steering CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1347 of 2399

(11) If oil pressure is low and pump is within spec-

ifications, inspect for worn engine bearings or other

reasons for oil pressure loss.

ASSEMBLY

(1) Assemble pump, using new parts as required.

Install the inner rotor with chamfer facing the

cast iron oil pump cover.

(2) Prime oil pump before installation by filling

rotor cavity with engine oil.

(3) Install cover and tighten screws to 12 N´m (105

in. lbs.).

(4) If removed, install the oil pressure relief valve.

(Refer to 9 - ENGINE/LUBRICATION/OIL PRES-

SURE RELIEF VALVE - INSTALLATION)

INSTALLATION

(1) Install oil pump. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - ASSEMBLY)

(2) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION) and oil pan (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

INTAKE MANIFOLD

DESCRIPTION

The intake system is made up of an upper and

lower intake manifold. The upper intake manifold is

made of a composite for both the 3.3L engine and for

the 3.8L engine (Fig. 123). The lower intake manifold

is common between the two engines (Fig. 127). It alsoprovides coolant crossover between cylinder heads

and houses the coolant thermostat (Fig. 127).

The intake manifold utilizes a compact design with

very low restriction and outstanding flow balance.

This design allows the engine to perform with a wide

torque curve while increasing higher rpm horse-

power.

If, for some reason, the molded-in vacuum ports

break, the composite manifold can be salvaged. The

vacuum ports are designed to break at the shoulder,

if overloaded. Additional material in the shoulder

area provides sufficient stock to repair. For more

information and procedure, (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - STANDARD

PROCEDURE). Also, if the special screws that attach

the MAP sensor, power steering reservoir, throttle

cable bracket, and the EGR tube become stripped, an

oversized screw is available to repair the stripped-out

condition. For more information and procedure,

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - STANDARD PROCEDURE)

OPERATION

The intake manifold delivers air to the combustion

chambers. This air allows the fuel delivered by the

fuel injectors to ignite when the spark plugs fire.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

INTAKE MANIFOLD - UPPER

STANDARD PROCEDURE

STANDARD PROCEDURE - MANIFOLD

STRIPPED THREAD REPAIR

The composite upper intake manifold thread

bosses, if stripped out, can be repaired by utilizing a

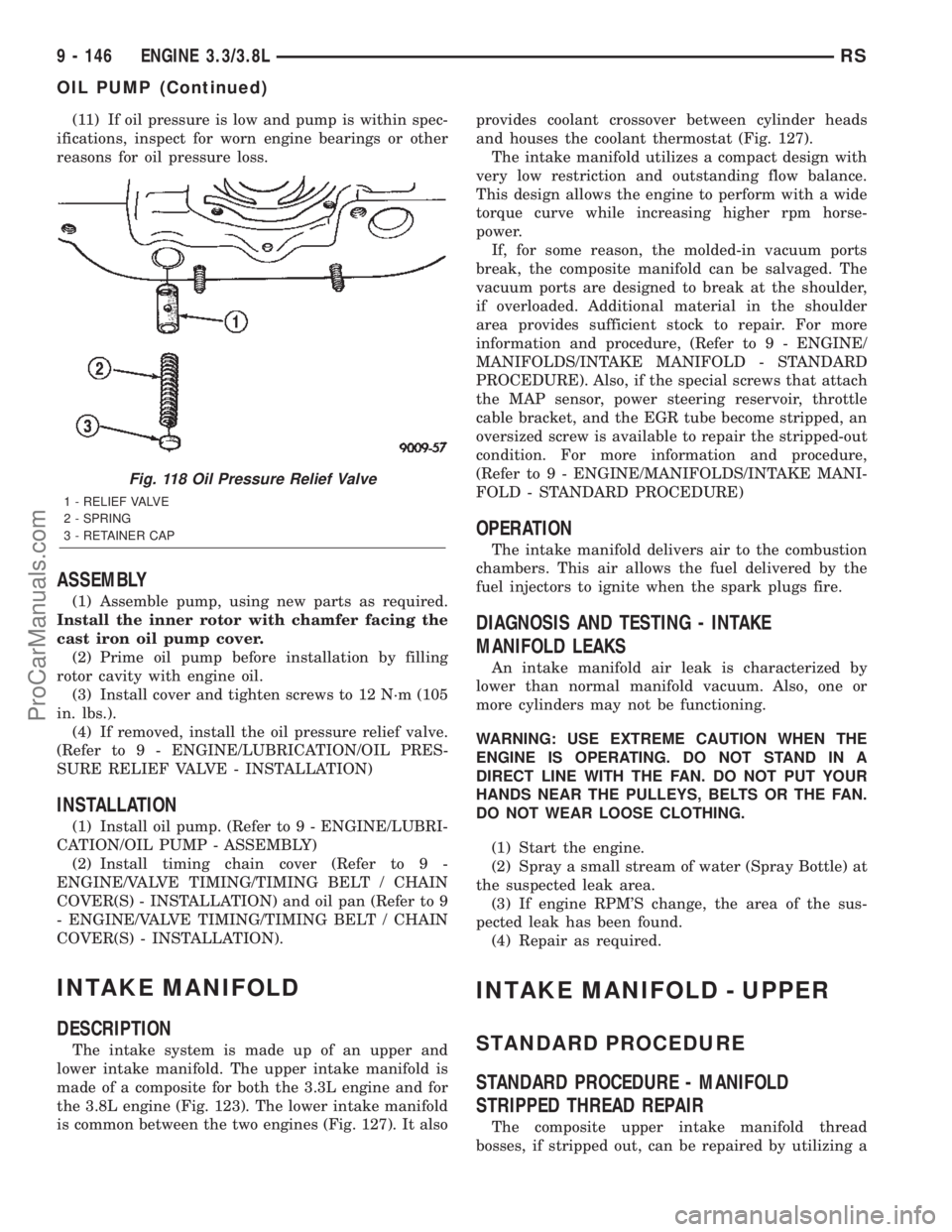

Fig. 118 Oil Pressure Relief Valve

1 - RELIEF VALVE

2 - SPRING

3 - RETAINER CAP

9 - 146 ENGINE 3.3/3.8LRS

OIL PUMP (Continued)

ProCarManuals.com

Page 1348 of 2399

repair screw available through Mopartparts. Repair

screws are available for the following manifold

attached components:

²MAP sensor

²Power steering reservoir

²EGR tube

²Throttle cable bracket

The repair screws require a unique tightening

torque specification from the original screw. Refer to

the following chart for specification.

DESCRIPTION TORQUE*

STRIP-OUT REPAIR SCREWS ONLY

MAP Sensor Repair

Screw4 N´m (35 in. lbs.)

Power Steering Reservoir

Repair Screw9 N´m (80 in. lbs.)

EGR Tube Attaching

Repair Screw9 N´m (80 in. lbs.)

Throttle Cable Bracket

Repair Screw9 N´m (80 in. lbs.)

*Install Slowly Using Hand Tools Only

STANDARD PROCEDURE - INTAKE MANIFOLD

VACUUM PORT REPAIR

The composite intake manifold vacuum ports can

be repaired. Although, if the manifold plenum cham-

ber is damaged or cracked, the manifold must be

replaced.

To repair a broken or damaged vacuum nipple

(port) on the composite intake manifold, perform the

following procedure:

PARTS REQUIRED TOOLS REQUIRED

´ Brass Nipple ± 1/49

O.D. x 1/89pipe thread

(LDP/Speed Control Port)´ Pipe Tap ± 1/89-18

NPT

´ Drill Bit ± 11/329

´ File/Sandpaper

´ Brass Nipple ± 1/29

O.D. x 1/49pipe thread

(Brake Booster Port)´ Pipe Tap ± 1/49-18

NPT

´ Drill Bit ± 7/169

´ File/Sandpaper

NOTE: While performing this procedure, avoid get-

ting the manifold material residue into the plenum

chamber.

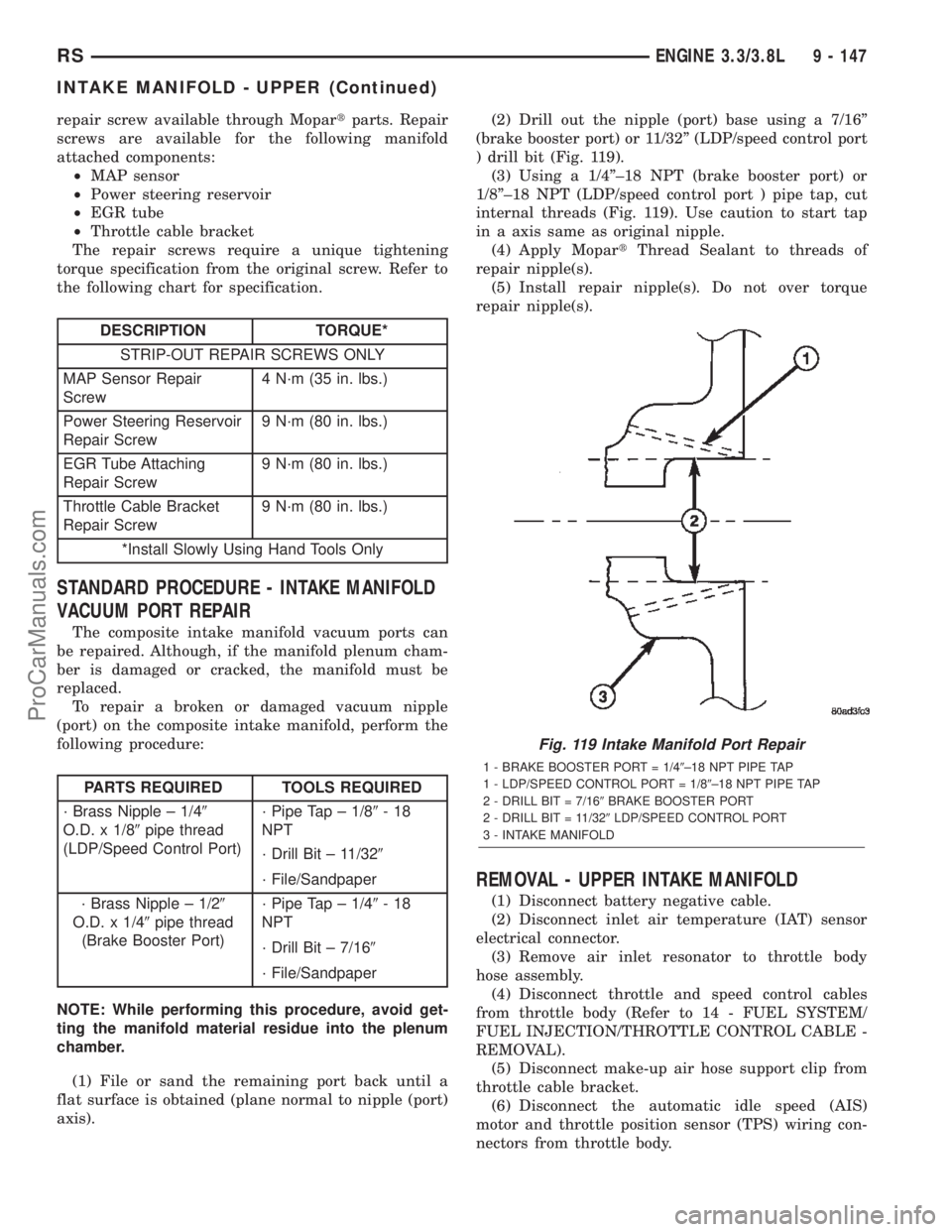

(1) File or sand the remaining port back until a

flat surface is obtained (plane normal to nipple (port)

axis).(2) Drill out the nipple (port) base using a 7/16º

(brake booster port) or 11/32º (LDP/speed control port

) drill bit (Fig. 119).

(3) Using a 1/4º±18 NPT (brake booster port) or

1/8º±18 NPT (LDP/speed control port ) pipe tap, cut

internal threads (Fig. 119). Use caution to start tap

in a axis same as original nipple.

(4) Apply MopartThread Sealant to threads of

repair nipple(s).

(5) Install repair nipple(s). Do not over torque

repair nipple(s).

REMOVAL - UPPER INTAKE MANIFOLD

(1) Disconnect battery negative cable.

(2) Disconnect inlet air temperature (IAT) sensor

electrical connector.

(3) Remove air inlet resonator to throttle body

hose assembly.

(4) Disconnect throttle and speed control cables

from throttle body (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/THROTTLE CONTROL CABLE -

REMOVAL).

(5) Disconnect make-up air hose support clip from

throttle cable bracket.

(6) Disconnect the automatic idle speed (AIS)

motor and throttle position sensor (TPS) wiring con-

nectors from throttle body.

Fig. 119 Intake Manifold Port Repair

1 - BRAKE BOOSTER PORT = 1/49±18 NPT PIPE TAP

1 - LDP/SPEED CONTROL PORT = 1/89±18 NPT PIPE TAP

2 - DRILL BIT = 7/169BRAKE BOOSTER PORT

2 - DRILL BIT = 11/329LDP/SPEED CONTROL PORT

3 - INTAKE MANIFOLD

RSENGINE 3.3/3.8L9 - 147

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1349 of 2399

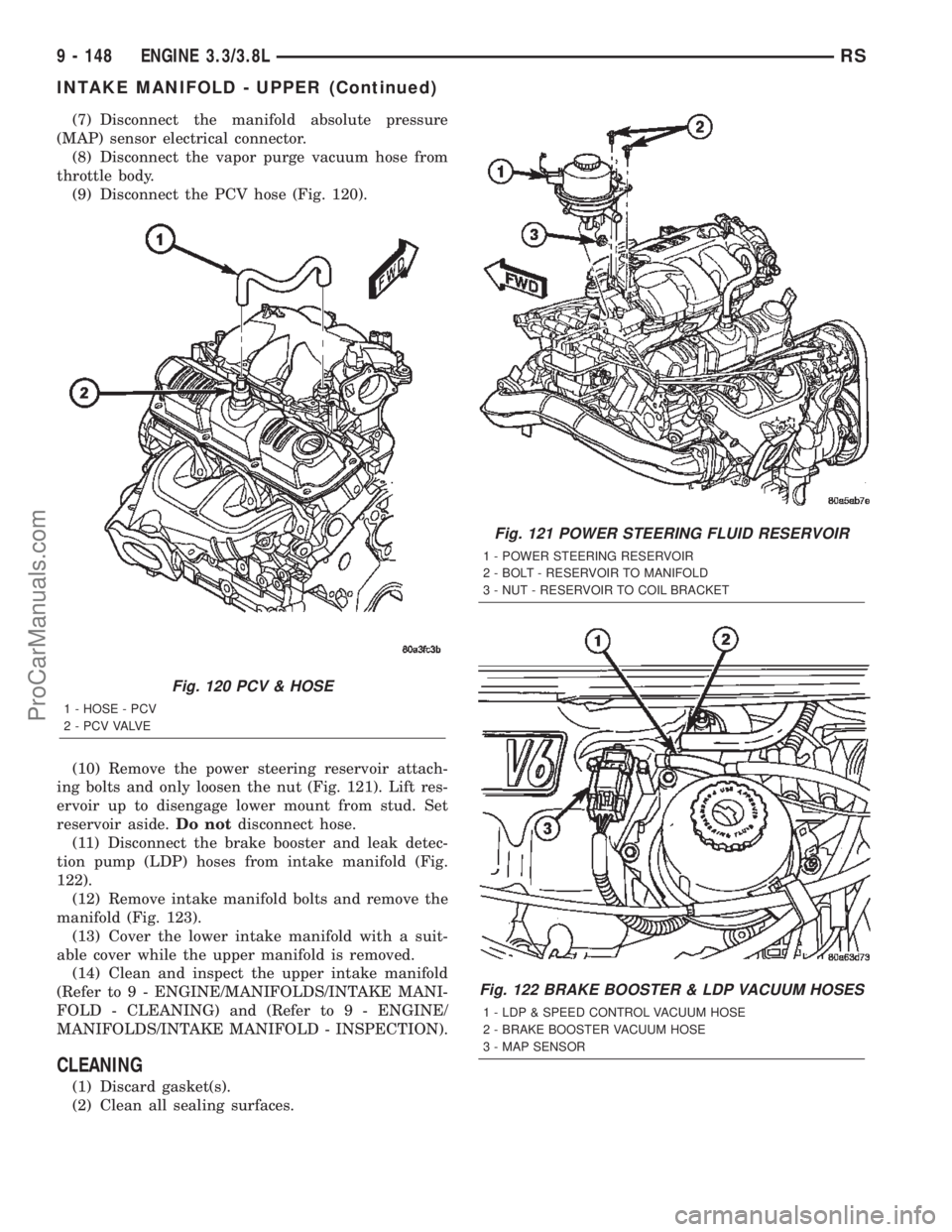

(7) Disconnect the manifold absolute pressure

(MAP) sensor electrical connector.

(8) Disconnect the vapor purge vacuum hose from

throttle body.

(9) Disconnect the PCV hose (Fig. 120).

(10) Remove the power steering reservoir attach-

ing bolts and only loosen the nut (Fig. 121). Lift res-

ervoir up to disengage lower mount from stud. Set

reservoir aside.Do notdisconnect hose.

(11) Disconnect the brake booster and leak detec-

tion pump (LDP) hoses from intake manifold (Fig.

122).

(12) Remove intake manifold bolts and remove the

manifold (Fig. 123).

(13) Cover the lower intake manifold with a suit-

able cover while the upper manifold is removed.

(14) Clean and inspect the upper intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - CLEANING) and (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSPECTION).

CLEANING

(1) Discard gasket(s).

(2) Clean all sealing surfaces.

Fig. 120 PCV & HOSE

1 - HOSE - PCV

2 - P C V VA LV E

Fig. 121 POWER STEERING FLUID RESERVOIR

1 - POWER STEERING RESERVOIR

2 - BOLT - RESERVOIR TO MANIFOLD

3 - NUT - RESERVOIR TO COIL BRACKET

Fig. 122 BRAKE BOOSTER & LDP VACUUM HOSES

1 - LDP & SPEED CONTROL VACUUM HOSE

2 - BRAKE BOOSTER VACUUM HOSE

3 - MAP SENSOR

9 - 148 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1350 of 2399

INSPECTION

Check manifold for:

²Damage and cracks.

²Mounting surface distortion by using a straight-

edge and thickness gauge.

INSTALLATION - UPPER INTAKE MANIFOLD

(1) If the following components were removed from

manifold, install and tighten to specifications:

CAUTION: The special screws used for the compos-

ite manifold attached components must be installed

slowly using hand tools only. This requirement is to

prevent the melting of material that causes stripped

threads. If threads become stripped, an oversize

repair screw is available. For more information and

procedure (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - STANDARD PROCEDURE - MAN-

IFOLD STRIPPED THREAD REPAIR).²MAP sensor - 1.7 N´m (15 in. lbs.)

²Throttle cable bracket - 5.6 N´m (50 in. lbs.)

(2) Remove covering on lower intake manifold and

clean surfaces.

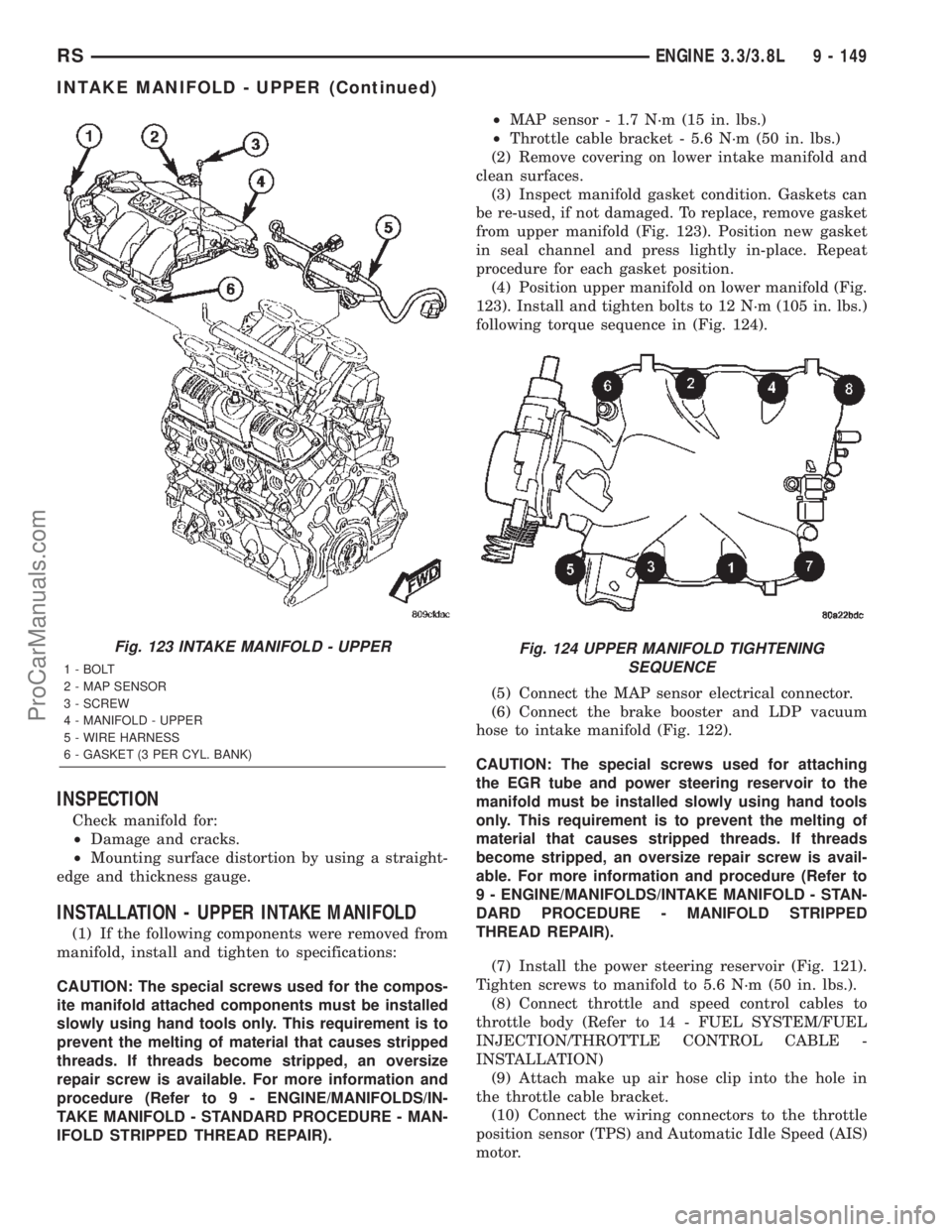

(3) Inspect manifold gasket condition. Gaskets can

be re-used, if not damaged. To replace, remove gasket

from upper manifold (Fig. 123). Position new gasket

in seal channel and press lightly in-place. Repeat

procedure for each gasket position.

(4) Position upper manifold on lower manifold (Fig.

123). Install and tighten bolts to 12 N´m (105 in. lbs.)

following torque sequence in (Fig. 124).

(5) Connect the MAP sensor electrical connector.

(6) Connect the brake booster and LDP vacuum

hose to intake manifold (Fig. 122).

CAUTION: The special screws used for attaching

the EGR tube and power steering reservoir to the

manifold must be installed slowly using hand tools

only. This requirement is to prevent the melting of

material that causes stripped threads. If threads

become stripped, an oversize repair screw is avail-

able. For more information and procedure (Refer to

9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - STAN-

DARD PROCEDURE - MANIFOLD STRIPPED

THREAD REPAIR).

(7) Install the power steering reservoir (Fig. 121).

Tighten screws to manifold to 5.6 N´m (50 in. lbs.).

(8) Connect throttle and speed control cables to

throttle body (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/THROTTLE CONTROL CABLE -

INSTALLATION)

(9) Attach make up air hose clip into the hole in

the throttle cable bracket.

(10) Connect the wiring connectors to the throttle

position sensor (TPS) and Automatic Idle Speed (AIS)

motor.

Fig. 123 INTAKE MANIFOLD - UPPER

1 - BOLT

2 - MAP SENSOR

3 - SCREW

4 - MANIFOLD - UPPER

5 - WIRE HARNESS

6 - GASKET (3 PER CYL. BANK)

Fig. 124 UPPER MANIFOLD TIGHTENING

SEQUENCE

RSENGINE 3.3/3.8L9 - 149

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1353 of 2399

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are log type and made of

Hi-Sil-Moly (high temperature resistant) nodular cast

iron. The exhaust manifolds are attached directly to

the cylinder heads and a cross-over pipe connects the

two manifolds.

OPERATION

The exhaust manifolds collects the exhaust gases

exiting the combustion chambers. It then channels

the exhaust gases to the exhaust pipe that is

attached to the rear (right side) manifold.

EXHAUST MANIFOLD - RIGHT

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL)

(3) Disconnect spark plug wires.

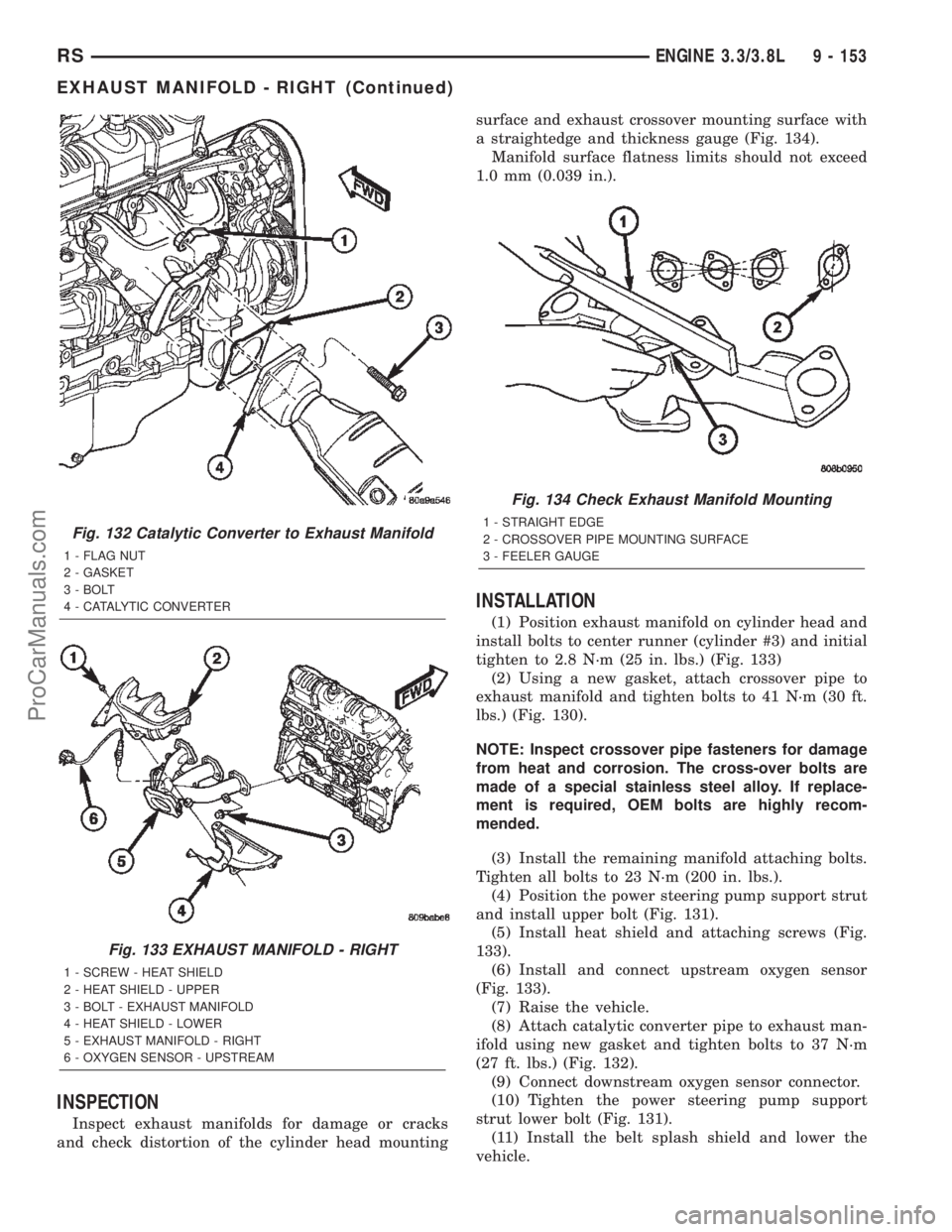

(4) Remove bolts fastening crossover pipe to

exhaust manifold (Fig. 130).

(5) Disconnect and remove the upstream oxygen

sensor (Fig. 133).

(6) Remove the heat shield attaching screws (Fig.

133).

(7) Remove the upper heat shield (Fig. 133).

(8) Raise vehicle on hoist and remove drive belt

shield.

(9) Loosen the power steering pump support strut

lower bolt (Fig. 131).

(10) Disconnect downstream oxygen sensor connec-

tor.(11) Disconnect catalytic converter pipe from

exhaust manifold (Fig. 132).

(12) Lower vehicle and remove the power steering

pump support strut upper bolt (Fig. 131).

(13) Remove bolts attaching exhaust manifold to

cylinder head and remove manifold (Fig. 133).

(14) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

CLEANING) (Refer to 9 - ENGINE/MANIFOLDS/

EXHAUST MANIFOLD - INSPECTION)

CLEANING

(1) Discard gasket (if equipped) and clean all sur-

faces of manifold and cylinder head.

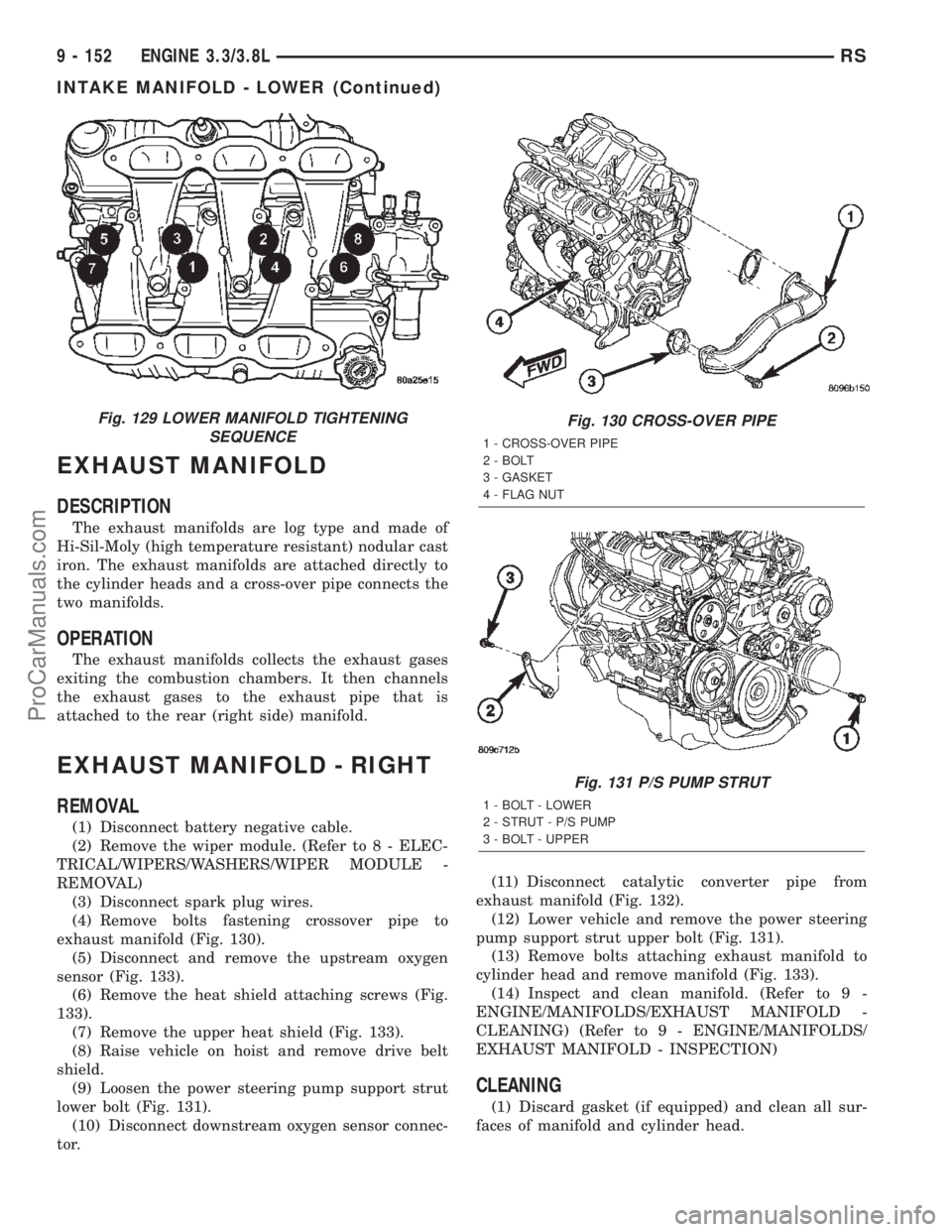

Fig. 129 LOWER MANIFOLD TIGHTENING

SEQUENCEFig. 130 CROSS-OVER PIPE

1 - CROSS-OVER PIPE

2 - BOLT

3 - GASKET

4 - FLAG NUT

Fig. 131 P/S PUMP STRUT

1 - BOLT - LOWER

2 - STRUT - P/S PUMP

3 - BOLT - UPPER

9 - 152 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - LOWER (Continued)

ProCarManuals.com

Page 1354 of 2399

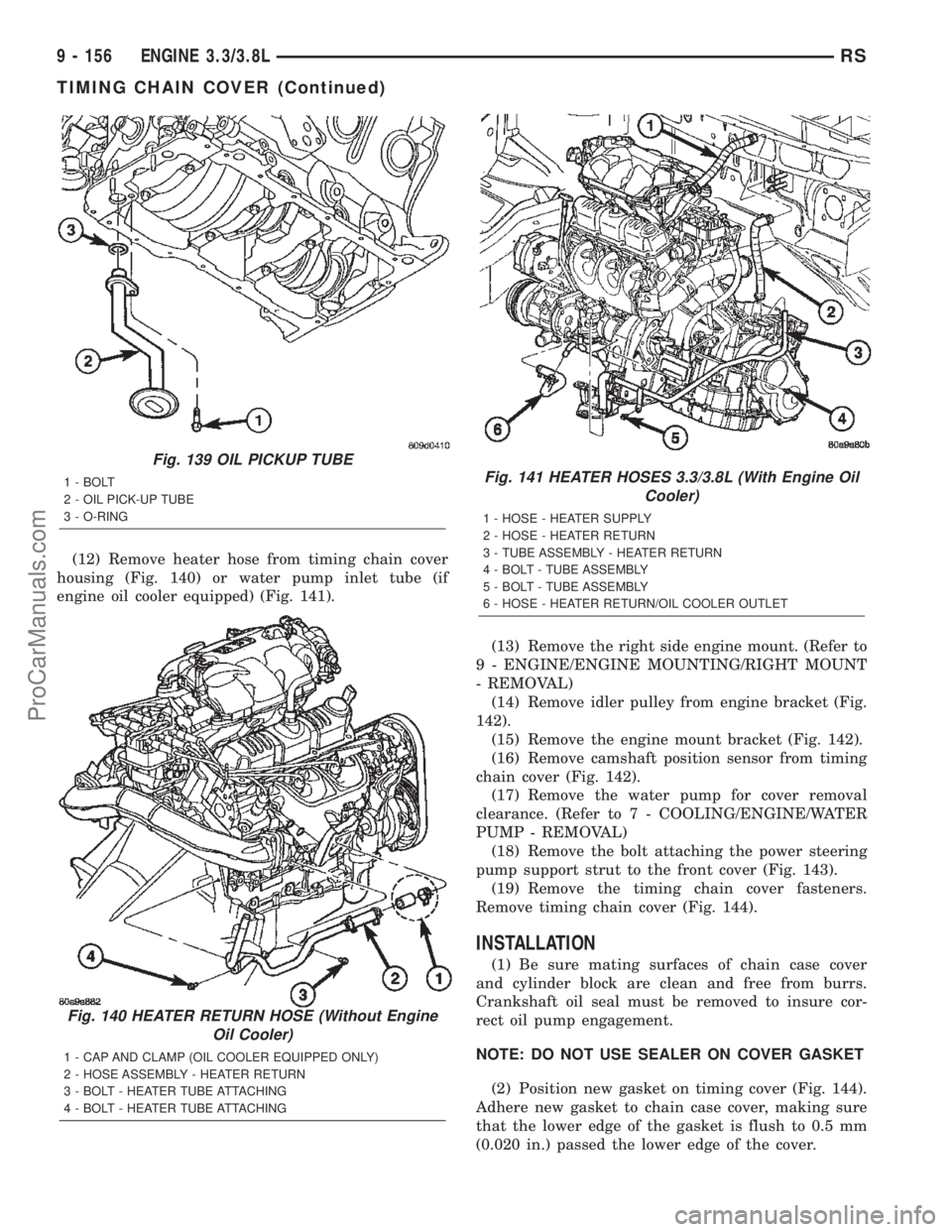

INSPECTION

Inspect exhaust manifolds for damage or cracks

and check distortion of the cylinder head mountingsurface and exhaust crossover mounting surface with

a straightedge and thickness gauge (Fig. 134).

Manifold surface flatness limits should not exceed

1.0 mm (0.039 in.).

INSTALLATION

(1) Position exhaust manifold on cylinder head and

install bolts to center runner (cylinder #3) and initial

tighten to 2.8 N´m (25 in. lbs.) (Fig. 133)

(2) Using a new gasket, attach crossover pipe to

exhaust manifold and tighten bolts to 41 N´m (30 ft.

lbs.) (Fig. 130).

NOTE: Inspect crossover pipe fasteners for damage

from heat and corrosion. The cross-over bolts are

made of a special stainless steel alloy. If replace-

ment is required, OEM bolts are highly recom-

mended.

(3) Install the remaining manifold attaching bolts.

Tighten all bolts to 23 N´m (200 in. lbs.).

(4) Position the power steering pump support strut

and install upper bolt (Fig. 131).

(5) Install heat shield and attaching screws (Fig.

133).

(6) Install and connect upstream oxygen sensor

(Fig. 133).

(7) Raise the vehicle.

(8) Attach catalytic converter pipe to exhaust man-

ifold using new gasket and tighten bolts to 37 N´m

(27 ft. lbs.) (Fig. 132).

(9) Connect downstream oxygen sensor connector.

(10) Tighten the power steering pump support

strut lower bolt (Fig. 131).

(11) Install the belt splash shield and lower the

vehicle.

Fig. 132 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

Fig. 133 EXHAUST MANIFOLD - RIGHT

1 - SCREW - HEAT SHIELD

2 - HEAT SHIELD - UPPER

3 - BOLT - EXHAUST MANIFOLD

4 - HEAT SHIELD - LOWER

5 - EXHAUST MANIFOLD - RIGHT

6 - OXYGEN SENSOR - UPSTREAM

Fig. 134 Check Exhaust Manifold Mounting

1 - STRAIGHT EDGE

2 - CROSSOVER PIPE MOUNTING SURFACE

3 - FEELER GAUGE

RSENGINE 3.3/3.8L9 - 153

EXHAUST MANIFOLD - RIGHT (Continued)

ProCarManuals.com

Page 1357 of 2399

(12) Remove heater hose from timing chain cover

housing (Fig. 140) or water pump inlet tube (if

engine oil cooler equipped) (Fig. 141).

(13) Remove the right side engine mount. (Refer to

9 - ENGINE/ENGINE MOUNTING/RIGHT MOUNT

- REMOVAL)

(14) Remove idler pulley from engine bracket (Fig.

142).

(15) Remove the engine mount bracket (Fig. 142).

(16) Remove camshaft position sensor from timing

chain cover (Fig. 142).

(17) Remove the water pump for cover removal

clearance. (Refer to 7 - COOLING/ENGINE/WATER

PUMP - REMOVAL)

(18) Remove the bolt attaching the power steering

pump support strut to the front cover (Fig. 143).

(19) Remove the timing chain cover fasteners.

Remove timing chain cover (Fig. 144).

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

Crankshaft oil seal must be removed to insure cor-

rect oil pump engagement.

NOTE: DO NOT USE SEALER ON COVER GASKET

(2) Position new gasket on timing cover (Fig. 144).

Adhere new gasket to chain case cover, making sure

that the lower edge of the gasket is flush to 0.5 mm

(0.020 in.) passed the lower edge of the cover.

Fig. 139 OIL PICKUP TUBE

1 - BOLT

2 - OIL PICK-UP TUBE

3 - O-RING

Fig. 140 HEATER RETURN HOSE (Without Engine

Oil Cooler)

1 - CAP AND CLAMP (OIL COOLER EQUIPPED ONLY)

2 - HOSE ASSEMBLY - HEATER RETURN

3 - BOLT - HEATER TUBE ATTACHING

4 - BOLT - HEATER TUBE ATTACHING

Fig. 141 HEATER HOSES 3.3/3.8L (With Engine Oil

Cooler)

1 - HOSE - HEATER SUPPLY

2 - HOSE - HEATER RETURN

3 - TUBE ASSEMBLY - HEATER RETURN

4 - BOLT - TUBE ASSEMBLY

5 - BOLT - TUBE ASSEMBLY

6 - HOSE - HEATER RETURN/OIL COOLER OUTLET

9 - 156 ENGINE 3.3/3.8LRS

TIMING CHAIN COVER (Continued)

ProCarManuals.com

Page 1358 of 2399

(3) Rotate crankshaft so that the oil pump drive

flats are in the vertical position.

(4) Position oil pump inner rotor so the mating

flats are in the same position as the crankshaft drive

flats (Fig. 144).CAUTION: Make sure the oil pump is engaged on

the crankshaft correctly or severe damage may

result.

(5) Install timing cover (Fig. 144).

(6) Install timing chain cover bolts. Tighten M8

bolts to 27 N´m (20 ft. lbs.) and M10 bolts to 54 N´m

(40 ft. lbs.) (Fig. 145).

(7) Install crankshaft front oil seal. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION)

(8) Install water pump and pulley. (Refer to 7 -

COOLING/ENGINE/WATER PUMP - INSTALLA-

TION)

(9) Install crankshaft vibration damper. (Refer to 9

- ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(10) Install engine mount bracket (Fig. 142) and

tighten M10 to 54 N´m (40 ft. lbs.), M8 bolt to 28

N´m (21 ft. lb. lbs.).

(11) Install idler pulley on engine mount bracket

(Fig. 142).

(12) Install right side engine mount. (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION)

(13) Install camshaft position sensor (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/CAMSHAFT

POSITION SENSOR - INSTALLATION).

(14) Connect the heater return hose at rear of tim-

ing chain cover (Fig. 140) or at water pump inlet

tube (if engine oil cooler equipped) (Fig. 141).

(15) Connect the radiator lower hose.

(16) Install A/C compressor.

(17) Install accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

Fig. 142 Engine Mount Bracket

1 - CAMSHAFT SENSOR

2 - BOLT - CAMSHAFT SENSOR

3 - BOLT - MOUNT BRACKET (VERTICAL)

4 - BRACKET - ENGINE MOUNT

5 - BOLT - MOUNT BRACKET (HORIZONTAL)

6 - PULLEY - IDLER

7 - BOLT - IDLER PULLEY

8 - SPACER - IDLER PULLEY BOLT

9 - BOLT - MOUNT BRACKET (HORIZONTAL)

Fig. 143 Power Steering Pump Strut

1 - BOLT - LOWER

2 - STRUT - P/S PUMP

3 - BOLT - UPPER

Fig. 144 Timing Chain Cover and Gasket

1 - GASKET

2 - TIMING CHAIN COVER

RSENGINE 3.3/3.8L9 - 157

TIMING CHAIN COVER (Continued)

ProCarManuals.com

Page 1365 of 2399

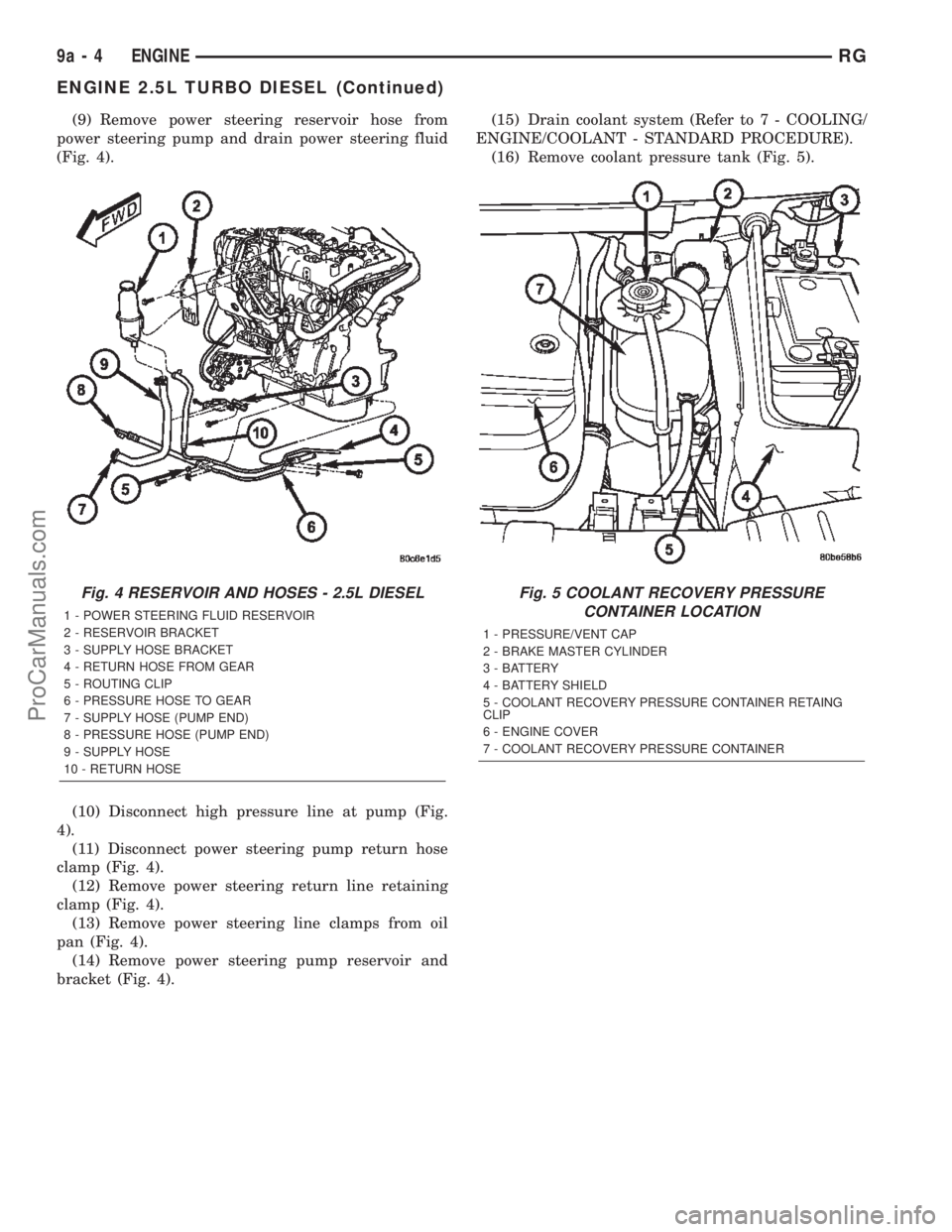

(9) Remove power steering reservoir hose from

power steering pump and drain power steering fluid

(Fig. 4).

(10) Disconnect high pressure line at pump (Fig.

4).

(11) Disconnect power steering pump return hose

clamp (Fig. 4).

(12) Remove power steering return line retaining

clamp (Fig. 4).

(13) Remove power steering line clamps from oil

pan (Fig. 4).

(14) Remove power steering pump reservoir and

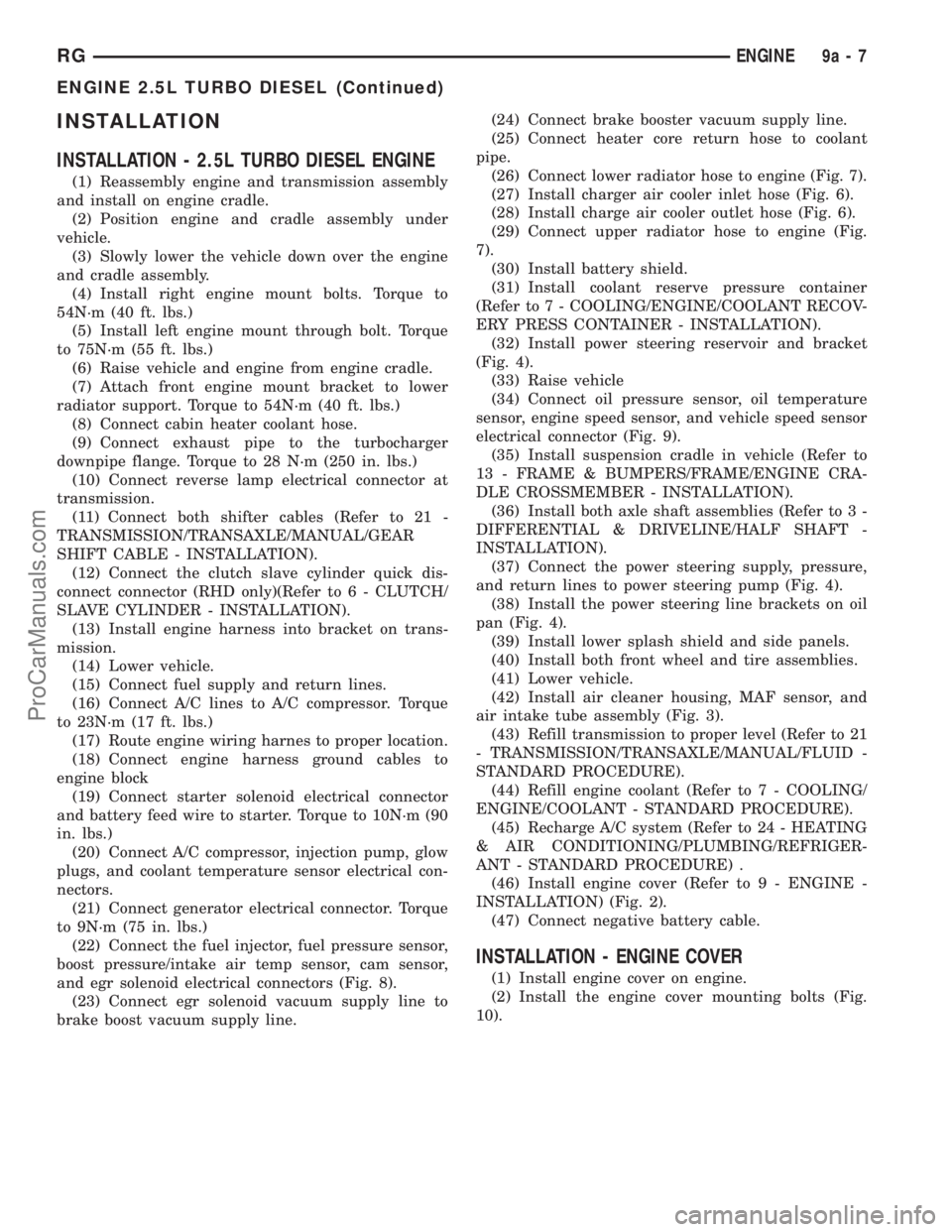

bracket (Fig. 4).(15) Drain coolant system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(16) Remove coolant pressure tank (Fig. 5).

Fig. 4 RESERVOIR AND HOSES - 2.5L DIESEL

1 - POWER STEERING FLUID RESERVOIR

2 - RESERVOIR BRACKET

3 - SUPPLY HOSE BRACKET

4 - RETURN HOSE FROM GEAR

5 - ROUTING CLIP

6 - PRESSURE HOSE TO GEAR

7 - SUPPLY HOSE (PUMP END)

8 - PRESSURE HOSE (PUMP END)

9 - SUPPLY HOSE

10 - RETURN HOSE

Fig. 5 COOLANT RECOVERY PRESSURE

CONTAINER LOCATION

1 - PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - BATTERY

4 - BATTERY SHIELD

5 - COOLANT RECOVERY PRESSURE CONTAINER RETAING

CLIP

6 - ENGINE COVER

7 - COOLANT RECOVERY PRESSURE CONTAINER

9a - 4 ENGINERG

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1368 of 2399

INSTALLATION

INSTALLATION - 2.5L TURBO DIESEL ENGINE

(1) Reassembly engine and transmission assembly

and install on engine cradle.

(2) Position engine and cradle assembly under

vehicle.

(3) Slowly lower the vehicle down over the engine

and cradle assembly.

(4) Install right engine mount bolts. Torque to

54N´m (40 ft. lbs.)

(5) Install left engine mount through bolt. Torque

to 75N´m (55 ft. lbs.)

(6) Raise vehicle and engine from engine cradle.

(7) Attach front engine mount bracket to lower

radiator support. Torque to 54N´m (40 ft. lbs.)

(8) Connect cabin heater coolant hose.

(9) Connect exhaust pipe to the turbocharger

downpipe flange. Torque to 28 N´m (250 in. lbs.)

(10) Connect reverse lamp electrical connector at

transmission.

(11) Connect both shifter cables (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/GEAR

SHIFT CABLE - INSTALLATION).

(12) Connect the clutch slave cylinder quick dis-

connect connector (RHD only)(Refer to 6 - CLUTCH/

SLAVE CYLINDER - INSTALLATION).

(13) Install engine harness into bracket on trans-

mission.

(14) Lower vehicle.

(15) Connect fuel supply and return lines.

(16) Connect A/C lines to A/C compressor. Torque

to 23N´m (17 ft. lbs.)

(17) Route engine wiring harnes to proper location.

(18) Connect engine harness ground cables to

engine block

(19) Connect starter solenoid electrical connector

and battery feed wire to starter. Torque to 10N´m (90

in. lbs.)

(20) Connect A/C compressor, injection pump, glow

plugs, and coolant temperature sensor electrical con-

nectors.

(21) Connect generator electrical connector. Torque

to 9N´m (75 in. lbs.)

(22) Connect the fuel injector, fuel pressure sensor,

boost pressure/intake air temp sensor, cam sensor,

and egr solenoid electrical connectors (Fig. 8).

(23) Connect egr solenoid vacuum supply line to

brake boost vacuum supply line.(24) Connect brake booster vacuum supply line.

(25) Connect heater core return hose to coolant

pipe.

(26) Connect lower radiator hose to engine (Fig. 7).

(27) Install charger air cooler inlet hose (Fig. 6).

(28) Install charge air cooler outlet hose (Fig. 6).

(29) Connect upper radiator hose to engine (Fig.

7).

(30) Install battery shield.

(31) Install coolant reserve pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

(32) Install power steering reservoir and bracket

(Fig. 4).

(33) Raise vehicle

(34) Connect oil pressure sensor, oil temperature

sensor, engine speed sensor, and vehicle speed sensor

electrical connector (Fig. 9).

(35) Install suspension cradle in vehicle (Refer to

13 - FRAME & BUMPERS/FRAME/ENGINE CRA-

DLE CROSSMEMBER - INSTALLATION).

(36) Install both axle shaft assemblies (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

INSTALLATION).

(37) Connect the power steering supply, pressure,

and return lines to power steering pump (Fig. 4).

(38) Install the power steering line brackets on oil

pan (Fig. 4).

(39) Install lower splash shield and side panels.

(40) Install both front wheel and tire assemblies.

(41) Lower vehicle.

(42) Install air cleaner housing, MAF sensor, and

air intake tube assembly (Fig. 3).

(43) Refill transmission to proper level (Refer to 21

- TRANSMISSION/TRANSAXLE/MANUAL/FLUID -

STANDARD PROCEDURE).

(44) Refill engine coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(45) Recharge A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-

ANT - STANDARD PROCEDURE) .

(46) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION) (Fig. 2).

(47) Connect negative battery cable.

INSTALLATION - ENGINE COVER

(1) Install engine cover on engine.

(2) Install the engine cover mounting bolts (Fig.

10).

RGENGINE9a-7

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com