuccessful attempt to update Service Reminder Indicator

(SRI or EMR) mileage in the control module EEPROM.

P1698 (M) No CCD/J1850 Message From TCM No CCD/J1850 messages received from the electronic

transmission control module (EATX) or the Aisin transmission

controller.

P1719 Skip Shift Solenoid Circuit An open or shorted condition detected in the transmission

2-3 gear lock-out solenoid control circuit.

P1756 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear. (Mid Pressure Malfunction)

P1757 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear (Zero Pressure Malfunction)

P1762 Gov Press Sen Offset Volts Too Low

or HighThe Governor Pressure Sensor input is greater than a

calibration limit or is less than a calibration limit for 3

consecutive park/neutral calibrations.

P1763 Governor Pressure Sensor Volts Too

HiThe Governor Pressure Sensor input is above an acceptable

voltage level.

P1764 Governor Pressure Sensor Volts Too

LowThe Governor Pressure Sensor input is below an acceptable

voltage level.

P1765 Trans 12 Volt Supply Relay CTRL

CircuitAn open or shorted condition is detected in the Transmission

Relay control circuit. This relay supplies power to the TCC>

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 1849 of 4284

²Output Shaft Speed Sensor

Some examples ofindirect inputsto the TCM

are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Speed Control ON/OFF Switch

²Engine Coolant Temperature

²Ambient/Battery Temperature

²Brake Switch Status

²DRB Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids (LR/CC, 2/4, OD and UD)

²Vehicle Speed (to PCM)

²Torque Reduction Request (to PCM)

An example of a TCMindirect outputis:

²Transmission Temperature (to PCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indices

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics²Diagnostic capabilities (with DRB scan tool)

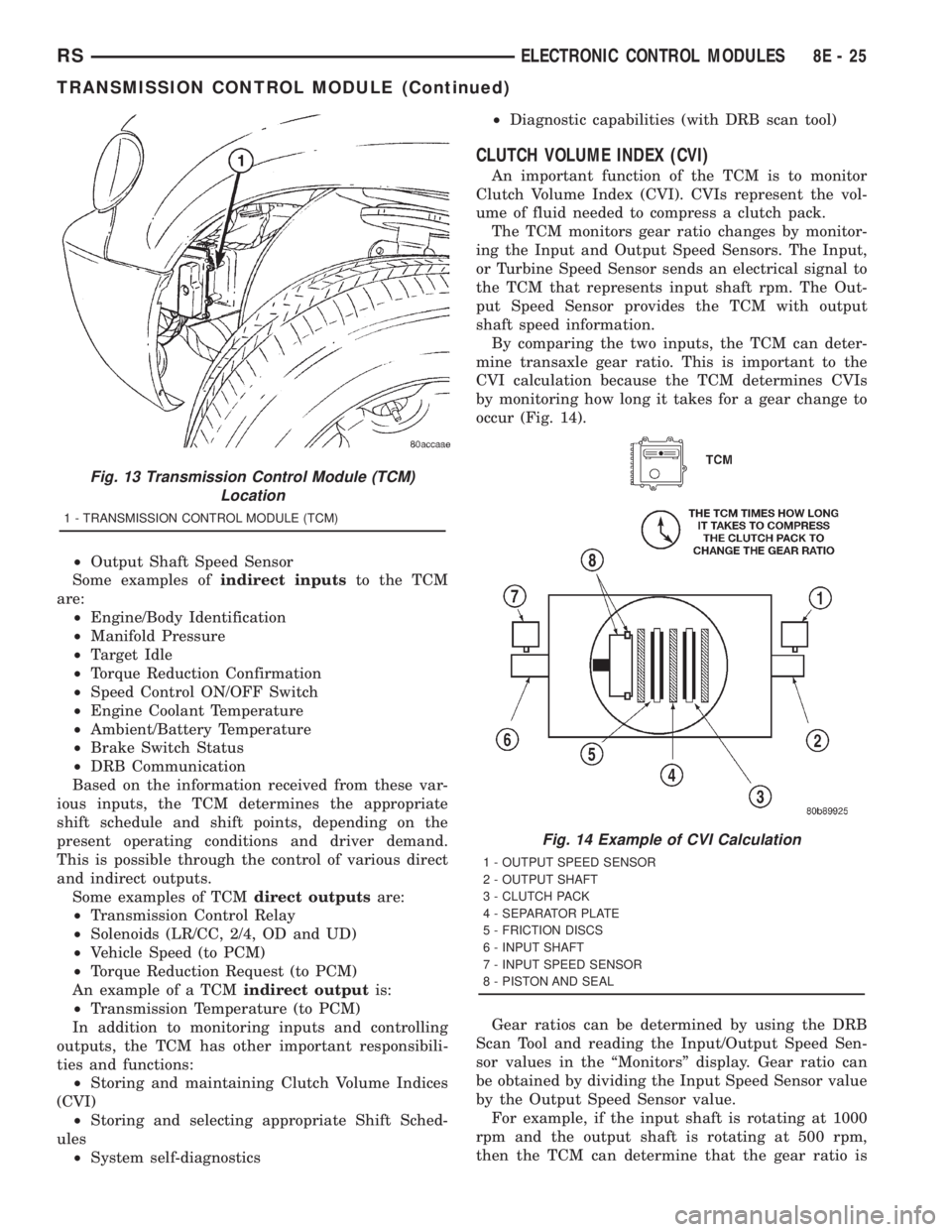

CLUTCH VOLUME INDEX (CVI)

An important function of the TCM is to monitor

Clutch Volume Index (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.

The TCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the TCM that represents input shaft rpm. The Out-

put Speed Sensor provides the TCM with output

shaft speed information.

By comparing the two inputs, the TCM can deter-

mine transaxle gear ratio. This is important to the

CVI calculation because the TCM determines CVIs

by monitoring how long it takes for a gear change to

occur (Fig. 14).

Gear ratios can be determined by using the DRB

Scan Tool and reading the Input/Output Speed Sen-

sor values in the ªMonitorsº display. Gear ratio can

be obtained by dividing the Input Speed Sensor value

by the Output Speed Sensor value.

For example, if the input shaft is rotating at 1000

rpm and the output shaft is rotating at 500 rpm,

then the TCM can determine that the gear ratio is

Fig. 13 Transmission Control Module (TCM)

Location

1 - TRANSMISSION CONTROL MODULE (TCM)

Fig. 14 Example of CVI Calculation

1 - OUTPUT SPEED SENSOR

2 - OUTPUT SHAFT

3 - CLUTCH PACK

4 - SEPARATOR PLATE

5 - FRICTION DISCS

6 - INPUT SHAFT

7 - INPUT SPEED SENSOR

8 - PISTON AND SEAL

RSELECTRONIC CONTROL MODULES8E-25

TRANSMISSION CONTROL MODULE (Continued)

Page 1852 of 4284

STANDARD PROCEDURE - TCC BREAK-IN

VIEW/RESTART PROCEDURE

The Transmission Control Module (TCM) employs

a strategy which modifies torque converter clutch

(TCC) operation. This strategy conditions the torque

converter clutch disc for optimum converter clutch

engagement and feel throughout the life of the trans-

axle. The cycle inhibits FEMCC until six hours of

PEMCC operation have taken place, or the vehicle

has been driven 6,035 km (3750 miles). The cycle

automatically terminates when either the time or

mileage has been achieved, however, the mileage

may vary slightly from vehicle to vehicle.

The TCC break-in cycle must be restarted using

the DRB Scan Tool, and upon:

²Replacement of TCM on vehicle with less than

6,035 km (3750 miles) or less than 6 hours of

PEMCC operation

²Replacement of torque converter assembly at

any vehicle mileage

NOTE: Failure to restart the TCC Break-In Cycle

upon TCM replacement in vehicles with less than

six hours of PEMCC or less than 6,035 km (3750

miles), or upon torque converter replacement at any

mileage, may result in vehicle shudder during cer-

tain operating conditions.

Procedure

The DRB Scan Tool is required to view and/or

restart the TCC Break-In cycle.

(1) Connect the DRB Scan Tool to the vehicle diag-

nostic connector.

(2) Navigate to ªTCC Break-Inº via Transmission/

Transmission Control Module/Miscellaneous.

(3) View or Start TCC Break-In as prompted by

DRB menu.

REMOVAL

NOTE: If transmission control module is being

replaced with a new or replacement unit, the Pinion

Factor and Quick Learn procedures must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE) (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE) If vehicle has less than 6,035 km

(3750 miles), the Torque Converter Clutch (TCC)

Break-In Strategy reset procedure must also be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

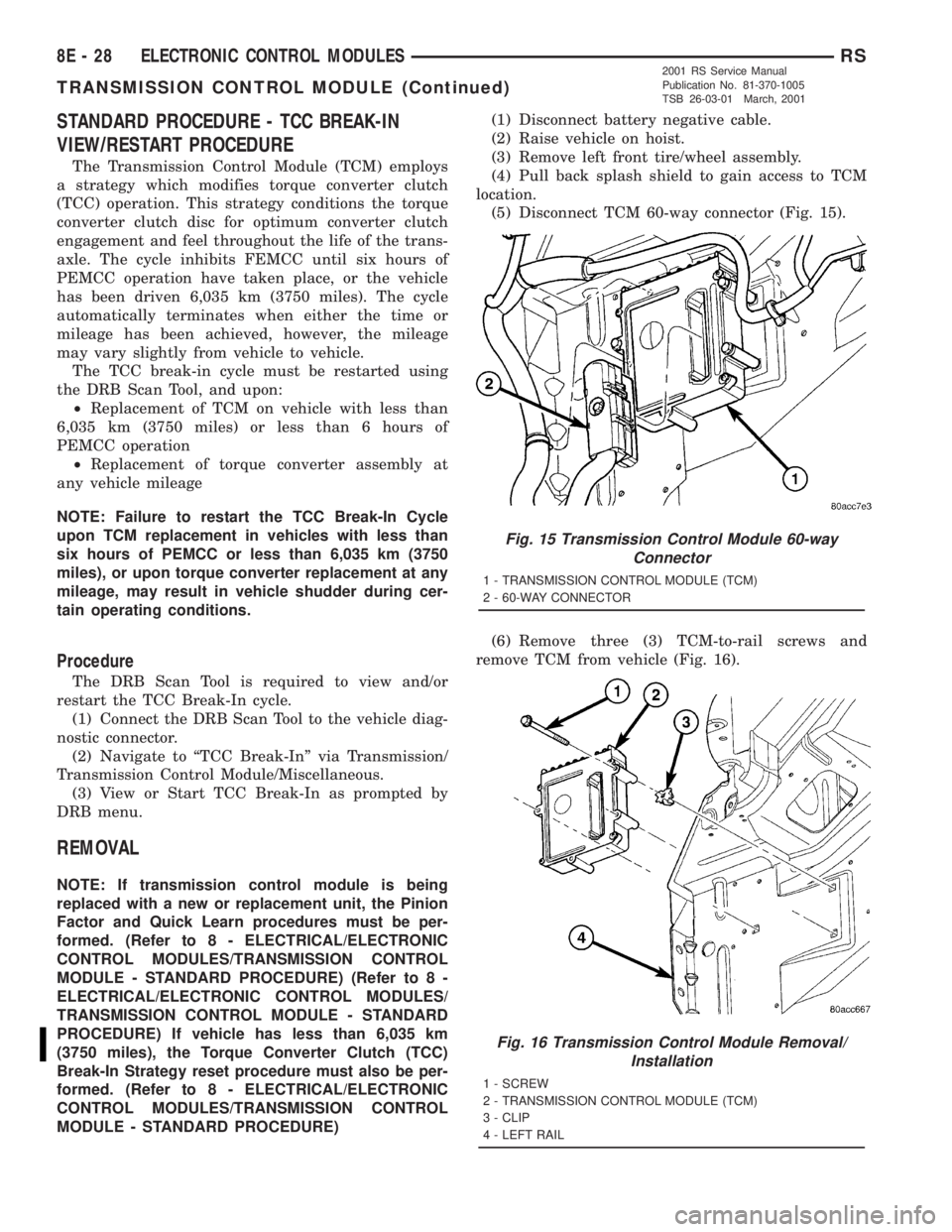

MODULE - STANDARD PROCEDURE)(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Remove left front tire/wheel assembly.

(4) Pull back splash shield to gain access to TCM

location.

(5) Disconnect TCM 60-way connector (Fig. 15).

(6) Remove three (3) TCM-to-rail screws and

remove TCM from vehicle (Fig. 16).

Fig. 15 Transmission Control Module 60-way

Connector

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60-WAY CONNECTOR

Fig. 16 Transmission Control Module Removal/

Installation

1 - SCREW

2 - TRANSMISSION CONTROL MODULE (TCM)

3 - CLIP

4 - LEFT RAIL

8E - 28 ELECTRONIC CONTROL MODULESRS

TRANSMISSION CONTROL MODULE (Continued)

2001 RS Service Manual

Publication No. 81-370-1005

TSB 26-03-01 March, 2001

Page 1856 of 4284

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery system is standard factory-

installed equipment on this model. All of the compo-

nents of the battery system are located within the

engine compartment of the vehicle. The service infor-

mation for the battery system in this vehicle covers

the following related components, which are covered

in further detail elsewhere in this service manual:

²Battery- The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

²Battery Cable- The battery cables connect the

battery terminal posts to the vehicle electrical sys-

tem.

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Thermoguard- The battery thermo-

guard insulates the battery to protect it from engine

compartment temperature extremes.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

For battery system maintenance schedules and

jump starting procedures, see the owner's manual in

the vehicle glove box. Optionally, refer to Lubrication

and Maintanance for the recommended battery main-

tenance schedules and for the proper battery jump

starting procedures. While battery charging can be

considered a maintenance procedure, the battery

charging procedures and related information are

located in the standard procedures section of this ser-

vice manual. This was done because the battery must

be fully-charged before any battery system diagnosis

or testing procedures can be performed. Refer to

Standard procedures for the proper battery charging

procedures.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a single complete system. In order for the engine

to start and the battery to charge properly, all of the

components that are used in these systems must per-

form within specifications. It is important that the

battery, starting, and charging systems be thoroughly

tested and inspected any time a battery needs to be

charged or replaced. The cause of abnormal battery

discharge, overcharging or early battery failure must

be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for any failure it detects. Refer to

Charging System for the proper charging system on-

board diagnostic test procedures.

8F - 2 BATTERY SYSTEMRS

Page 1861 of 4284

material protrude from the top of the molded plastic

battery case to provide the means for connecting the

battery to the vehicle electrical system. The battery

positive terminal post is visibly larger in diameter

than the negative terminal post, for easy identification.

The lettersPOS

andNEGare also molded into the

top of the battery case adjacent to their respective

positive and negative terminal posts for additional

identification confirmation. Refer toBattery Cables

in the index of this service manual for the location of

more information on the battery cables that connect

the battery to the vehicle electrical system.

This battery is designed to provide a safe, efficient

and reliable means of storing electrical energy in a

chemical form. This means of energy storage allows

the battery to produce the electrical energy required

to operate the engine starting system, as well as to

operate many of the other vehicle accessory systems

for limited durations while the engine and/or the

charging system are not operating. The battery is

made up of six individual cells that are connected in

series. Each cell contains positively charged plate

groups that are connected with lead straps to the

positive terminal post, and negatively charged plate

groups that are connected with lead straps to the

negative terminal post. Each plate consists of a stiff

mesh framework or grid coated with lead dioxide

(positive plate) or sponge lead (negative plate). Insu-

lators or plate separators made of a non-conductive

material are inserted between the positive and nega-

tive plates to prevent them from contacting or short-

ing against one another. These dissimilar metal

plates are submerged in a sulfuric acid and water

solution called an electrolyte.

Some factory-installed batteries have a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condi-

tion. For more information on the use of the built-in

test indicator, refer toStandard Procedures The

factory-installed low-maintenance battery has

removable battery cell caps.Distilled water can

be added to this battery. The battery is not sealed

and has vent holes in the cell caps. The chemical

composition of the metal coated plates within the

low-maintenance battery reduces battery gassing and

water loss, at normal charge and discharge rates.

Therefore, the battery should not require additional

water in normal service. If the electrolyte level in

this battery does become low, distilled water must be

added. However, rapid loss of electrolyte can be

caused by an overcharging condition. Be certain to

diagnose the charging system after replenishing the

water in the battery for a low electrolyte condition

and before returning the vehicle to service. Refer to

Charging Systemfor additional information.The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

found on the original equipment battery label. Be

certain that a replacement battery has the correct

Group Size number, as well as CCA, and RC or AH

ratings that equal or exceed the original equipment

specification for the vehicle being serviced. Refer to

Battery Specificationsin this group for the loca-

tion of the proper factory-installed battery specifica-

tions. Battery sizes and ratings are discussed in more

detail below.

Group Size

²The outside dimensions and terminal placement

of the battery conform to standards established by

the Battery Council International (BCI). Each bat-

tery is assigned a BCI Group Size number to help

identify a correctly-sized replacement.

Cold Cranking Amperage

²The Cold Cranking Amperage (CCA) rating spec-

ifies how much current (in amperes) the battery can

deliver for thirty seconds at -18É C (0É F). Terminal

voltage must not fall below 7.2 volts during or after

the thirty second discharge period. The CCA required

is generally higher as engine displacement increases,

depending also upon the starter current draw

requirements.

Reserve Capacity

²The Reserve Capacity (RC) rating specifies the

time (in minutes) it takes for battery terminal volt-

age to fall below 10.5 volts, at a discharge rate of 25

amperes. RC is determined with the battery fully-

charged at 26.7É C (80É F). This rating estimates how

long the battery might last after a charging system

failure, under minimum electrical load.

Ampere-Hours

²The Ampere-Hours (AH) rating specifies the cur-

rent (in amperes) that a battery can deliver steadily

for twenty hours, with the voltage in the battery not

falling below 10.5 volts. This rating is also sometimes

identified as the twenty-hour discharge rating.

OPERATION

The battery is designed to store electrical energy in

a chemical form. When an electrical load is applied to

the terminals of the battery, an electrochemical reac-

tion occurs. This reaction causes the battery to dis-

charge electrical current from its terminals. As the

RSBATTERY SYSTEM8F-7

BATTERY (Continued)

Page 1870 of 4284

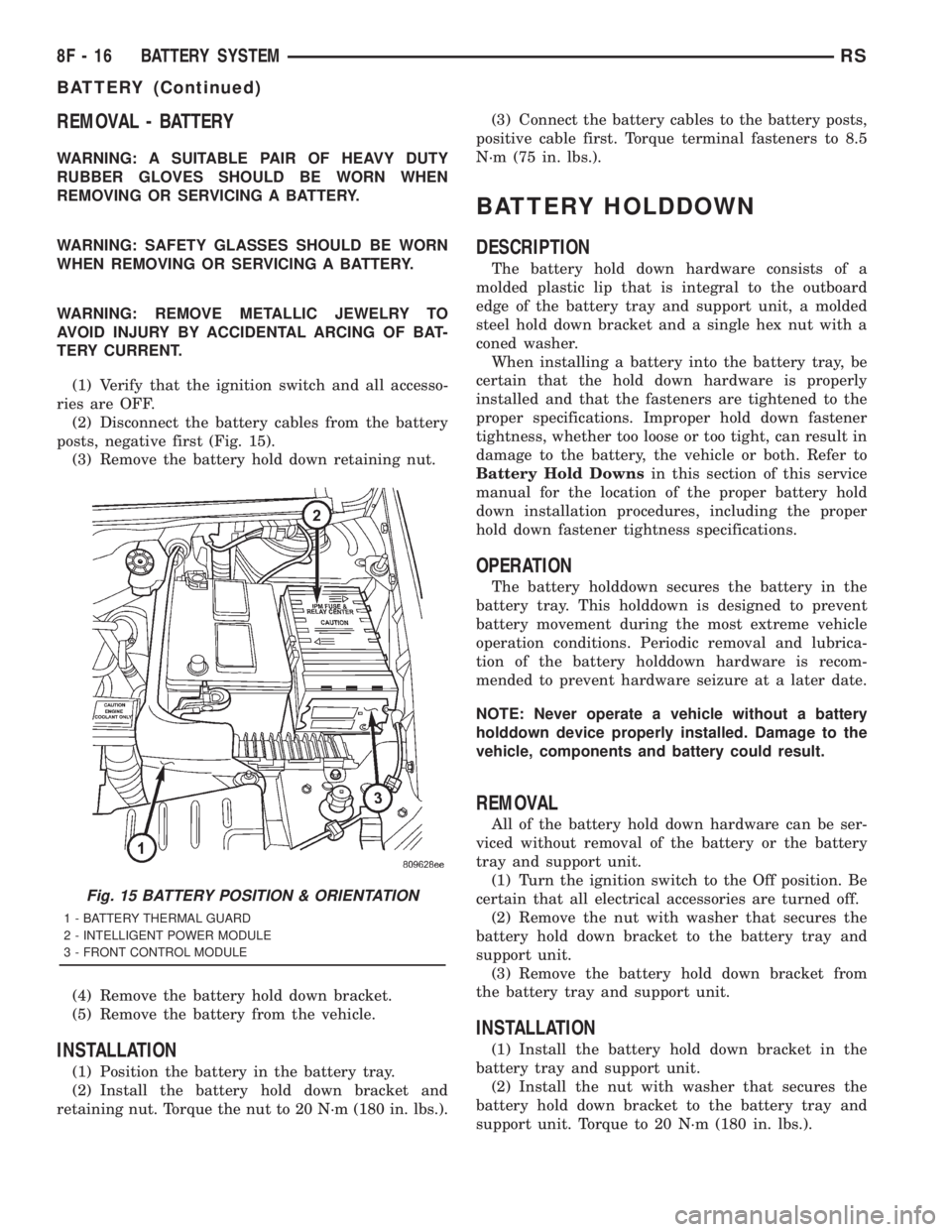

REMOVAL - BATTERY

WARNING: A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES SHOULD BE WORN WHEN

REMOVING OR SERVICING A BATTERY.

WARNING: SAFETY GLASSES SHOULD BE WORN

WHEN REMOVING OR SERVICING A BATTERY.

WARNING: REMOVE METALLIC JEWELRY TO

AVOID INJURY BY ACCIDENTAL ARCING OF BAT-

TERY CURRENT.

(1) Verify that the ignition switch and all accesso-

ries are OFF.

(2) Disconnect the battery cables from the battery

posts, negative first (Fig. 15).

(3) Remove the battery hold down retaining nut.

(4) Remove the battery hold down bracket.

(5) Remove the battery from the vehicle.

INSTALLATION

(1) Position the battery in the battery tray.

(2) Install the battery hold down bracket and

retaining nut. Torque the nut to 20 N´m (180 in. lbs.).(3) Connect the battery cables to the battery posts,

positive cable first. Torque terminal fasteners to 8.5

N´m (75 in. lbs.).

BATTERY HOLDDOWN

DESCRIPTION

The battery hold down hardware consists of a

molded plastic lip that is integral to the outboard

edge of the battery tray and support unit, a molded

steel hold down bracket and a single hex nut with a

coned washer.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both. Refer to

Battery Hold Downsin this section of this service

manual for the location of the proper battery hold

down installation procedures, including the proper

hold down fastener tightness specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

NOTE: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit.

(3) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

(1) Install the battery hold down bracket in the

battery tray and support unit.

(2) Install the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. Torque to 20 N´m (180 in. lbs.).

Fig. 15 BATTERY POSITION & ORIENTATION

1 - BATTERY THERMAL GUARD

2 - INTELLIGENT POWER MODULE

3 - FRONT CONTROL MODULE

8F - 16 BATTERY SYSTEMRS

BATTERY (Continued)

Page 1871 of 4284

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

Refer toWiring Diagramsin the index of this ser-

vice manual for the location of the proper battery

cable wire gauge information.

A clamping type female battery terminal made of

soft lead is die cast onto one end of the battery cable

wire. A square headed pinch-bolt and hex nut are

installed at the open end of the female battery termi-

nal clamp. Large eyelet type terminals are crimped

onto the opposite end of the battery cable wire and

then solder-dipped. The battery positive cable wires

have a red insulating jacket to provide visual identi-

fication and feature a larger female battery terminal

clamp to allow connection to the larger battery posi-

tive terminal post. The battery negative cable wires

have a black insulating jacket and a smaller female

battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsin the

index of this service manual for the location of more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.The battery positive cable terminal clamp is die

cast onto the ends of two wires. One wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the Intelligent Power

Module (IPM), and the other wire has an eyelet ter-

minal that connects the battery positive cable to the

B(+) terminal stud of the engine starter motor sole-

noid. The battery negative cable terminal clamp is

also die cast onto the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the left front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLE

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures.

²Fully engage the parking brake.

RSBATTERY SYSTEM8F-17