check engine CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4244 of 4284

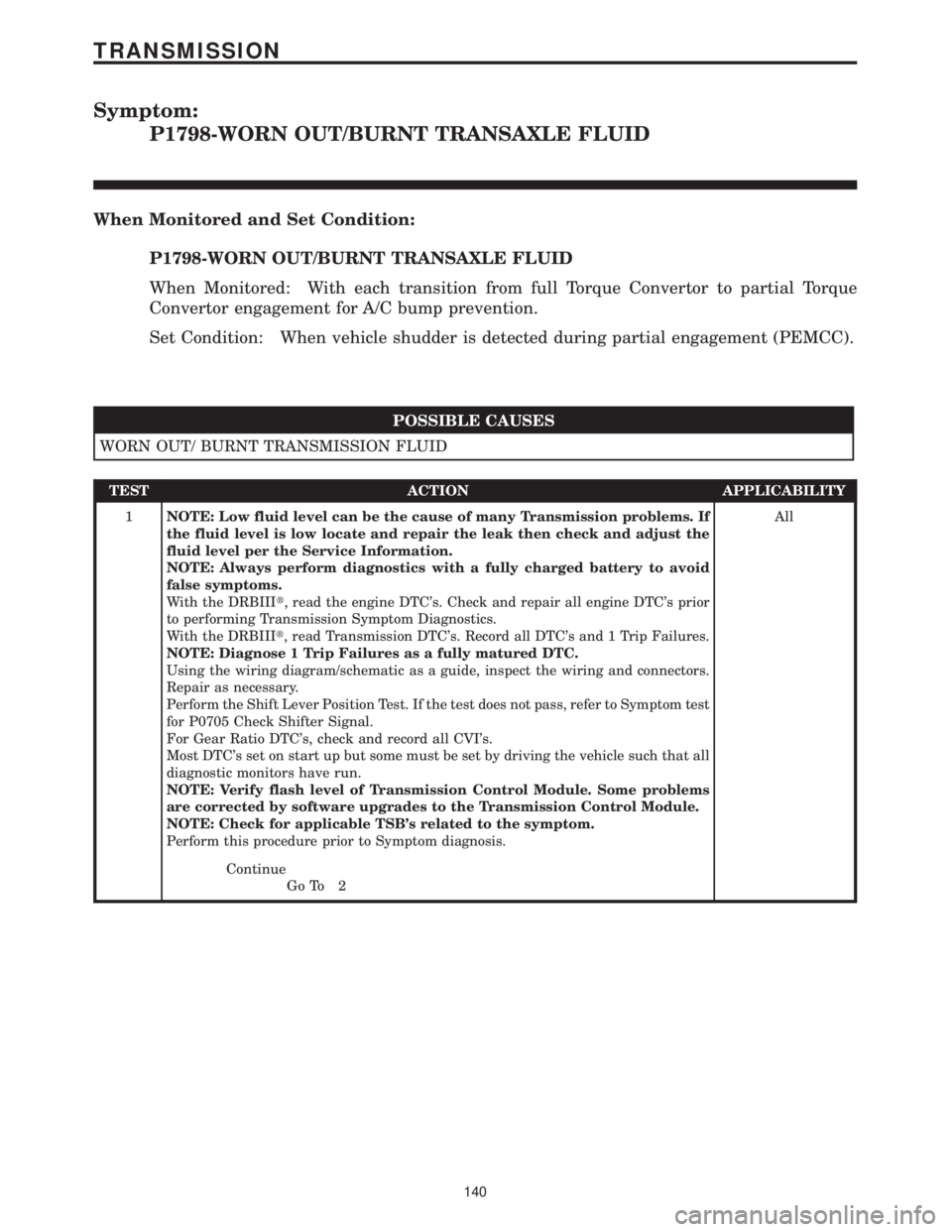

Symptom:

P1798-WORN OUT/BURNT TRANSAXLE FLUID

When Monitored and Set Condition:

P1798-WORN OUT/BURNT TRANSAXLE FLUID

When Monitored: With each transition from full Torque Convertor to partial Torque

Convertor engagement for A/C bump prevention.

Set Condition: When vehicle shudder is detected during partial engagement (PEMCC).

POSSIBLE CAUSES

WORN OUT/ BURNT TRANSMISSION FLUID

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many Transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the Service Information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTC's. Check and repair all engine DTC's prior

to performing Transmission Symptom Diagnostics.

With the DRBIIIt, read Transmission DTC's. Record all DTC's and 1 Trip Failures.

NOTE: Diagnose 1 Trip Failures as a fully matured DTC.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Perform the Shift Lever Position Test. If the test does not pass, refer to Symptom test

for P0705 Check Shifter Signal.

For Gear Ratio DTC's, check and record all CVI's.

Most DTC's set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

NOTE: Verify flash level of Transmission Control Module. Some problems

are corrected by software upgrades to the Transmission Control Module.

NOTE: Check for applicable TSB's related to the symptom.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

140

TRANSMISSION

Page 4245 of 4284

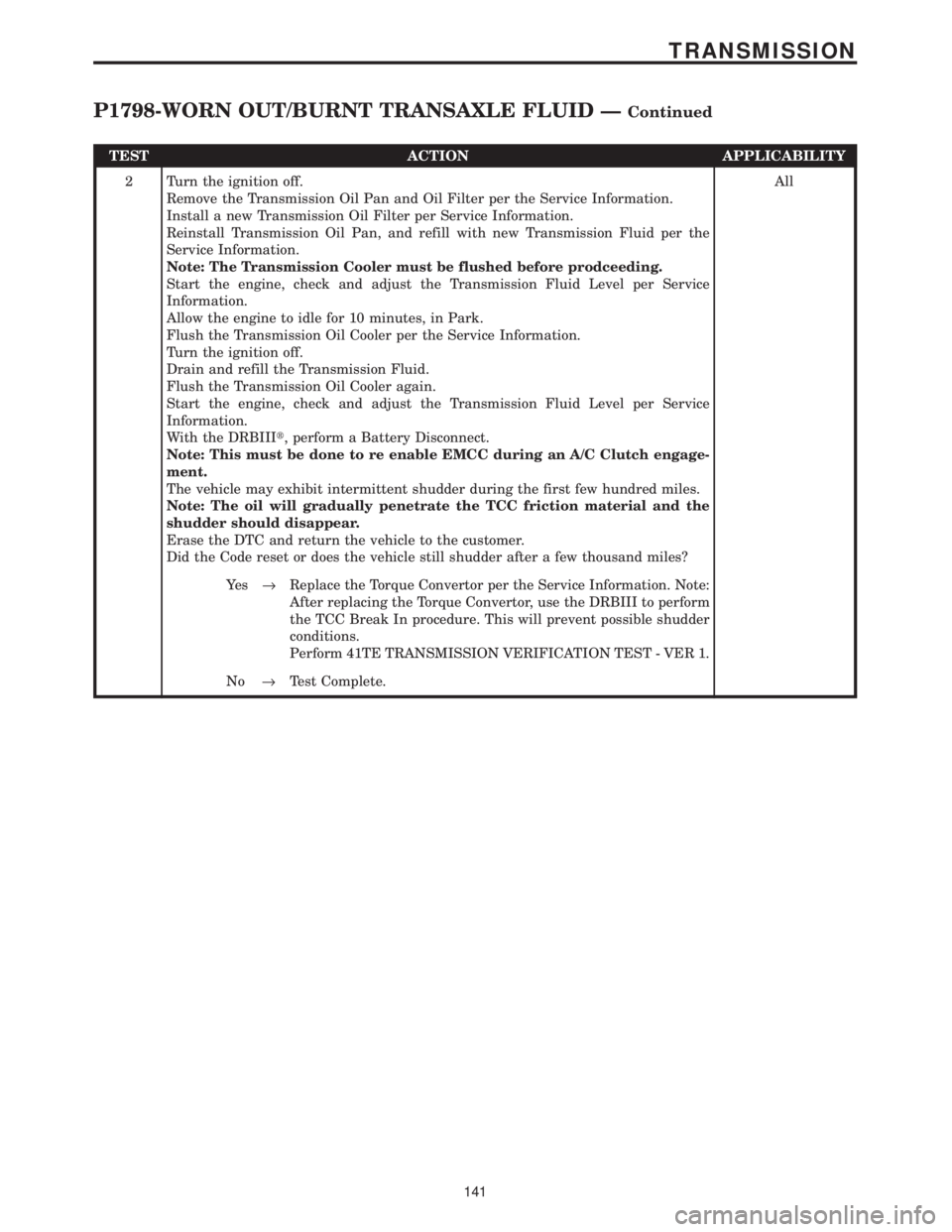

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Remove the Transmission Oil Pan and Oil Filter per the Service Information.

Install a new Transmission Oil Filter per Service Information.

Reinstall Transmission Oil Pan, and refill with new Transmission Fluid per the

Service Information.

Note: The Transmission Cooler must be flushed before prodceeding.

Start the engine, check and adjust the Transmission Fluid Level per Service

Information.

Allow the engine to idle for 10 minutes, in Park.

Flush the Transmission Oil Cooler per the Service Information.

Turn the ignition off.

Drain and refill the Transmission Fluid.

Flush the Transmission Oil Cooler again.

Start the engine, check and adjust the Transmission Fluid Level per Service

Information.

With the DRBIIIt, perform a Battery Disconnect.

Note: This must be done to re enable EMCC during an A/C Clutch engage-

ment.

The vehicle may exhibit intermittent shudder during the first few hundred miles.

Note: The oil will gradually penetrate the TCC friction material and the

shudder should disappear.

Erase the DTC and return the vehicle to the customer.

Did the Code reset or does the vehicle still shudder after a few thousand miles?All

Ye s®Replace the Torque Convertor per the Service Information. Note:

After replacing the Torque Convertor, use the DRBIII to perform

the TCC Break In procedure. This will prevent possible shudder

conditions.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Test Complete.

141

TRANSMISSION

P1798-WORN OUT/BURNT TRANSAXLE FLUID ÐContinued

Page 4246 of 4284

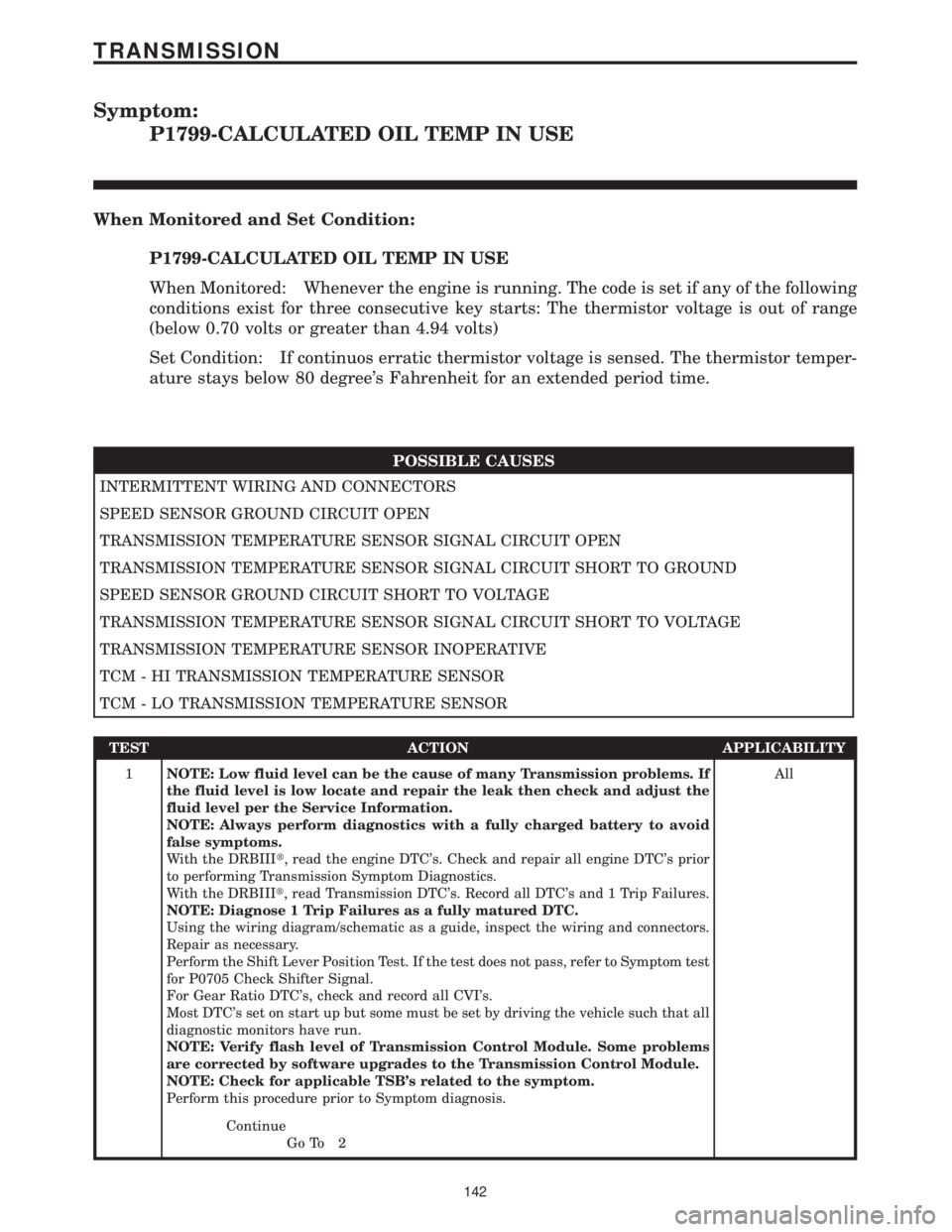

Symptom:

P1799-CALCULATED OIL TEMP IN USE

When Monitored and Set Condition:

P1799-CALCULATED OIL TEMP IN USE

When Monitored: Whenever the engine is running. The code is set if any of the following

conditions exist for three consecutive key starts: The thermistor voltage is out of range

(below 0.70 volts or greater than 4.94 volts)

Set Condition: If continuos erratic thermistor voltage is sensed. The thermistor temper-

ature stays below 80 degree's Fahrenheit for an extended period time.

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

SPEED SENSOR GROUND CIRCUIT OPEN

TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT OPEN

TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

SPEED SENSOR GROUND CIRCUIT SHORT TO VOLTAGE

TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

TRANSMISSION TEMPERATURE SENSOR INOPERATIVE

TCM - HI TRANSMISSION TEMPERATURE SENSOR

TCM - LO TRANSMISSION TEMPERATURE SENSOR

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many Transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the Service Information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTC's. Check and repair all engine DTC's prior

to performing Transmission Symptom Diagnostics.

With the DRBIIIt, read Transmission DTC's. Record all DTC's and 1 Trip Failures.

NOTE: Diagnose 1 Trip Failures as a fully matured DTC.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Perform the Shift Lever Position Test. If the test does not pass, refer to Symptom test

for P0705 Check Shifter Signal.

For Gear Ratio DTC's, check and record all CVI's.

Most DTC's set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

NOTE: Verify flash level of Transmission Control Module. Some problems

are corrected by software upgrades to the Transmission Control Module.

NOTE: Check for applicable TSB's related to the symptom.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

142

TRANSMISSION

Page 4247 of 4284

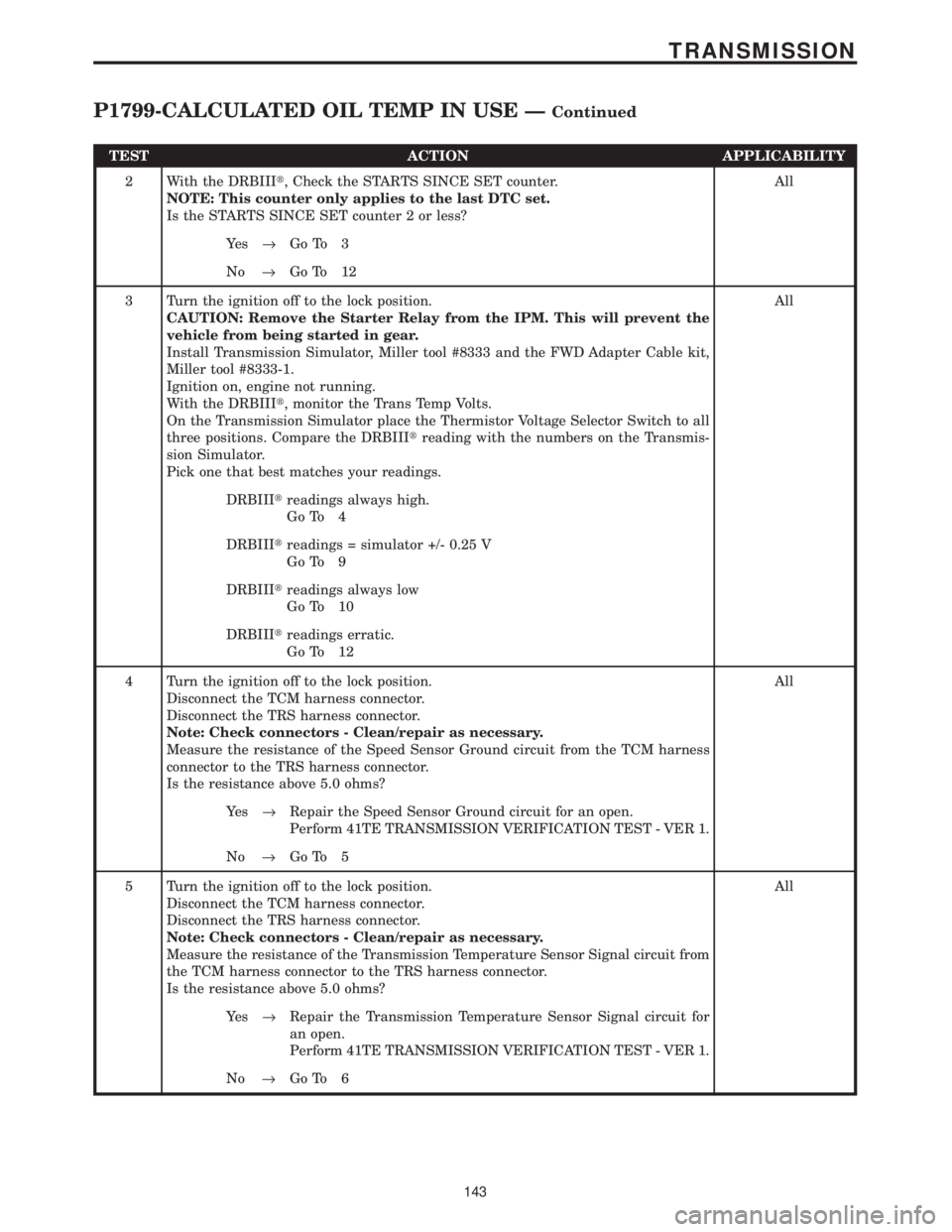

TEST ACTION APPLICABILITY

2 With the DRBIIIt, Check the STARTS SINCE SET counter.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?All

Ye s®Go To 3

No®Go To 12

3 Turn the ignition off to the lock position.

CAUTION: Remove the Starter Relay from the IPM. This will prevent the

vehicle from being started in gear.

Install Transmission Simulator, Miller tool #8333 and the FWD Adapter Cable kit,

Miller tool #8333-1.

Ignition on, engine not running.

With the DRBIIIt, monitor the Trans Temp Volts.

On the Transmission Simulator place the Thermistor Voltage Selector Switch to all

three positions. Compare the DRBIIItreading with the numbers on the Transmis-

sion Simulator.

Pick one that best matches your readings.All

DRBIIItreadings always high.

Go To 4

DRBIIItreadings = simulator +/- 0.25 V

Go To 9

DRBIIItreadings always low

Go To 10

DRBIIItreadings erratic.

Go To 12

4 Turn the ignition off to the lock position.

Disconnect the TCM harness connector.

Disconnect the TRS harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Speed Sensor Ground circuit from the TCM harness

connector to the TRS harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Speed Sensor Ground circuit for an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off to the lock position.

Disconnect the TCM harness connector.

Disconnect the TRS harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Transmission Temperature Sensor Signal circuit from

the TCM harness connector to the TRS harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Transmission Temperature Sensor Signal circuit for

an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Go To 6

143

TRANSMISSION

P1799-CALCULATED OIL TEMP IN USE ÐContinued

Page 4248 of 4284

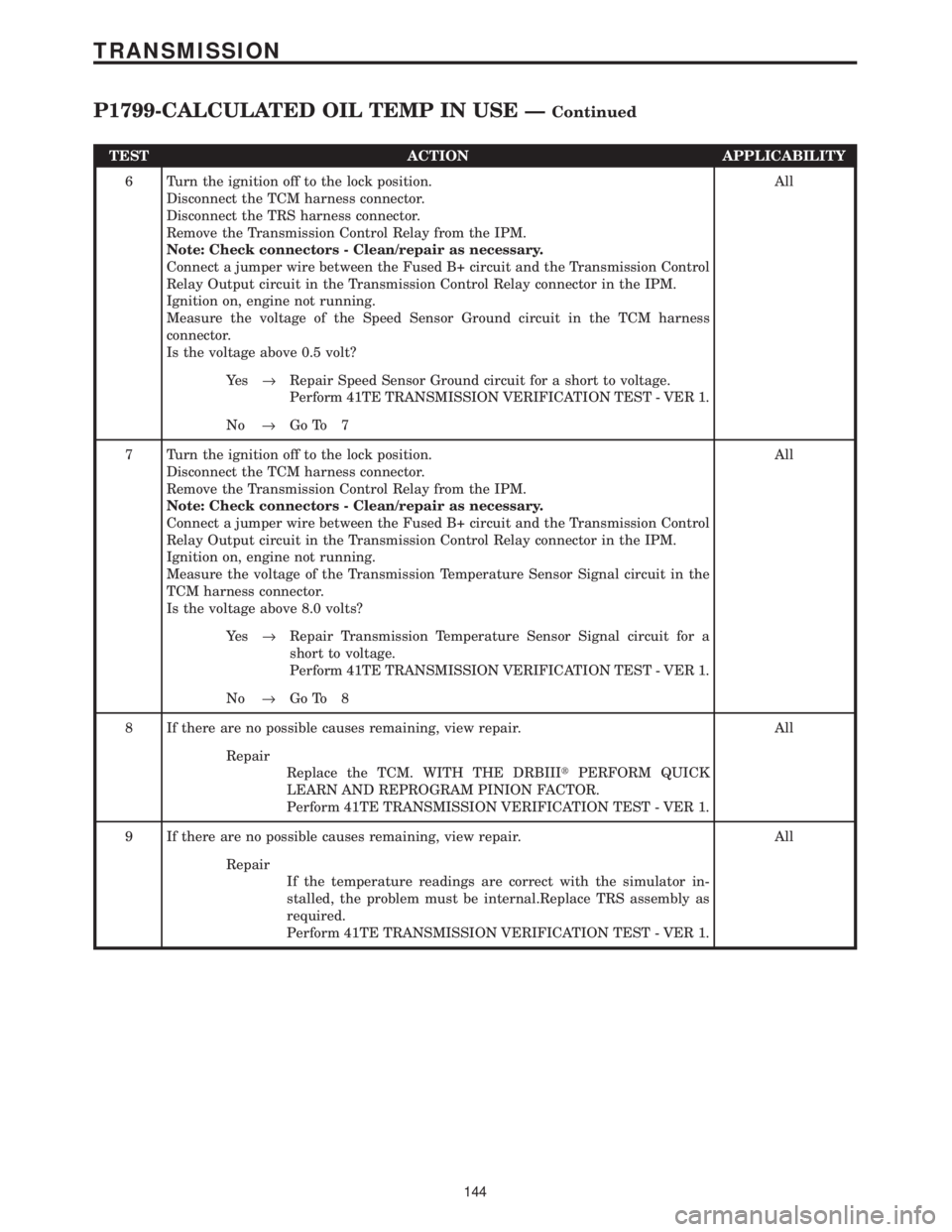

TEST ACTION APPLICABILITY

6 Turn the ignition off to the lock position.

Disconnect the TCM harness connector.

Disconnect the TRS harness connector.

Remove the Transmission Control Relay from the IPM.

Note: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the Fused B+ circuit and the Transmission Control

Relay Output circuit in the Transmission Control Relay connector in the IPM.

Ignition on, engine not running.

Measure the voltage of the Speed Sensor Ground circuit in the TCM harness

connector.

Is the voltage above 0.5 volt?All

Ye s®Repair Speed Sensor Ground circuit for a short to voltage.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Go To 7

7 Turn the ignition off to the lock position.

Disconnect the TCM harness connector.

Remove the Transmission Control Relay from the IPM.

Note: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the Fused B+ circuit and the Transmission Control

Relay Output circuit in the Transmission Control Relay connector in the IPM.

Ignition on, engine not running.

Measure the voltage of the Transmission Temperature Sensor Signal circuit in the

TCM harness connector.

Is the voltage above 8.0 volts?All

Ye s®Repair Transmission Temperature Sensor Signal circuit for a

short to voltage.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Go To 8

8 If there are no possible causes remaining, view repair. All

Repair

Replace the TCM. WITH THE DRBIIItPERFORM QUICK

LEARN AND REPROGRAM PINION FACTOR.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

9 If there are no possible causes remaining, view repair. All

Repair

If the temperature readings are correct with the simulator in-

stalled, the problem must be internal.Replace TRS assembly as

required.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

144

TRANSMISSION

P1799-CALCULATED OIL TEMP IN USE ÐContinued

Page 4250 of 4284

Symptom:

*BRAKE SHIFT INTERLOCK OUTPUT OPEN

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

BRAKE SHIFT INTERLOCK CONTROL CIRCUIT OPEN

BRAKE SHIFT INTERLOCK FEED CIRCUIT OPEN

BRAKE SHIFT INTERLOCK SOLENOID

FRONT CONTROL MODULE

TEST ACTION APPLICABILITY

1 Ignition on, engine not running.

With the DRBIIIt, record and erase DTC's.

Turn the ignition off to the lock position.

Turn the ignition on.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay BRAKE SHIFT INTERLOCK OUTPUT OPEN?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off to the lock position.

Disconnect the Brake Shift Interlock harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to B+, check the Brake Shift Interlock Control

circuit in the Brake Shift Interlock harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Go To 6

3 Turn the ignition off to the lock position.

Disconnect the Brake Shift Interlock harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to ground, check the Brake Shift Interlock Feed

circuit in the Brake Shift Interlock harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Go To 5

4 If there are no possible causes remaining, view repair. All

Repair

Replace the Brake Shift Interlock Solenoid in accordance with the

Service Information.

146

TRANSMISSION

Page 4258 of 4284

Symptom:

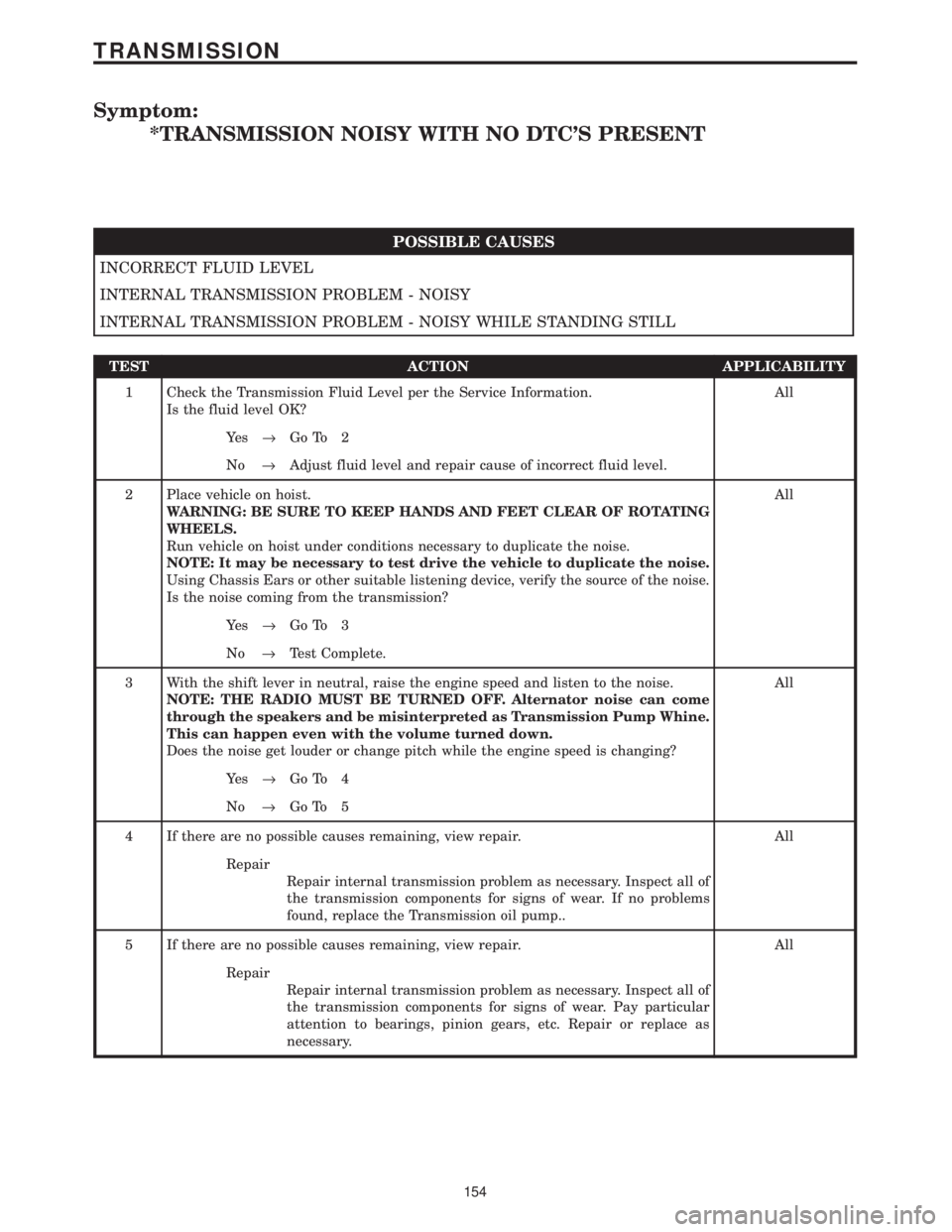

*TRANSMISSION NOISY WITH NO DTC'S PRESENT

POSSIBLE CAUSES

INCORRECT FLUID LEVEL

INTERNAL TRANSMISSION PROBLEM - NOISY

INTERNAL TRANSMISSION PROBLEM - NOISY WHILE STANDING STILL

TEST ACTION APPLICABILITY

1 Check the Transmission Fluid Level per the Service Information.

Is the fluid level OK?All

Ye s®Go To 2

No®Adjust fluid level and repair cause of incorrect fluid level.

2 Place vehicle on hoist.

WARNING: BE SURE TO KEEP HANDS AND FEET CLEAR OF ROTATING

WHEELS.

Run vehicle on hoist under conditions necessary to duplicate the noise.

NOTE: It may be necessary to test drive the vehicle to duplicate the noise.

Using Chassis Ears or other suitable listening device, verify the source of the noise.

Is the noise coming from the transmission?All

Ye s®Go To 3

No®Test Complete.

3 With the shift lever in neutral, raise the engine speed and listen to the noise.

NOTE: THE RADIO MUST BE TURNED OFF. Alternator noise can come

through the speakers and be misinterpreted as Transmission Pump Whine.

This can happen even with the volume turned down.

Does the noise get louder or change pitch while the engine speed is changing?All

Ye s®Go To 4

No®Go To 5

4 If there are no possible causes remaining, view repair. All

Repair

Repair internal transmission problem as necessary. Inspect all of

the transmission components for signs of wear. If no problems

found, replace the Transmission oil pump..

5 If there are no possible causes remaining, view repair. All

Repair

Repair internal transmission problem as necessary. Inspect all of

the transmission components for signs of wear. Pay particular

attention to bearings, pinion gears, etc. Repair or replace as

necessary.

154

TRANSMISSION

Page 4261 of 4284

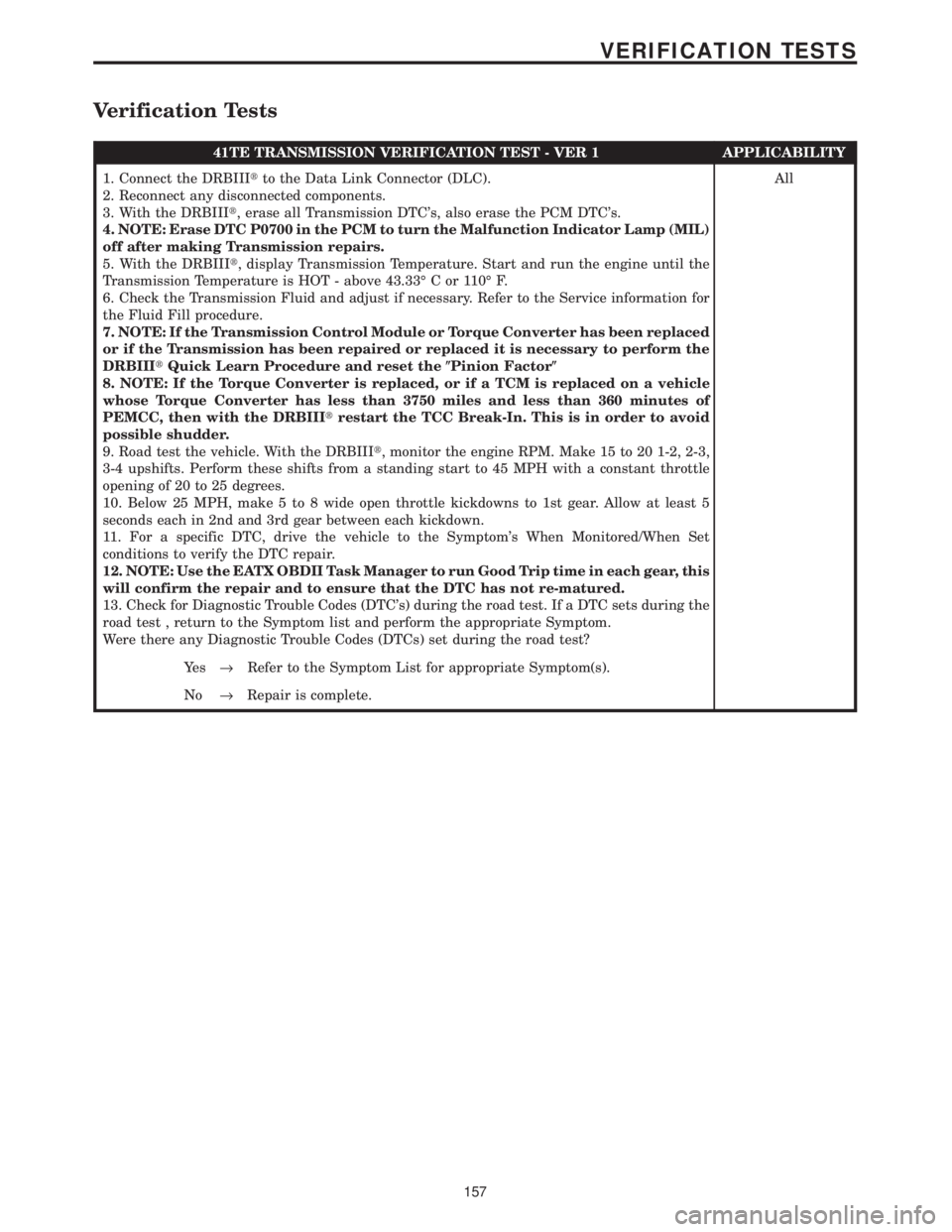

Verification Tests

41TE TRANSMISSION VERIFICATION TEST - VER 1 APPLICABILITY

1. Connect the DRBIIItto the Data Link Connector (DLC).

2. Reconnect any disconnected components.

3. With the DRBIIIt, erase all Transmission DTC's, also erase the PCM DTC's.

4. NOTE: Erase DTC P0700 in the PCM to turn the Malfunction Indicator Lamp (MIL)

off after making Transmission repairs.

5. With the DRBIIIt, display Transmission Temperature. Start and run the engine until the

Transmission Temperature is HOT - above 43.33É C or 110É F.

6. Check the Transmission Fluid and adjust if necessary. Refer to the Service information for

the Fluid Fill procedure.

7. NOTE: If the Transmission Control Module or Torque Converter has been replaced

or if the Transmission has been repaired or replaced it is necessary to perform the

DRBIIItQuick Learn Procedure and reset the(Pinion Factor(

8. NOTE: If the Torque Converter is replaced, or if a TCM is replaced on a vehicle

whose Torque Converter has less than 3750 miles and less than 360 minutes of

PEMCC, then with the DRBIIItrestart the TCC Break-In. This is in order to avoid

possible shudder.

9. Road test the vehicle. With the DRBIIIt, monitor the engine RPM. Make 15 to 20 1-2, 2-3,

3-4 upshifts. Perform these shifts from a standing start to 45 MPH with a constant throttle

opening of 20 to 25 degrees.

10. Below 25 MPH, make 5 to 8 wide open throttle kickdowns to 1st gear. Allow at least 5

seconds each in 2nd and 3rd gear between each kickdown.

11. For a specific DTC, drive the vehicle to the Symptom's When Monitored/When Set

conditions to verify the DTC repair.

12. NOTE: Use the EATX OBDII Task Manager to run Good Trip time in each gear, this

will confirm the repair and to ensure that the DTC has not re-matured.

13. Check for Diagnostic Trouble Codes (DTC's) during the road test. If a DTC sets during the

road test , return to the Symptom list and perform the appropriate Symptom.

Were there any Diagnostic Trouble Codes (DTCs) set during the road test?All

Ye s®Refer to the Symptom List for appropriate Symptom(s).

No®Repair is complete.

157

VERIFICATION TESTS