check engine light CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1384 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Install a substitute relay in place of the Fuel Heater Relay.

Disconnect the ECM harness connectors.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fuel Heater Relay Output

circuit.

Is the test light on?All

Ye s®Replace the initial Fuel Heater Relay.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 5

5 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Crankcase Vent Heater harness connector.

Disconnect the Fuel Heater harness connector.

Remove the Fuel Heater Relay from the IPM.

Measure the resistance between ground and the Battery(+) Sense circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 6

No®Repair the Battery(+) Sense circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running and at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

165

DRIVEABILITY - DIESEL

P1511-BATTERY SENSE LINE 1 VOLTAGE TOO LOW ÐContinued

Page 1404 of 4284

Symptom:

*CHECKING THE EGR SYSTEM

POSSIBLE CAUSES

ECM/PCM RELAY OUTPUT CIRCUIT OPEN

EGR SOLENOID CONTROL CIRCUIT OPEN

EGR VALVE

VACUUM SUPPLY HOSE

TEST ACTION APPLICABILITY

1 Disconnect the Vacuum Supply Hose at the EGR solenoid.

Connect a vacuum gauge to the Vacuum Supply Hose.

Start the engine and allow the engine to idle.

Is the vacuum above 10 inches of mercury at idle?All

Ye s®Go To 2

No®Repair leaking or restricted Vacuum Supply Hose or faulty

Vacuum Supply Pump.

Perform ROAD TEST VERIFICATION - VER-2.

2 Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the ECM/PCM Relay Output

circuit at the EGR Solenoid harness connector.

Is the test light on?All

Ye s®Go To 3

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the EGR Solenoid Control circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 4

No®Repair the EGR Solenoid Control circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4NOTE: The Vacuum Output Hose must not be leaking or restricted for the

result of this test to be valid.

Turn the ignition off.

Disconnect the Vacuum Supply and Vacuum Output Hoses in the EGR Solenoid

vacuum connector.

Connect the Vacuum Supply Hose to the Vacuum Output Hose.

Test drive the vehicle and observe vehicle performance.

Is there a power reduction on vehicle acceleration?All

Ye s®Test Complete.

No®Replace the EGR Valve.

Perform ROAD TEST VERIFICATION - VER-2.

185

DRIVEABILITY - DIESEL

Page 1407 of 4284

TEST ACTION APPLICABILITY

6 Turn the ignition on.

With the DRB, actuate the Low Speed Rad Fan and observe the Radiator Fans.

NOTE: Both Radiator Fans should operate at low speed.

Did both Radiator Fans operate as they should?All

Ye s®Go To 7

Fans do not operate on Low

Go To 15

Fan 1 on High/Fan 2 not on

Go To 23

Fan 1 not on/Fan 2 on High

Go To 26

7 Turn the ignition on.

With the DRB, actuate the High and Low Speed Rad Fans at the same time and

observe the Radiator Fans.

NOTE: Both Radiator Fans should operate at high speed.

Did both Radiator Fans operate as they should?All

Ye s®The test is complete. Ensure the ECM will turn the fans on when

the engine is hot.

Perform ROAD TEST VERIFICATION - VER-2.

Fan 1 on High/Fan 2 not on

Go To 8

Fan 1 not on/Fan 2 on High

Go To 11

8 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 2 harness connector.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Did the test light illuminate brightly?All

Ye s®Go To 9

No®Repair the Radiator Fan Relay No. 2 Fused B+ circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

9 Turn the ignition off.

Install a substitute relay in place of Radiator Fan Relay No. 2.

Turn the ignition on.

With the DRB, actuate the High Speed Fan Relay.

Does Radiator Fan No. 2 cycle on and off?All

Ye s®Replace Radiator Fan Relay No. 2.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 10

188

DRIVEABILITY - DIESEL

*CHECKING THE ELECTRIC RADIATOR FAN OPERATION ÐContinued

Page 1430 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Relay from the PDC.

WARNING: THE TRANSMISSION MUST BE IN NEUTRAL AND THE PARK

BRAKE MUST BE SET FOR THIS TEST.

WARNING: THE ENGINE MAY CRANK IN THE NEXT STEP. WHEN THE

ENGINE IS CRANKING, DO NOT STAND IN A DIRECT LINE WITH THE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN.

DO NOT WEAR LOOSE CLOTHING.

Momentarily jumper Starter Relay connector cavities 30 and 87 in the IPM

connector.

Did the engine crank?All

Ye s®Go To 4

No®Go To 11

4 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit while fully depressing the clutch pedal and turning the ignition switch

to the START position.

Does the test light illuminate with the ignition switch in the START position?All

Ye s®Go To 5

No®Go To 9

5 Turn the ignition off.

Remove the Starter Relay From the PDC.

Install a substitute relay in place of the Starter Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s®Replace the Starter Relay.

Perform NO START VERIFICATION - VER-1.

No®Go To 6

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to ground, probe ECM harness connector cavity

49 while fully depressing the clutch pedal and turning the ignition switch to the

START position.

Does the test light illuminate while the ignition is in the Start position.All

Ye s®Go To 7

No®Repair the Ignition Switch Start Output circuit to the ECM.

Perform NO START VERIFICATION - VER-1.

211

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1431 of 4284

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Remove the ECM/PCM Relay from the IPM.

Using a jumper wire, connect ECM/PCM relay connector cavities 30 and 87 in the

IPM.

Turn the ignition on.

Measure the voltage of the Starter Relay Control circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Starter Relay Control circuit for a short to voltage.

Perform NO START VERIFICATION - VER-1.

No®Go To 8

8 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Turn the ignition on.

Measure the resistance of the Starter Relay Control circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace and program the ECM in accordance with the Service

Information.

Perform NO START VERIFICATION - VER-1.

No®Repair the Starter Relay Control circuit for an open.

Perform NO START VERIFICATION - VER-1.

9 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Clutch Interlock Switch harness connector.

Connect a jumper wire across the Clutch Interlock Switch harness connector.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit at the Starter Relay connector in the PDC and turning the ignition

switch to the crank position.

Does the test light illuminate with the ignition switch in the crank position?All

Ye s®Replace the Clutch Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Go To 10

10 Turn the ignition off.

Disconnect the Clutch Interlock Switch harness connector.

Remove the Starter Relay from the PDC.

Measure the resistance of the Clutch Interlock Switch Output circuit between the

PDC and the Clutch Interlock Switch harness connector.

Is the resistance below 10.0 ohms?All

Ye s®Repair the Ignition Switch Start Output circuit to the Clutch

Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Repair the Clutch Interlock Switch Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

212

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1432 of 4284

TEST ACTION APPLICABILITY

11 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Is the test light on?All

Ye s®Go To 12

No®Repair the Fused B(+) circuit for an open.

Perform NO START VERIFICATION - VER-1.

12 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Starter Relay Output wire from the Starter Solenoid.

Connect the Starter Relay Output wire (at the Starter) to ground.

Using a 12-volt test light connected to 12-volts, check the Starter Relay Output

circuit at the Starter Relay connector in the IPM.

Does the test light illuminate brightly?All

Ye s®Go To 13

No®Repair the Starter Relay Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

13 Using the Service Information, check the battery cables for high resistance.

Did either battery cable have a voltage drop greater than 0.2 volts?All

Ye s®Replace the battery cable(s).

Perform NO START VERIFICATION - VER-1.

No®Go To 14

14 Turn the ignition off.

Attempt to manually rotate the crankshaft 360É.

Is the crankshaft able to rotate 360É?All

Ye s®Replace the Starter Motor.

Perform NO START VERIFICATION - VER-1.

No®Repair the engine mechanical problem.

Perform NO START VERIFICATION - VER-1.

213

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1492 of 4284

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 5).

This symbol on the front of an oil container means

that the oil has been certified by the American Petro-

leum Institute (API) to meet all the lubrication

requirements specified by DaimlerChrysler.

FLEXIBLE FUEL ENGINE OIL - 3.3L

Engine Oil Selection for Operating on E-85 Fuel

If vehicle operates on E-85 fuel either full or part-

time, use only MopartFlexible Fuel 5W-30 engine oil

or an equivalent that meets DaimlerChrysler Stan-

dard MS-9214. Equivalent commercial Flexible Fuel

engine oils may be labeled as Multi-Fuel, Variable

Fuel, Flexible Fuel, etc. These engine oils may be

satisfactory if they meet the DaimlerChrysler Stan-

dard.

SAE 5W-30 engine oil is preferred for use in Flex-

ible Fuel engines.

CAUTION: If Flexible Fuel engine oil is not used

when using E-85 fuel, engine wear or damage may

result.

DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to the maintenance schedules for the

recommended maintenance (fluid/filter change)

intervals for this transaxle.

NOTE: For fluid level checking procedures, (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/FLUID - STANDARD PROCEDURE) (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC - 41TE/

FLUID - STANDARD PROCEDURE)NOTE: The 41TE transaxle has a common transmis-

sion and differential sump. Filling the transaxle

accommodates the differential as well.

TRANSMISSION FLUID

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) is required in this transaxle. Substitute

fluids can induce torque converter clutch shudder.

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown.This is normal.A dark brown/black fluid

accompanied with a burnt odor and/or deterioration

in shift quality may indicate fluid deterioration or

transmission component failure.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

DESCRIPTION - FUEL REQUIREMENTS

Your engine is designed to meet all emissions reg-

ulations and provide excellent fuel economy and per-

formance when using high quality unleaded gasoline

having an octane rating of 87. The use of premium

gasoline is not recommended. The use of premium

gasoline will provide no benefit over high quality reg-

ular gasoline, and in some circumstances may result

in poorer performance.

Light spark knock at low engine speeds is not

harmful to your engine. However, continued heavy

spark knock at high speeds can cause damage and

immediate service is required. Engine damage result-

ing from operation with a heavy spark knock may

not be covered by the new vehicle warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling and hesitations. If you experi-

ence these symptoms, try another brand of gasoline

before considering service for the vehicle.

Fig. 5 Engine Oil Container Standard Notations

0 - 4 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

Page 1493 of 4284

Over 40 auto manufacturers world-wide have

issued and endorsed consistent gasoline specifications

(the Worldwide Fuel Charter, WWFC) to define fuel

properties necessary to deliver enhanced emissions,

performance and durability for your vehicle. We rec-

ommend the use of gasolines that meet the WWFC

specifications if they are available.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as ªreformulat-

edº gasoline. Reformulated gasoline contain oxygen-

ates, and are specifically blended to reduce vehicle

emissions and improve air quality.

We strongly supports the use of reformulated gas-

oline. Properly blended reformulated gasoline will

provide excellent performance and durability for the

engine and fuel system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as 10% ethanol, MTBE, and ETBE.

Oxygenates are required in some areas of the country

during the winter months to reduce carbon monoxide

emissions. Fuels blended with these oxygenates may

be used in your vehicle.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT IN GASOLINE

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase octane.

Gasoline blended with MMT provide no performance

advantage beyond gasoline of the same octane num-

ber without MMT. Gasoline blended with MMT

reduce spark plug life and reduce emission system

performance in some vehicles. We recommend that

gasolines free of MMT be used in your vehicle. The

MMT content of gasoline may not be indicated on the

gasoline pump; therefore, you should ask your gaso-

line retailer whether or not his/her gasoline contains

MMT.

It is even more important to look for gasoline with-

out MMT in Canada because MMT can be used at

levels higher than allowed in the United States.

MMT is prohibited in Federal and California refor-

mulated gasoline.

SULFUR IN GASOLINE

If you live in the northeast United States, your

vehicle may have been designed to meet California

low emission standards with Cleaner-Burning Cali-

fornia reformulated gasoline with low sulfur. If such

fuels are not available in states adopting Californiaemission standards, your vehicles will operate satis-

factorily on fuels meeting federal specifications, but

emission control system performance may be

adversely affected. Gasoline sold outside of California

is permitted to have higher sulfur levels which may

affect the performance of the vehicle's catalytic con-

verter. This may cause the Malfunction Indicator

Lamp (MIL), Check Engine or Service Engine Soon

light to illuminate. We recommend that you try a dif-

ferent brand of unleaded gasoline having lower sulfur

to determine if the problem is fuel related prior to

returning your vehicle to an authorized dealer for

service.

CAUTION: If the Malfunction Indicator Lamp (MIL),

Check Engine or Service Engine Soon light is flash-

ing, immediate service is required; see on-board

diagnostics system section.

MATERIALS ADDED TO FUEL

All gasoline sold in the United States and Canada

are required to contain effective detergent additives.

Use of additional detergents or other additives is not

needed under normal conditions.

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicle's performance:

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of Daimler-

Chrysler Corporation and may not be covered under

the new vehicle warranty.

RSLUBRICATION & MAINTENANCE0-5

FLUID TYPES (Continued)

Page 1495 of 4284

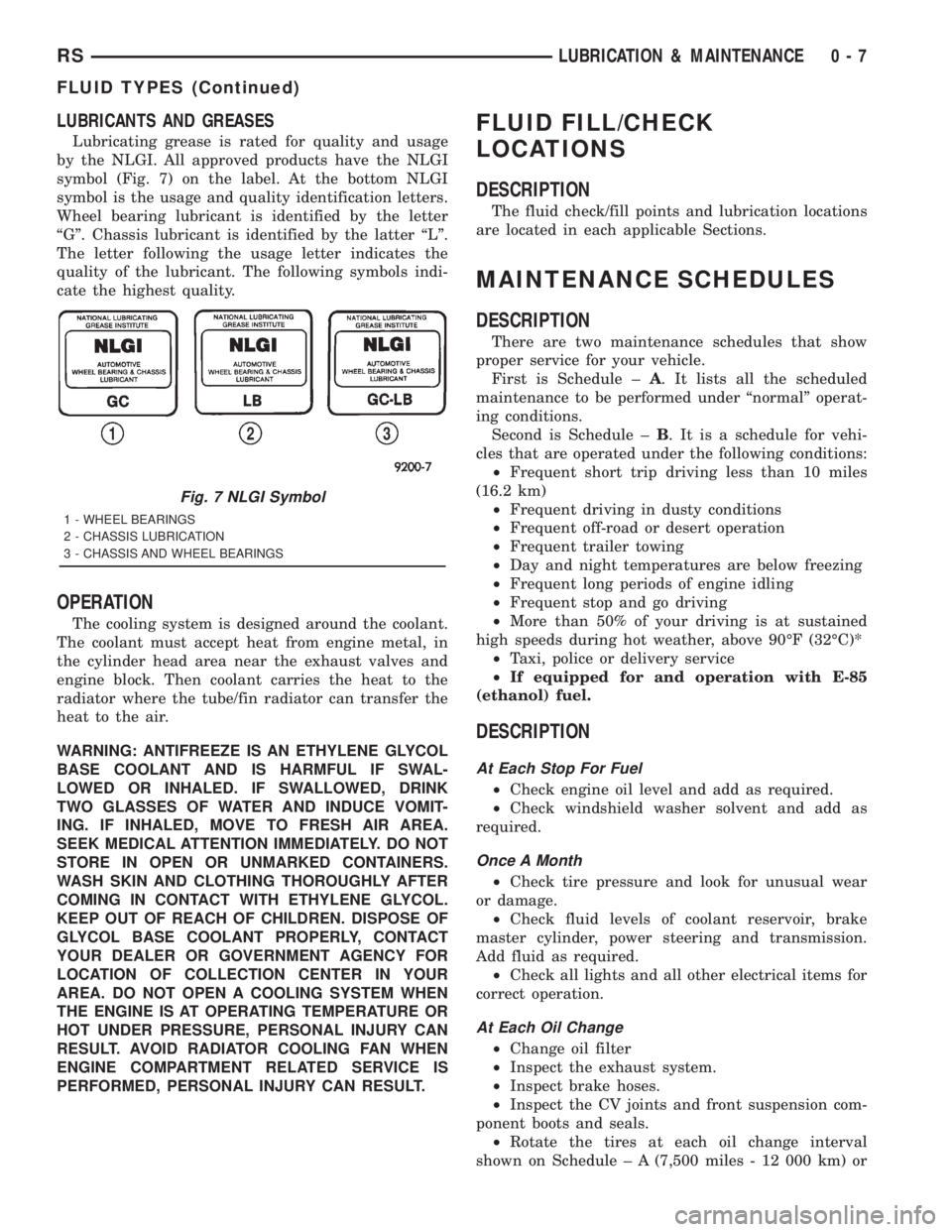

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 7) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

OPERATION

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fluid check/fill points and lubrication locations

are located in each applicable Sections.

MAINTENANCE SCHEDULES

DESCRIPTION

There are two maintenance schedules that show

proper service for your vehicle.

First is Schedule ±A. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is Schedule ±B. It is a schedule for vehi-

cles that are operated under the following conditions:

²Frequent short trip driving less than 10 miles

(16.2 km)

²Frequent driving in dusty conditions

²Frequent off-road or desert operation

²Frequent trailer towing

²Day and night temperatures are below freezing

²Frequent long periods of engine idling

²Frequent stop and go driving

²More than 50% of your driving is at sustained

high speeds during hot weather, above 90ÉF (32ÉC)*

²Taxi, police or delivery service

²If equipped for and operation with E-85

(ethanol) fuel.

DESCRIPTION

At Each Stop For Fuel

²Check engine oil level and add as required.

²Check windshield washer solvent and add as

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission.

Add fluid as required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change oil filter

²Inspect the exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponent boots and seals.

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles - 12 000 km) or

Fig. 7 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

RSLUBRICATION & MAINTENANCE0-7

FLUID TYPES (Continued)

Page 1511 of 4284

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fluid check/fill points and lubrication locations

are located in each applicable service manual section.

MAINTENANCE SCHEDULES

MAINTENANCE SCHEDULES - DIESEL ENGINE

There are two maintenance schedules that show

proper service for the vehicle.

First is ScheduleªAº. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is ScheduleªBº. It is a schedule for vehi-

cles that are operated under the conditions listed at

the beginning of the schedule.

Use the schedule that best describes the driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

At Each Stop for Fuel

²Check the engine oil level, add as required.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check the tire pressure and look for unusual

wear or damage.

²Inspect the battery and clean and tighten termi-

nals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check the rubber seals on each side of the radi-

ator for proper fit.

At Each Oil Change

²Replace the engine oil filter at each oil change.

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on schedule ªAº 20 000 km or every other

interval shown on schedule ªBº 20 000 km.

²Check the coolant level, hoses, and clamps.

²Inspect brake linings, hoses and calipers.

²Inspect engine accessory drive belts.

²Inspect for presence of water in fuel filter/water

separator, drain if necessary.

SCHEDULE ªAº

20 000 km (12 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

40 000 km (24 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

60 000 km (37 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

80 000 km (49 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

100 000 km (62 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

120 000 km (75 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

140 000 km (86 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

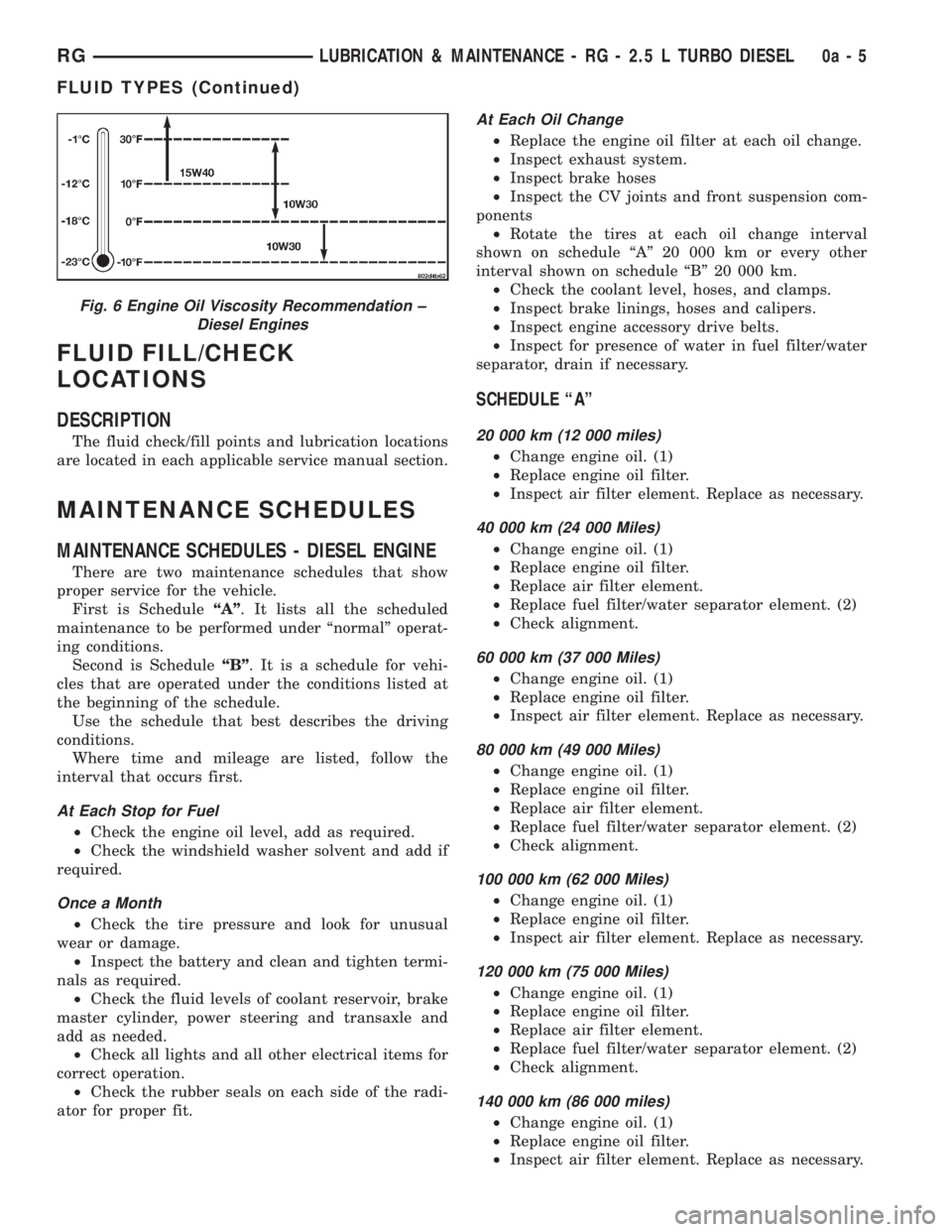

Fig. 6 Engine Oil Viscosity Recommendation ±

Diesel Engines

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-5

FLUID TYPES (Continued)