diagnostic menu CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1851 of 4284

Schedule Condition Expected Operation

HotOil temperature at start-up above

80É F± Normal operation (upshift,

kickdowns, and coastdowns)

± Full EMCC, no PEMCC except to

engage FEMCC (except at closed

throttle at speeds above 70-83 mph)

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F± Delayed 2-3 upshift (25-32 mph)

± Delayed 3-4 upshift (41-48 mph)

± 3rd gear FEMCC from 30-48 mph

± 3rd gear PEMCC from 27-31 mph

Super OverheatOil temperature above 260É F ± All9Overheat9shift schedule

features apply

± 2nd gear PEMCC above 22 mph

± Above 22 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

Transmission Control Module (TCM) has been

replaced with a NEW or replacement unit. Failure to

perform this procedure will result in an inoperative

or improperly calibrated speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The TCM must

be calibrated to the different combinations of equip-

ment (final drive and tires) available. Pinion Factor

allows the technician to set the Transmission Control

Module initial setting so that the speedometer read-

ings will be correct. To properly read and/or reset the

Pinion Factor, it is necessary to use a DRB scan tool.

(1) Plug the DRB scan tool into the diagnostic con-

nector located under the instrument panel.

(2) Select the Transmission menu.

(3) Select the Miscellaneous menu.

(4) Select Pinion Factor. Then follow the instruc-

tions on the DRB scan tool screen.

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE

The quick learn procedure requires the use of the

DRB scan tool. This program allows the electronic

transaxle system to recalibrate itself. This will pro-

vide the best possible transaxle operation.NOTE: The quick learn procedure should be per-

formed if any of the following procedures are per-

formed:

²Transaxle Assembly Replacement

²Transmission Control Module Replacement

²Solenoid/Pressure Switch Assembly Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRB

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

(1) Plug the DRB scan tool into the diagnostic con-

nector. The connector is located under the instrument

panel.

(2) Go to the Transmission screen.

(3) Go to the Miscellaneous screen.

(4) Select Quick Learn Procedure. Follow the

instructions of the DRB to perform the Quick Learn

Procedure.

RSELECTRONIC CONTROL MODULES8E-27

TRANSMISSION CONTROL MODULE (Continued)

Page 1975 of 4284

The EVIC module contains a central processing

unit and interfaces with other electronic modules in

the vehicle over the Programmable Communications

Interface (PCI) J1850 data bus circuit. The PCI data

bus circuit allows the sharing of sensor information.

This helps to reduce wire harness complexity, reduce

internal controller hardware, and reduce component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities.

The EVIC ªMenuº push button provides the vehicle

operator with a user interface, which allows the

selection of several optional customer programmable

electronic features to suit individual preferences.

Refer toELECTRONIC VEHICLE INFORMA-

TION CENTER PROGRAMMINGin the Service

Procedures section of this group for more information

on the customer programmable feature options.

If the vehicle is equipped with the optional

Homelinkttransceiver, the EVIC will also display

messages and an icon indicating when the

Homelinkttransceiver is being trained, which of the

three transmitter buttons is transmitting, and when

the transceiver is cleared.

Data input for all EVIC functions, including VFD

dimming level, is received through the J1850 PCI

data bus circuit. The EVIC module uses its internal

programming and all of its data inputs to calculate

and display the requested data. If the data displayed

is incorrect, perform the self-diagnostic tests as

described in this group. If these tests prove inconclu-

sive, the use of a DRBIIItscan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the EVIC module and the J1850

PCI data bus circuit.

The EVIC module cannot be repaired, and is avail-

able for service only as a unit. This unit includes the

plastic module and display lens. If any of these com-

ponents is faulty or damaged, the complete EVIC

module must be replaced.

OPERATION

The EVIC has access to both non-switched and

ignition switched sources of battery current so that

some of its features remain operational at any time,

while others may only operate with the ignition

switch in the On position. When the ignition switch

is turned to the On position, the EVIC module VFD

will return to the last function being displayed before

the ignition was turned to the Off position.

The compass/thermometer display is the normal

EVIC display. With the ignition switch in the Onposition, momentarily depressing and releasing the

C/T (compass/thermometer) push button switch will

cause the EVIC to return to the compass/thermome-

ter/trip computer display mode from any other mode.

While in the compass/thermometer/trip computer dis-

play mode, momentarily depressing and releasing the

Step push button will step through the available trip

computer display options.

The EVIC trip computer features several functions

that can be reset. The functions that can be reset

are: average fuel economy, trip odometer and elapsed

time. With the ignition switch in the On position and

with one of the functions of the trip computer that

can be reset currently displayed, depressing the

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and the

function that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CEN-

TER PROGRAMMINGin the Service Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control func-

tions and setting procedures for the EVIC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS & TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

Electronic Vehicle Information Center (EVIC) data

is obtained from the Body Control Module (BCM) on

the J1850 Data Bus circuit. The EVIC will display

dashes (- -) for any of the screens it did not receive

the bus messages. The label corresponding to the

missing information will be lit. If no EVIC data is

displayed, check the J1850 Data Bus circuit commu-

nications and the BCM. If the brightness level is

improper check the J1850 Data Bus circuit.

The DRB IIItis recommended for checking the

J1850 Data Bus circuit and the BCM. Perform the

EVIC self diagnosis before replacing the EVIC mod-

ule.

RSOVERHEAD CONSOLE8M-7

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 2008 of 4284

STANDARD PROCEDURE - WELLNUT

REPLACEMENT

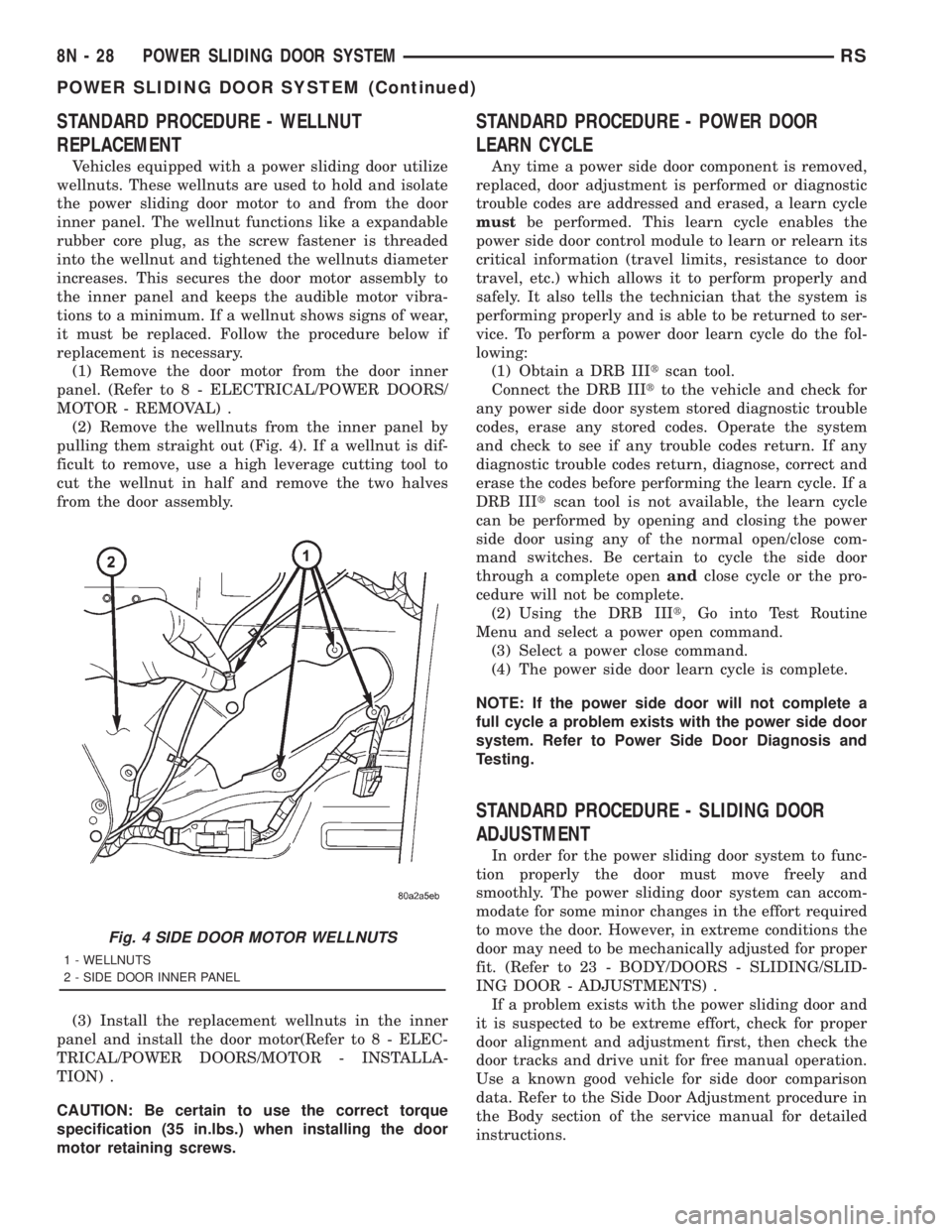

Vehicles equipped with a power sliding door utilize

wellnuts. These wellnuts are used to hold and isolate

the power sliding door motor to and from the door

inner panel. The wellnut functions like a expandable

rubber core plug, as the screw fastener is threaded

into the wellnut and tightened the wellnuts diameter

increases. This secures the door motor assembly to

the inner panel and keeps the audible motor vibra-

tions to a minimum. If a wellnut shows signs of wear,

it must be replaced. Follow the procedure below if

replacement is necessary.

(1) Remove the door motor from the door inner

panel. (Refer to 8 - ELECTRICAL/POWER DOORS/

MOTOR - REMOVAL) .

(2) Remove the wellnuts from the inner panel by

pulling them straight out (Fig. 4). If a wellnut is dif-

ficult to remove, use a high leverage cutting tool to

cut the wellnut in half and remove the two halves

from the door assembly.

(3) Install the replacement wellnuts in the inner

panel and install the door motor(Refer to 8 - ELEC-

TRICAL/POWER DOORS/MOTOR - INSTALLA-

TION) .

CAUTION: Be certain to use the correct torque

specification (35 in.lbs.) when installing the door

motor retaining screws.

STANDARD PROCEDURE - POWER DOOR

LEARN CYCLE

Any time a power side door component is removed,

replaced, door adjustment is performed or diagnostic

trouble codes are addressed and erased, a learn cycle

mustbe performed. This learn cycle enables the

power side door control module to learn or relearn its

critical information (travel limits, resistance to door

travel, etc.) which allows it to perform properly and

safely. It also tells the technician that the system is

performing properly and is able to be returned to ser-

vice. To perform a power door learn cycle do the fol-

lowing:

(1) Obtain a DRB IIItscan tool.

Connect the DRB IIItto the vehicle and check for

any power side door system stored diagnostic trouble

codes, erase any stored codes. Operate the system

and check to see if any trouble codes return. If any

diagnostic trouble codes return, diagnose, correct and

erase the codes before performing the learn cycle. If a

DRB IIItscan tool is not available, the learn cycle

can be performed by opening and closing the power

side door using any of the normal open/close com-

mand switches. Be certain to cycle the side door

through a complete openandclose cycle or the pro-

cedure will not be complete.

(2) Using the DRB IIIt, Go into Test Routine

Menu and select a power open command.

(3) Select a power close command.

(4) The power side door learn cycle is complete.

NOTE: If the power side door will not complete a

full cycle a problem exists with the power side door

system. Refer to Power Side Door Diagnosis and

Testing.

STANDARD PROCEDURE - SLIDING DOOR

ADJUSTMENT

In order for the power sliding door system to func-

tion properly the door must move freely and

smoothly. The power sliding door system can accom-

modate for some minor changes in the effort required

to move the door. However, in extreme conditions the

door may need to be mechanically adjusted for proper

fit. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS) .

If a problem exists with the power sliding door and

it is suspected to be extreme effort, check for proper

door alignment and adjustment first, then check the

door tracks and drive unit for free manual operation.

Use a known good vehicle for side door comparison

data. Refer to the Side Door Adjustment procedure in

the Body section of the service manual for detailed

instructions.

Fig. 4 SIDE DOOR MOTOR WELLNUTS

1 - WELLNUTS

2 - SIDE DOOR INNER PANEL

8N - 28 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)