CHRYSLER VOYAGER 2002 Service Manual

Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1671 of 2399

DISASSEMBLY

(1) Back off low/reverse band adjustment and posi-

tion lever out of the way (Fig. 204).

(2) Remove low/reverse servo snap ring (Fig. 205).

(3) Remove retainer, spring and servo (Fig. 206).

CLEANING

Remove and discard the servo piston seal ring (Fig.

207). Then clean the servo components with solvent

and dry with compressed air. Replace either spring if

collapsed, distorted or broken. Replace the plug and

piston if cracked, bent, or worn. Discard the servo

snap-rings and use new ones at assembly.

Fig. 204 Low/Reverse Lever

1 - LOW-REVERSE LEVER

Fig. 205 Low/Reverse Servo Snap Ring

1 - SNAP-RING PLIERS

Fig. 206 Remove Retainer, Spring and Servo

1 - SERVO PISTON

2 - SPRING AND RETAINER

Fig. 207 Rear Servo Components

1 - SNAP-RING

2 - PISTON SEAL

3 - PISTON PLUG

4 - SPRING RETAINER

5 - SNAP-RING

6 - PISTON SPRING

7 - CUSHION SPRING

8 - PISTON

21 - 114 31TH AUTOMATIC TRANSAXLERS

SERVO - LOW/REVERSE (Continued)

ProCarManuals.com

Page 1672 of 2399

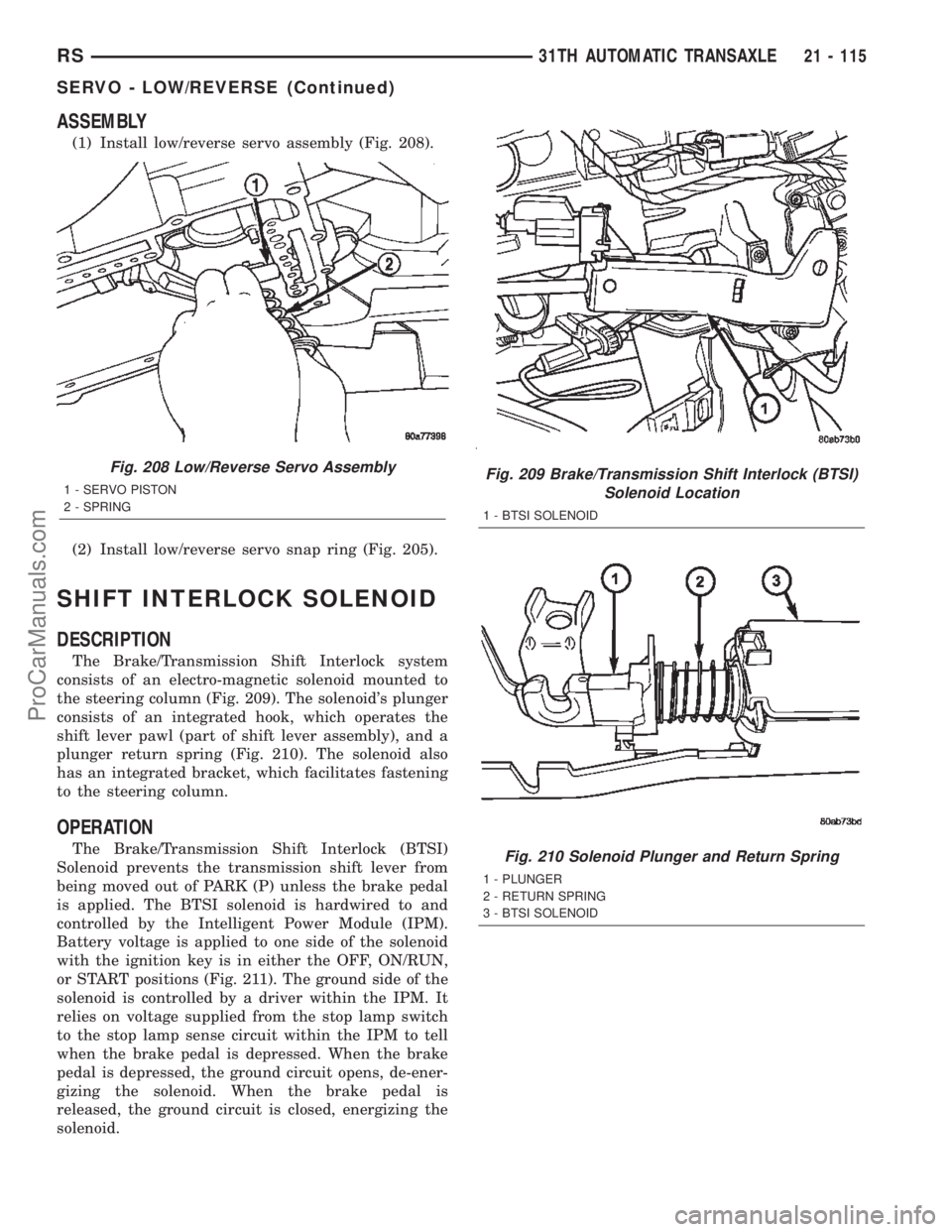

ASSEMBLY

(1) Install low/reverse servo assembly (Fig. 208).

(2) Install low/reverse servo snap ring (Fig. 205).

SHIFT INTERLOCK SOLENOID

DESCRIPTION

The Brake/Transmission Shift Interlock system

consists of an electro-magnetic solenoid mounted to

the steering column (Fig. 209). The solenoid's plunger

consists of an integrated hook, which operates the

shift lever pawl (part of shift lever assembly), and a

plunger return spring (Fig. 210). The solenoid also

has an integrated bracket, which facilitates fastening

to the steering column.

OPERATION

The Brake/Transmission Shift Interlock (BTSI)

Solenoid prevents the transmission shift lever from

being moved out of PARK (P) unless the brake pedal

is applied. The BTSI solenoid is hardwired to and

controlled by the Intelligent Power Module (IPM).

Battery voltage is applied to one side of the solenoid

with the ignition key is in either the OFF, ON/RUN,

or START positions (Fig. 211). The ground side of the

solenoid is controlled by a driver within the IPM. It

relies on voltage supplied from the stop lamp switch

to the stop lamp sense circuit within the IPM to tell

when the brake pedal is depressed. When the brake

pedal is depressed, the ground circuit opens, de-ener-

gizing the solenoid. When the brake pedal is

released, the ground circuit is closed, energizing the

solenoid.

Fig. 208 Low/Reverse Servo Assembly

1 - SERVO PISTON

2 - SPRINGFig. 209 Brake/Transmission Shift Interlock (BTSI)

Solenoid Location

1 - BTSI SOLENOID

Fig. 210 Solenoid Plunger and Return Spring

1 - PLUNGER

2 - RETURN SPRING

3 - BTSI SOLENOID

RS31TH AUTOMATIC TRANSAXLE21 - 115

SERVO - LOW/REVERSE (Continued)

ProCarManuals.com

Page 1673 of 2399

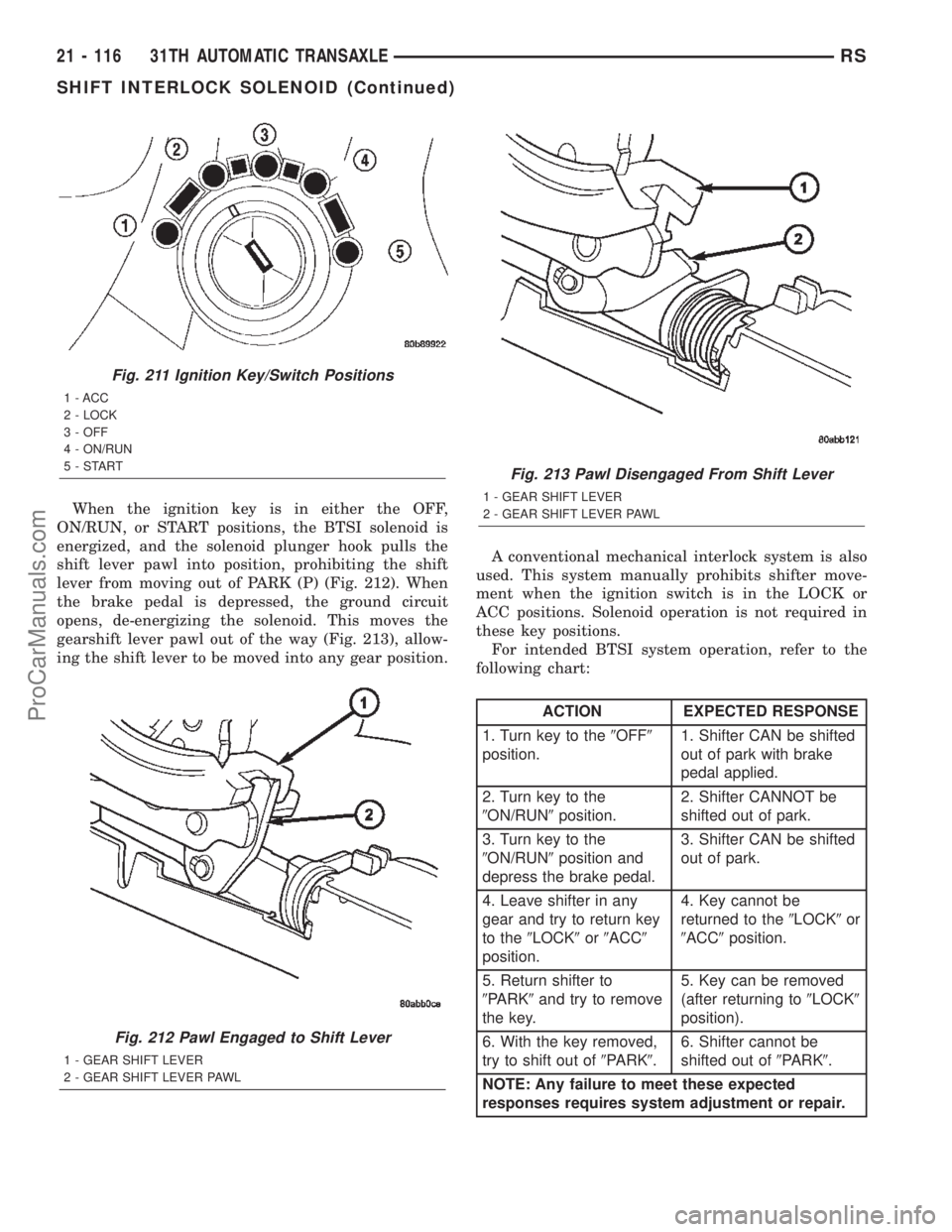

When the ignition key is in either the OFF,

ON/RUN, or START positions, the BTSI solenoid is

energized, and the solenoid plunger hook pulls the

shift lever pawl into position, prohibiting the shift

lever from moving out of PARK (P) (Fig. 212). When

the brake pedal is depressed, the ground circuit

opens, de-energizing the solenoid. This moves the

gearshift lever pawl out of the way (Fig. 213), allow-

ing the shift lever to be moved into any gear position.A conventional mechanical interlock system is also

used. This system manually prohibits shifter move-

ment when the ignition switch is in the LOCK or

ACC positions. Solenoid operation is not required in

these key positions.

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

Fig. 211 Ignition Key/Switch Positions

1 - ACC

2 - LOCK

3 - OFF

4 - ON/RUN

5-START

Fig. 212 Pawl Engaged to Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

Fig. 213 Pawl Disengaged From Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

21 - 116 31TH AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1674 of 2399

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK SOLENOID

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system repair. Refer to the

appropriate Diagnostic Information.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower shroud (Fig.

214).(3) Remove knee bolster (Fig. 215).

(4) Remove steering column lower shroud.

(5) Disconnect brake/transmission shift interlock

(BTSI) solenoid connector (Fig. 216).

Fig. 214 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 215 Knee Bolster

1 - KNEE BOLSTER

Fig. 216 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

RS31TH AUTOMATIC TRANSAXLE21 - 117

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1675 of 2399

(6) Remove two (2) solenoid-to-column screws (Fig.

217).

(7) Remove solenoid.

INSTALLATION

(1) Place interlock solenoid into position ensuring

hook on end of solenoid plunger engages gearshift

lever pawl pin. Install and tighten screws (Fig. 218).(2) Verify gearshift lever is in PARK (P) and con-

nect solenoid connector (Fig. 219).

(3) Install steering column lower shroud.

(4) Install knee bolster (Fig. 220).

Fig. 217 Solenoid Retaining Screw

1 - SOLENOID RETAINING SCREW (2)

Fig. 218 Solenoid Retaining Screw

1 - SOLENOID RETAINING SCREW (2)

Fig. 219 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

Fig. 220 Knee Bolster

1 - KNEE BOLSTER

21 - 118 31TH AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1676 of 2399

(5) Install instrument panel lower silencer (Fig.

221).

(6) Connect battery negative cable.

(7) Verify proper shift interlock system operation.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/SHIFT INTERLOCK SOLENOID -

OPERATION)

SOLENOID - TCC

DESCRIPTION

The torque converter clutch (TCC) solenoid is fas-

tened to the transaxle valve body, and its connector

protrudes through the transaxle case (Fig. 222).

OPERATION

The torque converter clutch solenoid is responsible

for controlling application of the torque converter

clutch. It is controlled by the Powertrain Control

Module (PCM), which determines when conditions

are acceptable for torque converter lock-up.

REMOVAL

(1) Remove valve body from transaxle. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/VALVE BODY - REMOVAL)

(2) Remove three (3) torque converter clutch sole-

noid-to-valve body screws (Fig. 223).

(3) Remove torque converter clutch solenoid (Fig.

223). Note orientation of plug and spring.

Fig. 221 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 222 Torque Converter Clutch Solenoid

1 - TCC SOLENOID WIRING CONNECTOR

RS31TH AUTOMATIC TRANSAXLE21 - 119

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1677 of 2399

INSTALLATION

(1) Install plug and spring as shown in (Fig. 223).

(2) Install torque converter clutch solenoid to valve

body (Fig. 223) and torque screws to 5 N´m (45 in.

lbs.).

(3) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/VALVE BODY - INSTALLATION)

THROTTLE VALVE CABLE

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect cable core from throttle lever pin

(Fig. 224).

(3) Disconnect cable retainer from throttle body

bracket (Fig. 224).

Fig. 223 Torque Converter Clutch Solenoid and Regulator/Control Valves

1 - CONVERTER PRESSURE CONTROL VALVE 3 - SCREW (3) 5 - REGULATOR VALVE THROTTLE PRESSURE

PLUG

2 - END COVER 4 - REGULATOR VALVE THROTTLE PRESSURE

PLUG SPRING 6 - SWITCH VALVE

Fig. 224 Throttle Valve Cable at Throttle Body

1 - THROTTLE VALVE CABLE CLIP

2 - THROTTLE BODY LEVER

3 - CABLE RETAINER

21 - 120 31TH AUTOMATIC TRANSAXLERS

SOLENOID - TCC (Continued)

ProCarManuals.com

Page 1678 of 2399

(4) Disconnect cable from throttle valve lever at

transaxle (Fig. 225).

(5) Disconnect cable retainer at transaxle bracket

(Fig. 225).

INSTALLATION

(1) Install throttle valve cable to bracket at trans-

axle (Fig. 226). Connect cable to transaxle throttle

valve lever.

(2) Route cable through center of intake manifold

(#2 & #3) runners.

(3) Connect throttle valve cable retainer to throttle

body bracket (Fig. 227).

(4) Connect cable core clip to throttle lever (Fig.

227).

(5) Adjust throttle valve cable. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/THROTTLE VALVE CABLE - ADJUST-

MENTS)

(6) Connect battery negative cable.

Fig. 225 Throttle Valve Cable at Transaxle

1 - LEVER

2 - BRACKET

3 - THROTTLE VALVE CABLE

Fig. 226 Throttle Valve Cable at Transaxle

1 - LEVER

2 - BRACKET

3 - THROTTLE VALVE CABLE

Fig. 227 Throttle Valve Cable at Throttle Body

1 - THROTTLE VALVE CABLE CLIP

2 - THROTTLE BODY LEVER

3 - CABLE RETAINER

RS31TH AUTOMATIC TRANSAXLE21 - 121

THROTTLE VALVE CABLE (Continued)

ProCarManuals.com

Page 1679 of 2399

ADJUSTMENTS

THROTTLE VALVE LINKAGE ADJUSTMENT

The throttle valve linkage adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too short, early shifts and slippage

between shifts may occur. If the setting is too long,

shifts may be delayed and part throttle downshifts

may be very sensitive.

LINKAGE ADJUSTMENT PROCEDURE

(1) Perform transaxle throttle valve linkage

adjustment while engine is at normal operating tem-

perature.

(2) Using small screwdriver, disengage adjustment

lock at transaxle.

(3) Rotate lever at transaxle all the way to the left

side of vehicle against stop.

(4) Slide cable adjuster until cable core end

touches clip at throttle valve lever.

(5) Press adjuster lock (Fig. 228) to retain setting.

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 229) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the fluid cooler and lines.

Fig. 228 Throttle Valve Cable Adjustment Lock

1 - ADJUSTER LOCK

Fig. 229 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21 - 122 31TH AUTOMATIC TRANSAXLERS

THROTTLE VALVE CABLE (Continued)

ProCarManuals.com

Page 1680 of 2399

IMPELLER

The impeller (Fig. 230) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving member of the system.

Fig. 230 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

RS31TH AUTOMATIC TRANSAXLE21 - 123

TORQUE CONVERTER (Continued)

ProCarManuals.com