center console CHRYSLER VOYAGER 2001 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2443 of 4284

Component Page

Intelligent Power Module C4.......... 8W-80-69

Intelligent Power Module C5.......... 8W-80-69

Intelligent Power Module C6.......... 8W-80-70

Intelligent Power Module C7.......... 8W-80-70

Intelligent Power Module C8.......... 8W-80-71

Intelligent Power Module C9.......... 8W-80-71

Knock Sensor (2.4L)................. 8W-80-71

Knock Sensor (3.3L/3.8L)............. 8W-80-71

Leak Detection Pump

(Except Built-Up-Export)........... 8W-80-72

Left B-Pillar Switch................. 8W-80-72

Left Cinch/Release Motor

(Power Sliding Door)............... 8W-80-72

Left Combination Relay (Trailer Tow).... 8W-80-72

Left Cylinder Lock Switch............. 8W-80-72

Left Door Speaker................... 8W-80-73

Left Fog Lamp..................... 8W-80-73

Left Front Door Ajar Switch (Base)...... 8W-80-73

Left Front Door Lock Motor/Ajar Switch

(Except Base).................... 8W-80-73

Left Front Park/Turn Signal Lamp (Except

Built-Up-Export).................. 8W-80-74

Left Front Wheel Speed Sensor......... 8W-80-74

Left Full Open Switch (Power Sliding Door). 8W-80-74

Left Headlamp (Except Built-Up-Export) . 8W-80-74

Left Headlamp Leveling Motor

(Built-Up-Export)................. 8W-80-74

Left High Beam Lamp (Built-Up-Export) . 8W-80-75

Left Instrument Panel Speaker......... 8W-80-75

Left Liftgate Flood Lamp............. 8W-80-75

Left Low Beam Lamp (Built-Up-Export) . . 8W-80-75

Left Mid Reading Lamp

(Premium/Luxury)................. 8W-80-75

Left Park Lamp (Built-Up-Export)...... 8W-80-76

Left Power Mirror................... 8W-80-76

Left Rear Lamp Assembly............. 8W-80-76

Left Rear Pillar Speaker.............. 8W-80-77

Left Rear Reading Lamp (Luxury)...... 8W-80-77

Left Rear Speaker................... 8W-80-77

Left Rear Vent Motor................ 8W-80-77

Left Rear Wheel Speed Sensor......... 8W-80-77

Left Remote Radio Switch............. 8W-80-78

Left Repeater Lamp (Built-Up-Export) . . . 8W-80-78

Left Seat Airbag.................... 8W-80-78

Left Side Impact Airbag Control Module . . 8W-80-78

Left Sliding Door Control Module C1

(Power Sliding Door)............... 8W-80-78

Left Sliding Door Control Module C2

(Power Sliding Door)............... 8W-80-79

Left Sliding Door Latch Sensing Switch

(Power Sliding Door)............... 8W-80-79

Left Sliding Door Lock Motor

(Power Sliding Door)............... 8W-80-79

Left Sliding Door Lock Motor/Ajar Switch

(Manual Sliding Door).............. 8W-80-80Component Page

Left Sliding Door Motor

(Power Sliding Door)............... 8W-80-80

Left Speed Control Switch............ 8W-80-80

Left Stop/Turn Signal Relay (Trailer Tow) . 8W-80-80

Left Turn Signal Lamp

(Built-Up-Export)................. 8W-80-81

Left Visor/Vanity Lamp

(Premium/Luxury)................. 8W-80-81

License Lamp (Manual Release)........ 8W-80-81

License Lamp (Power Liftgate)......... 8W-80-81

License Lamp (Power Release)......... 8W-80-82

Liftgate Ajar Switch (Manual Release) . . . 8W-80-82

Liftgate Ajar Switch (Power Release).... 8W-80-82

Liftgate Cinch/Release Motor

(Power Liftgate).................. 8W-80-82

Liftgate Cylinder Lock Switch.......... 8W-80-82

Liftgate Left Pinch Sensor

(Power Liftgate).................. 8W-80-83

Liftgate Right Pinch Sensor

(Power Liftgate).................. 8W-80-83

Lift Pump Motor (Diesel)............. 8W-80-83

Low Note Horn..................... 8W-80-83

Manifold Absolute Pressure

Sensor (Gas)..................... 8W-80-83

Mass Air Flow Sensor (Diesel)......... 8W-80-84

Memory Power Seat Switch........... 8W-80-84

Memory Seat/Mirror Module C1........ 8W-80-84

Memory Seat/Mirror Module C2........ 8W-80-85

Memory Seat/Mirror Module C3........ 8W-80-85

Memory Seat/Mirror Module C4........ 8W-80-86

Memory Seat Front Vertical Motor...... 8W-80-86

Memory Seat Front Vertical

Position Sensor................... 8W-80-86

Memory Seat Horizontal Motor......... 8W-80-86

Memory Seat Horizontal

Position Sensor................... 8W-80-86

Memory Seat Rear Vertical Motor....... 8W-80-87

Memory Seat Rear Vertical

Position Sensor................... 8W-80-87

Memory Seat Recliner Motor.......... 8W-80-87

Memory Seat Recliner Position Sensor . . . 8W-80-87

Memory Seat Switch................. 8W-80-87

Message Center (High Line)........... 8W-80-88

Mode Door Actuator (ATC)............ 8W-80-88

Mode Door Actuator (MTC)............ 8W-80-88

Multi-Function Switch............... 8W-80-88

Occupant Restraint Controller......... 8W-80-89

Overhead Console (Except Base)........ 8W-80-89

Oxygen Sensor 1/1 Upstream (Gas)...... 8W-80-90

Oxygen Sensor 1/2 Downstream (Gas) . . . 8W-80-90

Park/Neutral Position Switch (ATX)..... 8W-80-90

Passenger Airbag................... 8W-80-90

Passenger Blend Door Actuator (ATC) . . . 8W-80-90

Passenger Blend Door Actuator (MTC) . . . 8W-80-91

Passenger Door Courtesy Lamp........ 8W-80-91

RG8W-80 CONNECTOR PIN-OUTS8Wa-80-3

Page 2570 of 4284

Component/Ground Color Location Fig.

Memory Seat Rear Vertical Motor RD Under Seat N/S

Memory Seat Rear Vertical

Position SensorBK Under Seat N/S

Memory Seat Recliner Motor GN Under Seat N/S

Memory Seat Recliner Position

SensorBK Under Seat N/S

Memory Seat Switch BK At Switch Driver Door N/S

Message Center WT Rear of Message Center 16, 17, 23

Mode Door Actuator BK Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 16, 17, 18,

19, 26

Occupant Restraint Controller YL/RD Right Side of Instrument Panel 16, 20, 21

Output Speed Sensor GY Front of Transmission 15

Overhead Console BK Front of Console N/S

Oxygen Sensor 1/1 Upstream GY Rear of Engine 10, 11, 15

Oxygen Sensor 1/2 Downstream BK Rear of Engine 10, 11, 15

Park/Neutral Positon Switch BK Front of Transmission 11

Passenger Airbag YL Passenger Side of Instrument Panel 16, 19, 20,

25

Passenger Blend Door Actuator On HVAC N/S

Passenger Door Courtesy Lamp BK At Lamp 33

Passenger Door Lock Switch BK At Switch 33

Passenger Folding Mirror Relay BL Right Kick Panel N/S

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module

C1GY At Heated Seat N/S

Passenger Heated Seat Module

C2GY At Heated Seat Back N/S

Passenger Heated Seat Module

C3GN At Heated Seat N/S

Passenger Power Seat Front

Riser MotorRD Under Seat N/S

Passenger Power Seat Horizontal

MotorBK Under Seat N/S

Passenger Power Seat Rear

Riser MotorRD Under Seat N/S

Passenger Power Seat Recliner

MotorGN Under Seat N/S

Passenger Power Seat Switch GN At Switch N/S

Passenger Power Window Motor RD At Motor 33

Passenger Power Window Switch BK At Switch 33

Passenger Seatbelt Switch On Seat Harness N/S

Passenger Seatbelt Tensioner On Seat Harness N/S

Power Folding Mirror Switch BK Near Steering Column 26

8Wa - 90 - 8 8W-90 CONNECTOR/GROUND LOCATIONS BUXRG

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 3319 of 4284

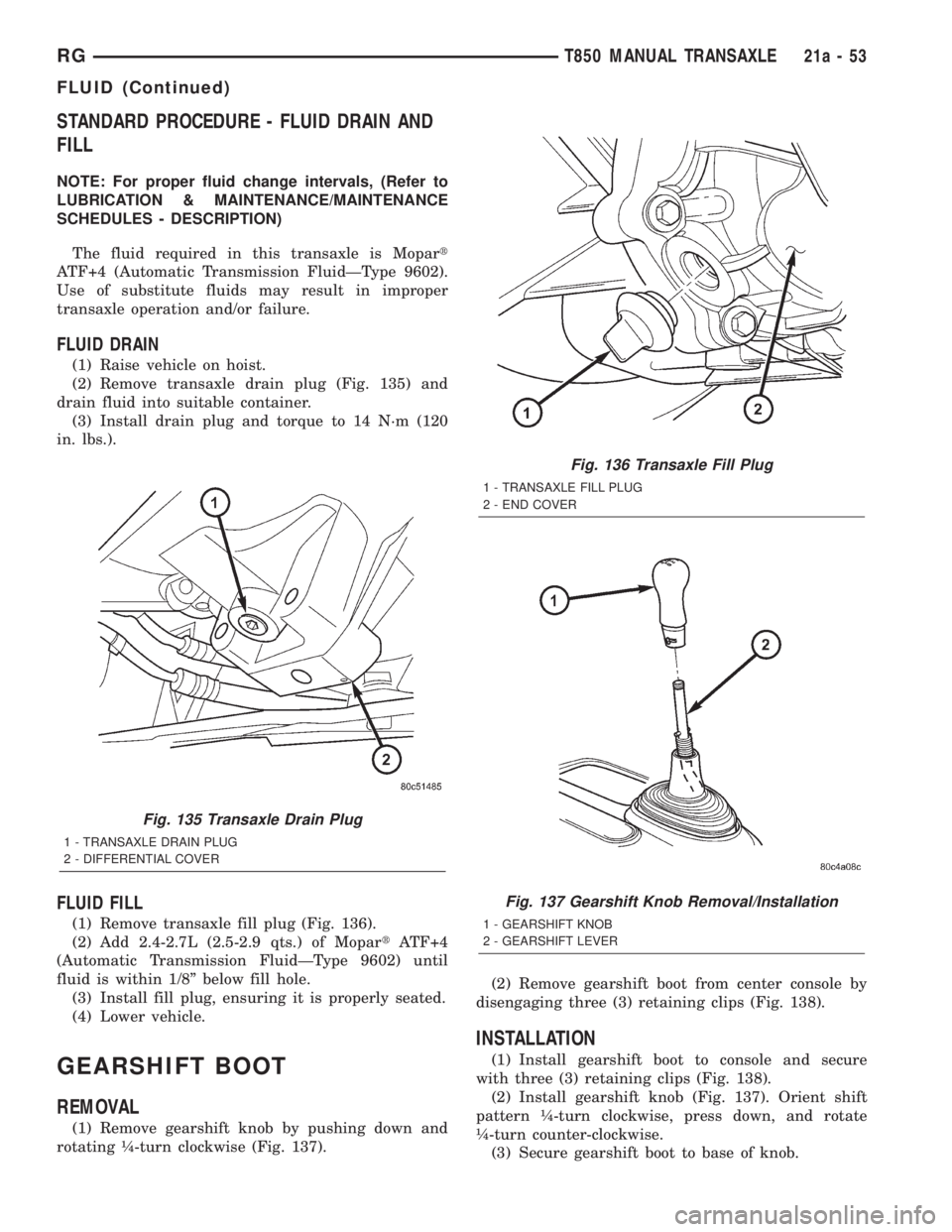

STANDARD PROCEDURE - FLUID DRAIN AND

FILL

NOTE: For proper fluid change intervals, (Refer to

LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

The fluid required in this transaxle is Mopart

ATF+4 (Automatic Transmission FluidÐType 9602).

Use of substitute fluids may result in improper

transaxle operation and/or failure.

FLUID DRAIN

(1) Raise vehicle on hoist.

(2) Remove transaxle drain plug (Fig. 135) and

drain fluid into suitable container.

(3) Install drain plug and torque to 14 N´m (120

in. lbs.).

FLUID FILL

(1) Remove transaxle fill plug (Fig. 136).

(2) Add 2.4-2.7L (2.5-2.9 qts.) of MopartATF+4

(Automatic Transmission FluidÐType 9602) until

fluid is within 1/8º below fill hole.

(3) Install fill plug, ensuring it is properly seated.

(4) Lower vehicle.

GEARSHIFT BOOT

REMOVAL

(1) Remove gearshift knob by pushing down and

rotating ò-turn clockwise (Fig. 137).(2) Remove gearshift boot from center console by

disengaging three (3) retaining clips (Fig. 138).

INSTALLATION

(1) Install gearshift boot to console and secure

with three (3) retaining clips (Fig. 138).

(2) Install gearshift knob (Fig. 137). Orient shift

pattern ò-turn clockwise, press down, and rotate

ò-turn counter-clockwise.

(3) Secure gearshift boot to base of knob.

Fig. 135 Transaxle Drain Plug

1 - TRANSAXLE DRAIN PLUG

2 - DIFFERENTIAL COVER

Fig. 136 Transaxle Fill Plug

1 - TRANSAXLE FILL PLUG

2 - END COVER

Fig. 137 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-53

FLUID (Continued)

Page 3320 of 4284

GEARSHIFT CABLE -

CROSSOVER

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 139).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 140).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

141).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

142).

Fig. 138 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 139 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 140 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 141 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 54 T850 MANUAL TRANSAXLERG

GEARSHIFT BOOT (Continued)

Page 3321 of 4284

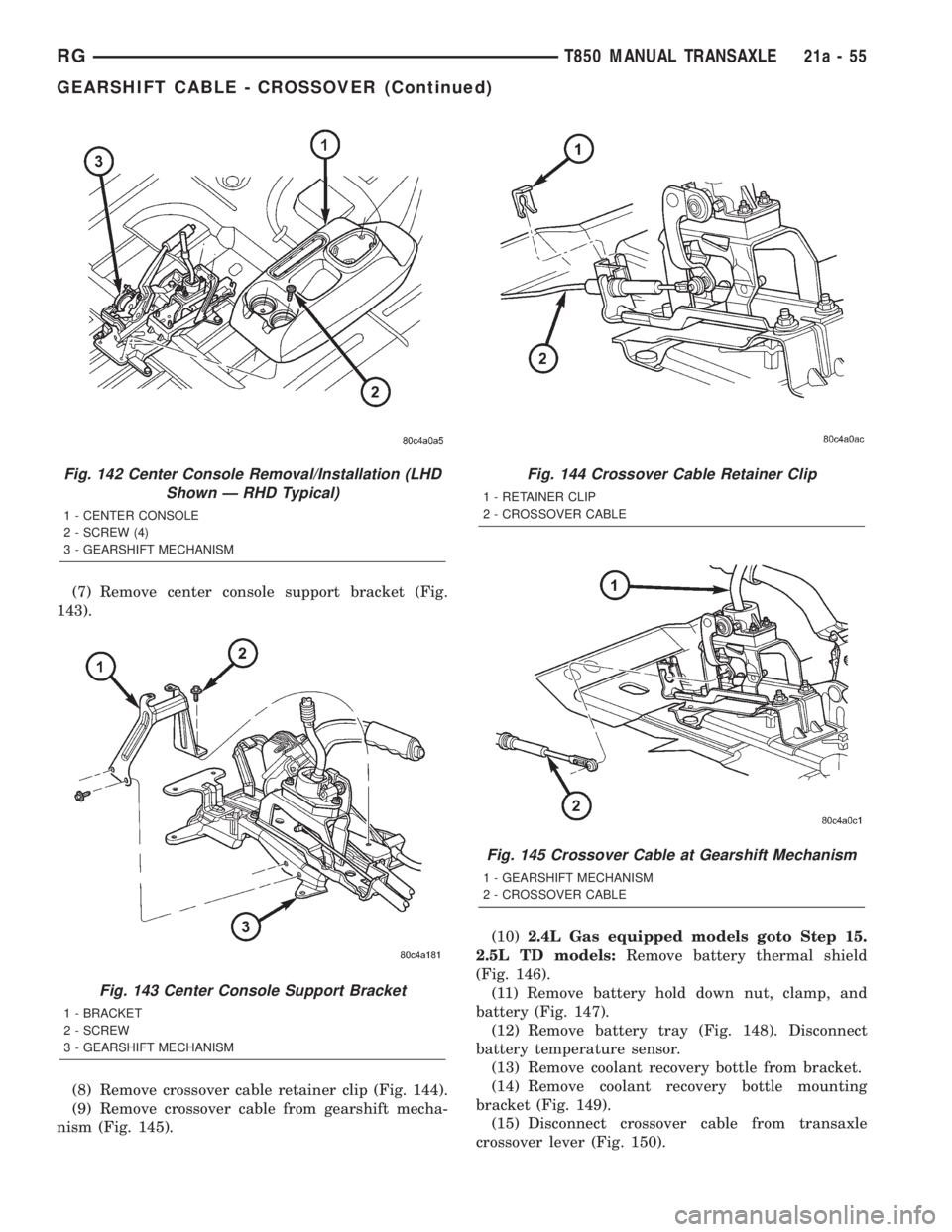

(7) Remove center console support bracket (Fig.

143).

(8) Remove crossover cable retainer clip (Fig. 144).

(9) Remove crossover cable from gearshift mecha-

nism (Fig. 145).(10)2.4L Gas equipped models goto Step 15.

2.5L TD models:Remove battery thermal shield

(Fig. 146).

(11) Remove battery hold down nut, clamp, and

battery (Fig. 147).

(12) Remove battery tray (Fig. 148). Disconnect

battery temperature sensor.

(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 149).

(15) Disconnect crossover cable from transaxle

crossover lever (Fig. 150).

Fig. 142 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 143 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 144 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 145 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

RGT850 MANUAL TRANSAXLE21a-55

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 3325 of 4284

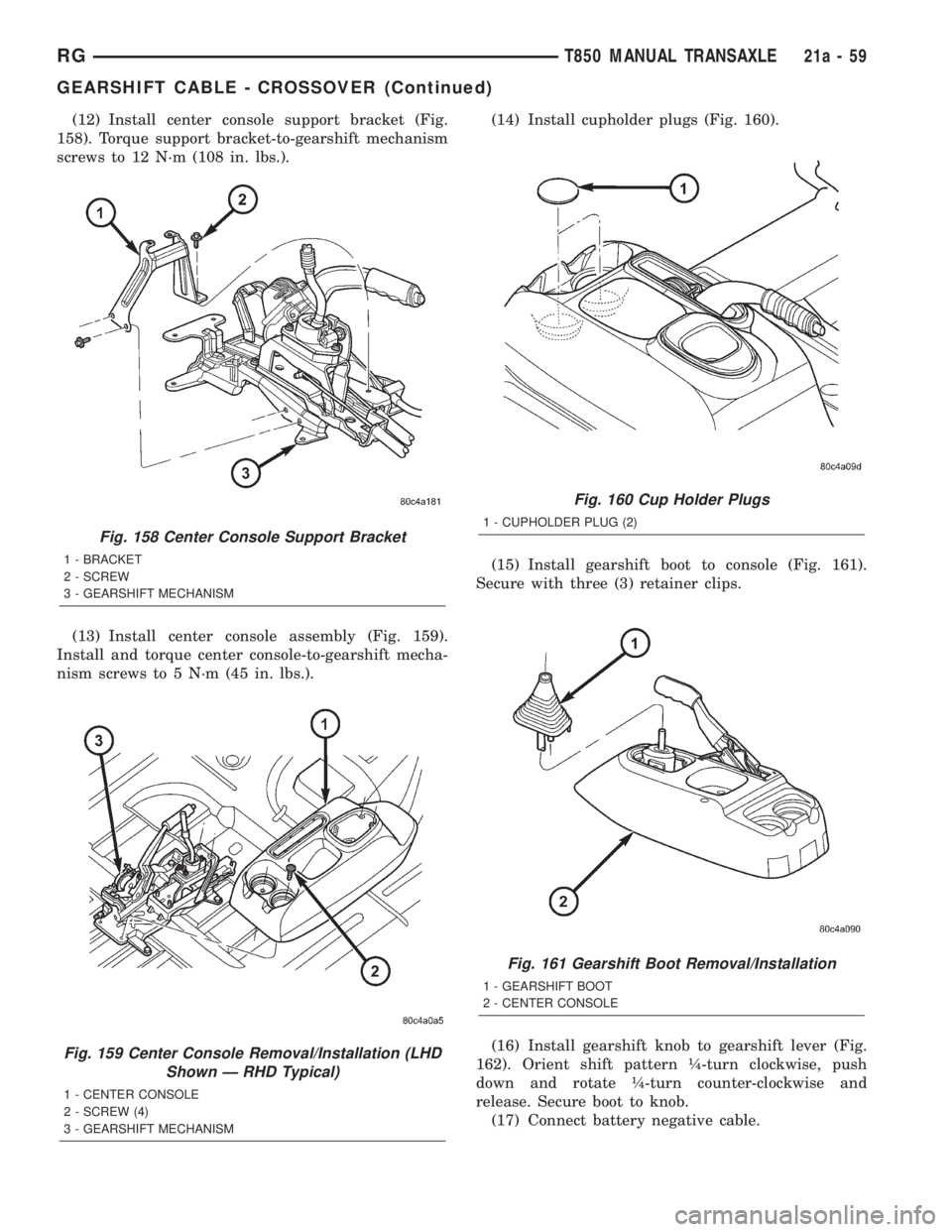

(12) Install center console support bracket (Fig.

158). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(13) Install center console assembly (Fig. 159).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).(14) Install cupholder plugs (Fig. 160).

(15) Install gearshift boot to console (Fig. 161).

Secure with three (3) retainer clips.

(16) Install gearshift knob to gearshift lever (Fig.

162). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(17) Connect battery negative cable.

Fig. 158 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 159 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 160 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 161 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

RGT850 MANUAL TRANSAXLE21a-59

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 3326 of 4284

ADJUSTMENT

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 163).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 164).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

165).

Fig. 162 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 163 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 164 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 165 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 60 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 3327 of 4284

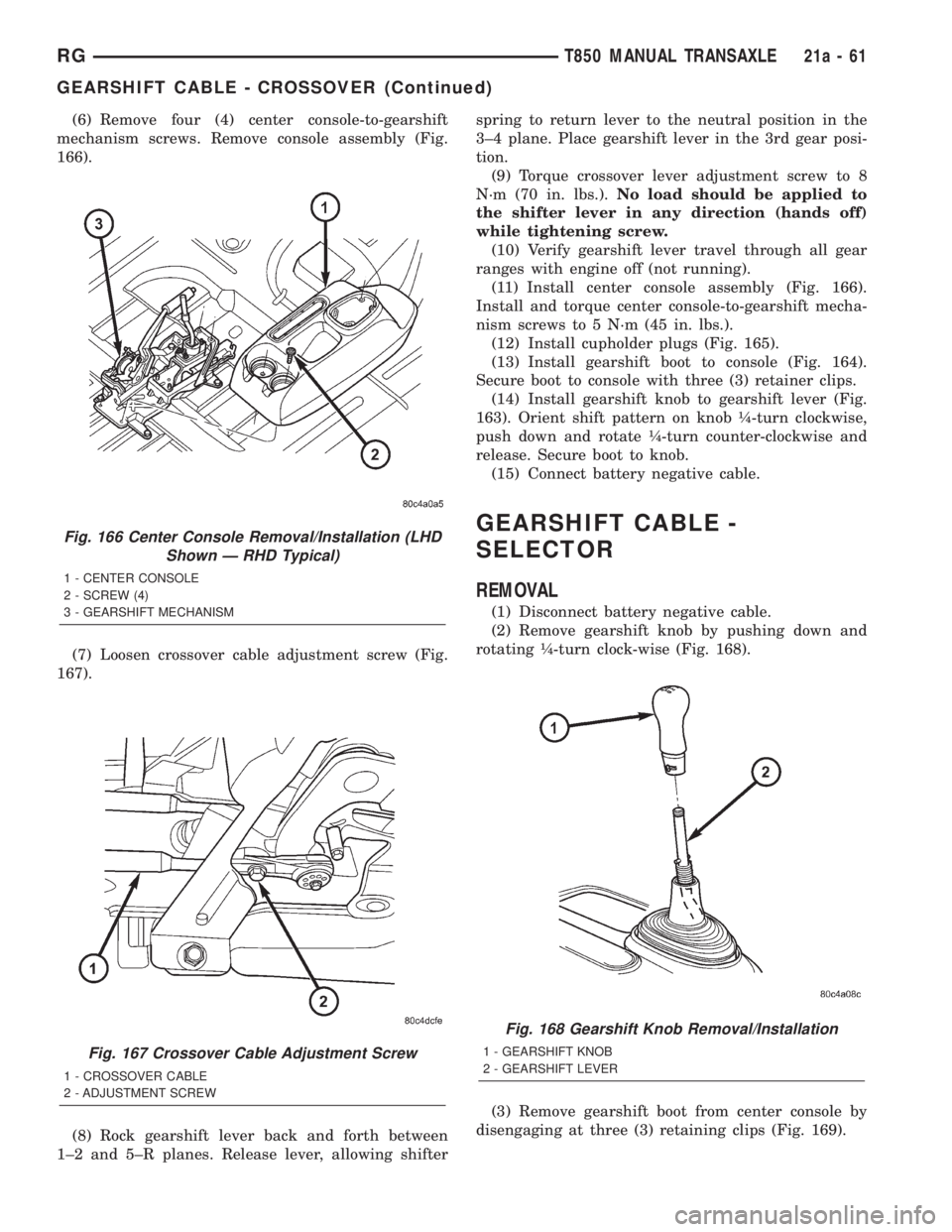

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

166).

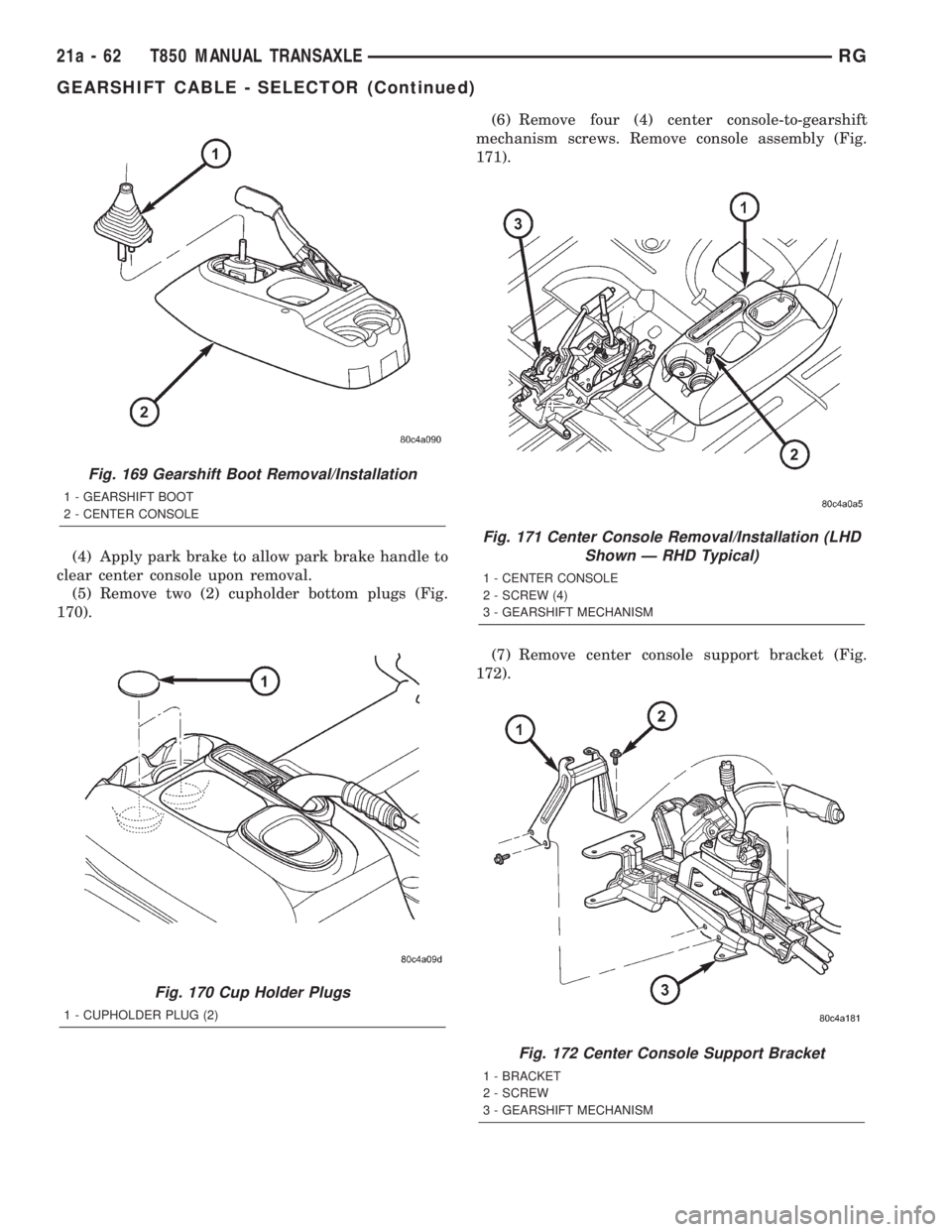

(7) Loosen crossover cable adjustment screw (Fig.

167).

(8) Rock gearshift lever back and forth between

1±2 and 5±R planes. Release lever, allowing shifterspring to return lever to the neutral position in the

3±4 plane. Place gearshift lever in the 3rd gear posi-

tion.

(9) Torque crossover lever adjustment screw to 8

N´m (70 in. lbs.).No load should be applied to

the shifter lever in any direction (hands off)

while tightening screw.

(10) Verify gearshift lever travel through all gear

ranges with engine off (not running).

(11) Install center console assembly (Fig. 166).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(12) Install cupholder plugs (Fig. 165).

(13) Install gearshift boot to console (Fig. 164).

Secure boot to console with three (3) retainer clips.

(14) Install gearshift knob to gearshift lever (Fig.

163). Orient shift pattern on knob ò-turn clockwise,

push down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(15) Connect battery negative cable.

GEARSHIFT CABLE -

SELECTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 168).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 169).

Fig. 166 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 167 Crossover Cable Adjustment Screw

1 - CROSSOVER CABLE

2 - ADJUSTMENT SCREW

Fig. 168 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-61

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 3328 of 4284

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

170).(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

171).

(7) Remove center console support bracket (Fig.

172).

Fig. 169 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 170 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 171 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 172 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

21a - 62 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - SELECTOR (Continued)

Page 3332 of 4284

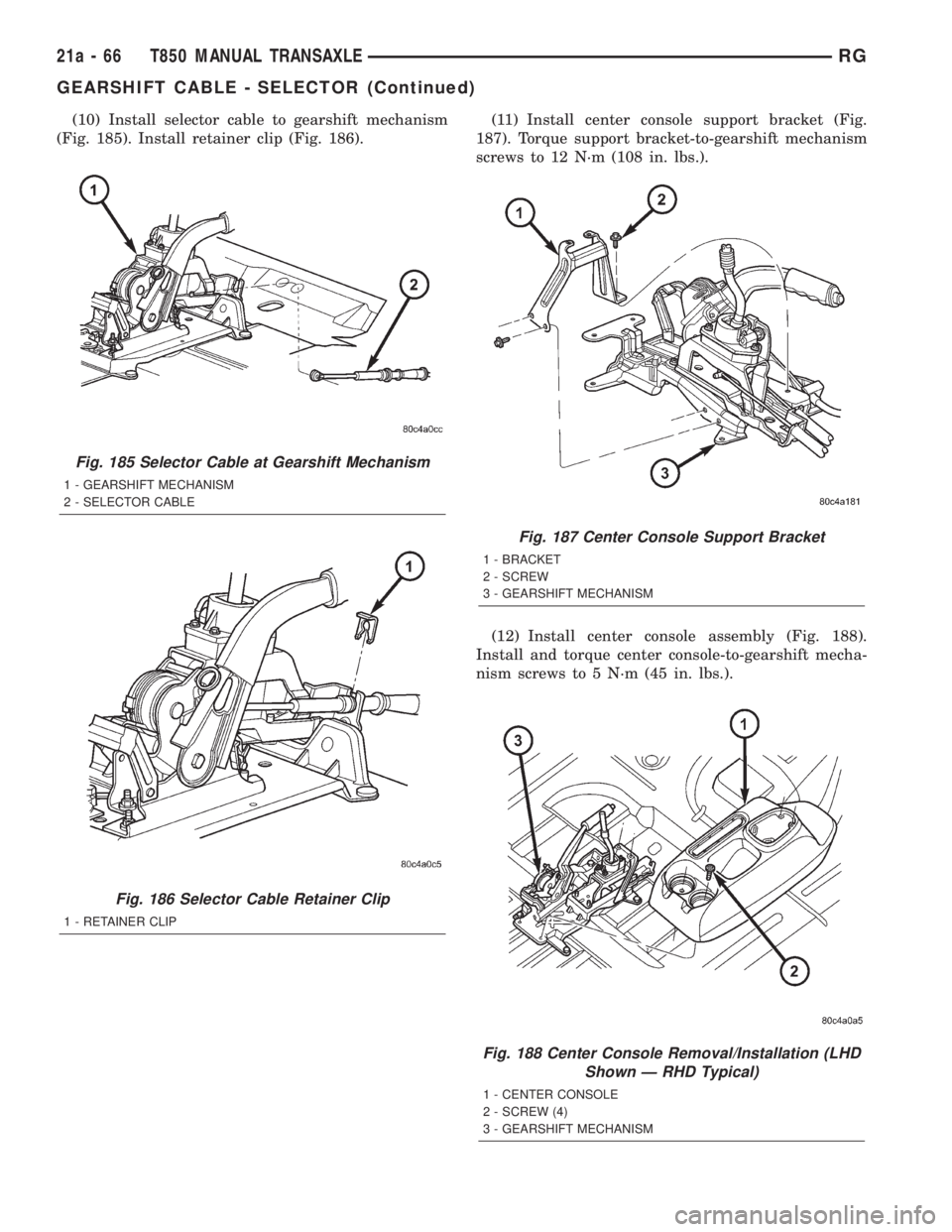

(10) Install selector cable to gearshift mechanism

(Fig. 185). Install retainer clip (Fig. 186).(11) Install center console support bracket (Fig.

187). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(12) Install center console assembly (Fig. 188).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

Fig. 185 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 186 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 187 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 188 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

21a - 66 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - SELECTOR (Continued)