sensor CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 540 of 2399

firmed to be OK, but the temperature display is

inoperative or incorrect, refer toDiagnosis and

Testing - Overhead Consolein this group. For

complete circuit diagrams, refer to the appropriate

wiring information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At ±40É C (±40É F), the sensor resis-

tance is 336.6 kilohms. At 60É C (140É F), the sensor

resistance is 2.49 kilohms. The sensor resistance

should read between these two values. If OK, refer to

Diagnosis and Testing - Ambient Temperature

Sensor Circuitin this group. If not OK, replace the

faulty ambient temperature sensor.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Front Control Module wire

harness connector.

(2) Connect a jumper wire between the two termi-

nals in the body half of the ambient temperature sen-

sor wire harness connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signalcircuit cavities of the Front Control Module wire har-

ness connector. There should be continuity. If OK, go

to Step 4. If not OK, repair the open sensor return

circuit or ambient temperature sensor signal circuit

to the ambient temperature sensor as required.

(4) Remove the jumper wire from the body half of

the ambient temperature sensor wire harness con-

nector. Check for continuity between the sensor

return circuit cavity of the Front Control Module

wire harness connector and a good ground. There

should be no continuity. If OK, go to Step 5. If not

OK, repair the shorted sensor return circuit as

required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the Front

Control Module wire harness connector and a good

ground. There should be no continuity. If OK, refer to

Diagnosis and Testing - Overhead Consolein

this group. If not OK, repair the shorted ambient

temperature sensor signal circuit as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support vehicle on safety stands.

(3) From behind front bumper fascia, remove

screw holding sensor to radiator closure panel.

(4) Remove sensor from vehicle.

INSTALLATION

(1) Position the sensor in the vehicle.

(2) From behind the front bumper fascia, install

the screw holding sensor to radiator closure panel.

(3) Connect the battery negative cable.

RSMESSAGE SYSTEMS8M-11

AMBIENT TEMP SENSOR (Continued)

ProCarManuals.com

Page 542 of 2399

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM.................. 1

POWER SLIDING DOOR SYSTEM............ 18

POWER LOCKS........................... 39POWER MIRRORS........................ 46

POWER SEAT SYSTEM..................... 51

POWER WINDOWS........................ 64

POWER LIFTGATE SYSTEM

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM

DESCRIPTION..........................2

OPERATION............................3

DIAGNOSIS AND TESTING - POWER

LIFTGATE SYSTEM.....................4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIFTGATE

ADJUSTMENT.........................8

STANDARD PROCEDURE - POWER

LIFTGATE LEARN CYCLE................9

PINCH SENSOR

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION..........................9

FULL OPEN SWITCH

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................10

LIFTGATE MOTOR

DESCRIPTION.........................10

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

ENGAGE ACTUATOR

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................12

INSTALLATION.........................12TRANSVERSE BRACKET

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................13

INSTALLATION.........................13

LIFT GEAR & LINK ROD

DESCRIPTION.........................13

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

LATCH

DESCRIPTION.........................14

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................15

LATCH ACTUATOR

DESCRIPTION.........................15

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................16

EXTERIOR HANDLE SWITCH

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

CHIME/THERMISTOR

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

RSPOWER SYSTEMS8N-1

ProCarManuals.com

Page 543 of 2399

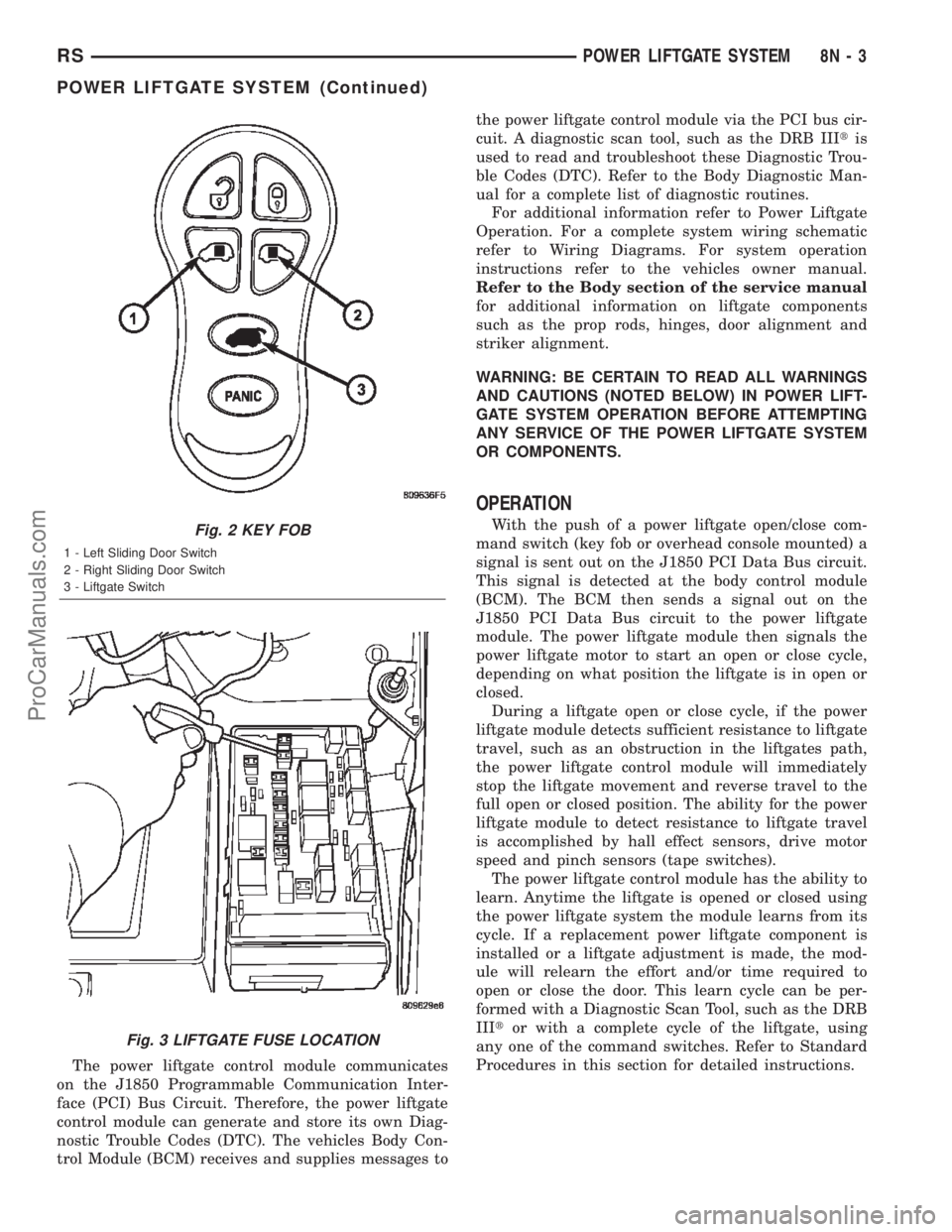

POWER LIFTGATE SYSTEM

DESCRIPTION

Some vehicles are equipped with an automatic

opening and closing power liftgate system (Fig. 1).

This power liftgate system is a complex system con-

sisting of many components. Some of these compo-

nents are the liftgate gear motor assembly, latch

assembly, lift gear and rod, liftgate control module,

chime/thermistor, full open switch, engage actuator,

pinch sensor, liftgate handle switch, overhead console

switch, key fob switches (Fig. 2), pawl switch and

ratchet switch.

The power liftgate system has its own door control

module, located on the vehicles left body D-pillar

behind the trim panel. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/DOOR CON-

TROL MODULE - DESCRIPTION) The power

liftgate gear motor assembly is located just above the

control module. The latch assembly is located in the

bottom center of the power liftgate, below the exte-

rior liftgate handle switch. The power liftgate full

open switch, engage actuator, lift gear and rod are

part of the liftgate gear motor assembly. The pawl

and ratchet switches are part of the latch assembly.The pinch sensor or sensors are located along the

right and left sides of the power liftgate, just above

the body line. The liftgate handle switch is an power

release switch and is located in the rear light bar

assembly, just above the license plate. The overhead

console switch is an power open and close command

switch located in the vehicles overhead console.

Safety is of the utmost concern with the power lift-

gate system. Software technology has enabled the

power liftgate control module to detect resistance to

liftgate travel, which allows the power liftgate to stop

and reverse direction anytime an obstruction is felt

or any of the command switches are operated (only in

closing direction). Battery voltage is supplied to the

power liftgate system through a 40 amp fuse, located

in the Intelligent Power Module (IPM) assembly (Fig.

3). In the unlikely event that the power liftgate sys-

tem develops a fault the power liftgate can still be

operated manually with a key, just like a standard

manual liftgate.

Fig. 1 POWER LIFTGATE INTRODUCTION

8N - 2 POWER LIFTGATE SYSTEMRS

ProCarManuals.com

Page 544 of 2399

The power liftgate control module communicates

on the J1850 Programmable Communication Inter-

face (PCI) Bus Circuit. Therefore, the power liftgate

control module can generate and store its own Diag-

nostic Trouble Codes (DTC). The vehicles Body Con-

trol Module (BCM) receives and supplies messages tothe power liftgate control module via the PCI bus cir-

cuit. A diagnostic scan tool, such as the DRB IIItis

used to read and troubleshoot these Diagnostic Trou-

ble Codes (DTC). Refer to the Body Diagnostic Man-

ual for a complete list of diagnostic routines.

For additional information refer to Power Liftgate

Operation. For a complete system wiring schematic

refer to Wiring Diagrams. For system operation

instructions refer to the vehicles owner manual.

Refer to the Body section of the service manual

for additional information on liftgate components

such as the prop rods, hinges, door alignment and

striker alignment.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS (NOTED BELOW) IN POWER LIFT-

GATE SYSTEM OPERATION BEFORE ATTEMPTING

ANY SERVICE OF THE POWER LIFTGATE SYSTEM

OR COMPONENTS.

OPERATION

With the push of a power liftgate open/close com-

mand switch (key fob or overhead console mounted) a

signal is sent out on the J1850 PCI Data Bus circuit.

This signal is detected at the body control module

(BCM). The BCM then sends a signal out on the

J1850 PCI Data Bus circuit to the power liftgate

module. The power liftgate module then signals the

power liftgate motor to start an open or close cycle,

depending on what position the liftgate is in open or

closed.

During a liftgate open or close cycle, if the power

liftgate module detects sufficient resistance to liftgate

travel, such as an obstruction in the liftgates path,

the power liftgate control module will immediately

stop the liftgate movement and reverse travel to the

full open or closed position. The ability for the power

liftgate module to detect resistance to liftgate travel

is accomplished by hall effect sensors, drive motor

speed and pinch sensors (tape switches).

The power liftgate control module has the ability to

learn. Anytime the liftgate is opened or closed using

the power liftgate system the module learns from its

cycle. If a replacement power liftgate component is

installed or a liftgate adjustment is made, the mod-

ule will relearn the effort and/or time required to

open or close the door. This learn cycle can be per-

formed with a Diagnostic Scan Tool, such as the DRB

IIItor with a complete cycle of the liftgate, using

any one of the command switches. Refer to Standard

Procedures in this section for detailed instructions.Fig. 2 KEY FOB

1 - Left Sliding Door Switch

2 - Right Sliding Door Switch

3 - Liftgate Switch

Fig. 3 LIFTGATE FUSE LOCATION

RSPOWER LIFTGATE SYSTEM8N-3

POWER LIFTGATE SYSTEM (Continued)

ProCarManuals.com

Page 545 of 2399

The power liftgate system is designed with a num-

ber of system inhibitors. These inhibitors are neces-

sary for safety and / or feasibility of the power

liftgate system. Refer to power liftgate system inhib-

itors noted below:

POWER LIFTGATE SYSTEM INHIBITORS

²The Power Liftgate may not operate in extreme

temperatures. These extreme temperatures will be

approximately -12É F (-24.4É C) on the low side and

143É F (61.6É C) for the high side. A chime/thermister

assembly in the rear light bar assembly monitors the

outside temperature.

²The vehicles transmission must be in park or

neutral for the power liftgate to start a cycle.

²If multiple obstacles are detected during the

same power open or close cycle the liftgate goes into

manual operation.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power liftgate control module.

POWER LIFTGATE SYSTEM CAUTIONS AND

WARNINGS

WARNING: ALWAYS DISCONNECT THE NEGATIVE

BATTERY CABLE BEFORE ATTEMPTING ANY

POWER LIFTGATE SYSTEM SERVICE.

WARNING: THERE IS A SMALL AREA ON BOTH

SIDES OF THE LOWER POWER LIFTGATE WHICH

ARE NOT PROTECTED BY PINCH SENSORS.

EXTREME CARE MUST BE TAKEN TO PREVENT

OBJECTS FROM ENTERING THIS AREA ONCE THE

LIFTGATE REACHES THE SECONDARY LATCH

CONTACT (APPROXIMATELY 1/2 INCH BEFORE

FULLY CLOSED).

WARNING: NEVER ATTEMPT TO ENTER OR EXIT

THE VEHICLE WITH THE LIFTGATE IN MOTION.

YOU COULD DAMAGE THE POWER LIFTGATE SYS-TEM AND/OR COMPONENTS AND/OR CAUSE PER-

SONAL INJURY.

WARNING: NEVER STICK OBJECTS IN THE POWER

LIFTGATE WHEN CINCHING CLOSED. YOU COULD

DAMAGE THE VEHICLE, POWER LIFTGATE SYS-

TEM COMPONENTS AND/OR CAUSE PERSONAL

INJURY.

DIAGNOSIS AND TESTING - POWER LIFTGATE

SYSTEM

The power opening and closing power liftgate sys-

tem is a complex system containing many compo-

nents and modules. In order to obtain conclusive

testing the Programmable Communications Interface

(J1850) data bus network and all of the electronic

modules that provide inputs to, or receive outputs

from the power liftgate system must be checked.

The power liftgate system was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the power liftgate system

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual. The

DRB IIItcan be used to observe various switch sta-

tuses throughout the power liftgate system to help

the technician diagnose a defective switch or compo-

nent. The DRB IIItcan also be used to actuate var-

ious components throughout the power liftgate

system to help the technician diagnose a defective

component.

Before any testing of the power liftgate system is

attempted, the battery should be fully charged, all

built-in power liftgate system inhibitors read and

understood (Refer to power liftgate system operation)

and all wire harness and ground connections

inspected around the affected areas on the vehicle.

Following are quick reference diagnostic tables to

help when diagnosing and testing the power liftgate

system.

8N - 4 POWER LIFTGATE SYSTEMRS

POWER LIFTGATE SYSTEM (Continued)

ProCarManuals.com

Page 550 of 2399

STANDARD PROCEDURE - POWER LIFTGATE

LEARN CYCLE

Any time a power liftgate component is removed,

replaced or a liftgate adjustment is performed a learn

cycle must be performed. This learn cycle enables the

power liftgate control module to learn or relearn

information (travel limits, resistance to door travel,

etc.) which allows it to perform properly and safely.

To perform a learn cycle do the following:

(1) Obtain a DRB IIItscan tool.

(2) Connect the DRB IIItto the vehicle and check

for any power liftgate system stored trouble codes,

correct and erase any stored codes.

(3) Using the DRB IIIt, Go into Test Routine

Menu and select the power open command.

(4) Select the power close command.

(5) The liftgate learn cycle is complete.

If a DRB IIItscan tool is not available the learn

cycle can be performed by actuating the liftgate by

using any of the normal command switches. Be cer-

tain to cycle the liftgate through a complete open and

close cycle before returning the vehicle to service.

NOTE: If the power liftgate will not complete a full

cycle a problem exists with the power liftgate sys-

tem. (Refer to 8 - ELECTRICAL/POWER DOORS -

DIAGNOSIS AND TESTING).

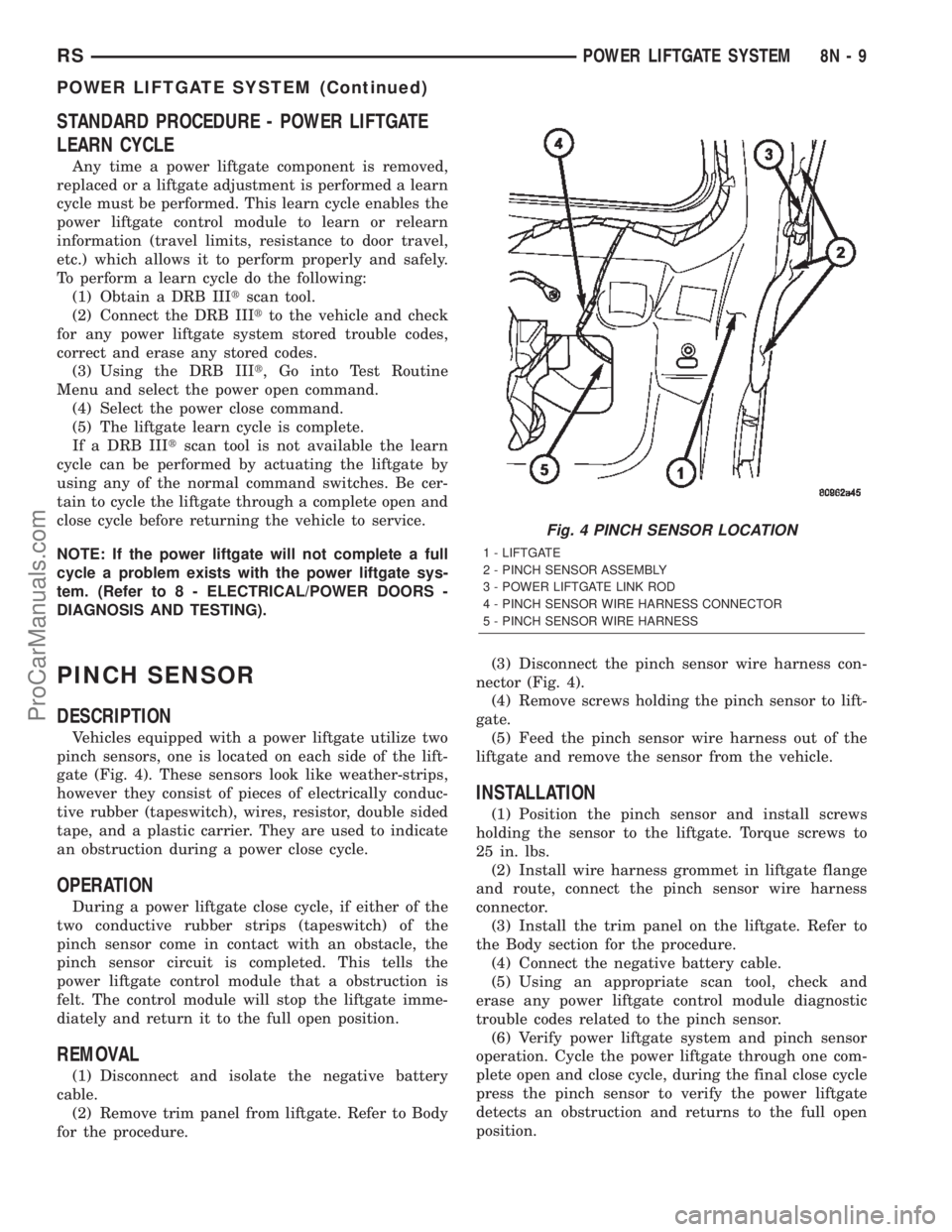

PINCH SENSOR

DESCRIPTION

Vehicles equipped with a power liftgate utilize two

pinch sensors, one is located on each side of the lift-

gate (Fig. 4). These sensors look like weather-strips,

however they consist of pieces of electrically conduc-

tive rubber (tapeswitch), wires, resistor, double sided

tape, and a plastic carrier. They are used to indicate

an obstruction during a power close cycle.

OPERATION

During a power liftgate close cycle, if either of the

two conductive rubber strips (tapeswitch) of the

pinch sensor come in contact with an obstacle, the

pinch sensor circuit is completed. This tells the

power liftgate control module that a obstruction is

felt. The control module will stop the liftgate imme-

diately and return it to the full open position.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove trim panel from liftgate. Refer to Body

for the procedure.(3) Disconnect the pinch sensor wire harness con-

nector (Fig. 4).

(4) Remove screws holding the pinch sensor to lift-

gate.

(5) Feed the pinch sensor wire harness out of the

liftgate and remove the sensor from the vehicle.

INSTALLATION

(1) Position the pinch sensor and install screws

holding the sensor to the liftgate. Torque screws to

25 in. lbs.

(2) Install wire harness grommet in liftgate flange

and route, connect the pinch sensor wire harness

connector.

(3) Install the trim panel on the liftgate. Refer to

the Body section for the procedure.

(4) Connect the negative battery cable.

(5) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the pinch sensor.

(6) Verify power liftgate system and pinch sensor

operation. Cycle the power liftgate through one com-

plete open and close cycle, during the final close cycle

press the pinch sensor to verify the power liftgate

detects an obstruction and returns to the full open

position.

Fig. 4 PINCH SENSOR LOCATION

1 - LIFTGATE

2 - PINCH SENSOR ASSEMBLY

3 - POWER LIFTGATE LINK ROD

4 - PINCH SENSOR WIRE HARNESS CONNECTOR

5 - PINCH SENSOR WIRE HARNESS

RSPOWER LIFTGATE SYSTEM8N-9

POWER LIFTGATE SYSTEM (Continued)

ProCarManuals.com

Page 551 of 2399

WARNING: USE EXTREME CAUTION WHEN TEST-

ING PINCH SENSOR OPERATION.

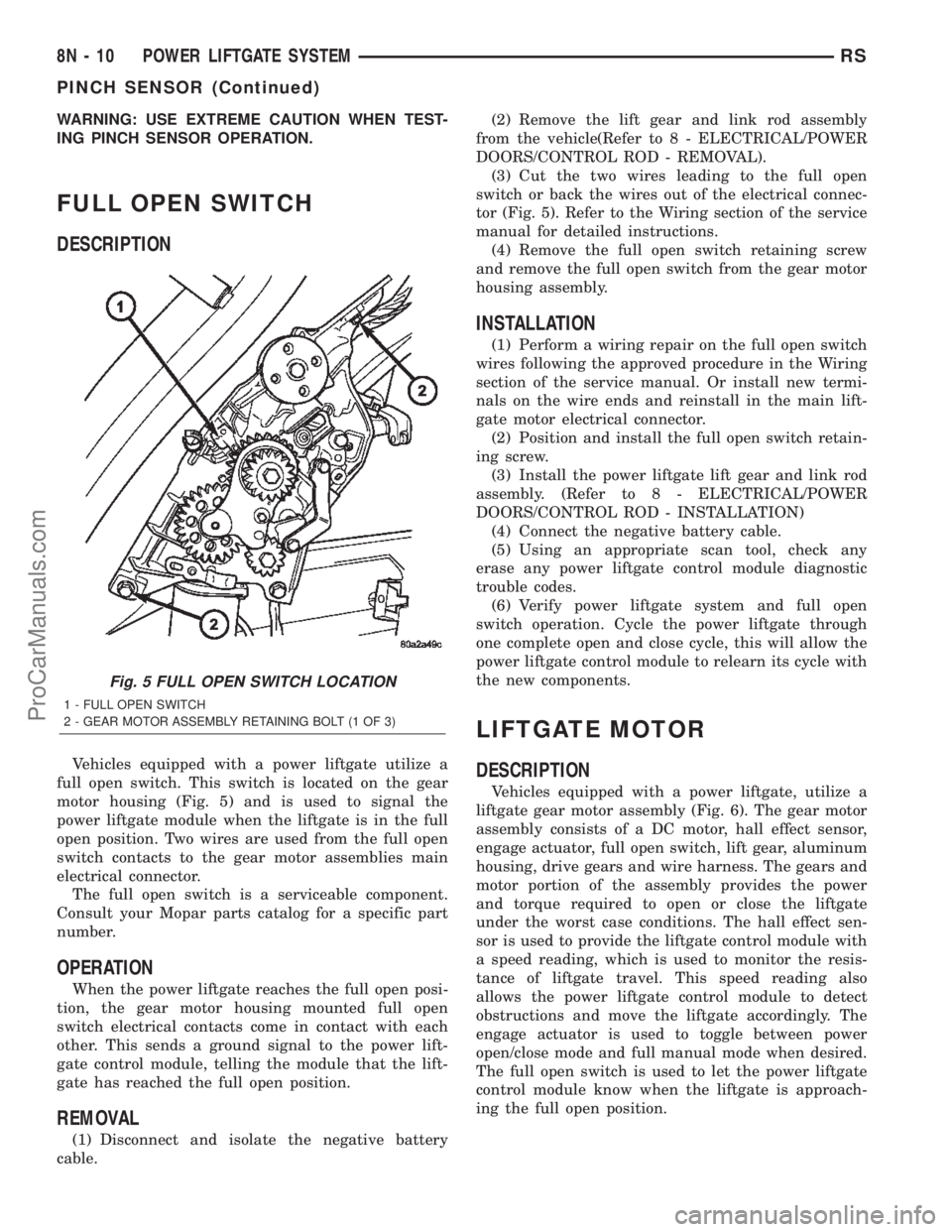

FULL OPEN SWITCH

DESCRIPTION

Vehicles equipped with a power liftgate utilize a

full open switch. This switch is located on the gear

motor housing (Fig. 5) and is used to signal the

power liftgate module when the liftgate is in the full

open position. Two wires are used from the full open

switch contacts to the gear motor assemblies main

electrical connector.

The full open switch is a serviceable component.

Consult your Mopar parts catalog for a specific part

number.

OPERATION

When the power liftgate reaches the full open posi-

tion, the gear motor housing mounted full open

switch electrical contacts come in contact with each

other. This sends a ground signal to the power lift-

gate control module, telling the module that the lift-

gate has reached the full open position.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.(2) Remove the lift gear and link rod assembly

from the vehicle(Refer to 8 - ELECTRICAL/POWER

DOORS/CONTROL ROD - REMOVAL).

(3) Cut the two wires leading to the full open

switch or back the wires out of the electrical connec-

tor (Fig. 5). Refer to the Wiring section of the service

manual for detailed instructions.

(4) Remove the full open switch retaining screw

and remove the full open switch from the gear motor

housing assembly.

INSTALLATION

(1) Perform a wiring repair on the full open switch

wires following the approved procedure in the Wiring

section of the service manual. Or install new termi-

nals on the wire ends and reinstall in the main lift-

gate motor electrical connector.

(2) Position and install the full open switch retain-

ing screw.

(3) Install the power liftgate lift gear and link rod

assembly. (Refer to 8 - ELECTRICAL/POWER

DOORS/CONTROL ROD - INSTALLATION)

(4) Connect the negative battery cable.

(5) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes.

(6) Verify power liftgate system and full open

switch operation. Cycle the power liftgate through

one complete open and close cycle, this will allow the

power liftgate control module to relearn its cycle with

the new components.

LIFTGATE MOTOR

DESCRIPTION

Vehicles equipped with a power liftgate, utilize a

liftgate gear motor assembly (Fig. 6). The gear motor

assembly consists of a DC motor, hall effect sensor,

engage actuator, full open switch, lift gear, aluminum

housing, drive gears and wire harness. The gears and

motor portion of the assembly provides the power

and torque required to open or close the liftgate

under the worst case conditions. The hall effect sen-

sor is used to provide the liftgate control module with

a speed reading, which is used to monitor the resis-

tance of liftgate travel. This speed reading also

allows the power liftgate control module to detect

obstructions and move the liftgate accordingly. The

engage actuator is used to toggle between power

open/close mode and full manual mode when desired.

The full open switch is used to let the power liftgate

control module know when the liftgate is approach-

ing the full open position.

Fig. 5 FULL OPEN SWITCH LOCATION

1 - FULL OPEN SWITCH

2 - GEAR MOTOR ASSEMBLY RETAINING BOLT (1 OF 3)

8N - 10 POWER LIFTGATE SYSTEMRS

PINCH SENSOR (Continued)

ProCarManuals.com

Page 558 of 2399

(6) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes.

(7) Verify power liftgate system and handle switch

operation. Cycle the power liftgate through one com-

plete open and close cycle, this will allow the power

liftgate control module to relearn its cycle with the

new components.

CHIME/THERMISTOR

DESCRIPTION

Vehicles equipped with a power liftgate utilize a

chime/thermistor assembly. The chime/thermistor

assembly is a small capacitor shaped electrical com-

ponent mounted to the rear license plate lamp hous-

ing assembly (Fig. 15) , located just above the license

plate. The chime portion of the assembly controls the

audible chime sound heard at the rear of the vehicle

when the power liftgate is in motion. The thermistor

portion of the assembly is a temperature sensor, used

by the power liftgate module.

The chime/thermistor assembly is a serviceable

component. Consult your MoparŸ parts catalog for a

specific part number.

OPERATION

The chime/thermistor assembly performs two dif-

ferent functions for the power liftgate system. First,

the chime portion provides an audible chime sound

which is controlled by the power liftgate module. Thechime/thermistor assembly is hardwired to the power

liftgate module. Second the thermistor provides a

outside temperature reading by way of a resistance

reading (V- ohms) supplied to the power liftgate

module. As temperature increases the resistance

reading (V- ohms) increases , as temperature

decreases the resistance reading (V- ohms)

decreases.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the rear light bar assembly from the

vehicle. Refer to Body for the procedure.

(3) Using your hands, grasp the light bar at its

sides next to thermistor/chime assembly and gently

pull the two sides of the light bar apart until the

thermistor/chime assembly can be removed.

INSTALLATION

(1) Gently pull the two sides of the light bar apart

until the thermistor/chime assembly can be installed.

(2) Install the rear light bar assembly on the vehi-

cle. Refer to the Body section of the service manual

for the procedure.

(3) Connect the negative battery cable.

Fig. 14 REAR LIGHT BAR

1 - CHIME / THERMISTOR

2 - ELECTRIC RELEASE HANDLE SWITCH

3 - LICENSE PLATE LAMPS

Fig. 15 REAR LIGHT BAR

1 - CHIME / THERMISTOR

2 - ELECTRIC RELEASE HANDLE SWITCH

3 - LICENSE PLATE LAMPS

RSPOWER LIFTGATE SYSTEM8N-17

EXTERIOR HANDLE SWITCH (Continued)

ProCarManuals.com

Page 561 of 2399

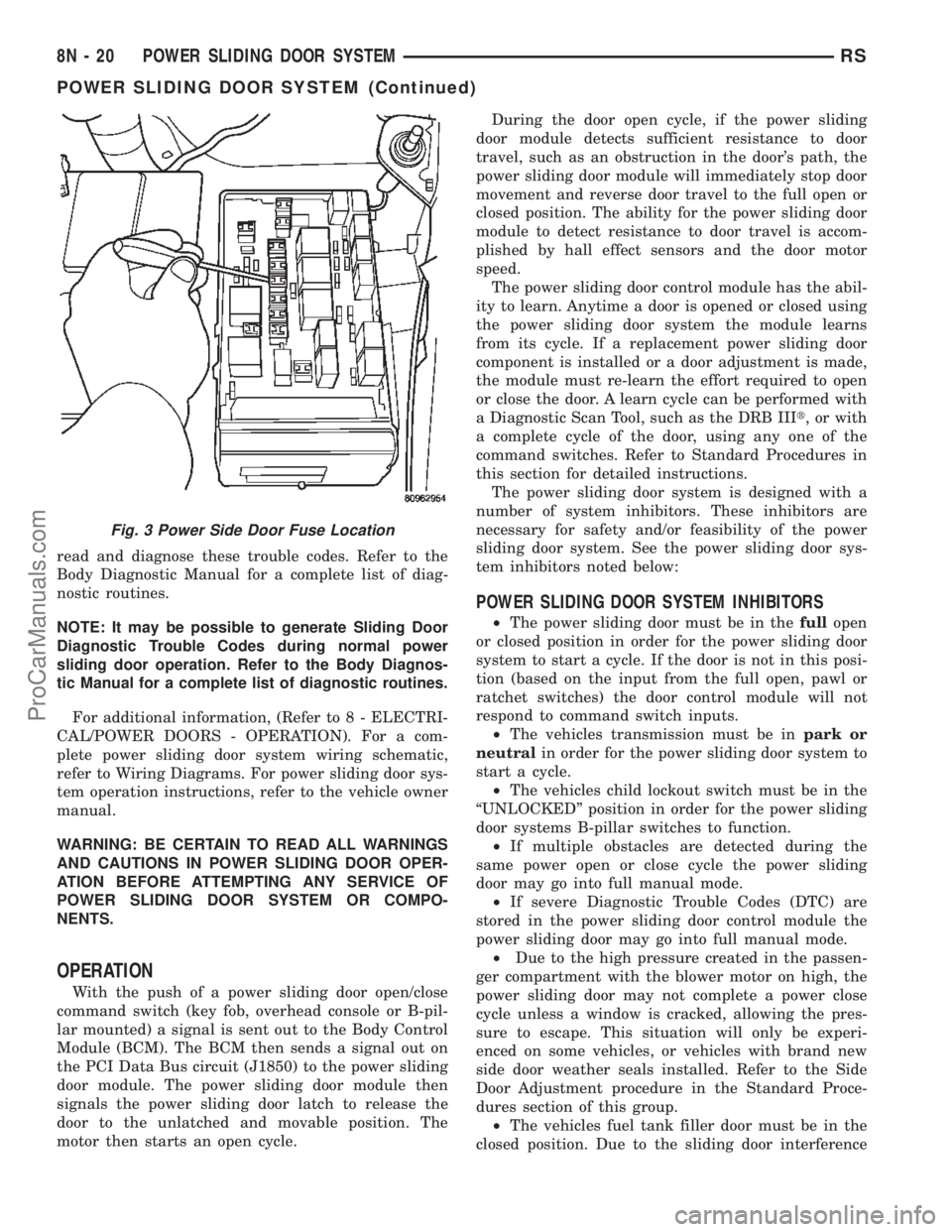

read and diagnose these trouble codes. Refer to the

Body Diagnostic Manual for a complete list of diag-

nostic routines.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). For a com-

plete power sliding door system wiring schematic,

refer to Wiring Diagrams. For power sliding door sys-

tem operation instructions, refer to the vehicle owner

manual.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the PCI Data Bus circuit (J1850) to the power sliding

door module. The power sliding door module then

signals the power sliding door latch to release the

door to the unlatched and movable position. The

motor then starts an open cycle.During the door open cycle, if the power sliding

door module detects sufficient resistance to door

travel, such as an obstruction in the door's path, the

power sliding door module will immediately stop door

movement and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors and the door motor

speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a Diagnostic Scan Tool, such as the DRB IIIt, or with

a complete cycle of the door, using any one of the

command switches. Refer to Standard Procedures in

this section for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. See the power sliding door sys-

tem inhibitors noted below:

POWER SLIDING DOOR SYSTEM INHIBITORS

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The vehicles transmission must be inpark or

neutralin order for the power sliding door system to

start a cycle.

²The vehicles child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

²If multiple obstacles are detected during the

same power open or close cycle the power sliding

door may go into full manual mode.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power sliding door control module the

power sliding door may go into full manual mode.

²Due to the high pressure created in the passen-

ger compartment with the blower motor on high, the

power sliding door may not complete a power close

cycle unless a window is cracked, allowing the pres-

sure to escape. This situation will only be experi-

enced on some vehicles, or vehicles with brand new

side door weather seals installed. Refer to the Side

Door Adjustment procedure in the Standard Proce-

dures section of this group.

²The vehicles fuel tank filler door must be in the

closed position. Due to the sliding door interference

Fig. 3 Power Side Door Fuse Location

8N - 20 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 587 of 2399

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION.........................46

OPERATION...........................46

DIAGNOSIS AND TESTING - POWER

MIRRORS...........................46

AUTOMATIC DAY / NIGHT MIRROR

DESCRIPTION.........................47

OPERATION...........................47

DIAGNOSIS AND TESTING - AUTOMATIC DAY

/ NIGHT MIRROR......................48

REMOTE SWITCH

DIAGNOSIS AND TESTING - REMOTE

SWITCH............................49REMOVAL.............................49

INSTALLATION.........................49

SIDEVIEW MIRROR

REMOVAL.............................49

POWER FOLDAWAY MIRROR SWITCH -

EXPORT

DESCRIPTION.........................49

OPERATION...........................50

REMOVAL.............................50

INSTALLATION.........................50

POWER MIRRORS

DESCRIPTION

If equipped with power mirrors, the control switch

is located on the instrument panel to the left of the

headlamp switch.

OPERATION

The power mirrors are connected to battery feed at

all times. Each mirror head contains two electric

motors, two drive mechanisms, an electric heating

element, and the mirror glass. If the vehicle is

equipped with the optional memory system, each

mirror head also contains both a horizontal and a

vertical motor position sensor. One motor and drive

controls mirror up-and-down movement, and the

other controls right-and-left movement.

An optional driver side outside electrochromic mir-

ror is able to automatically change its reflectance

level. This mirror is controlled by the circuitry of the

automatic day/night inside rear view mirror. A thin

layer of electrochromic material between two pieces

of conductive glass make up the face of the mirror.Two photocell sensors on the inside rear view mirror

are used to monitor light levels and adjust the reflec-

tance of both the inside and driver side outside mir-

rors. This change in reflectance helps to reduce the

glare of headlamps approaching the vehicle from the

rear. (Refer to 8 - ELECTRICAL/POWER MIRRORS/

AUTOMATIC DAY / NIGHT MIRROR - DESCRIP-

TION) for more information on this system.

The motors which operate the mirrors are part of

the mirror assembly and cannot be serviced sepa-

rately.

DIAGNOSIS AND TESTING - POWER MIRRORS

(1) Remove Power Mirror Switch. (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(2) Disconnect wiring harness connector to the

power mirror switch and headlamp switch.

(3) Using two jumper wires:

²Connect one to a 12-volt source

²Connect the other to a good body ground

²Refer to the Mirror Test Chart for wire hookups

at the switch connector (Fig. 1).

8N - 46 POWER MIRRORSRS

ProCarManuals.com