COOLING SYSTEM CHRYSLER VOYAGER 2001 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1803 of 4284

INSTALLATION - UPPER RADIATOR HOSE

(1) Install upper radiator hose (Fig. 26).

(2) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

INSTALLATION - LOWER RADIATOR HOSE

(1) Install lower radiator hose (Fig. 26).

(2) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

INSTALLATION - COOLANT BYPASS HOSE

(1) Install cooling system bypass hose (Fig. 26).

(2) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

Fig. 26 UPPER AND LOWER RADIATOR HOSES

1 - COOLANT BYPASS HOSE

2 - RADIATOR ASSEMBLY

3 - UPPER RADIATOR HOSE

4 - COOLING FAN

5 - LOWER RADIATOR HOSE

6 - CHARGE AIR COOLER

7 - RADIATOR BRACKET

RGENGINE7a-29

COOLANT SYSTEM HOSES (Continued)

Page 1833 of 4284

²Throttle Position Sensor

²Torque Management Input (From TCM)

²Transaxle Control Module (TCM)

²Transaxle Gear Engagement (From TCM)

²Vehicle Speed (from transmission control mod-

ule)

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid

²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral (transmission gear selection)

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed (from Transmission Control Mod-

ule)The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral (transmission gear selection)

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

fuel pump and the heating element in each oxygen

sensor.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the engine

coolant temperature sensor, intake air temperature

sensor, manifold absolute pressure sensor and throt-

tle position sensor.

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage in new PCM. Use

the DRB scan tool to change the mileage in the PCM.

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRB scan tool.

DIAGNOSTIC TROUBLE CODE

DESCRIPTION

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

RSELECTRONIC CONTROL MODULES8E-9

POWERTRAIN CONTROL MODULE (Continued)

Page 1858 of 4284

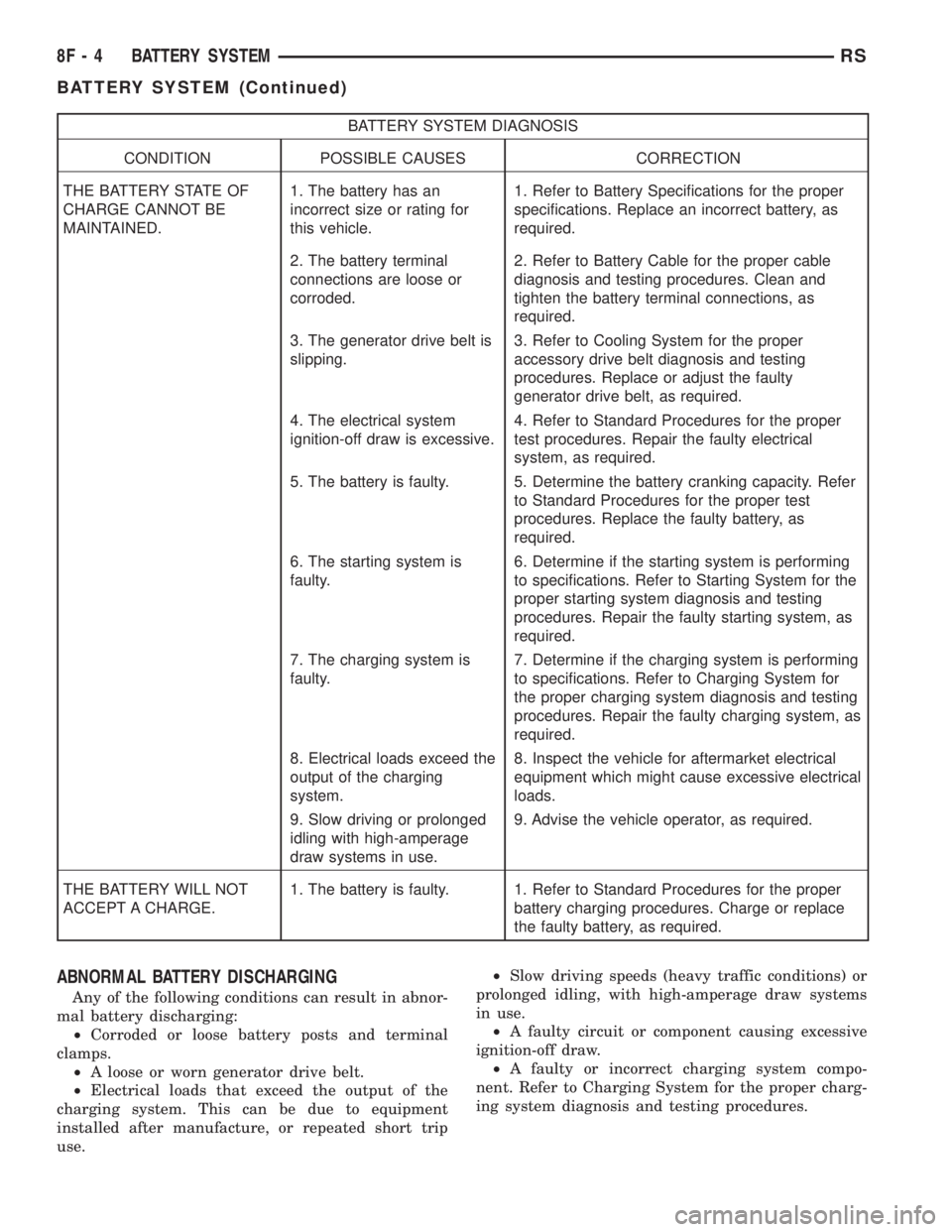

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY STATE OF

CHARGE CANNOT BE

MAINTAINED.1. The battery has an

incorrect size or rating for

this vehicle.1. Refer to Battery Specifications for the proper

specifications. Replace an incorrect battery, as

required.

2. The battery terminal

connections are loose or

corroded.2. Refer to Battery Cable for the proper cable

diagnosis and testing procedures. Clean and

tighten the battery terminal connections, as

required.

3. The generator drive belt is

slipping.3. Refer to Cooling System for the proper

accessory drive belt diagnosis and testing

procedures. Replace or adjust the faulty

generator drive belt, as required.

4. The electrical system

ignition-off draw is excessive.4. Refer to Standard Procedures for the proper

test procedures. Repair the faulty electrical

system, as required.

5. The battery is faulty. 5. Determine the battery cranking capacity. Refer

to Standard Procedures for the proper test

procedures. Replace the faulty battery, as

required.

6. The starting system is

faulty.6. Determine if the starting system is performing

to specifications. Refer to Starting System for the

proper starting system diagnosis and testing

procedures. Repair the faulty starting system, as

required.

7. The charging system is

faulty.7. Determine if the charging system is performing

to specifications. Refer to Charging System for

the proper charging system diagnosis and testing

procedures. Repair the faulty charging system, as

required.

8. Electrical loads exceed the

output of the charging

system.8. Inspect the vehicle for aftermarket electrical

equipment which might cause excessive electrical

loads.

9. Slow driving or prolonged

idling with high-amperage

draw systems in use.9. Advise the vehicle operator, as required.

THE BATTERY WILL NOT

ACCEPT A CHARGE.1. The battery is faulty. 1. Refer to Standard Procedures for the proper

battery charging procedures. Charge or replace

the faulty battery, as required.

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnor-

mal battery discharging:

²Corroded or loose battery posts and terminal

clamps.

²A loose or worn generator drive belt.

²Electrical loads that exceed the output of the

charging system. This can be due to equipment

installed after manufacture, or repeated short trip

use.²Slow driving speeds (heavy traffic conditions) or

prolonged idling, with high-amperage draw systems

in use.

²A faulty circuit or component causing excessive

ignition-off draw.

²A faulty or incorrect charging system compo-

nent. Refer to Charging System for the proper charg-

ing system diagnosis and testing procedures.

8F - 4 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

Page 1875 of 4284

CHARGING

TABLE OF CONTENTS

page page

CHARGING

DESCRIPTION...........................21

OPERATION.............................21

DIAGNOSIS AND TESTING.................22

ON-BOARD DIAGNOSTIC SYSTEM.........22

SPECIFICATIONS........................22

SPECIAL TOOLS.........................23

BATTERY TEMPERATURE SENSOR

DESCRIPTION...........................23

OPERATION.............................23

REMOVAL..............................23

GENERATOR

DESCRIPTION...........................23

OPERATION.............................23REMOVAL..............................23

INSTALLATION...........................24

GENERATOR DECOUPLER PULLEY

DESCRIPTION...........................25

OPERATION.............................25

DIAGNOSIS AND TESTING.................25

GENERATOR DECOUPLER...............25

REMOVAL..............................25

INSTALLATION...........................26

VOLTAGE REGULATOR

DESCRIPTION...........................26

OPERATION.............................26

REMOVAL..............................26

CHARGING

DESCRIPTION - CHARGING SYSTEM

The charging system consists of:

²Generator

²Decoupler Pulley (If equipped)

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch (refer to the Ignition System sec-

tion for information)

²Battery (refer to the Battery section for informa-

tion)

²Battery temperature sensor

²Voltmeter (refer to the Instrument Cluster sec-

tion for information)

²Wiring harness and connections (refer to the

Wiring section for information)

²Accessory drive belt (refer to the Cooling section

for more information)

OPERATION - CHARGING SYSTEM

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. When the

ASD relay is on, voltage is supplied to the ASD relay

sense circuit at the PCM. This voltage is connected

through the PCM and supplied to one of the genera-

tor field terminals (Gen. Source +) at the back of the

generator.

The generator is driven by the engine through a

serpentine belt and pulley or decoupler pulley

arrangement.The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

A battery temperature sensor is used to sense bat-

tery temperature. This temperature data, along with

data from monitored line voltage, is used by the PCM

to vary the battery charging rate. This is done by

cycling the ground path to control the strength of the

rotor magnetic field. The PCM then compensates and

regulates generator current output accordingly to

maintain system voltage at the targeted system volt-

age based on battery temperature.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for certain failures it detects. Refer to

On-Board Diagnostics in the Electronic Control Mod-

ules(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/POWERTRAIN CONTROL

MODULE - DESCRIPTION) section for more DTC

information.

The Check Gauges Lamp (if equipped) monitors:

charging system voltage,engine coolant tempera-

ture and engine oil pressure. If an extreme condition

is indicated, the lamp will be illuminated. This is

done as reminder to check the three gauges. The sig-

nal to activate the lamp is sent via the PCI bus cir-

cuits. The lamp is located on the instrument panel.

Refer to the Instrument Cluster section for additional

information.

RSCHARGING8F-21

Page 1878 of 4284

REMOVAL - 3.3/3.8L

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable.

(3) Disconnect the push-in field wire connector

from back of generator.

(4) Remove nut holding B+ wire terminal to back

of generator.

(5) Separate B+ terminal from generator.

(6) Raise vehicle and support.

(7) Remove the right front lower splash shield.

(8) Remove accessory drive belt, refer to the Cool-

ing System section for proper procedures.

(9) Remove the lower oil dip stick tube bolt (Fig.

2).

(10) Remove wiring harness from the oil dip stick

tube

(11) Remove the 3 mounting bolts.

(12) Lower vehicle.

(13) Remove oil dip stick tube from vehicle.

(14) Roll and remove the generator from vehicle

(Fig. 3).

INSTALLATION - 2.4L

(1) Install the generator.

(2) Install the accessory drive belt, refer to the

Cooling System section for proper procedures.

(3) Connect B+ terminal to generator.

(4) Install nut holding B+ wire terminal to back of

generator.

(5) Connect the push-in field wire connector to

back of generator.

(6) Install the EVAP Purge solenoid to its bracket.(7) Install the Air Box, refer to the Engine/Air

Cleaner for more information.

(8) Connect the Inlet Air Temperature sensor.

(9) Connect battery negative cable.

INSTALLATION - 3.3/3.8L

(1) Roll and place generator in position on vehicle

(Fig. 3).

(2) Install upper bolts to hold generator in place.

(3) Lubricate the o-ring. Install oil dip stick tube.

(4) Install the upper oil dip stick tube bolt.

(5) Place B+ terminal in position on generator.

(6) Install nut to hold B+ wire terminal to back of

generator.

(7) Connect the push-in field wire connector into

back of generator.

(8) Raise vehicle and support.

(9) Install the lower mounting bolt and tighten.

(10) Install the lower oil dip stick tube bolt and

tighten (Fig. 2).

(11) Install accessory drive belt, refer to the Cool-

ing System section for proper procedures.

(12) Install the right front lower splash shield.

(13) Lower vehicle.

(14) Install wiring harness to the oil dip stick tube

(15) Connect battery negative cable.

(16) Verify generator output rate.

Fig. 2 DIP STICK LOWER BOLT

Fig. 3 GENERATOR 3.3/3.8L

8F - 24 CHARGINGRS

GENERATOR (Continued)

Page 1880 of 4284

INSTALLATION

(1) Install the Generator Decoupler to the genera-

tor shaft.

(2) Use Special Tool #8433 (Fig. 6) to tighten the

Generator Decoupler. Refer to the torque chart for

the proper torque.

(3) Install the Air Box, refer to the Engine section

for more information.

(4) Raise vehicle and support.

(5) Install accessory drive belt, refer to the Cooling

System section for proper procedures (Fig. 5).

(6) Install the right front lower splash shield.

(7) Lower vehicle.

(8) Connect battery negative cable.

VOLTAGE REGULATOR

DESCRIPTION

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

OPERATION

The amount of DC current produced by the gener-

ator is controlled by EVR circuitry contained within

the PCM. This circuitry is connected in series with

the generators second rotor field terminal and its

ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage (B+) and

battery temperature or inlet air temperature sensor

(refer to Battery Temperature Sensor or Inlet Air

Temperature Sensor for more information). It then

determines a target charging voltage. If sensed bat-

tery voltage is 325 mv or lower than the target volt-

age, the PCM grounds the field winding until sensed

battery volage is 325 mv above target voltage. A cir-

cuit in the PCM cycles the ground side of the gener-

ator field up to 250 times per second (250Hz), but

has the capability to ground the field control wire

100% of the time (full field) to achieve the target

voltage. If the charging rate cannot be monitored

(limp-in), a duty cycle of 25% is used by the PCM in

order to have some generator output. Also refer to

Charging System Operation for additional informa-

tion.

REMOVAL

The electronic voltage regulator is not a serviced

separately. If replacement is necessary, the PCM

must be replaced.

Fig. 6 SPECIAL TOOL 8433 AND DECOUPLER

8F - 26 CHARGINGRS

GENERATOR DECOUPLER PULLEY (Continued)

Page 2633 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

OIL CONSUMPTION OR SPARK

PLUGS FOULED1. PCV system malfunction. 1. Check system and repair as

necessary. (Refer to 25 -

EMISSIONS CONTROL/

EVAPORATIVE EMISSIONS/PCV

VALVE - DIAGNOSIS AND

TESTING)

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new

rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check

grooves. If groove is not proper

width, replace piston.

5. Worn valve guide(s). 5. Replace cylinder head assembly.

6. Valve stem seal(s) worn or

damaged.6. Replace seal(s).

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 2).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS

Damaged or worn threads (excluding spark plug

and camshaft bearing cap attaching threads) can be

repaired. Essentially, this repair consists of drilling

out worn or damaged threads, tapping the hole with

a special Heli-Coil Tap, (or equivalent) and installing

an insert into the tapped hole. This brings the hole

back to its original thread size.

CAUTION: Be sure that the tapped holes maintain

the original center line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

Fig. 2 CORE HOLE PLUG REMOVAL

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

Page 2636 of 4284

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) (Refer to 9

- ENGINE/ENGINE BLOCK/CONNECTING ROD

BEARINGS - STANDARD PROCEDURE)

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect battery negative cable.

(3) Remove air cleaner housing and inlet tube.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- STANDARD PROCEDURE)

(5) Disconnect all vacuum hoses.

(6) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(7) Remove radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL)

(8) Remove radiator upper and lower hoses.

(9) Disconnect automatic transmission cooler lines

and plug.(10) Disconnect transmission shift linkage and

electrical connectors.

(11) Disconnect throttle body linkage.

(12) Disconnect engine wiring harness.

(13) Disconnect heater hoses from heater (Fig. 5).

(14) Discharge air conditioning system. (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE)

(15) Hoist vehicle and remove front wheels and

tires.

(16) Remove accessory drive belt splash shield.

(17) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(18) Remove axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)

(19) Drain engine oil and remove oil filter. (Refer

to 9 - ENGINE/LUBRICATION/OIL - STANDARD

PROCEDURE)

(20) Remove crossmember cradle plate (Fig. 6).

(21) Disconnect exhaust pipe from manifold (Fig.

7).

(22) Remove engine front mount and bracket from

engine. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - REMOVAL)

(23) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

Fig. 5 HEATER HOSES - 2.4L

1 - HEATER HOSES TO HEATER 3 - HEATER HOSE TO ENGINE - SUPPLY AND RETURN

2 - BOLT - HEATER TUBE SUPPORT

9 - 12 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 2637 of 4284

(24) Remove rear engine mount bracket. (Refer to

9 - ENGINE/ENGINE MOUNTING/REAR MOUNT -

REMOVAL)

(25) Mark flex plate to torque converter and

remove torque converter bolts.

(26) Pinch-off power steering supply hose at pump.

Remove hose from pump.

(27) Remove and set aside the power steering

pump and bracket. Do not disconnect pressure line.

(28) Lower vehicle.(29) Remove A/C lines at compressor and cap open-

ings.

(30) Remove engine ground straps (strap at engine

right mount and at starter).

(31) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 to be installed under vehicle

(Fig. 8).

(32) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

oil pan rails (Fig. 8). Lower vehicle and position cra-

dle mounts until the engine is resting on mounts.

Tighten mounts to cradle frame. This will keep

mounts from moving when removing or installing

engine and transmission.

(33) Install safety straps around the engine to cra-

dle. Tighten straps and lock.

(34) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(35) Remove engine and transmission mount bolts.

(36) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around the body.

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

(Fig. 9) and left mounts (Fig. 10).

(3) Remove safety straps.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(5) Install rear mount bracket and rear mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/REAR MOUNT - INSTALLATION)

(6) Install the flex plate to torque converter bolts.

(7) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(8) Install front mount bracket and front mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/FRONT MOUNT - INSTALLATION)

(9) Connect exhaust system to manifold (Fig. 7).

(10) Install crossmember cradle plate (Fig. 6).

(11) Install new oil filter.

(12) Install power steering pump and bracket.

(13) Connect power steering supply line to pump

and remove pinch-off pliers.

(14) Connect A/C compressor hoses to compressor.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - CATALYTIC CONVERTER

2 - BOLT

3 - GASKET

4 - FLAG NUT

RSENGINE 2.4L9-13

ENGINE 2.4L (Continued)

Page 2639 of 4284

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Connect automatic transmission cooler lines

to transaxle.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.(24) Connect all vacuum lines.

(25) Connect the throttle cables.

(26) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(27) Connect radiator lower and upper hoses.

(28) Install radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION)

(29) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(30) Connect battery cables.

(31) Install air cleaner and inlet hose.

(32) Fill engine crankcase with proper oil to cor-

rect level.

(33) Start engine and run until operating temper-

ature is reached.

(34) Adjust transmission linkage, if necessary.

1 - SPECIAL TOOL POSTS 6848 4 - SPECIAL TOOL 6710 CRADLE

2 - SPECIAL TOOL 6135 DOLLY 5 - SPECIAL TOOL 6848 - POST CONTACT ON PAN RAIL

3 - SPECIAL TOOL POSTS 6848

Fig. 9 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 10 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

RSENGINE 2.4L9-15

ENGINE 2.4L (Continued)