steering wheel CHRYSLER VOYAGER 2001 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1908 of 4284

depressed, the Low position is selected and the high

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the low position LED indica-

tor illuminates. When the switch rocker is moved to

its neutral position (middle), Off is selected and both

LED indicators are extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the BCM to indicate the

selected switch position. The BCM monitors the

switch inputs and sends heated seat switch status

messages to the Heated Seat Module (HSM) or the

Memory Heated Seat Module (MHSM) over the Pro-

grammable Communications Interface (PCI) data

bus. The HSM or MHSM responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS & TESTING - HEATED SEAT

SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run)

fuse in the intelligent power module. If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the intelligent power module. If

OK, go to Step 3. If not OK, repair the open fused

ignition switch output (run) circuit to the ignition

switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel and disconnect the instrument panel wire har-

ness connectors from the heated seat switch connec-

tor receptacle. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seat

switch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the intelligent power

module fuse as required.

(5) Test the heated seat switch(es) as shown in the

Heated Seat Switch Test chart (Fig. 6). If OK, go to

Step 6. If not OK, replace the faulty heated seat

switch(es).

PASSENGER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin3&4OPEN

Low Pin3&43570

High Pin3&41430

All resistance values are61%.

(6) Disconnect the instrument panel wire harness

connector from the Body Control Module (BCM) con-

nector receptacle. Check for continuity between the

seat heater switch sensor ground circuit cavity of the

instrument panel wire harness connector for the

inoperative heated seat switch(es) and a good ground.

There should be no continuity. If OK, go to Step 7. If

not OK, repair the shorted seat heater switch sensor

ground circuit as required.

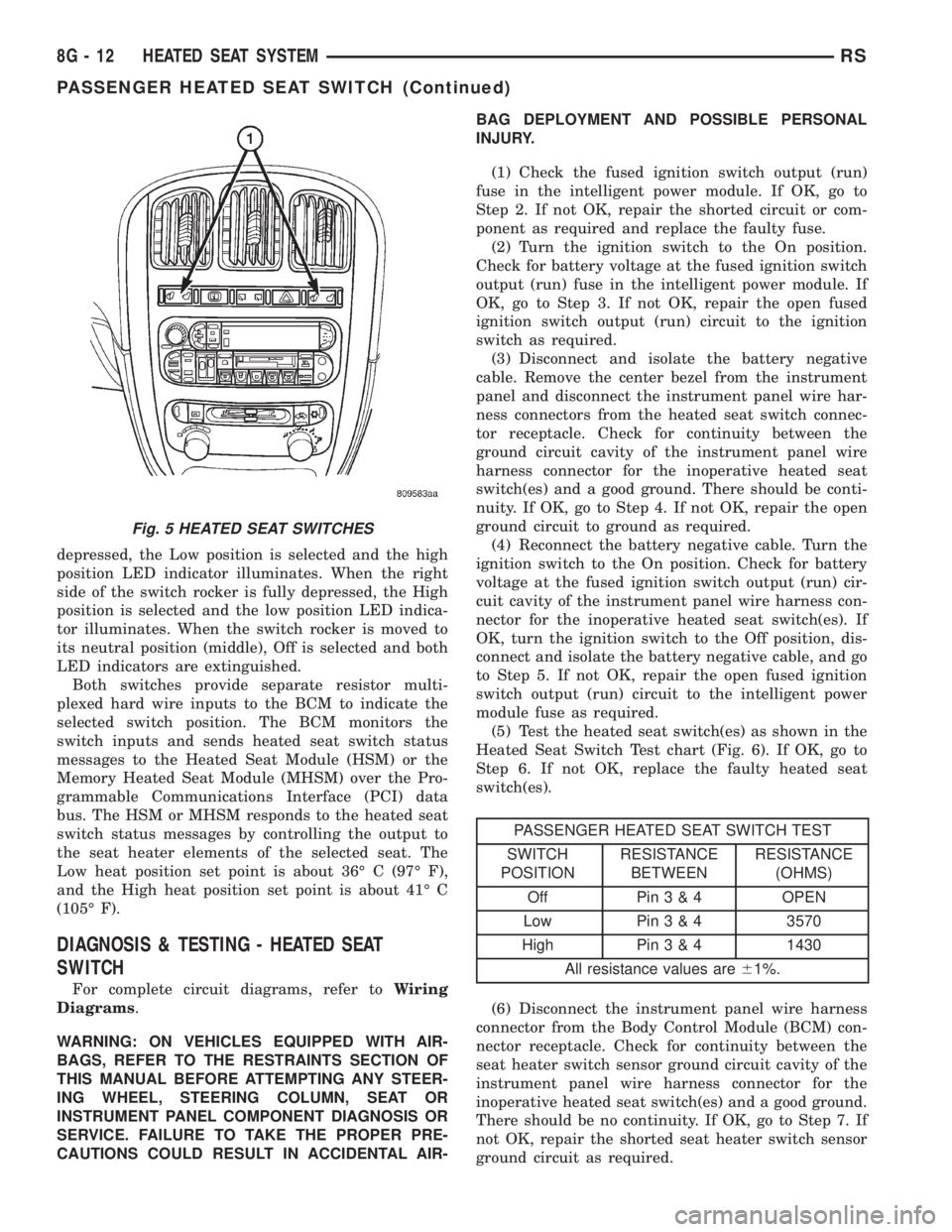

Fig. 5 HEATED SEAT SWITCHES

8G - 12 HEATED SEAT SYSTEMRS

PASSENGER HEATED SEAT SWITCH (Continued)

Page 1909 of 4284

(7) Check for continuity between the seat heater

switch sensor ground circuit cavities of the instru-

ment panel wire harness connector for the in opera-

tive heated seat switch and the instrument panel

wire harness connector for the BCM. There should be

continuity. If OK, go to Step 8. If not OK, repair the

open seat heater switch sensor ground circuit as

required.

(8) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and a good ground. There should be no

continuity. If OK, go to Step 9. If not OK, repair the

shorted seat heater switch mux circuit as required.

(9) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and the instrument panel wire harness

connector for the BCM. There should be continuity. If

OK, use a DRB IIItscan tool and the proper Diag-

nostic Procedures manual to test the BCM. If not

OK, repair the open seat heater switch mux circuit

as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

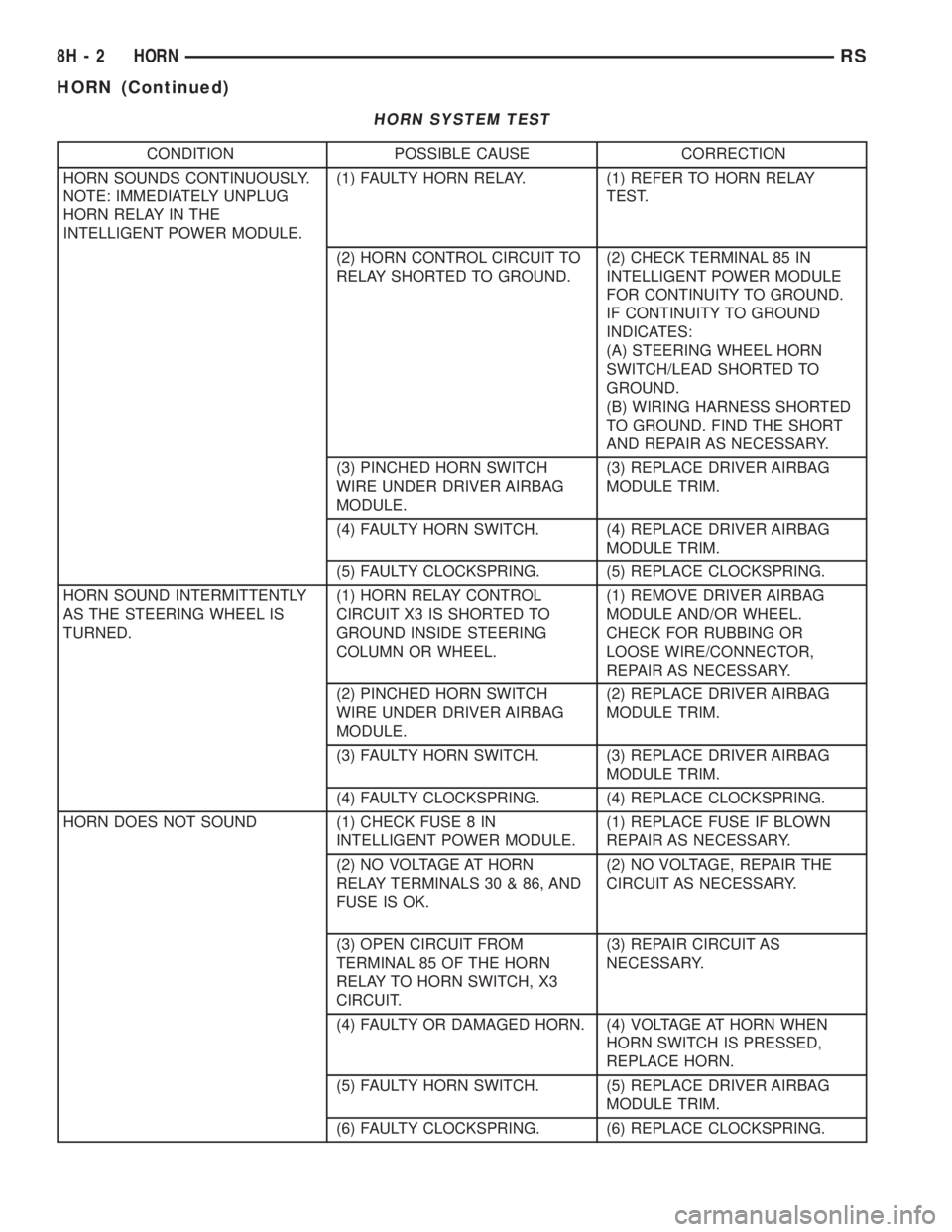

(3) Remove the three screws (Fig. 7) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel. Tighten the screws to 1.5 N´m (13

in. lbs.) (Fig. 4).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.

(4) Reconnect the battery negative cable.

Fig. 6 SWITCH CONNECTOR

Fig. 7 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

RSHEATED SEAT SYSTEM8G-13

PASSENGER HEATED SEAT SWITCH (Continued)

Page 1912 of 4284

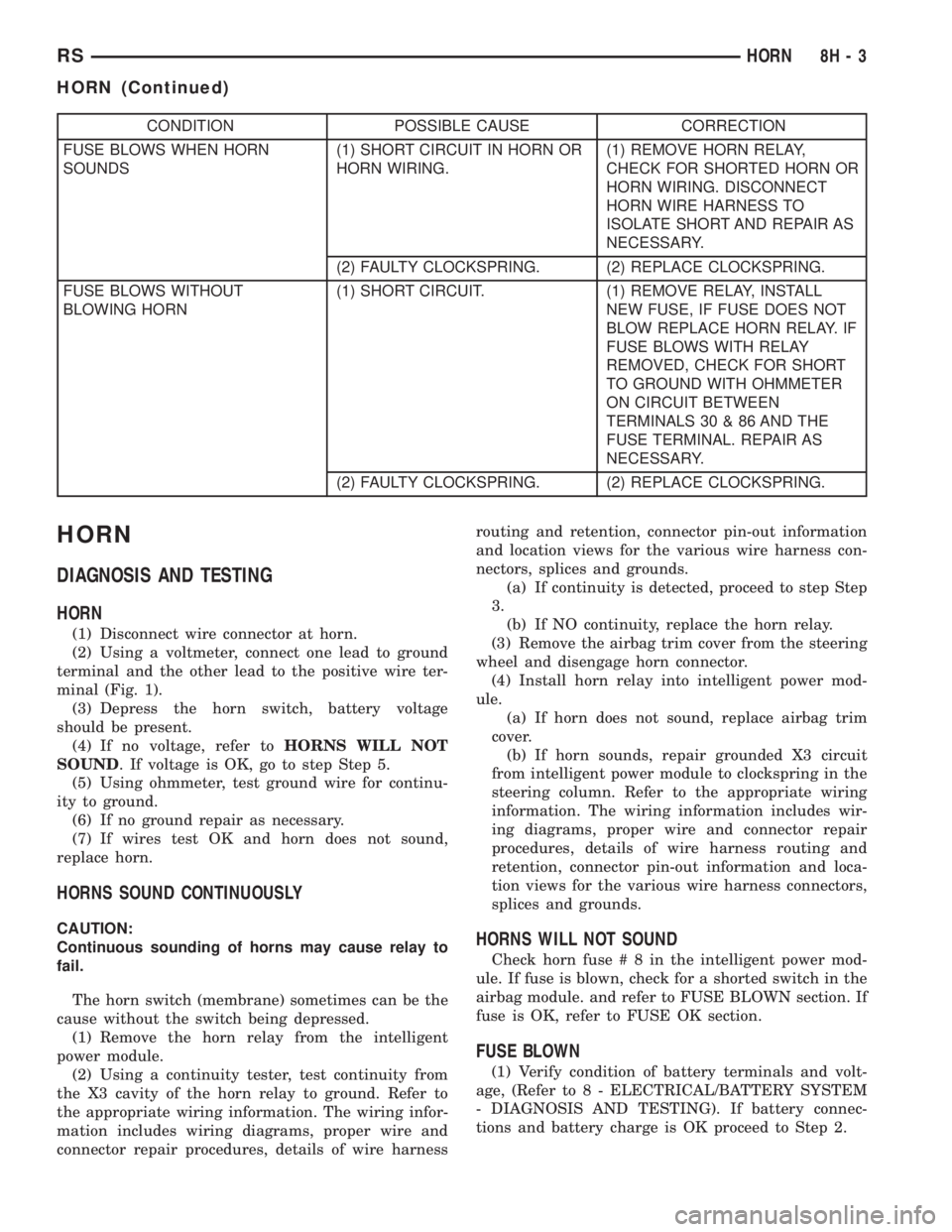

HORN SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

HORN SOUNDS CONTINUOUSLY.

NOTE: IMMEDIATELY UNPLUG

HORN RELAY IN THE

INTELLIGENT POWER MODULE.(1) FAULTY HORN RELAY. (1) REFER TO HORN RELAY

TEST.

(2) HORN CONTROL CIRCUIT TO

RELAY SHORTED TO GROUND.(2) CHECK TERMINAL 85 IN

INTELLIGENT POWER MODULE

FOR CONTINUITY TO GROUND.

IF CONTINUITY TO GROUND

INDICATES:

(A) STEERING WHEEL HORN

SWITCH/LEAD SHORTED TO

GROUND.

(B) WIRING HARNESS SHORTED

TO GROUND. FIND THE SHORT

AND REPAIR AS NECESSARY.

(3) PINCHED HORN SWITCH

WIRE UNDER DRIVER AIRBAG

MODULE.(3) REPLACE DRIVER AIRBAG

MODULE TRIM.

(4) FAULTY HORN SWITCH. (4) REPLACE DRIVER AIRBAG

MODULE TRIM.

(5) FAULTY CLOCKSPRING. (5) REPLACE CLOCKSPRING.

HORN SOUND INTERMITTENTLY

AS THE STEERING WHEEL IS

TURNED.(1) HORN RELAY CONTROL

CIRCUIT X3 IS SHORTED TO

GROUND INSIDE STEERING

COLUMN OR WHEEL.(1) REMOVE DRIVER AIRBAG

MODULE AND/OR WHEEL.

CHECK FOR RUBBING OR

LOOSE WIRE/CONNECTOR,

REPAIR AS NECESSARY.

(2) PINCHED HORN SWITCH

WIRE UNDER DRIVER AIRBAG

MODULE.(2) REPLACE DRIVER AIRBAG

MODULE TRIM.

(3) FAULTY HORN SWITCH. (3) REPLACE DRIVER AIRBAG

MODULE TRIM.

(4) FAULTY CLOCKSPRING. (4) REPLACE CLOCKSPRING.

HORN DOES NOT SOUND (1) CHECK FUSE 8 IN

INTELLIGENT POWER MODULE.(1) REPLACE FUSE IF BLOWN

REPAIR AS NECESSARY.

(2) NO VOLTAGE AT HORN

RELAY TERMINALS 30 & 86, AND

FUSE IS OK.(2) NO VOLTAGE, REPAIR THE

CIRCUIT AS NECESSARY.

(3) OPEN CIRCUIT FROM

TERMINAL 85 OF THE HORN

RELAY TO HORN SWITCH, X3

CIRCUIT.(3) REPAIR CIRCUIT AS

NECESSARY.

(4) FAULTY OR DAMAGED HORN. (4) VOLTAGE AT HORN WHEN

HORN SWITCH IS PRESSED,

REPLACE HORN.

(5) FAULTY HORN SWITCH. (5) REPLACE DRIVER AIRBAG

MODULE TRIM.

(6) FAULTY CLOCKSPRING. (6) REPLACE CLOCKSPRING.

8H - 2 HORNRS

HORN (Continued)

Page 1913 of 4284

CONDITION POSSIBLE CAUSE CORRECTION

FUSE BLOWS WHEN HORN

SOUNDS(1) SHORT CIRCUIT IN HORN OR

HORN WIRING.(1) REMOVE HORN RELAY,

CHECK FOR SHORTED HORN OR

HORN WIRING. DISCONNECT

HORN WIRE HARNESS TO

ISOLATE SHORT AND REPAIR AS

NECESSARY.

(2) FAULTY CLOCKSPRING. (2) REPLACE CLOCKSPRING.

FUSE BLOWS WITHOUT

BLOWING HORN(1) SHORT CIRCUIT. (1) REMOVE RELAY, INSTALL

NEW FUSE, IF FUSE DOES NOT

BLOW REPLACE HORN RELAY. IF

FUSE BLOWS WITH RELAY

REMOVED, CHECK FOR SHORT

TO GROUND WITH OHMMETER

ON CIRCUIT BETWEEN

TERMINALS 30 & 86 AND THE

FUSE TERMINAL. REPAIR AS

NECESSARY.

(2) FAULTY CLOCKSPRING. (2) REPLACE CLOCKSPRING.

HORN

DIAGNOSIS AND TESTING

HORN

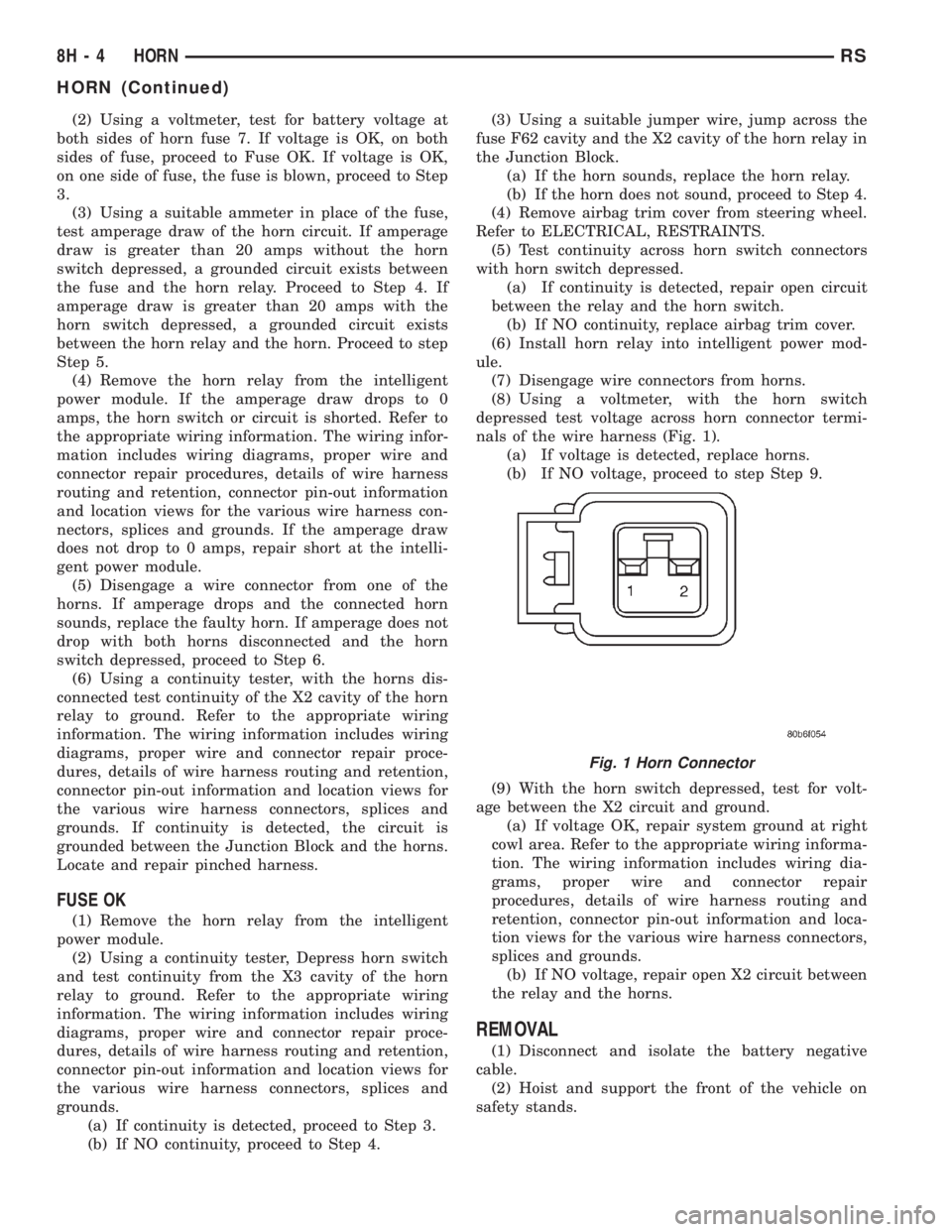

(1) Disconnect wire connector at horn.

(2) Using a voltmeter, connect one lead to ground

terminal and the other lead to the positive wire ter-

minal (Fig. 1).

(3) Depress the horn switch, battery voltage

should be present.

(4) If no voltage, refer toHORNS WILL NOT

SOUND. If voltage is OK, go to step Step 5.

(5) Using ohmmeter, test ground wire for continu-

ity to ground.

(6) If no ground repair as necessary.

(7) If wires test OK and horn does not sound,

replace horn.

HORNS SOUND CONTINUOUSLY

CAUTION:

Continuous sounding of horns may cause relay to

fail.

The horn switch (membrane) sometimes can be the

cause without the switch being depressed.

(1) Remove the horn relay from the intelligent

power module.

(2) Using a continuity tester, test continuity from

the X3 cavity of the horn relay to ground. Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harnessrouting and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(a) If continuity is detected, proceed to step Step

3.

(b) If NO continuity, replace the horn relay.

(3) Remove the airbag trim cover from the steering

wheel and disengage horn connector.

(4) Install horn relay into intelligent power mod-

ule.

(a) If horn does not sound, replace airbag trim

cover.

(b) If horn sounds, repair grounded X3 circuit

from intelligent power module to clockspring in the

steering column. Refer to the appropriate wiring

information. The wiring information includes wir-

ing diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and loca-

tion views for the various wire harness connectors,

splices and grounds.HORNS WILL NOT SOUND

Check horn fuse#8intheintelligent power mod-

ule. If fuse is blown, check for a shorted switch in the

airbag module. and refer to FUSE BLOWN section. If

fuse is OK, refer to FUSE OK section.

FUSE BLOWN

(1) Verify condition of battery terminals and volt-

age, (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- DIAGNOSIS AND TESTING). If battery connec-

tions and battery charge is OK proceed to Step 2.

RSHORN8H-3

HORN (Continued)

Page 1914 of 4284

(2) Using a voltmeter, test for battery voltage at

both sides of horn fuse 7. If voltage is OK, on both

sides of fuse, proceed to Fuse OK. If voltage is OK,

on one side of fuse, the fuse is blown, proceed to Step

3.

(3) Using a suitable ammeter in place of the fuse,

test amperage draw of the horn circuit. If amperage

draw is greater than 20 amps without the horn

switch depressed, a grounded circuit exists between

the fuse and the horn relay. Proceed to Step 4. If

amperage draw is greater than 20 amps with the

horn switch depressed, a grounded circuit exists

between the horn relay and the horn. Proceed to step

Step 5.

(4) Remove the horn relay from the intelligent

power module. If the amperage draw drops to 0

amps, the horn switch or circuit is shorted. Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. If the amperage draw

does not drop to 0 amps, repair short at the intelli-

gent power module.

(5) Disengage a wire connector from one of the

horns. If amperage drops and the connected horn

sounds, replace the faulty horn. If amperage does not

drop with both horns disconnected and the horn

switch depressed, proceed to Step 6.

(6) Using a continuity tester, with the horns dis-

connected test continuity of the X2 cavity of the horn

relay to ground. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds. If continuity is detected, the circuit is

grounded between the Junction Block and the horns.

Locate and repair pinched harness.

FUSE OK

(1) Remove the horn relay from the intelligent

power module.

(2) Using a continuity tester, Depress horn switch

and test continuity from the X3 cavity of the horn

relay to ground. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.

(a) If continuity is detected, proceed to Step 3.

(b) If NO continuity, proceed to Step 4.(3) Using a suitable jumper wire, jump across the

fuse F62 cavity and the X2 cavity of the horn relay in

the Junction Block.

(a) If the horn sounds, replace the horn relay.

(b) If the horn does not sound, proceed to Step 4.

(4) Remove airbag trim cover from steering wheel.

Refer to ELECTRICAL, RESTRAINTS.

(5) Test continuity across horn switch connectors

with horn switch depressed.

(a) If continuity is detected, repair open circuit

between the relay and the horn switch.

(b) If NO continuity, replace airbag trim cover.

(6) Install horn relay into intelligent power mod-

ule.

(7) Disengage wire connectors from horns.

(8) Using a voltmeter, with the horn switch

depressed test voltage across horn connector termi-

nals of the wire harness (Fig. 1).

(a) If voltage is detected, replace horns.

(b) If NO voltage, proceed to step Step 9.

(9) With the horn switch depressed, test for volt-

age between the X2 circuit and ground.

(a) If voltage OK, repair system ground at right

cowl area. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and loca-

tion views for the various wire harness connectors,

splices and grounds.

(b) If NO voltage, repair open X2 circuit between

the relay and the horns.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Hoist and support the front of the vehicle on

safety stands.

Fig. 1 Horn Connector

8H - 4 HORNRS

HORN (Continued)

Page 1923 of 4284

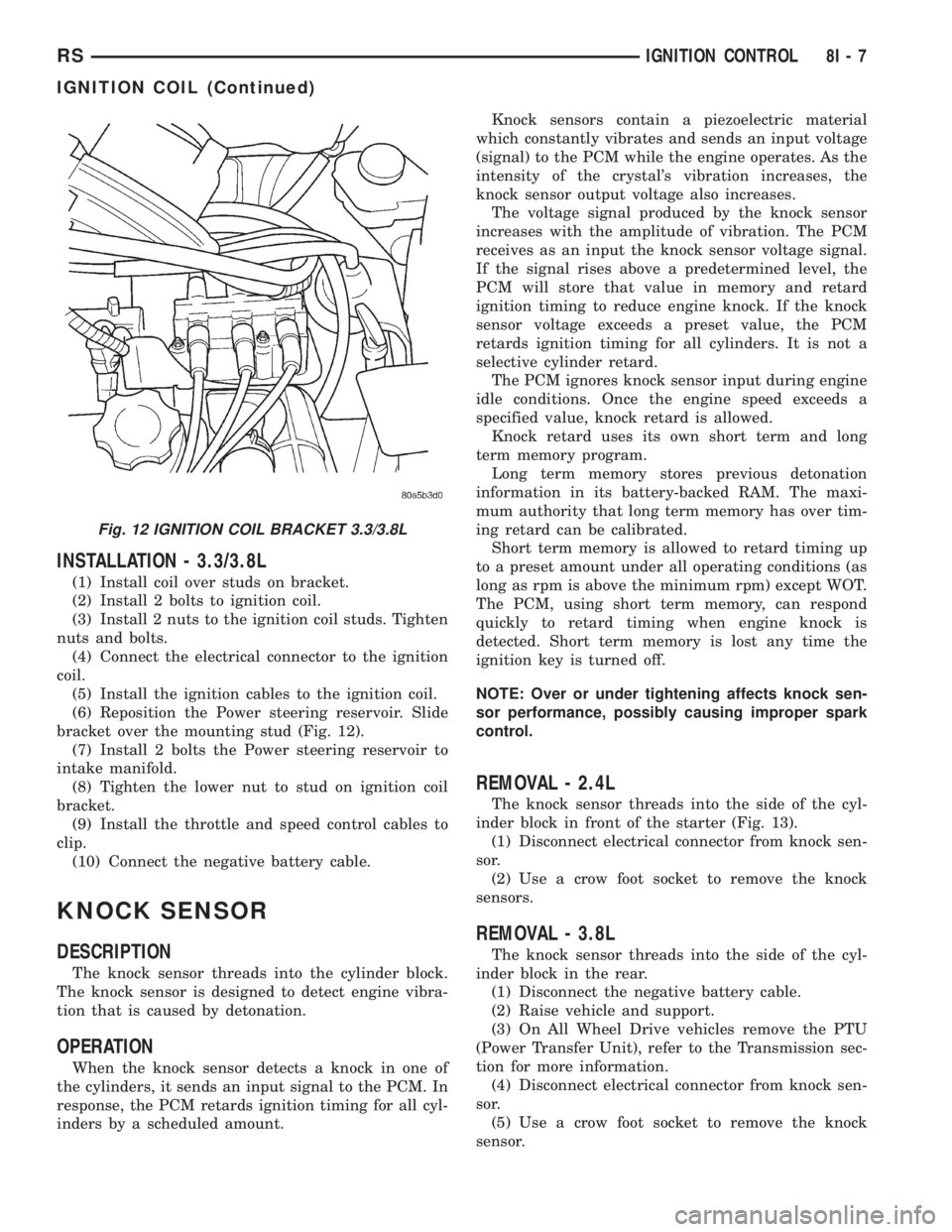

INSTALLATION - 3.3/3.8L

(1) Install coil over studs on bracket.

(2) Install 2 bolts to ignition coil.

(3) Install 2 nuts to the ignition coil studs. Tighten

nuts and bolts.

(4) Connect the electrical connector to the ignition

coil.

(5) Install the ignition cables to the ignition coil.

(6) Reposition the Power steering reservoir. Slide

bracket over the mounting stud (Fig. 12).

(7) Install 2 bolts the Power steering reservoir to

intake manifold.

(8) Tighten the lower nut to stud on ignition coil

bracket.

(9) Install the throttle and speed control cables to

clip.

(10) Connect the negative battery cable.

KNOCK SENSOR

DESCRIPTION

The knock sensor threads into the cylinder block.

The knock sensor is designed to detect engine vibra-

tion that is caused by detonation.

OPERATION

When the knock sensor detects a knock in one of

the cylinders, it sends an input signal to the PCM. In

response, the PCM retards ignition timing for all cyl-

inders by a scheduled amount.Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increases, the

knock sensor output voltage also increases.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives as an input the knock sensor voltage signal.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except WOT.

The PCM, using short term memory, can respond

quickly to retard timing when engine knock is

detected. Short term memory is lost any time the

ignition key is turned off.

NOTE: Over or under tightening affects knock sen-

sor performance, possibly causing improper spark

control.

REMOVAL - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 13).

(1) Disconnect electrical connector from knock sen-

sor.

(2) Use a crow foot socket to remove the knock

sensors.

REMOVAL - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) On All Wheel Drive vehicles remove the PTU

(Power Transfer Unit), refer to the Transmission sec-

tion for more information.

(4) Disconnect electrical connector from knock sen-

sor.

(5) Use a crow foot socket to remove the knock

sensor.

Fig. 12 IGNITION COIL BRACKET 3.3/3.8L

RSIGNITION CONTROL8I-7

IGNITION COIL (Continued)

Page 1936 of 4284

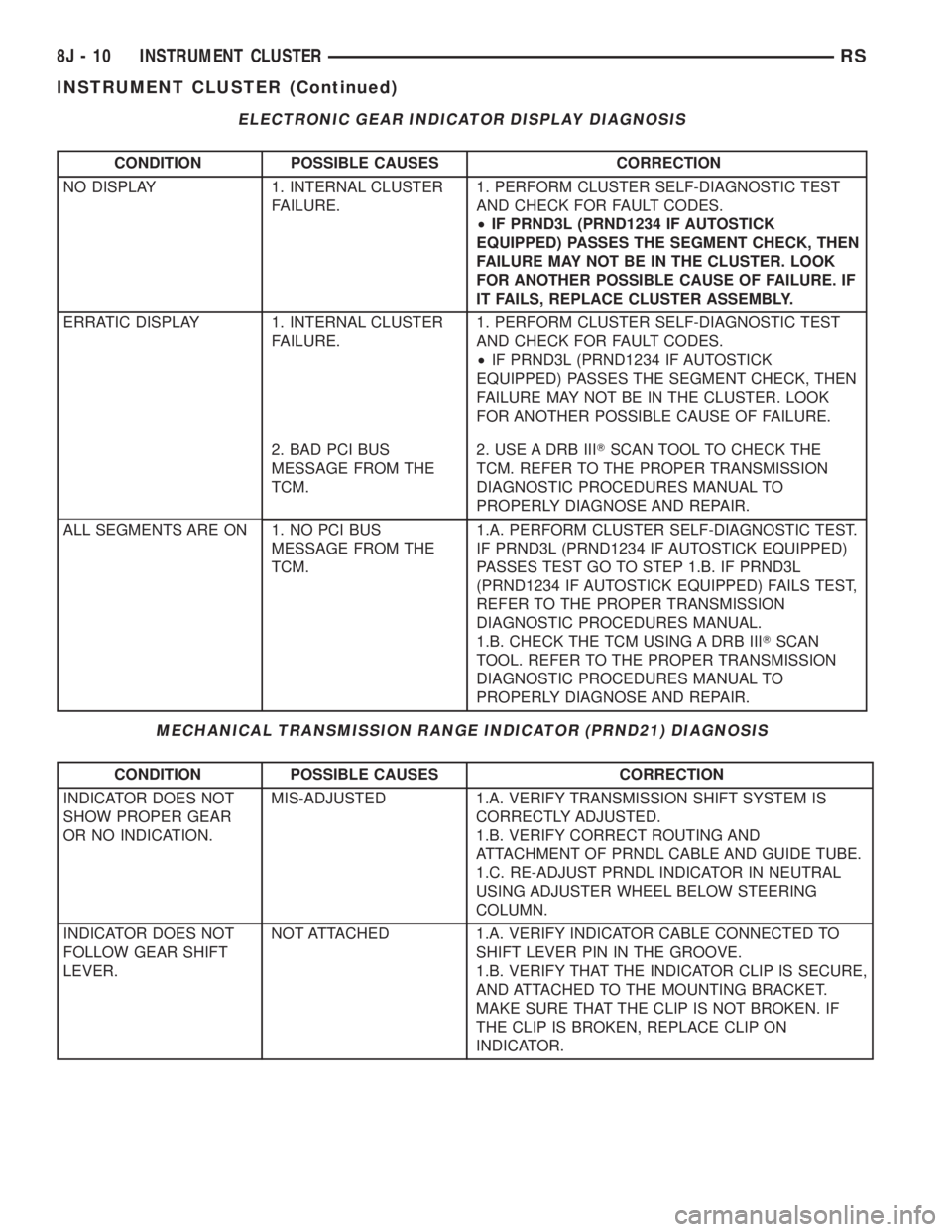

ELECTRONIC GEAR INDICATOR DISPLAY DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO DISPLAY 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK

EQUIPPED) PASSES THE SEGMENT CHECK, THEN

FAILURE MAY NOT BE IN THE CLUSTER. LOOK

FOR ANOTHER POSSIBLE CAUSE OF FAILURE. IF

IT FAILS, REPLACE CLUSTER ASSEMBLY.

ERRATIC DISPLAY 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK

EQUIPPED) PASSES THE SEGMENT CHECK, THEN

FAILURE MAY NOT BE IN THE CLUSTER. LOOK

FOR ANOTHER POSSIBLE CAUSE OF FAILURE.

2. BAD PCI BUS

MESSAGE FROM THE

TCM.2. USE A DRB IIITSCAN TOOL TO CHECK THE

TCM. REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO

PROPERLY DIAGNOSE AND REPAIR.

ALL SEGMENTS ARE ON 1. NO PCI BUS

MESSAGE FROM THE

TCM.1.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

IF PRND3L (PRND1234 IF AUTOSTICK EQUIPPED)

PASSES TEST GO TO STEP 1.B. IF PRND3L

(PRND1234 IF AUTOSTICK EQUIPPED) FAILS TEST,

REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL.

1.B. CHECK THE TCM USING A DRB IIITSCAN

TOOL. REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO

PROPERLY DIAGNOSE AND REPAIR.

MECHANICAL TRANSMISSION RANGE INDICATOR (PRND21) DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INDICATOR DOES NOT

SHOW PROPER GEAR

OR NO INDICATION.MIS-ADJUSTED 1.A. VERIFY TRANSMISSION SHIFT SYSTEM IS

CORRECTLY ADJUSTED.

1.B. VERIFY CORRECT ROUTING AND

ATTACHMENT OF PRNDL CABLE AND GUIDE TUBE.

1.C. RE-ADJUST PRNDL INDICATOR IN NEUTRAL

USING ADJUSTER WHEEL BELOW STEERING

COLUMN.

INDICATOR DOES NOT

FOLLOW GEAR SHIFT

LEVER.NOT ATTACHED 1.A. VERIFY INDICATOR CABLE CONNECTED TO

SHIFT LEVER PIN IN THE GROOVE.

1.B. VERIFY THAT THE INDICATOR CLIP IS SECURE,

AND ATTACHED TO THE MOUNTING BRACKET.

MAKE SURE THAT THE CLIP IS NOT BROKEN. IF

THE CLIP IS BROKEN, REPLACE CLIP ON

INDICATOR.

8J - 10 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 1954 of 4284

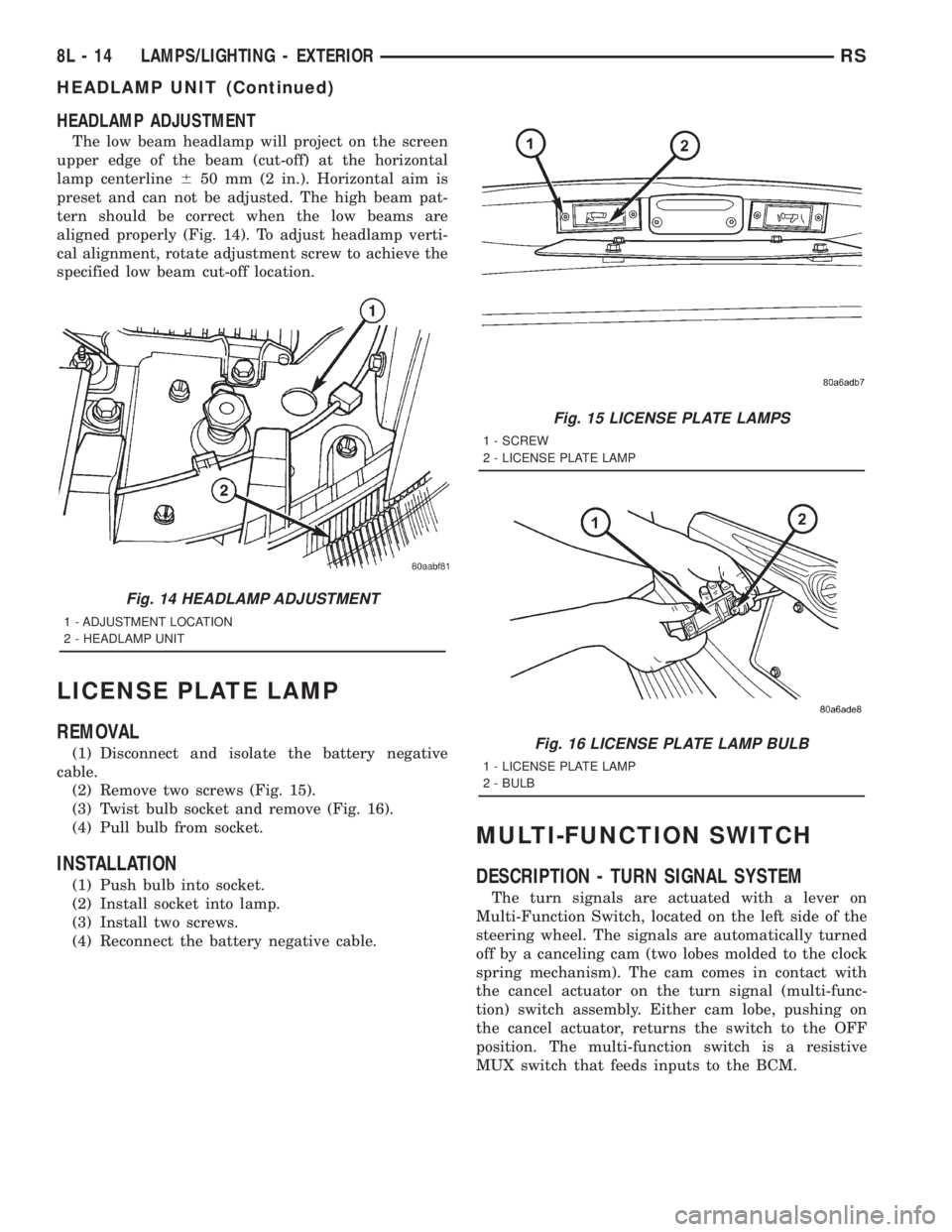

HEADLAMP ADJUSTMENT

The low beam headlamp will project on the screen

upper edge of the beam (cut-off) at the horizontal

lamp centerline650 mm (2 in.). Horizontal aim is

preset and can not be adjusted. The high beam pat-

tern should be correct when the low beams are

aligned properly (Fig. 14). To adjust headlamp verti-

cal alignment, rotate adjustment screw to achieve the

specified low beam cut-off location.

LICENSE PLATE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two screws (Fig. 15).

(3) Twist bulb socket and remove (Fig. 16).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into lamp.

(3) Install two screws.

(4) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The turn signals are actuated with a lever on

Multi-Function Switch, located on the left side of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position. The multi-function switch is a resistive

MUX switch that feeds inputs to the BCM.

Fig. 14 HEADLAMP ADJUSTMENT

1 - ADJUSTMENT LOCATION

2 - HEADLAMP UNIT

Fig. 15 LICENSE PLATE LAMPS

1 - SCREW

2 - LICENSE PLATE LAMP

Fig. 16 LICENSE PLATE LAMP BULB

1 - LICENSE PLATE LAMP

2 - BULB

8L - 14 LAMPS/LIGHTING - EXTERIORRS

HEADLAMP UNIT (Continued)

Page 2049 of 4284

AIRBAG SQUIB STATUS

(1) Using a DRBIIItread Airbag DTC's

Ifthe following active codes are present:

DTC CONDITIONS ACTIVE SQUIB

Driver Squib 1 openAND IFthe stored minutes for both are within 15

minutes of each other, both Driver Squib 1 and 2 were

used.Both Driver Squib 1 and

2 were used.

Driver Squib 2 open

Driver Squib 1 openAND IFthe stored minutes for Driver Squib 2 open is

GREATER than the stored minutes for Driver Squib 1

by 15 minutes or more.Driver Squib 1 was used;

Driver Squib 2 is live.

Driver Squib 2 open

Driver Squib 1 openAND IFthe stored minutes for Driver Squib 1 open is

GREATER than the stored minutes for Driver Squib 2

by 15 minutes or more.Driver Squib 1 is live;

Driver Squib 2 was used.

Driver Squib 2 open

IfDriver Squib 1 open is

an active codeAND IFDriver Squib 2 open is NOT an active code.Driver Squib 1 was used;

Driver Squib 2 is live.

IfDriver Squib 2 open is

an active codeAND IFDriver Squib 1 open is NOT an active code.Driver Squib 1 is live;

Driver Squib 2 was used.

Ifneither of the following codes is an active code:

DTC ACTIVE SQUIB

Driver squib 1 open

Status of Airbag is

Unknown.

Driver squib 2 open

NOTE: If the Driver/Passenger Airbag is defective

and not deployed, refer to DaimlerChrysler Motors

Corporation current return policies for proper han-

dling procedures.

DIAGNOSIS AND TESTING - AIRBAG SYSTEM

(1) Connect a DRBIIItscan tool to the Data Link

Connector (DLC), located at left side of the steering

column and at the lower edge of the lower instru-

ment panel.

(2) Turn the ignition key to ON position. Exit vehi-

cle with scan tool. Use the latest version of the

proper cartridge.

(3) After checking that no one is inside the vehicle,

connect the battery negative terminal.

(4) Using the DRBIIItscan tool, read and record

active diagnostic code data.

(5) Read and record any stored diagnostic codes.

(6) Refer to the proper Body Diagnostic Procedures

manual if any diagnostic codes are found in Step 4 or

Step 5.

(7) Erase stored diagnostic codes if there are no

active diagnostic codes. If problems remain, diagnos-

tic codes will not erase. Refer to the Proper Body

Diagnostic Procedures Manual to diagnose the prob-

lem.If airbag warning lamp either fails to light,

or goes on and stays on, there is a system mal-function. Refer to the proper Body Diagnostic

Procedures manual to diagnose the problem.

CLOCK SPRING

DESCRIPTION

The clock spring is screwed to a plastic mounting

platform on the steering column behind the steering

wheel. The clock spring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the drivers airbag.

OPERATION

This assembly consists of a flat ribbon like electri-

cally conductive tape which winds and unwinds with

the steering wheel rotation. The clock spring cannot

be repaired. If the clock spring is faulty, damaged, or

if the airbag has been deployed, the clock spring

must be replaced.

STANDARD PROCEDURE - CLOCK SPRING

CENTERING

If the rotating tape (wire coil) in the clock spring is

not positioned properly with the steering wheel and

the front wheels, the clock spring may fail. The fol-

lowing procedure MUST BE USED to center the

clock spring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

(1) Adjust the steering wheel so that the tires are

in a straight ahead position.

(2) Remove Driver Airbag from steering wheel.

(3) Disconnect wire connectors from back of airbag.

RSRESTRAINTS8O-3

RESTRAINTS (Continued)

Page 2050 of 4284

(4) Remove steering wheel.

(5) Depress the two plastic locking pins to disen-

gage lock mechanism.

(6) With lock mechanism disengaged, rotate the

clock spring rotor clockwise until the rotor stops. Do

not apply excessive force.

(7) From the end of travel, rotate the rotor three

turns counterclockwise. The wires should end up at

the top. Release locking pins to engage clock spring

lock mechanism.

(8) Install steering wheel and airbag.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood. Disconnect

and isolate the battery negative cable.

(3) Remove driver airbag from steering wheel.

(4) Disconnect wire connectors from back of driver

airbag.

(5) Disconnect the 2±way connector from remote

radio control harness.

(6) Remove steering wheel.

(7) Remove steering column shrouds.

(8) Disconnect 2-way and 5-way connectors

between the clock spring and the instrument panel

wiring harness.

(9) Remove clock spring from housing assembly by

removing the two retaining screws retaining the

clock spring.

INSTALLATION

(1) Position the clock spring into the housing.

Install the two retaining screws to clock spring.

(2) Connect the two way and five way harness

between the clock spring and the instrument panel.

(3) Install the steering wheel. Refer to Steering,

Column, Steering Wheel, Installation.

(4) Connect the harness connector to the driver

airbag.

(5) Connect the remote radio control harness.

(6)

Install the driver airbag into the steering wheel.

(7) Install the steering column upper and lower

shrouds.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

DRIVER AIRBAG

DESCRIPTION

The Driver Airbag is located in the center of the

steering wheel. The most visible part of the airbag is

the cover/horn switch.

OPERATION

The Driver Airbag cover contains the horn switch,

inflator device, and a fabric bag. The airbag cover/

horn switch is serviced separately from the inflator

and bag components.

WHEN THE FRONT AIRBAG SYSTEM IS

DEPLOYED BECAUSE OF A COLLISION, THE

FOLLOWING MUST BE REPLACED:

²COMPLETE STEERING COLUMN ASSEMBLY

²LOWER STEERING COUPLER

²STEERING WHEEL

²STEERING COLUMN CLOCK SPRING

²DRIVER AIRBAG

²PASSENGER AIRBAG

²UPPER INSTRUMENT PANEL WITH PAD

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - DEPLOYED DRIVER

AIRBAG CLEAN UP

Roll or fold the driver airbag towards the steering

wheel and then tape the bag to the steering wheel.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may be necessary

to decontaminate the interior of the vehicle.

SERVICE OF DEPLOYED AIRBAG

If a Driver Airbag has been deployed, but not due

to a collision, replace the following:

²Driver Airbag

²Clock Spring Assembly

8O - 4 RESTRAINTSRS

CLOCK SPRING (Continued)