wiring CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4033 of 4284

Symptom:

P0645-A/C CLUTCH RELAY CKT

When Monitored and Set Condition:

P0645-A/C CLUTCH RELAY CKT

When Monitored: With the ignition on. Battery voltage greater than 10 volts. A/C Switch

on.

Set Condition: An open or shorted condition is detected in the A/C clutch relay control

circuit.

POSSIBLE CAUSES

A/C CLUTCH RELAY INTERMITTENT OPERATION

INTERMITTENT CONDITION

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

INTELLIGENT POWER MODULE

A/C CLUTCH RELAY

IPM FUSE & RELAY CENTER

A/C CLUTCH RELAY CONTROL CKT OPEN

A/C CLUTCH RELAY CONTROL CIRCUIT SHORT TO GROUND

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, actuate the A/C Clutch Relay.

Is the A/C Clutch Relay operating?All

Ye s®Go To 2

No®Go To 4

2 Turn the ignition on.

With the DRBIIIt, actuate the A/C Clutch Relay.

Wiggle the wiring harness from the A/C Clutch Relay to the PCM while the relay is

actuating.

Did the A/C Clutch Relay stop when wiggling the wiring harness?All

Ye s®Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

239

HEATING & A/C

Page 4034 of 4284

TEST ACTION APPLICABILITY

3WARNING: KEEP CLEAR OF THE ENGINE'S MOVING PARTS.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

4 Turn the ignition off.

Remove the A/C Clutch Relay from the IPM.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Fused Ignition Switch

circuit in the IPM.

Does the test light illuminate?All

Ye s®Go To 5

No®Go To 10

5 Turn the ignition off.

Remove the A/C Clutch Relay from the IPM.

Turn the ignition on.

Using a 12-volt test light connected to 12-volts, probe the A/C Clutch Relay circuit in

the IPM.

With the DRBIIIt, actuate the A/C Clutch Relay.

Does the test light flash on and off?All

Ye s®Replace the A/C Clutch Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 Turn the ignition off.

Disconnect the Intelligent Power Module C3 harness connector.

Turn the ignition on.

Using a 12-volt test light connected to 12-volts, probe the A/C Clutch Relay Control

circuit in the IPM harness connector.

With the DRBIIIt, actuate the A/C Clutch Relay.

Does the test light flash on and off?All

Ye s®Replace the IPM Fused & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

240

HEATING & A/C

P0645-A/C CLUTCH RELAY CKT ÐContinued

Page 4038 of 4284

TEST ACTION APPLICABILITY

8NOTE: Ensure the A/C refrigerant System is properly charged per the

Service Information.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Test Complete.

244

HEATING & A/C

P1598-A/C PRESSURE SENSOR VOLTS TOO HIGH ÐContinued

Page 4041 of 4284

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the 5 Volt Supply circuit between the A/C Pressure Sensor

harness connector and the PCM harness connector.

Is the resistance below 5 ohms?All

Ye s®Go To 9

No®Repair the 5 Volt Supply circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

9 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

10NOTE: Ensure the A/C refrigerant System is properly charges per the

Service Information.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Test Complete.

247

HEATING & A/C

P1599-A/C PRESSURE SENSOR VOLTS TOO LOW ÐContinued

Page 4046 of 4284

TEST ACTION APPLICABILITY

15 Turn the ignition off.

Disconnect the S/C Servo harness connector.

Using a 12-volt test light connected to 12-volts, probe the ground circuit in the S/C

Servo harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 16

No®Repair the ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

16WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 4.

No®Test Complete.

252

SPEED CONTROL

P1595-SPEED CONTROL SOLENOID CIRCUITS ÐContinued

Page 4048 of 4284

TEST ACTION APPLICABILITY

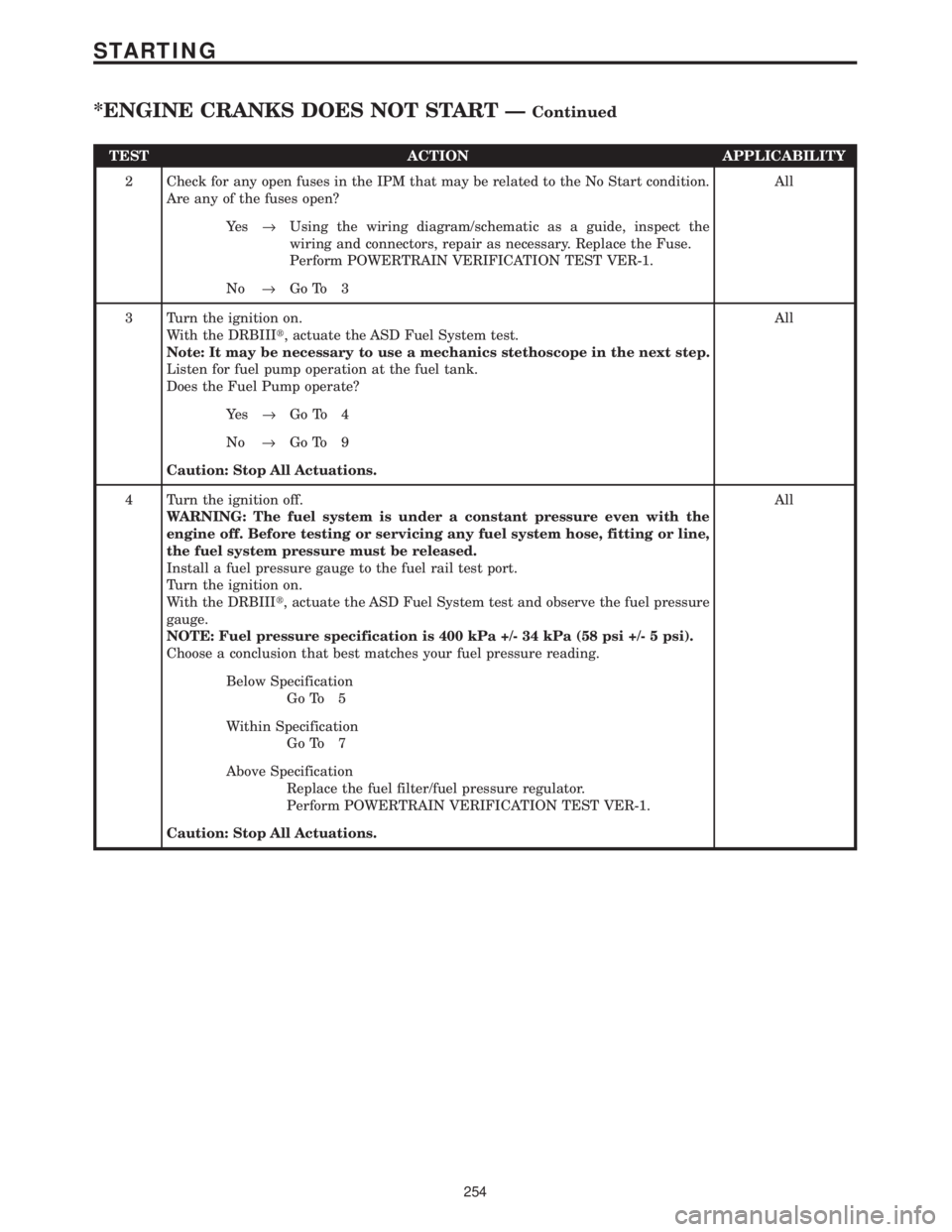

2 Check for any open fuses in the IPM that may be related to the No Start condition.

Are any of the fuses open?All

Ye s®Using the wiring diagram/schematic as a guide, inspect the

wiring and connectors, repair as necessary. Replace the Fuse.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 3

3 Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test.

Note: It may be necessary to use a mechanics stethoscope in the next step.

Listen for fuel pump operation at the fuel tank.

Does the Fuel Pump operate?All

Ye s®Go To 4

No®Go To 9

Caution: Stop All Actuations.

4 Turn the ignition off.

WARNING: The fuel system is under a constant pressure even with the

engine off. Before testing or servicing any fuel system hose, fitting or line,

the fuel system pressure must be released.

Install a fuel pressure gauge to the fuel rail test port.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test and observe the fuel pressure

gauge.

NOTE: Fuel pressure specification is 400 kPa +/- 34 kPa (58 psi +/- 5 psi).

Choose a conclusion that best matches your fuel pressure reading.All

Below Specification

Go To 5

Within Specification

Go To 7

Above Specification

Replace the fuel filter/fuel pressure regulator.

Perform POWERTRAIN VERIFICATION TEST VER-1.

Caution: Stop All Actuations.

254

STARTING

*ENGINE CRANKS DOES NOT START ÐContinued

Page 4062 of 4284

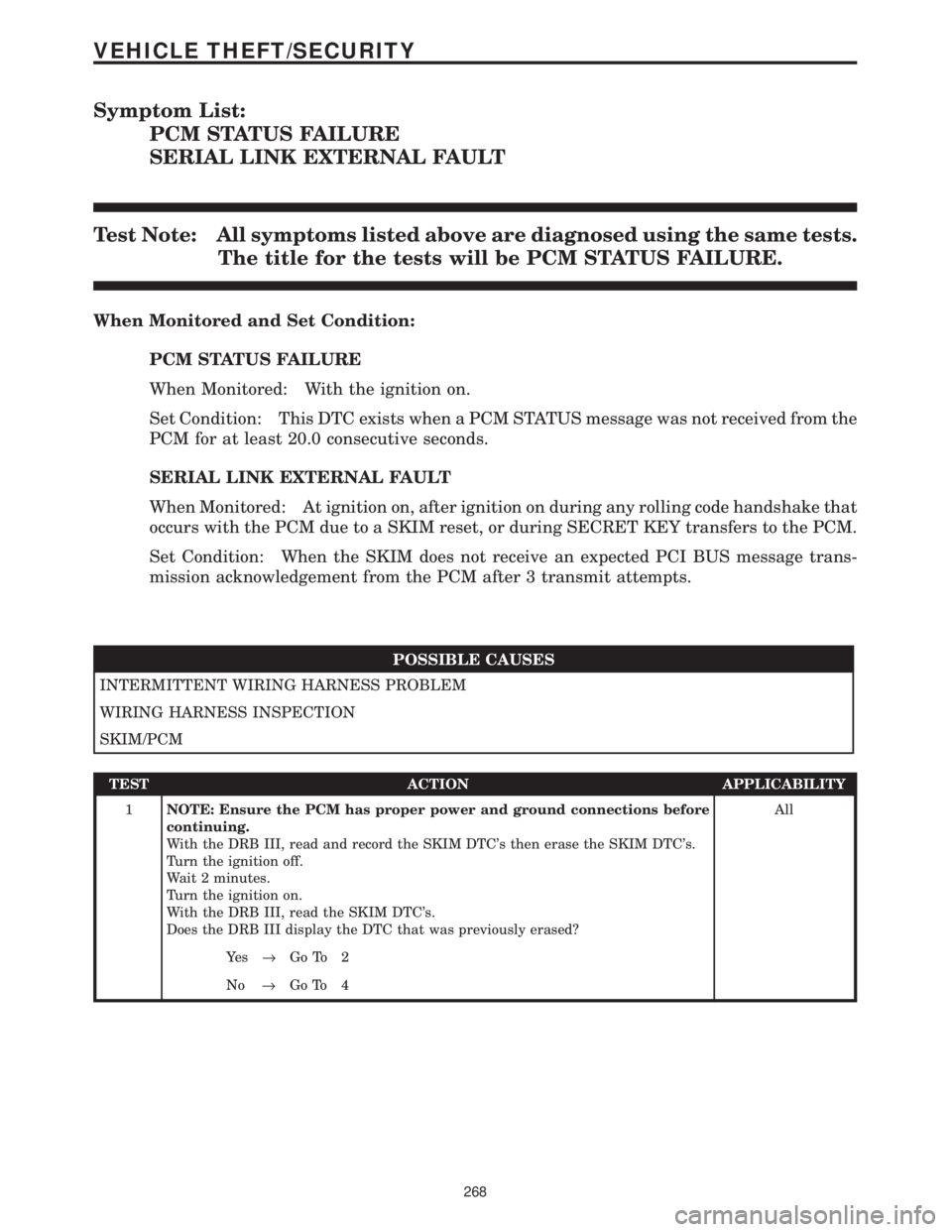

Symptom List:

PCM STATUS FAILURE

SERIAL LINK EXTERNAL FAULT

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be PCM STATUS FAILURE.

When Monitored and Set Condition:

PCM STATUS FAILURE

When Monitored: With the ignition on.

Set Condition: This DTC exists when a PCM STATUS message was not received from the

PCM for at least 20.0 consecutive seconds.

SERIAL LINK EXTERNAL FAULT

When Monitored: At ignition on, after ignition on during any rolling code handshake that

occurs with the PCM due to a SKIM reset, or during SECRET KEY transfers to the PCM.

Set Condition: When the SKIM does not receive an expected PCI BUS message trans-

mission acknowledgement from the PCM after 3 transmit attempts.

POSSIBLE CAUSES

INTERMITTENT WIRING HARNESS PROBLEM

WIRING HARNESS INSPECTION

SKIM/PCM

TEST ACTION APPLICABILITY

1NOTE: Ensure the PCM has proper power and ground connections before

continuing.

With the DRB III, read and record the SKIM DTC's then erase the SKIM DTC's.

Turn the ignition off.

Wait 2 minutes.

Turn the ignition on.

With the DRB III, read the SKIM DTC's.

Does the DRB III display the DTC that was previously erased?All

Ye s®Go To 2

No®Go To 4

268

VEHICLE THEFT/SECURITY

Page 4063 of 4284

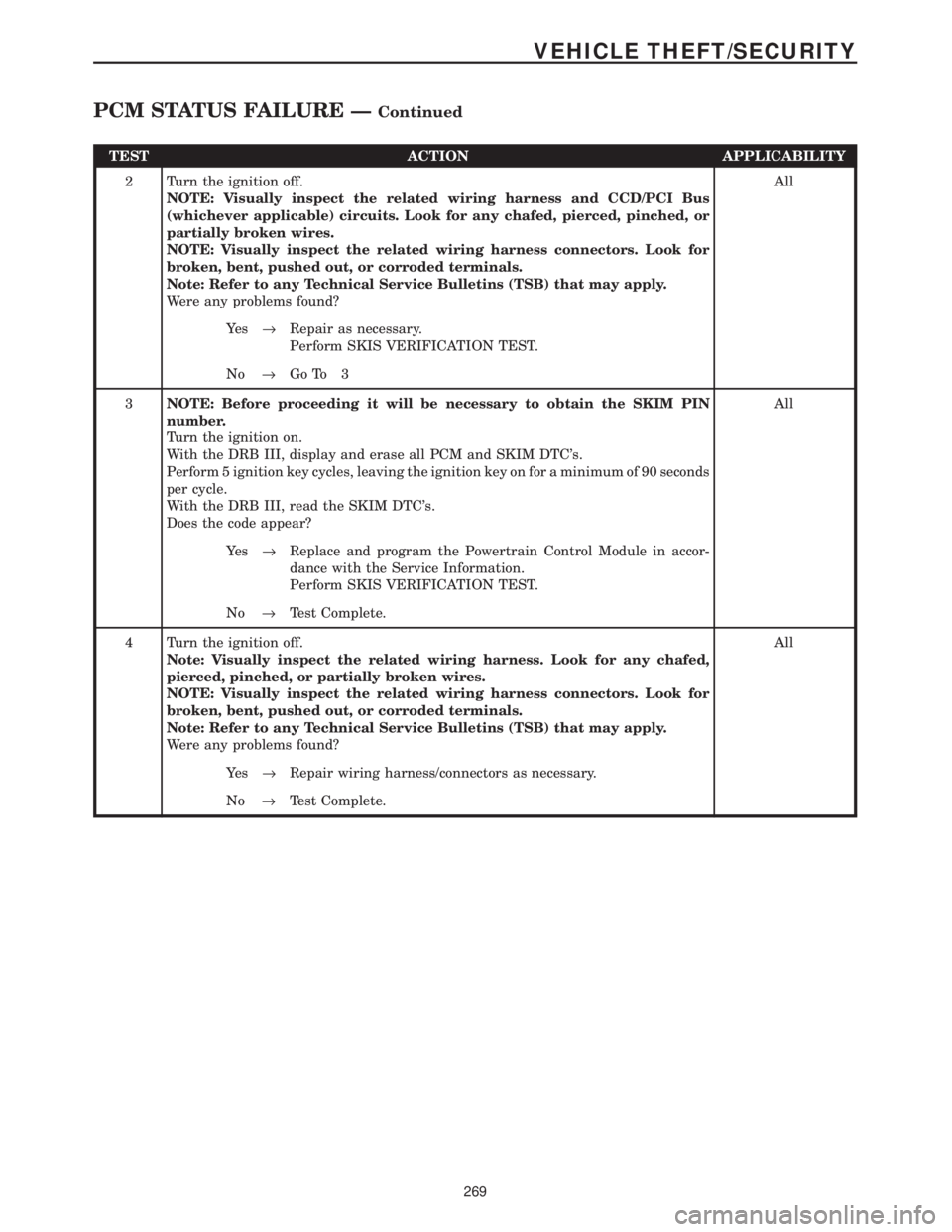

TEST ACTION APPLICABILITY

2 Turn the ignition off.

NOTE: Visually inspect the related wiring harness and CCD/PCI Bus

(whichever applicable) circuits. Look for any chafed, pierced, pinched, or

partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform SKIS VERIFICATION TEST.

No®Go To 3

3NOTE: Before proceeding it will be necessary to obtain the SKIM PIN

number.

Turn the ignition on.

With the DRB III, display and erase all PCM and SKIM DTC's.

Perform 5 ignition key cycles, leaving the ignition key on for a minimum of 90 seconds

per cycle.

With the DRB III, read the SKIM DTC's.

Does the code appear?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform SKIS VERIFICATION TEST.

No®Test Complete.

4 Turn the ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

No®Test Complete.

269

VEHICLE THEFT/SECURITY

PCM STATUS FAILURE ÐContinued

Page 4064 of 4284

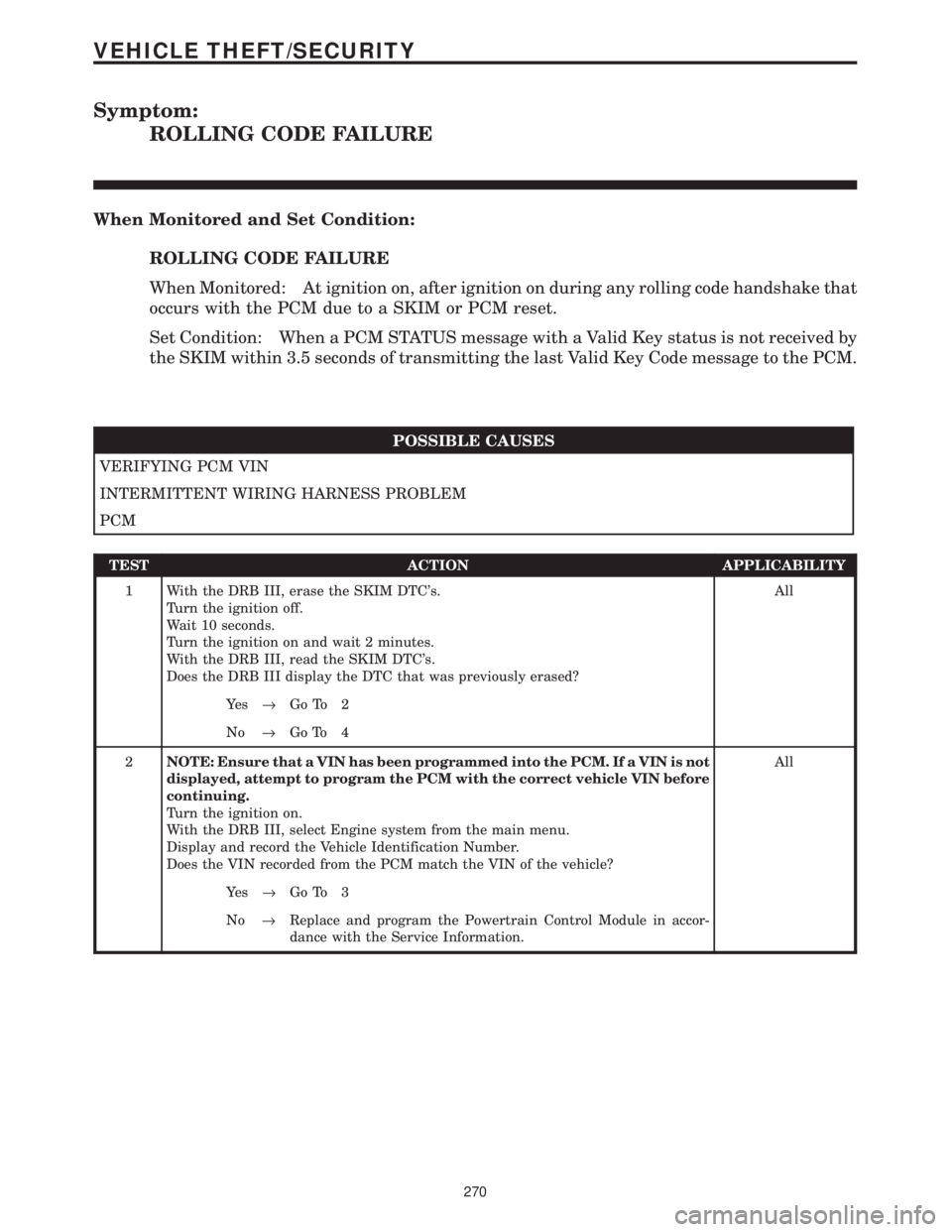

Symptom:

ROLLING CODE FAILURE

When Monitored and Set Condition:

ROLLING CODE FAILURE

When Monitored: At ignition on, after ignition on during any rolling code handshake that

occurs with the PCM due to a SKIM or PCM reset.

Set Condition: When a PCM STATUS message with a Valid Key status is not received by

the SKIM within 3.5 seconds of transmitting the last Valid Key Code message to the PCM.

POSSIBLE CAUSES

VERIFYING PCM VIN

INTERMITTENT WIRING HARNESS PROBLEM

PCM

TEST ACTION APPLICABILITY

1 With the DRB III, erase the SKIM DTC's.

Turn the ignition off.

Wait 10 seconds.

Turn the ignition on and wait 2 minutes.

With the DRB III, read the SKIM DTC's.

Does the DRB III display the DTC that was previously erased?All

Ye s®Go To 2

No®Go To 4

2NOTE: Ensure that a VIN has been programmed into the PCM. If a VIN is not

displayed, attempt to program the PCM with the correct vehicle VIN before

continuing.

Turn the ignition on.

With the DRB III, select Engine system from the main menu.

Display and record the Vehicle Identification Number.

Does the VIN recorded from the PCM match the VIN of the vehicle?All

Ye s®Go To 3

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

270

VEHICLE THEFT/SECURITY

Page 4065 of 4284

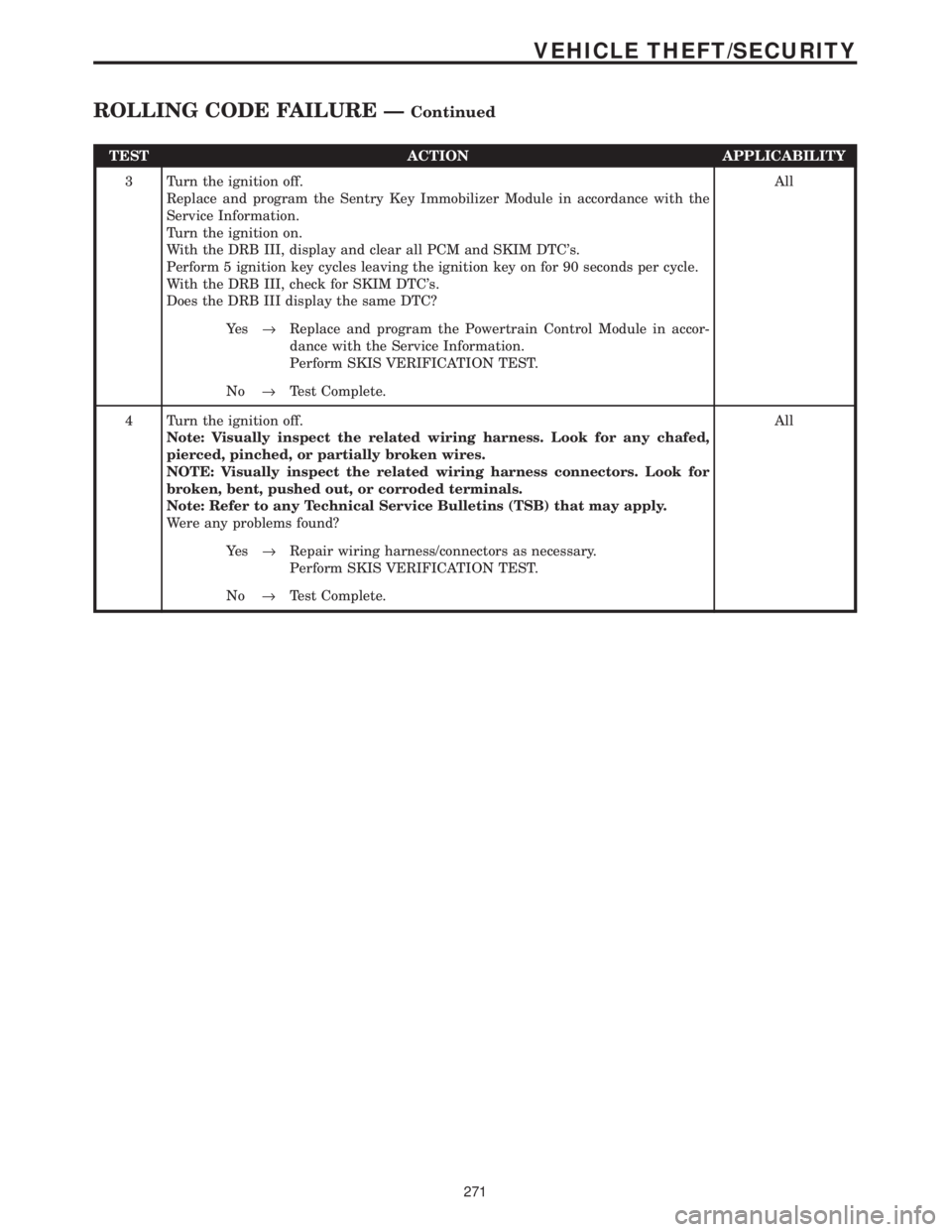

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Replace and program the Sentry Key Immobilizer Module in accordance with the

Service Information.

Turn the ignition on.

With the DRB III, display and clear all PCM and SKIM DTC's.

Perform 5 ignition key cycles leaving the ignition key on for 90 seconds per cycle.

With the DRB III, check for SKIM DTC's.

Does the DRB III display the same DTC?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform SKIS VERIFICATION TEST.

No®Test Complete.

4 Turn the ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform SKIS VERIFICATION TEST.

No®Test Complete.

271

VEHICLE THEFT/SECURITY

ROLLING CODE FAILURE ÐContinued