set clock CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 310 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Turn the ignition on.

Measure the voltage of the KDB Data circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the KDB Data circuit for a short to voltage.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and the red and

black test probes.

Connect the scope input cable to the channel one connector on the DRB. Attach the

red and black leads and the cable to probe adapter to the scope input cable.

Select Lab Scope.

Select Live.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the arrows to set the voltage range to 20 volts, the Offset to 4.0, and

the Probe to x10. Press F2 again and set the divisions to 40ms/Div, then press F2

again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the KDB Clock

circuit in the Rear Automatic Temperature Control Switch harness connector.

Turn the ignition on.

Observe the voltage display on the DRB Lab Scope.

NOTE: The lab scope pattern should look similar to the example given in the

support material and cycle from approximately 0 volts to 8.0 volts.

Did the lab scope pattern and voltage react as noted above?All

Ye s®Go To 6

No®Go To 7

6 If there are no possible causes remaining, view repair. All

Repair

Replace the Rear Automatic Temperature Control Switch.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

7 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Turn the ignition on.

Measure the voltage of the KDB Clock circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the KDB Clock circuit for a short to voltage.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 8

281

AUTOMATIC TEMPERATURE CONTROL

REAR KEYBOARD FAULT (ACTIVE) ÐContinued

Page 311 of 4284

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Measure the resistance between ground and the KDB Clock circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 9

No®Repair the KDB Clock circuit for a short to ground.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

9 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Measure the resistance of the KDB Clock circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 10

No®Repair the KDB Clock circuit for an open.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

10 If there are no possible causes remaining, view repair. All

Repair

Replace the ATC.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

11 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Measure the resistance between ground and the KDB Data circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 12

No®Repair the KDB Data circuit for a short to ground.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

12 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Measure the resistance of the KDB Data circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 13

No®Repair the KDB Data circuit for an open.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

282

AUTOMATIC TEMPERATURE CONTROL

REAR KEYBOARD FAULT (ACTIVE) ÐContinued

Page 1614 of 4284

lock the front wheels first. Any torque transfer from

the rear axle to the front axle disturbs the ABS/brak-

ing system and causes potential instabilities on a

slippery surface. The BOC de-couples the rear driv-

eline as soon the rear wheels begin to spin faster

than the front wheels (front wheels locked) in order

to provide increased braking stability. Furthermore

the BOC also reduces the likelihood of throttle off

over-steer during cornering. In a throttle off maneu-

ver, the BOC once again de-couples the rear driveline

forcing all the engine brake torque to the front

wheels. This eliminates the chance of lateral slip on

the rear axle and increases it on the front. The vehi-

cle will therefore tend to understeer, a situation

which is considered easier to manage in most circum-

stances. During this maneuver, and during the ABS

braking event, the BOC does not transmit torque

through to the rear wheels. The rear driveline mod-

ule, with the BOC, will perform the same as a front

wheel drive vehicle during these events. The gear

ratio offset between the front and rear differentials

force the BOC into the overrunning mode most of the

time. This allows BOC to significantly reduce the

rolling resistance of the vehicle, which improves fuel

consumption, allows the downsizing of the driveline

components, and prevents the PTU and propshaft

joints from overheating.

OPERATION

In order to achieve all-wheel drive operation in

reverse, the overrunning clutch locking functional

direction must be reversible. The bi-directional over-

running clutch (BOC) changes the operational mode

direction depending on the propeller shaft direction.

The propeller shaft rotates in the clockwise (when

viewed from the front) direction when the vehicle is

moving forward, which indexes the BOC to the for-

ward overrunning position. When the vehicle is in

reverse, the propeller shaft will rotate counter-clock-

wise and index the BOC to the reverse overrunning

position.

The BOC acts as a mechanical stator. It is active

(transmitting torque), or it is not active and in over-

running mode (not transmitting torque). This ªall or

nothingº approach to torque transfer would cause a

sudden application of all available power to the rear

wheels, which is not desirable. Therefore it is run in

series with a viscous coupler to smooth, dampen, and

limit the transmission of torque to the rear axle and

to prevent a step style torque input to the rear axle.

STEADY STATE, LOW TO MODERATE SPEED, NO

FRONT WHEEL SLIP, FORWARD DIRECTION

During normal driving conditions, (no wheel slip),

the inner shaft (front axle) and outer race (viscous

coupler) are running at different speeds due to the

different gear ratios between the front and rear dif-

ferentials. In this condition, the outer race is always

spinning faster (overdriving between 5-32 rpm) than

the inner shaft. When the BOC (Fig. 29) is running

under these conditions, at low vehicle speeds the

drag shoes and the cage keep the rollers up on the

left side (forward side) of the inner shaft flats. This is

what is known as ªoverrunning mode.º Notice that

when the clutch is in overrunning mode, the rollers

are spinning clockwise and with the outer race, thus

no torque is being transferred.

NOTE: Low speed, forward and reverse operation is

identical, just in opposite directions. (Fig. 29)

shows forward direction in reverse the rollers are

on the other side of the flats due to a reversal of

the cage force.

TRANSIENT CONDITION (BOC LOCKED), FRONT

WHEEL SLIP, FORWARD DIRECTION

When the front wheels lose traction and begin to

slip, the propeller shaft and rear axle pinion speed

difference decreases to zero. At this point the input

shaft (cam) becomes the driving member of the BOC

(Fig. 30), compressing the rollers against the outer

race. This locks the input shaft with the outer race

and transmits torque to the housing of the viscous

coupler, that in turn transmits torque to the rear

axle pinion. It should also be noted that when the

device is locked, the inner shaft and the outer race

are rotating at the same speed. The rollers are

pinched at this point and will stay locked until a

torque reversal (no front wheel slip) occurs. When

locked, the viscous coupler slips during the torque

transfer and the amount of torque transferred is

dependent on the coupling characteristic and the

amount of front wheel slip.

3 - 38 REAR DRIVELINE MODULERS

BI-DIRECTIONAL OVERRUNNING CLUTCH (Continued)

Page 1756 of 4284

DIAGNOSIS AND TESTING - ENGINE COOLANT

THERMOSTAT

The thermostat is operated by a wax filled cham-

ber (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.

Thermostat diagnostics is included in powertrain

control module's (PCM) programing for on-board

diagnosis. The malfunction indicator light (MIL) will

illuminate and a diagnostic trouble code (DTC) will

be set when an ªopen too soonº condition occurs. Do

not change a thermostat for lack of heater perfor-

mance or temperature gauge position, unless a DTC

is present. For other probable causes, (Refer to 7 -

COOLING/ENGINE - DIAGNOSIS AND TESTING) .

Thermostat failing shut is the normal long term

mode of failure, and normally, only on high mileage

vehicles. The temperature gauge will indicate this

(Refer to 7 - COOLING/ENGINE - DIAGNOSIS AND

TESTING) .

ENGINE COOLANT

THERMOSTAT - 2.4L

REMOVAL

(1) Drain cooling system below the thermostat

level. (Refer to 7 - COOLING - STANDARD PROCE-

DURE)

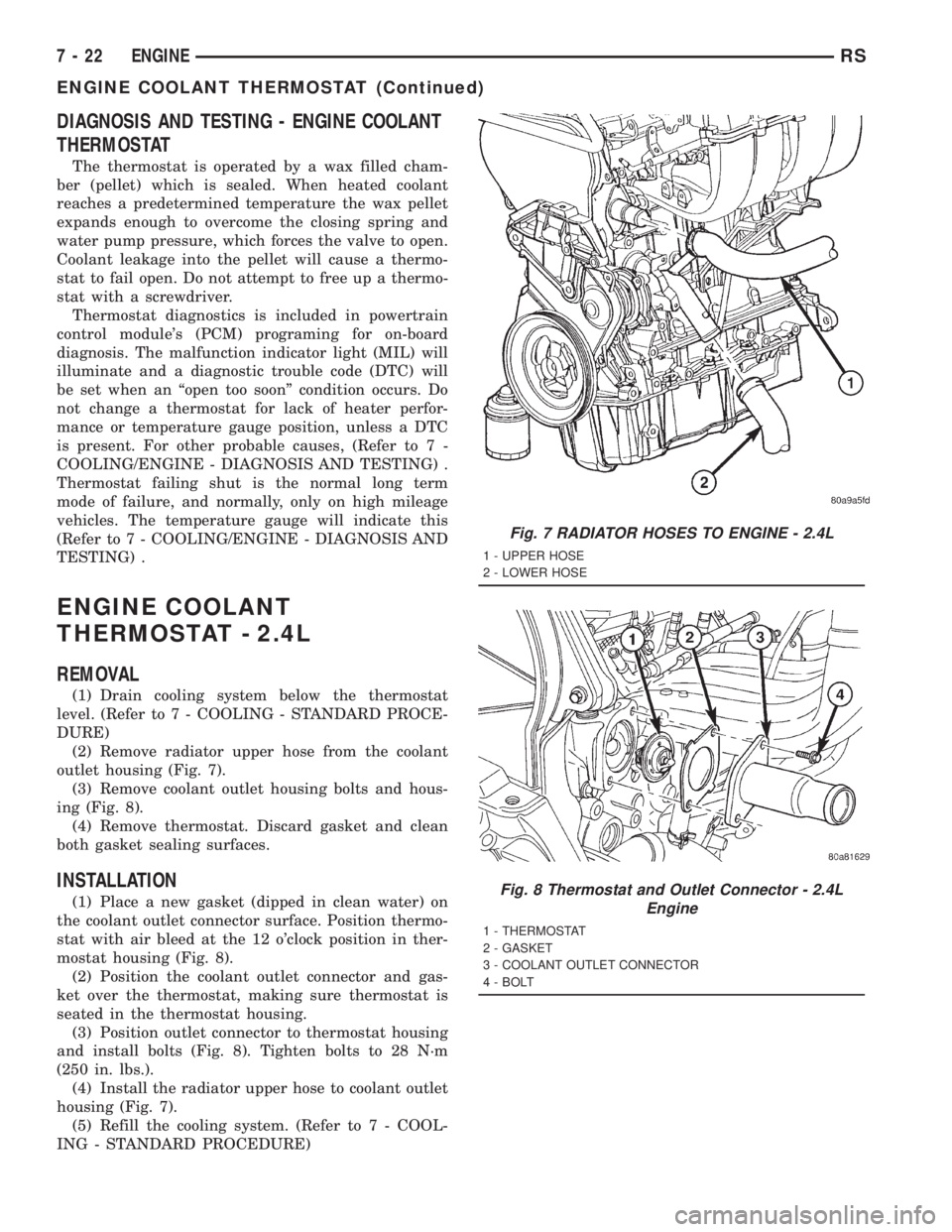

(2) Remove radiator upper hose from the coolant

outlet housing (Fig. 7).

(3) Remove coolant outlet housing bolts and hous-

ing (Fig. 8).

(4) Remove thermostat. Discard gasket and clean

both gasket sealing surfaces.

INSTALLATION

(1) Place a new gasket (dipped in clean water) on

the coolant outlet connector surface. Position thermo-

stat with air bleed at the 12 o'clock position in ther-

mostat housing (Fig. 8).

(2) Position the coolant outlet connector and gas-

ket over the thermostat, making sure thermostat is

seated in the thermostat housing.

(3) Position outlet connector to thermostat housing

and install bolts (Fig. 8). Tighten bolts to 28 N´m

(250 in. lbs.).

(4) Install the radiator upper hose to coolant outlet

housing (Fig. 7).

(5) Refill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

Fig. 7 RADIATOR HOSES TO ENGINE - 2.4L

1 - UPPER HOSE

2 - LOWER HOSE

Fig. 8 Thermostat and Outlet Connector - 2.4L

Engine

1 - THERMOSTAT

2 - GASKET

3 - COOLANT OUTLET CONNECTOR

4 - BOLT

7 - 22 ENGINERS

ENGINE COOLANT THERMOSTAT (Continued)

Page 1805 of 4284

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

ANTENNA BODY & CABLE

DESCRIPTION............................3

OPERATION.............................3

DIAGNOSIS AND TESTING..................3

REMOVAL...............................4

INSTALLATION............................4

CD CHANGER

DESCRIPTION............................6

OPERATION.............................6

REMOVAL...............................6

INSTALLATION............................6

CHOKE

DIAGNOSIS AND TESTING..................6

D-PILLAR SPEAKER

REMOVAL...............................6

INSTALLATION............................7

DASH PANEL SPEAKER

REMOVAL...............................7INSTALLATION............................7

DOOR MOUNTED SPEAKER

REMOVAL...............................7

INSTALLATION............................7

QUARTER PANEL SPEAKER

REMOVAL...............................8

INSTALLATION............................8

RADIO

DIAGNOSIS AND TESTING..................8

REMOVAL...............................9

INSTALLATION............................9

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION............................9

OPERATION.............................9

REMOTE SWITCHES

DESCRIPTION...........................10

OPERATION.............................10

DIAGNOSIS AND TESTING.................11

REMOVAL..............................11

INSTALLATION...........................12

AUDIO

DESCRIPTION

There are four different system combinations avail-

able on the RS models. The available radio options

are:

²AM/FM Cassette

²AM/FM Compact Disc with Compact Disc

Changer

²AM/FM Cassette with single Compact Disc

Player

²AM/FM Cassette with Compact Disc Changer

All factory installed radio receivers are stereo Elec-

tronically Tuned Radios (ETR) and include and elec-

tronic digital clock function.

OPERATION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with this vehicle.

DIAGNOSIS AND TESTING

WARNING:

ON VEHICLES EQUIPPED WITH AIRBAGS, REFER

TO ELECTRICAL, RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

RSAUDIO8A-1

Page 1814 of 4284

REMOTE SWITCHES

DESCRIPTION

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 15). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Chrysler Collision Detection (CCD)

data bus network to the radio receiver. For diagnosis

of the BCM or the CCD data bus, the use of a DRB

scan tool and the proper Diagnostic Procedures man-

ual are recommended. For more information on the

operation of the remote radio switch controls, refer to

the owner's manual in the vehicle glove box.

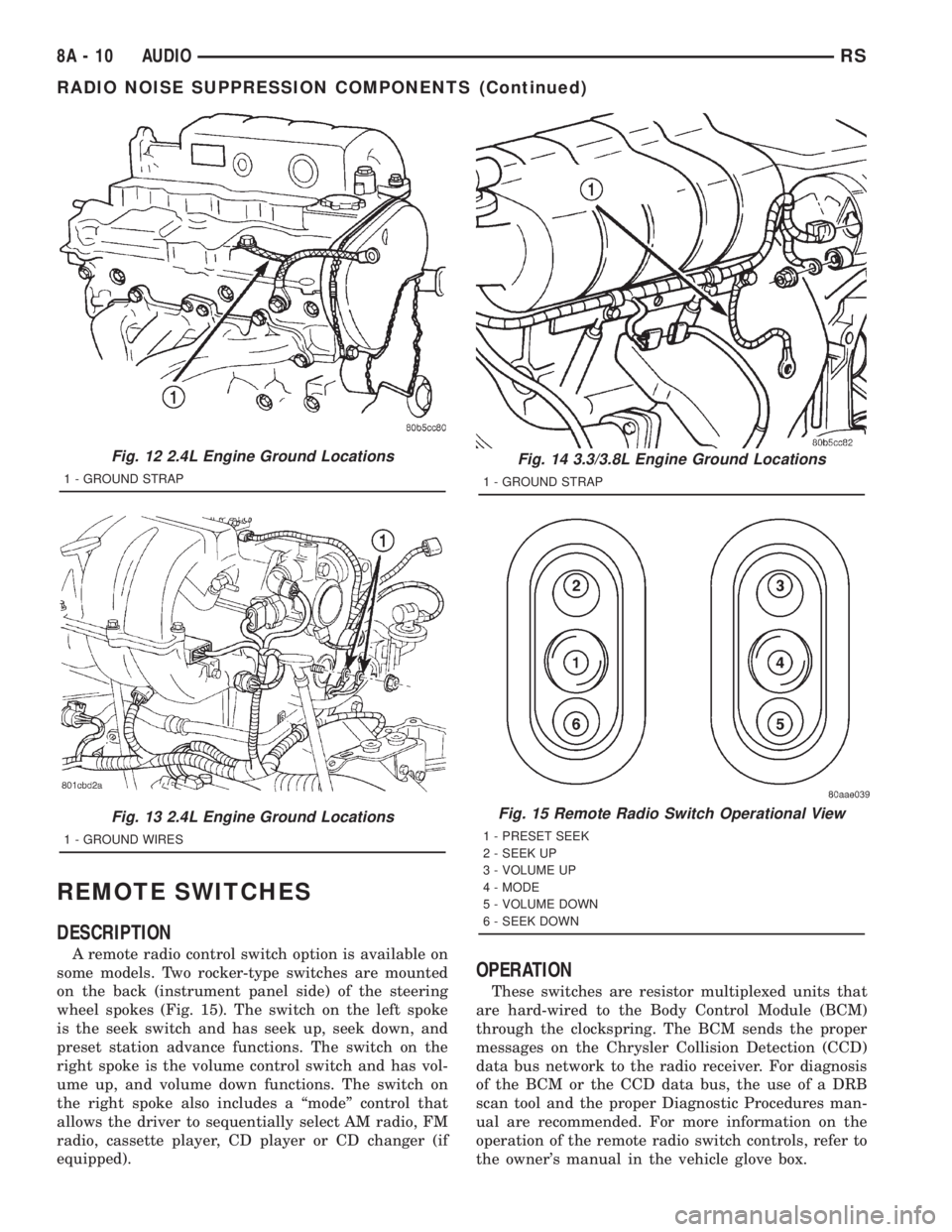

Fig. 12 2.4L Engine Ground Locations

1 - GROUND STRAP

Fig. 13 2.4L Engine Ground Locations

1 - GROUND WIRES

Fig. 14 3.3/3.8L Engine Ground Locations

1 - GROUND STRAP

Fig. 15 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

8A - 10 AUDIORS

RADIO NOISE SUPPRESSION COMPONENTS (Continued)

Page 1954 of 4284

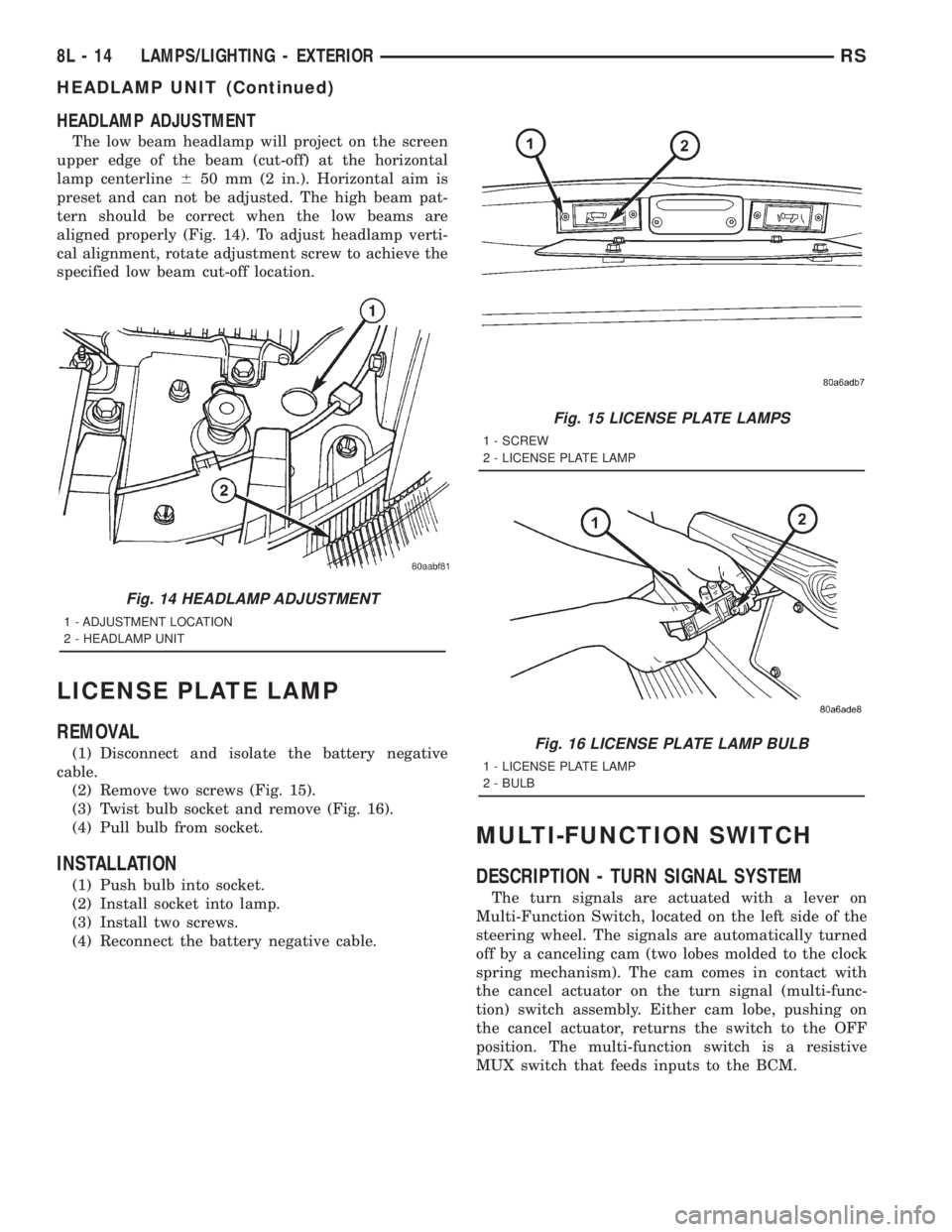

HEADLAMP ADJUSTMENT

The low beam headlamp will project on the screen

upper edge of the beam (cut-off) at the horizontal

lamp centerline650 mm (2 in.). Horizontal aim is

preset and can not be adjusted. The high beam pat-

tern should be correct when the low beams are

aligned properly (Fig. 14). To adjust headlamp verti-

cal alignment, rotate adjustment screw to achieve the

specified low beam cut-off location.

LICENSE PLATE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two screws (Fig. 15).

(3) Twist bulb socket and remove (Fig. 16).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into lamp.

(3) Install two screws.

(4) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The turn signals are actuated with a lever on

Multi-Function Switch, located on the left side of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position. The multi-function switch is a resistive

MUX switch that feeds inputs to the BCM.

Fig. 14 HEADLAMP ADJUSTMENT

1 - ADJUSTMENT LOCATION

2 - HEADLAMP UNIT

Fig. 15 LICENSE PLATE LAMPS

1 - SCREW

2 - LICENSE PLATE LAMP

Fig. 16 LICENSE PLATE LAMP BULB

1 - LICENSE PLATE LAMP

2 - BULB

8L - 14 LAMPS/LIGHTING - EXTERIORRS

HEADLAMP UNIT (Continued)

Page 1972 of 4284

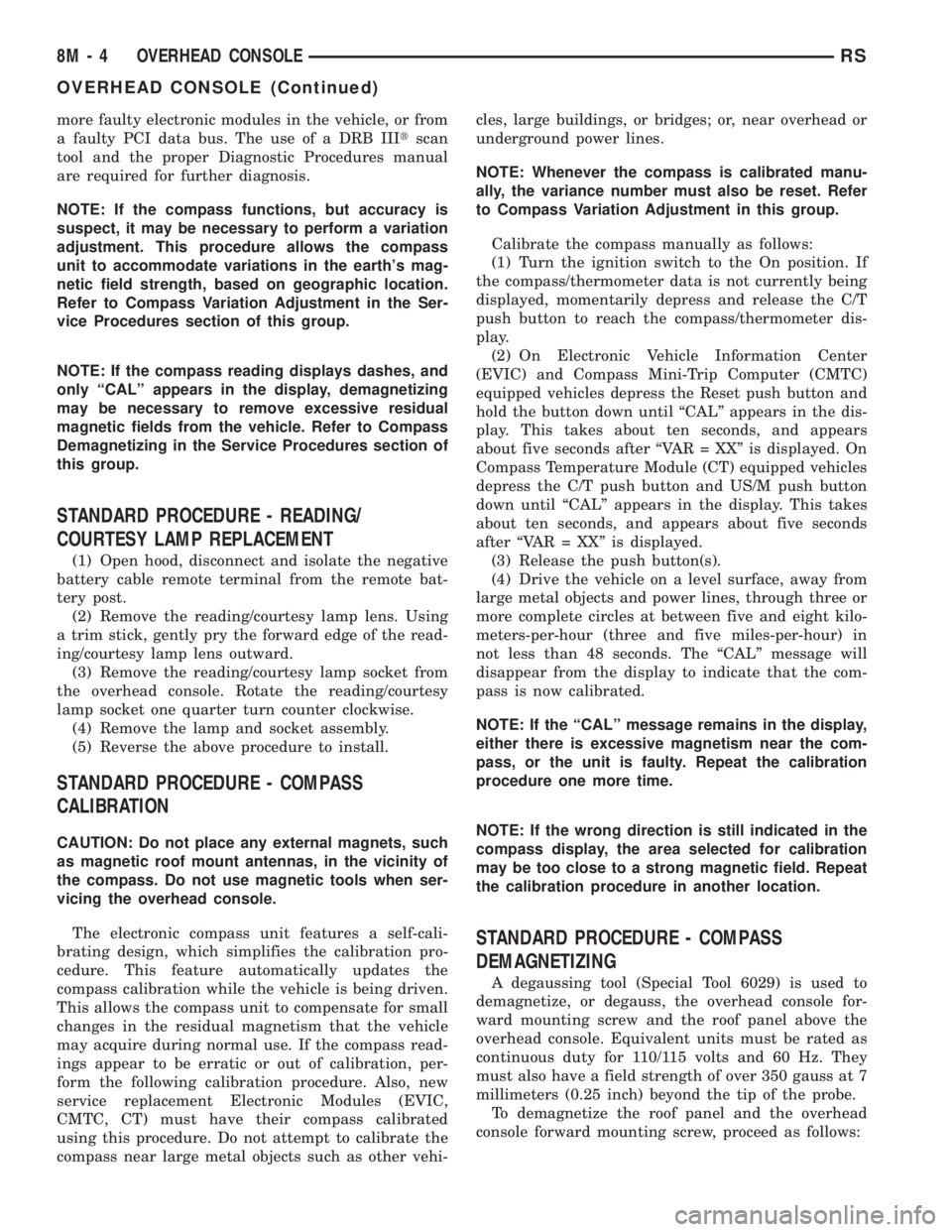

more faulty electronic modules in the vehicle, or from

a faulty PCI data bus. The use of a DRB IIItscan

tool and the proper Diagnostic Procedures manual

are required for further diagnosis.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Ser-

vice Procedures section of this group.

NOTE: If the compass reading displays dashes, and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Service Procedures section of

this group.

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable remote terminal from the remote bat-

tery post.

(2) Remove the reading/courtesy lamp lens. Using

a trim stick, gently pry the forward edge of the read-

ing/courtesy lamp lens outward.

(3) Remove the reading/courtesy lamp socket from

the overhead console. Rotate the reading/courtesy

lamp socket one quarter turn counter clockwise.

(4) Remove the lamp and socket assembly.

(5) Reverse the above procedure to install.

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.

The electronic compass unit features a self-cali-

brating design, which simplifies the calibration pro-

cedure. This feature automatically updates the

compass calibration while the vehicle is being driven.

This allows the compass unit to compensate for small

changes in the residual magnetism that the vehicle

may acquire during normal use. If the compass read-

ings appear to be erratic or out of calibration, per-

form the following calibration procedure. Also, new

service replacement Electronic Modules (EVIC,

CMTC, CT) must have their compass calibrated

using this procedure. Do not attempt to calibrate the

compass near large metal objects such as other vehi-cles, large buildings, or bridges; or, near overhead or

underground power lines.

NOTE: Whenever the compass is calibrated manu-

ally, the variance number must also be reset. Refer

to Compass Variation Adjustment in this group.

Calibrate the compass manually as follows:

(1) Turn the ignition switch to the On position. If

the compass/thermometer data is not currently being

displayed, momentarily depress and release the C/T

push button to reach the compass/thermometer dis-

play.

(2) On Electronic Vehicle Information Center

(EVIC) and Compass Mini-Trip Computer (CMTC)

equipped vehicles depress the Reset push button and

hold the button down until ªCALº appears in the dis-

play. This takes about ten seconds, and appears

about five seconds after ªVAR = XXº is displayed. On

Compass Temperature Module (CT) equipped vehicles

depress the C/T push button and US/M push button

down until ªCALº appears in the display. This takes

about ten seconds, and appears about five seconds

after ªVAR = XXº is displayed.

(3) Release the push button(s).

(4) Drive the vehicle on a level surface, away from

large metal objects and power lines, through three or

more complete circles at between five and eight kilo-

meters-per-hour (three and five miles-per-hour) in

not less than 48 seconds. The ªCALº message will

disappear from the display to indicate that the com-

pass is now calibrated.

NOTE: If the ªCALº message remains in the display,

either there is excessive magnetism near the com-

pass, or the unit is faulty. Repeat the calibration

procedure one more time.

NOTE: If the wrong direction is still indicated in the

compass display, the area selected for calibration

may be too close to a strong magnetic field. Repeat

the calibration procedure in another location.

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING

A degaussing tool (Special Tool 6029) is used to

demagnetize, or degauss, the overhead console for-

ward mounting screw and the roof panel above the

overhead console. Equivalent units must be rated as

continuous duty for 110/115 volts and 60 Hz. They

must also have a field strength of over 350 gauss at 7

millimeters (0.25 inch) beyond the tip of the probe.

To demagnetize the roof panel and the overhead

console forward mounting screw, proceed as follows:

8M - 4 OVERHEAD CONSOLERS

OVERHEAD CONSOLE (Continued)

Page 2067 of 4284

(4) Connect vacuum line to speed control servo

that leads to the battery tray/vacuum reservoir.

(5) Install speed control servo and bracket.

(6) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(7) Install speed control and throttle cable casing

to cable mount bracket.

(8) Connect the throttle and speed control cable

ends to throttle body.

(9) Connect the negative battery cable.

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system and are located on the

steering wheel.

OPERATION

The speed control system has five separate resis-

tive switches that provide a single multiplexed

(MUX) voltage inputs to the PCM.The switch names

are: ON, OFF, SET, COAST, RESUME, ACCEL, TAP-

UP, COAST, and CANCEL. Based on conditions when

the buttons are pushed (and released), the five volt-

ages ranges provided to the PCM result in the follow-

ing functions: ON, OFF, SET, COAST, RESUME,

ACCEL, TAP-UP, COAST, and CANCEL. Refer to the

Speed Control Section for more information

Also the PCM receives an input from the brake

switch to sense whether the brake pedal has been

depressed. When the PCM receives the brake

depressed input, it turns off power to the speed con-

trol servo and disengages speed control.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

REMOVAL

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Remove the negative battery cable.

(2) Turn off ignition.

(3) Remove the air bag, refer to the restraint sec-

tion for more information.

(4) Remove two screws from side of the switch.

(5) Remove switch from steering wheel.

(6) Disconnect two-way electrical connector.

(7) Repeat for the other switch.

INSTALLATION

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Connect two-way electrical connector.

(2) Install switch.

Fig. 3 BATTERY TRAY/VACUUM RESERVOIR

Fig. 4 SPEED CONTROL SERVO

RSSPEED CONTROL8P-5

SERVO (Continued)

Page 2686 of 4284

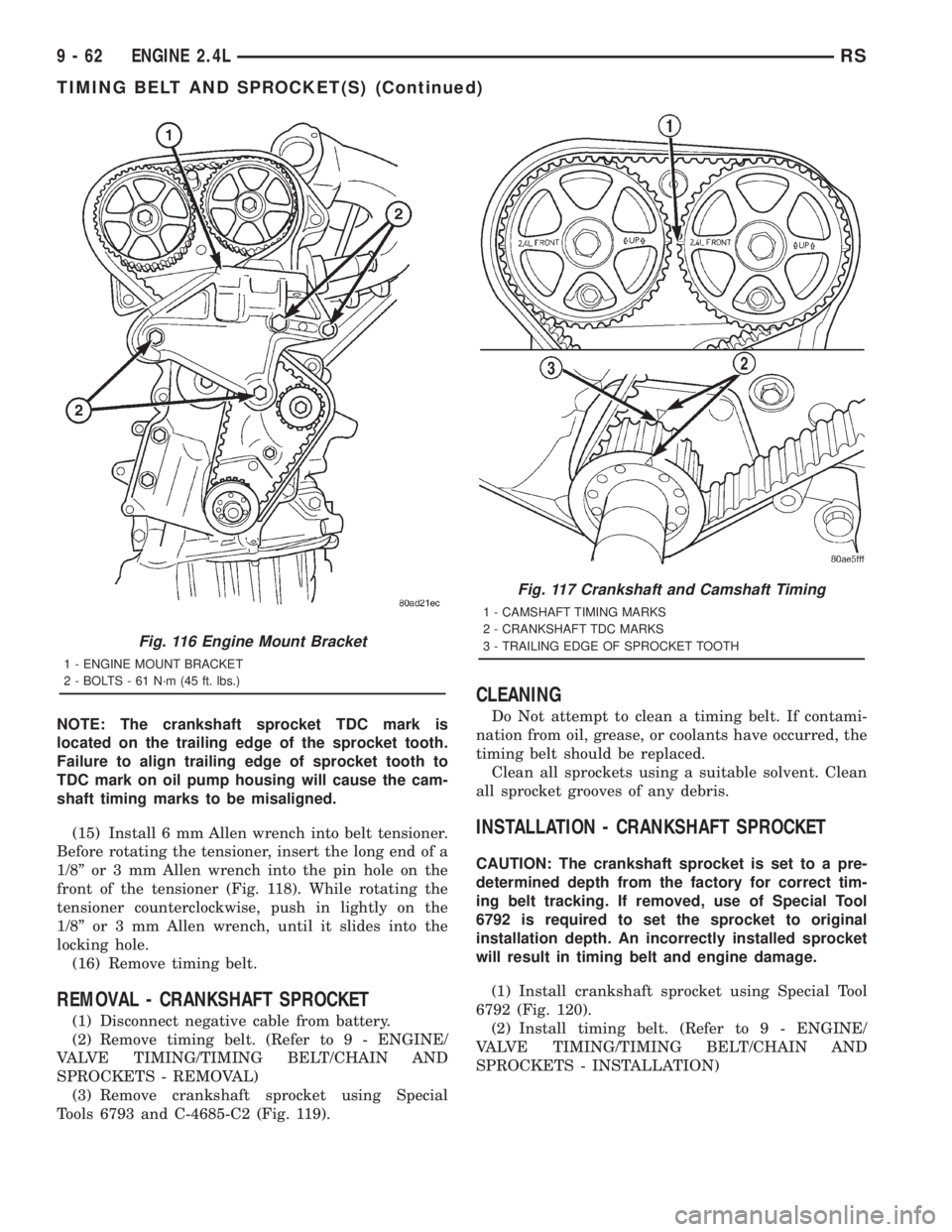

NOTE: The crankshaft sprocket TDC mark is

located on the trailing edge of the sprocket tooth.

Failure to align trailing edge of sprocket tooth to

TDC mark on oil pump housing will cause the cam-

shaft timing marks to be misaligned.

(15) Install 6 mm Allen wrench into belt tensioner.

Before rotating the tensioner, insert the long end of a

1/8º or 3 mm Allen wrench into the pin hole on the

front of the tensioner (Fig. 118). While rotating the

tensioner counterclockwise, push in lightly on the

1/8º or 3 mm Allen wrench, until it slides into the

locking hole.

(16) Remove timing belt.

REMOVAL - CRANKSHAFT SPROCKET

(1) Disconnect negative cable from battery.

(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Remove crankshaft sprocket using Special

Tools 6793 and C-4685-C2 (Fig. 119).

CLEANING

Do Not attempt to clean a timing belt. If contami-

nation from oil, grease, or coolants have occurred, the

timing belt should be replaced.

Clean all sprockets using a suitable solvent. Clean

all sprocket grooves of any debris.

INSTALLATION - CRANKSHAFT SPROCKET

CAUTION: The crankshaft sprocket is set to a pre-

determined depth from the factory for correct tim-

ing belt tracking. If removed, use of Special Tool

6792 is required to set the sprocket to original

installation depth. An incorrectly installed sprocket

will result in timing belt and engine damage.

(1) Install crankshaft sprocket using Special Tool

6792 (Fig. 120).

(2) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

Fig. 116 Engine Mount Bracket

1 - ENGINE MOUNT BRACKET

2 - BOLTS - 61 N´m (45 ft. lbs.)

Fig. 117 Crankshaft and Camshaft Timing

1 - CAMSHAFT TIMING MARKS

2 - CRANKSHAFT TDC MARKS

3 - TRAILING EDGE OF SPROCKET TOOTH

9 - 62 ENGINE 2.4LRS

TIMING BELT AND SPROCKET(S) (Continued)