torque CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 247 of 2399

CLUTCH DISC AND PRESSURE

PLATE - 2.5L TD

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove six (6) clutch pressure plate-to-fly-

wheel bolts. Remove pressure plate and disc from fly-

wheel (Fig. 21).

(3) Inspect flywheel. Resurface/replace as neces-

sary.

(4) Inspect clutch release bearing and lever.

Replace as necessary. (Refer to 6 - CLUTCH/

CLUTCH RELEASE BEARING - REMOVAL)

INSTALLATION

(1) Install clutch release bearing and lever (if

removed). (Refer to 6 - CLUTCH/CLUTCH RELEASE

BEARING - INSTALLATION)

(2) Install clutch disc and pressure plate to fly-

wheel (Fig. 21). Install clutch alignment tool, and

install and torque pressure plate-to-flywheel bolts to

28 N´m (250 in. lbs.).

(3) Install transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

Fig. 21 Clutch Disc and Pressure Plate

1 - FLYWHEEL

2 - DISC3 - PRESSURE PLATE

6 - 12 CLUTCHRS

ProCarManuals.com

Page 248 of 2399

FLYWHEEL

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove clutch pressure plate and disc. (Refer

to 6 - CLUTCH/CLUTCH DISC - REMOVAL)

(3) Remove flywheel assembly (Fig. 22).

INSTALLATION

(1) Install NEW flywheel-to-crankshaft bolts by

hand.

(2) Torque bolts in a criss-cross sequence to 25

N´m (18 ft. lbs.) (Fig. 22).

(3) Torque bolts in a criss-cross sequence an addi-

tional 60É.

(4) Install clutch pressure plate and disc. (Refer to

6 - CLUTCH/CLUTCH DISC - INSTALLATION)

(5) Install transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

INSTALLATION)

Fig. 22 Flywheel Bolt Torque Sequence

RSCLUTCH6-13

ProCarManuals.com

Page 250 of 2399

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM........1

DESCRIPTION - HOSE CLAMPS...........1

OPERATION

OPERATION - COOLING SYSTEM.........2

OPERATION - HOSE CLAMPS............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAK TEST....................2

DIAGNOSIS AND TESTING - COOLING

SYSTEM FLOW CHECK.................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM AERATION....................4

DIAGNOSIS AND TESTING - COOLING

SYSTEM DEAERATION..................4

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLING

SYSTEM DRAINING....................4STANDARD PROCEDURE - COOLING

SYSTEM FILLING......................4

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................4

STANDARD PROCEDURE - COOLANT

LEVEL CHECK........................5

SPECIFICATIONS

COOLING SYSTEM CAPACITY............6

ACCESSORY DRIVE BELT TENSION.......6

TORQUE.............................6

SPECIAL TOOLS

COOLING SYSTEM.....................7

ACCESSORY DRIVE.......................8

ENGINE...............................14

TRANSMISSION.........................38

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

The cooling system components consist of a radia-

tor, electric fan motors, shroud, pressure cap, thermo-

stat, transmission oil cooler, water pump, hoses,

clamps, coolant, and a coolant reserve system to com-

plete the circuit.

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopartequipment spring

type clamp.

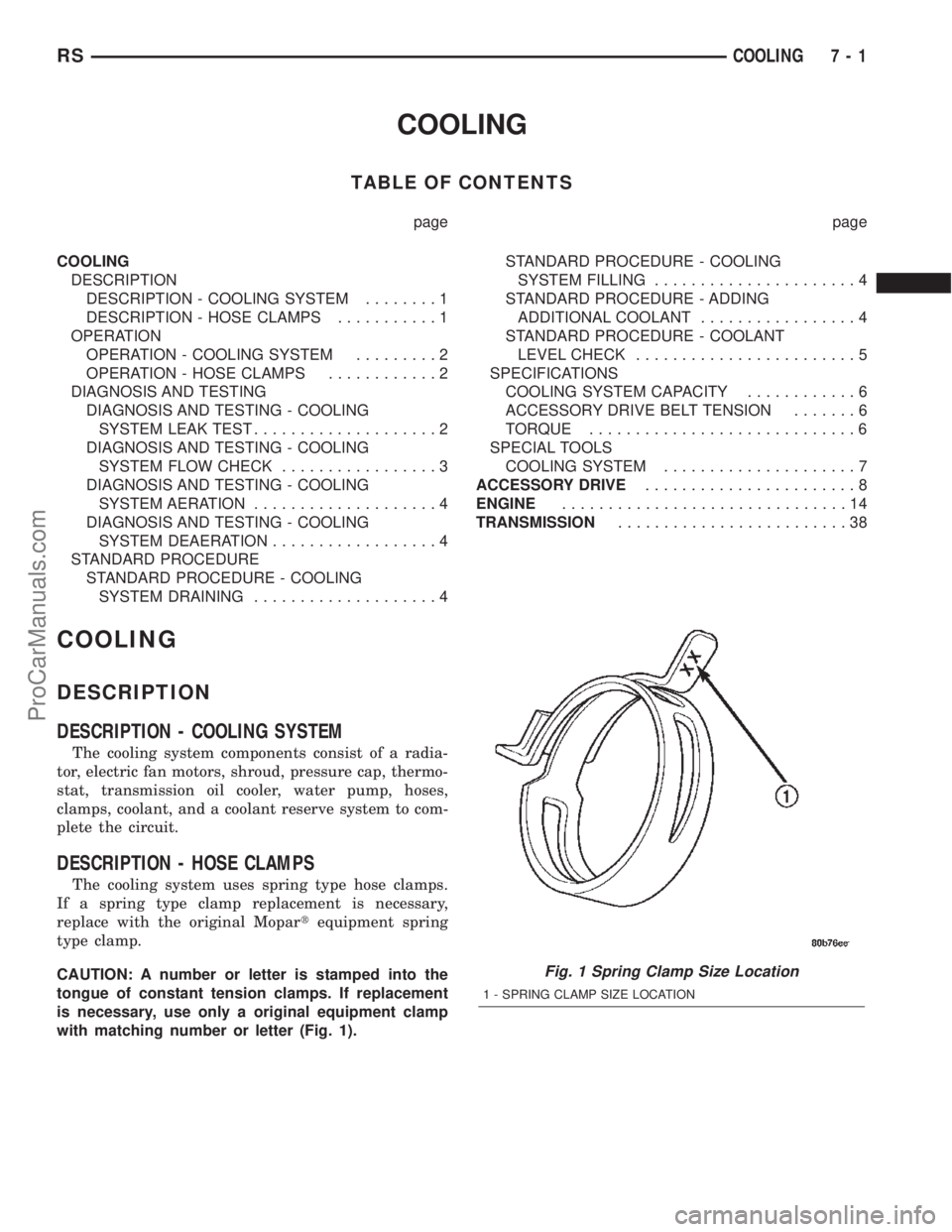

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 1).

Fig. 1 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

RSCOOLING7-1

ProCarManuals.com

Page 255 of 2399

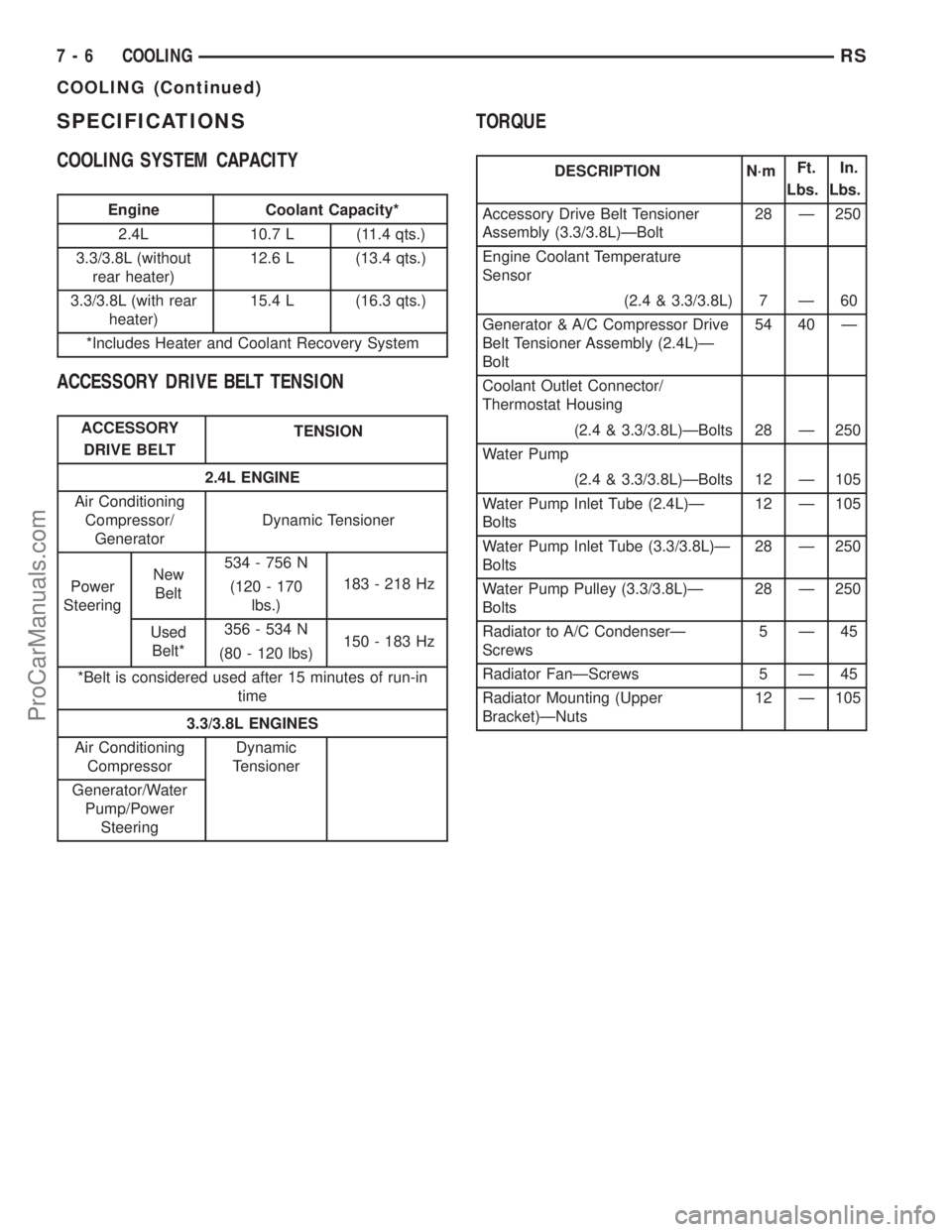

SPECIFICATIONS

COOLING SYSTEM CAPACITY

Engine Coolant Capacity*

2.4L 10.7 L (11.4 qts.)

3.3/3.8L (without

rear heater)12.6 L (13.4 qts.)

3.3/3.8L (with rear

heater)15.4 L (16.3 qts.)

*Includes Heater and Coolant Recovery System

ACCESSORY DRIVE BELT TENSION

ACCESSORY

DRIVE BELTTENSION

2.4L ENGINE

Air Conditioning

Compressor/

GeneratorDynamic Tensioner

Power

SteeringNew

Belt534 - 756 N

183 - 218 Hz

(120 - 170

lbs.)

Used

Belt*356 - 534 N

150 - 183 Hz

(80 - 120 lbs)

*Belt is considered used after 15 minutes of run-in

time

3.3/3.8L ENGINES

Air Conditioning

CompressorDynamic

Tensioner

Generator/Water

Pump/Power

Steering

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Accessory Drive Belt Tensioner

Assembly (3.3/3.8L)ÐBolt28 Ð 250

Engine Coolant Temperature

Sensor

(2.4 & 3.3/3.8L) 7 Ð 60

Generator & A/C Compressor Drive

Belt Tensioner Assembly (2.4L)Ð

Bolt54 40 Ð

Coolant Outlet Connector/

Thermostat Housing

(2.4 & 3.3/3.8L)ÐBolts 28 Ð 250

Water Pump

(2.4 & 3.3/3.8L)ÐBolts 12 Ð 105

Water Pump Inlet Tube (2.4L)Ð

Bolts12 Ð 105

Water Pump Inlet Tube (3.3/3.8L)Ð

Bolts28 Ð 250

Water Pump Pulley (3.3/3.8L)Ð

Bolts28 Ð 250

Radiator to A/C CondenserÐ

Screws5Ð45

Radiator FanÐScrews 5 Ð 45

Radiator Mounting (Upper

Bracket)ÐNuts12 Ð 105

7 - 6 COOLINGRS

COOLING (Continued)

ProCarManuals.com

Page 261 of 2399

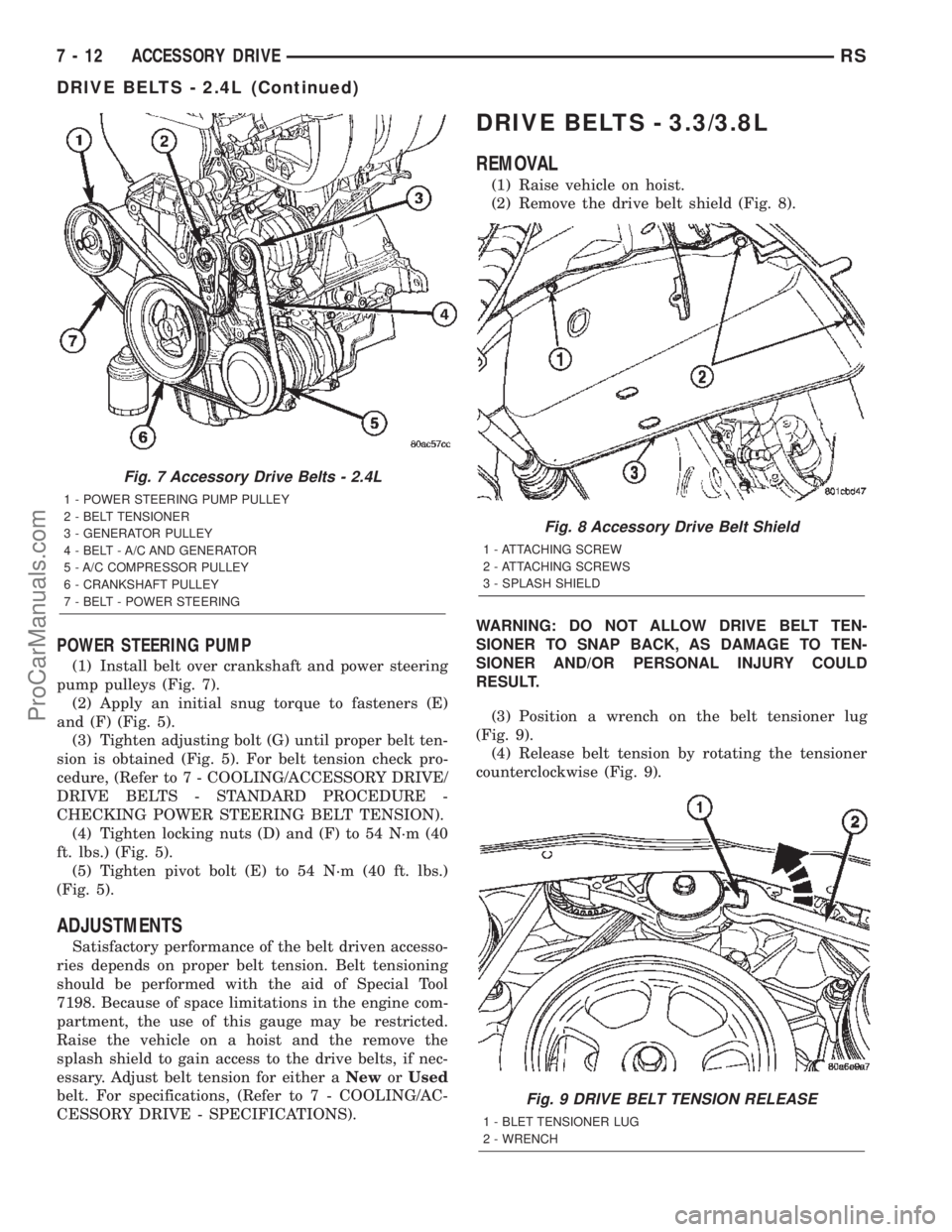

POWER STEERING PUMP

(1) Install belt over crankshaft and power steering

pump pulleys (Fig. 7).

(2) Apply an initial snug torque to fasteners (E)

and (F) (Fig. 5).

(3) Tighten adjusting bolt (G) until proper belt ten-

sion is obtained (Fig. 5). For belt tension check pro-

cedure, (Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - STANDARD PROCEDURE -

CHECKING POWER STEERING BELT TENSION).

(4) Tighten locking nuts (D) and (F) to 54 N´m (40

ft. lbs.) (Fig. 5).

(5) Tighten pivot bolt (E) to 54 N´m (40 ft. lbs.)

(Fig. 5).

ADJUSTMENTS

Satisfactory performance of the belt driven accesso-

ries depends on proper belt tension. Belt tensioning

should be performed with the aid of Special Tool

7198. Because of space limitations in the engine com-

partment, the use of this gauge may be restricted.

Raise the vehicle on a hoist and the remove the

splash shield to gain access to the drive belts, if nec-

essary. Adjust belt tension for either aNeworUsed

belt. For specifications, (Refer to 7 - COOLING/AC-

CESSORY DRIVE - SPECIFICATIONS).

DRIVE BELTS - 3.3/3.8L

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield (Fig. 8).

WARNING: DO NOT ALLOW DRIVE BELT TEN-

SIONER TO SNAP BACK, AS DAMAGE TO TEN-

SIONER AND/OR PERSONAL INJURY COULD

RESULT.

(3) Position a wrench on the belt tensioner lug

(Fig. 9).

(4) Release belt tension by rotating the tensioner

counterclockwise (Fig. 9).

Fig. 7 Accessory Drive Belts - 2.4L

1 - POWER STEERING PUMP PULLEY

2 - BELT TENSIONER

3 - GENERATOR PULLEY

4 - BELT - A/C AND GENERATOR

5 - A/C COMPRESSOR PULLEY

6 - CRANKSHAFT PULLEY

7 - BELT - POWER STEERING

Fig. 8 Accessory Drive Belt Shield

1 - ATTACHING SCREW

2 - ATTACHING SCREWS

3 - SPLASH SHIELD

Fig. 9 DRIVE BELT TENSION RELEASE

1 - BLET TENSIONER LUG

2 - WRENCH

7 - 12 ACCESSORY DRIVERS

DRIVE BELTS - 2.4L (Continued)

ProCarManuals.com

Page 281 of 2399

WATER PUMP - 2.4L

DESCRIPTION

The water pump has a cast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block (Fig. 23). The cylin-

der block to water pump seal is provided by a rubber

O-ring. The water pump is driven by the engine tim-

ing belt.

OPERATION

The water pump is the heart of the cooling system.

The coolant is pumped through the engine block, cyl-

inder head, heater core, and radiator.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on a hoist.

(3) Remove the right inner splash shield.

(4) Remove the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(6) Support engine from the bottom and remove

right engine mount. (Refer to 9 - ENGINE/ENGINE

MOUNTING/RIGHT MOUNT - REMOVAL).(7) Remove right engine mount bracket (Fig. 24).

(8) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- REMOVAL).

(9) Remove timing belt idler pulley.

(10) Hold camshaft sprocket with Special tool

C-4687 and adaptor C-4687-1 while removing bolt.

Remove both cam sprockets.

(11) Remove the timing belt rear cover (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - REMOVAL).

(12) Remove the generator and bracket (Fig. 24).

(13) Remove water pump to engine attaching

screws (Fig. 25).

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

wet coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring locating groove (Fig. 26).

CAUTION: Make sure O-ring is properly seated in

water pump groove before tightening screws. An

improperly located O-ring may be damaged and

cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.) (Fig. 25). Pressurize

cooling system to 103.4 Kpa (15 psi) with pressure

tester and check water pump shaft seal and O-ring

for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install the timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(5) Install camshaft sprockets and torque bolts to

101 N´m (75 ft. lbs.) while holding camshaft sprocket

with Special tool C-4687 and adaptor C-4687-1.

(6) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

Fig. 23 Water Pump

1 - CYLINDER BLOCK

2 - WATER PUMP

7 - 32 ENGINERS

ProCarManuals.com

Page 290 of 2399

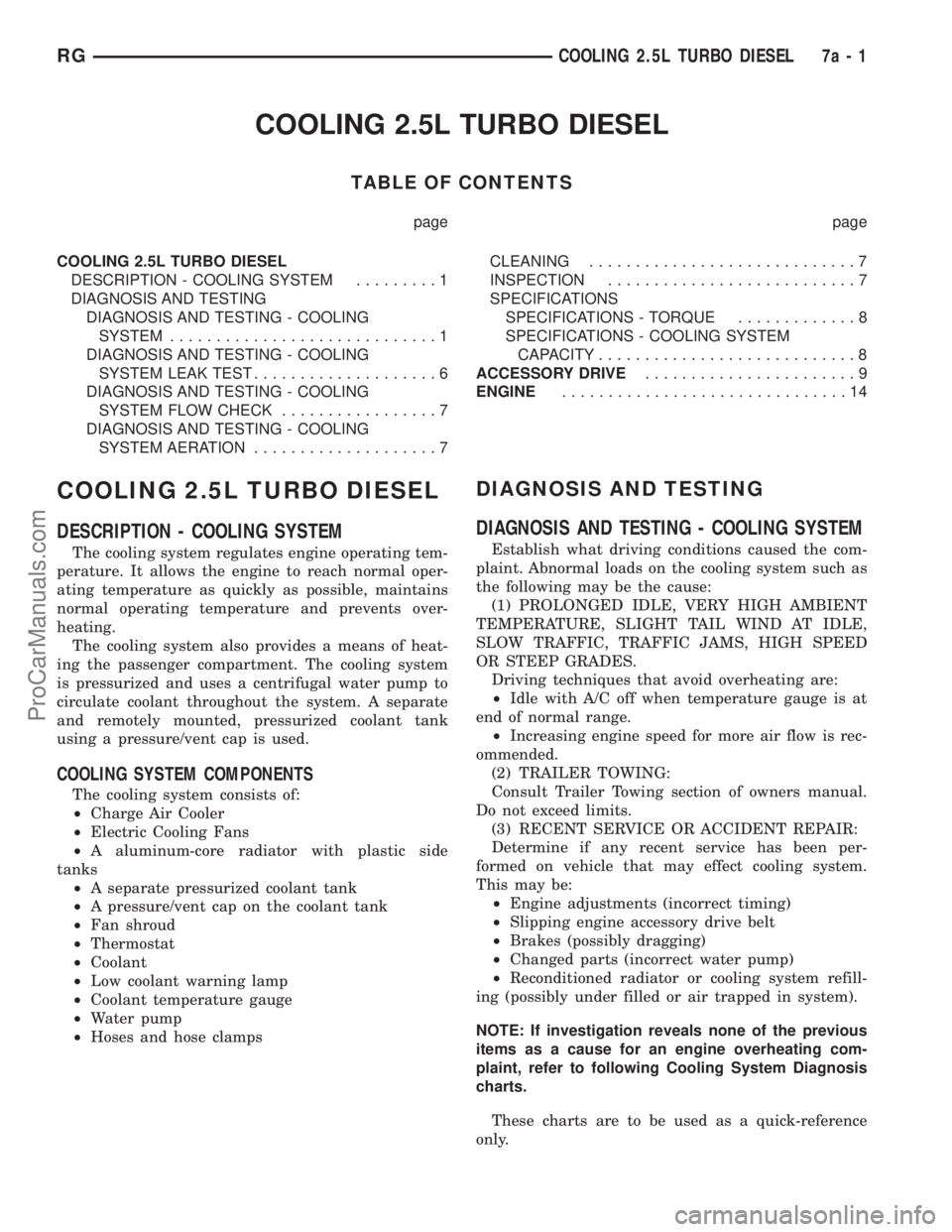

COOLING 2.5L TURBO DIESEL

TABLE OF CONTENTS

page page

COOLING 2.5L TURBO DIESEL

DESCRIPTION - COOLING SYSTEM.........1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM.............................1

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAK TEST....................6

DIAGNOSIS AND TESTING - COOLING

SYSTEM FLOW CHECK.................7

DIAGNOSIS AND TESTING - COOLING

SYSTEM AERATION....................7CLEANING.............................7

INSPECTION...........................7

SPECIFICATIONS

SPECIFICATIONS - TORQUE.............8

SPECIFICATIONS - COOLING SYSTEM

CAPACITY............................8

ACCESSORY DRIVE.......................9

ENGINE...............................14

COOLING 2.5L TURBO DIESEL

DESCRIPTION - COOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible, maintains

normal operating temperature and prevents over-

heating.

The cooling system also provides a means of heat-

ing the passenger compartment. The cooling system

is pressurized and uses a centrifugal water pump to

circulate coolant throughout the system. A separate

and remotely mounted, pressurized coolant tank

using a pressure/vent cap is used.

COOLING SYSTEM COMPONENTS

The cooling system consists of:

²Charge Air Cooler

²Electric Cooling Fans

²A aluminum-core radiator with plastic side

tanks

²A separate pressurized coolant tank

²A pressure/vent cap on the coolant tank

²Fan shroud

²Thermostat

²Coolant

²Low coolant warning lamp

²Coolant temperature gauge

²Water pump

²Hoses and hose clamps

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

(1) PROLONGED IDLE, VERY HIGH AMBIENT

TEMPERATURE, SLIGHT TAIL WIND AT IDLE,

SLOW TRAFFIC, TRAFFIC JAMS, HIGH SPEED

OR STEEP GRADES.

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

²Increasing engine speed for more air flow is rec-

ommended.

(2) TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

(3) RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt

²Brakes (possibly dragging)

²Changed parts (incorrect water pump)

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diagnosis

charts.

These charts are to be used as a quick-reference

only.

RGCOOLING 2.5L TURBO DIESEL7a-1

ProCarManuals.com

Page 297 of 2399

SPECIFICATIONS

SPECIFICATIONS - TORQUE

2.5L DIESEL - TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Water Pump Housing Nuts 24.4 18 215

Thermostat Housing Bolts 27.5 21 Ð

Accessory Drive Belt

Tensioner Bolt47.1 35 Ð

Accessory Drive Belt Idler

Bolt53 39 Ð

SPECIFICATIONS - COOLING SYSTEM

CAPACITY

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Cooling System With

Auxiliary Heater16.6 Liters (17.5 qts.)

Cooling System With Out

Auxiliary Heater13.8 Liters (14.6 qts.)

7a - 8 COOLING 2.5L TURBO DIESELRG

COOLING 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 298 of 2399

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

ACCESSORY DRIVE

SPECIFICATIONS - ACCESSORY BELT

TENSION.............................9

BELT TENSIONER

REMOVAL.............................9

INSTALLATION..........................9

IDLER PULLEY

REMOVAL.............................10

INSTALLATION.........................10

DRIVE BELTS

DESCRIPTION

DESCRIPTION - ACCESSORY DRIVE BELT . 10DESCRIPTION - POWER STEERING BELT . . 10

OPERATION

OPERATION-ACCESSORY DRIVE BELT....10

OPERATION-POWER STEERING BELT.....10

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................11

REMOVAL

REMOVAL-ACCESSORY DRIVE BELT......11

REMOVAL...........................11

INSTALLATION

INSTALLATION-ACCESSORY DRIVE BELT . . 13

INSTALLATION-POWER STEERING BELT . . . 13

ACCESSORY DRIVE

SPECIFICATIONS - ACCESSORY BELT TENSION

ACCESSORY DRIVE

BELTGAUGE

2.5L DIESEL ENGINE

A/C Compressor/

GeneratorDynamic Tensioner

Power Steering Belt 300 N (67 lbs.)

BELT TENSIONER

REMOVAL

WARNING:: BECAUSE OF HIGH SPRING TENSION,

DO NOT ATTEMPT TO DISASSEMBLE THE AUTO-

MATIC BELT TENSIONER. THE TENSIONER IS SER-

VICED AS AN ASSEMBLY.

(1) Remove the power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

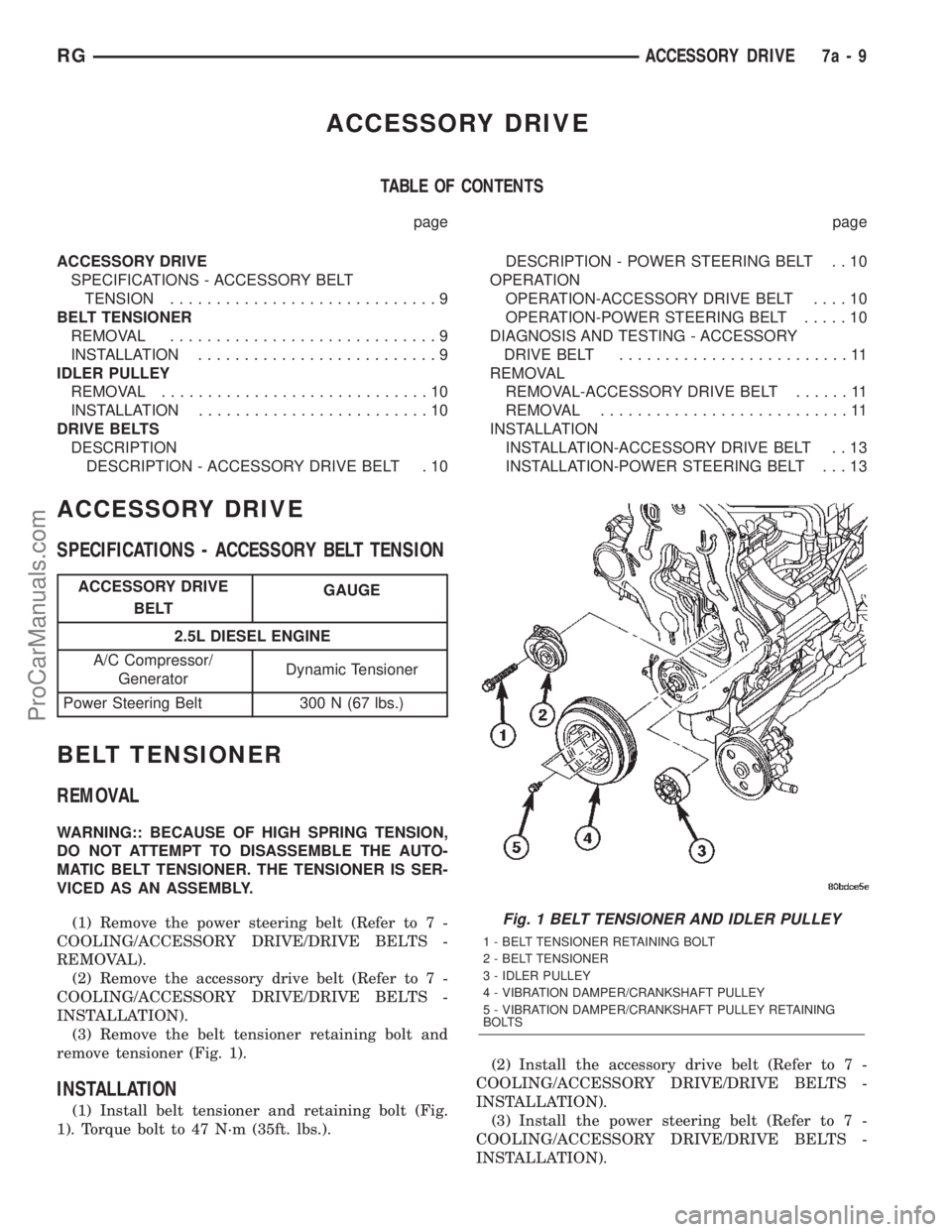

(3) Remove the belt tensioner retaining bolt and

remove tensioner (Fig. 1).

INSTALLATION

(1) Install belt tensioner and retaining bolt (Fig.

1). Torque bolt to 47 N´m (35ft. lbs.).(2) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(3) Install the power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 1 BELT TENSIONER AND IDLER PULLEY

1 - BELT TENSIONER RETAINING BOLT

2 - BELT TENSIONER

3 - IDLER PULLEY

4 - VIBRATION DAMPER/CRANKSHAFT PULLEY

5 - VIBRATION DAMPER/CRANKSHAFT PULLEY RETAINING

BOLTS

RGACCESSORY DRIVE7a-9

ProCarManuals.com

Page 299 of 2399

IDLER PULLEY

REMOVAL

(1) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

CAUTION: IDLER PULLEY RETAINING BOLT HAS

LEFT HAND THREAD

(2) Remove the idler pulley (Fig. 2).

INSTALLATION

(1) Install the idler pulley (Fig. 2). Torque retain-

ing bolt to 22 N´m (16 ft. lbs.).

(2) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(3) Install the power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

DRIVE BELTS

DESCRIPTION

DESCRIPTION - ACCESSORY DRIVE BELT

The accessory drive belt is a serpentine type belt

(Fig. 3). Satisfactory performance of these belts

depends on belt condition and proper belt tension.

DESCRIPTION - POWER STEERING BELT

The power steering belt is a serpentine type belt

(Fig. 3). Satisfactory performance of this belt depends

on condition of the belt.

OPERATION

OPERATION-ACCESSORY DRIVE BELT

The accessory drive belts form the link between

the engine crankshaft and the engine driven accesso-

ries.

OPERATION-POWER STEERING BELT

The power steering belt forms a link between the

engine crankshaft and the power steering pump.

Fig. 2 BELT TENSIONER AND IDLER PULLEY

1 - BELT TENSIONER RETAINING BOLT

2 - BELT TENSIONER

3 - IDLER PULLEY

4 - VIBRATION DAMPER/CRANKSHAFT PULLEY

5 - VIBRATION DAMPER/CRANKSHAFT PULLEY RETAINING

BOLTS

Fig. 3 ACCESSORY DRIVE BELT ROUTING

1 - GENERATOR

2 - IDLER PULLEY

3 - A/C COMPRESSOR CLUTCH

4 - POWER STEERING PUMP PULLEY

5 - POWER STEERING BELT

6 - CRANKSHAFT DAMPER/PULLEY

7 - BELT TENSIONER

8 - ACCESSORY DRIVE BELT

7a - 10 ACCESSORY DRIVERG

ProCarManuals.com