CHRYSLER VOYAGER 2002 Service Manual

VOYAGER 2002

CHRYSLER

CHRYSLER

https://www.carmanualsonline.info/img/25/56871/w960_56871-0.png

CHRYSLER VOYAGER 2002 Service Manual

Trending: electr, trip computer, climate control, CD player, open hood, spare tire location, Vtss

Page 1941 of 2399

(1) Install input shaft into fixture 8487.

(2) Install thrust washer if removed upon disas-

sembly.

(3) Install 3rd gear (Fig. 216).

(4) Install 3rd gear blocker ring (Fig. 217).(5) Install 3/4 synchronizer (Fig. 218).When

installing 3/4 synchronizer hub to shaft, make

sure to align oil slots on synchronizer hub face

with oil hole in the shaft splined hub journal.

(6) InstallNEW3/4 synchronizer snap ring (Fig.

219).

Fig. 216 3rd Gear Removal/Installation

1 - 3RD GEAR

Fig. 217 3rd Gear Blocker Ring

1 - 3RD GEAR BLOCKER RING

Fig. 218 3/4 Synchro Assembly

1 - 3/4 SYNCHRONIZER

Fig. 219 3/4 Synchro Snap Ring

1 - SNAP RING

2 - 3/4 SYNCHRONIZER

21 - 384 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

ProCarManuals.com

Page 1942 of 2399

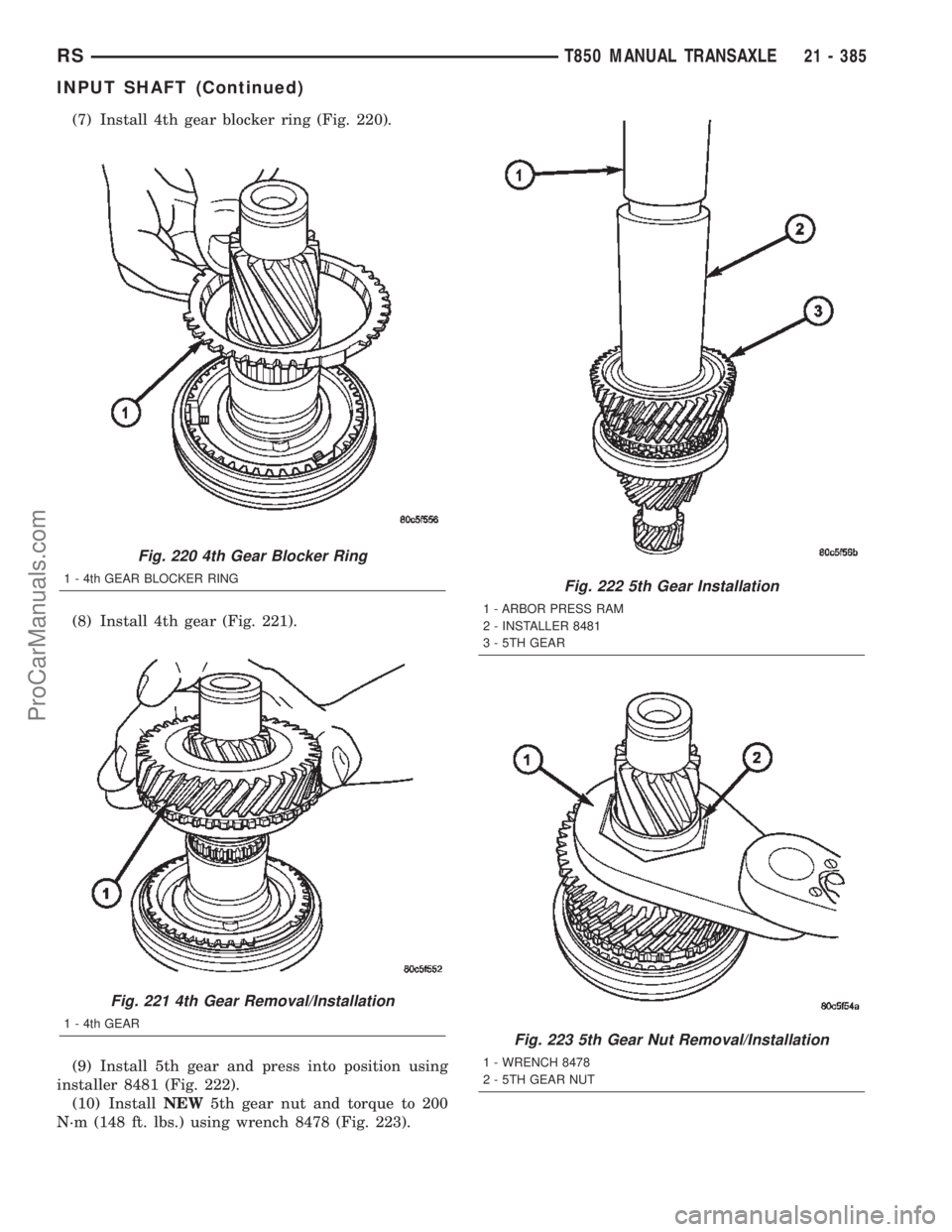

(7) Install 4th gear blocker ring (Fig. 220).

(8) Install 4th gear (Fig. 221).

(9) Install 5th gear and press into position using

installer 8481 (Fig. 222).

(10) InstallNEW5th gear nut and torque to 200

N´m (148 ft. lbs.) using wrench 8478 (Fig. 223).

Fig. 220 4th Gear Blocker Ring

1 - 4th GEAR BLOCKER RING

Fig. 221 4th Gear Removal/Installation

1 - 4th GEAR

Fig. 222 5th Gear Installation

1 - ARBOR PRESS RAM

2 - INSTALLER 8481

3 - 5TH GEAR

Fig. 223 5th Gear Nut Removal/Installation

1 - WRENCH 8478

2 - 5TH GEAR NUT

RST850 MANUAL TRANSAXLE21 - 385

INPUT SHAFT (Continued)

ProCarManuals.com

Page 1943 of 2399

(11) Stake 5th Gear nut as follows:

(a) Install staking tool 8479 to 5th gear nut.

(b) Tighten upper thumb screw by hand (Fig.

224).

(c) Tighten two (2) side thumb screws by hand.

(d) Tighten both staking screws until they bot-

tom on tool body (Fig. 225).

(e) Loosen staking screws and thumb screws.

Remove tool and visually inspect stake (Fig. 226).

NOTE: The input shaft sealed roller bearing and

snap ring do not get installed until transaxle assem-

bly to facilitate installation of the reverse idler gear

mechanism.

Fig. 224 Staking Tool Set-Up

1 - STAKING TOOL 8479

2 - THUMB SCREWS (3)

Fig. 225 Tighten Stake Screws

1 - STAKING TOOL 8479

Fig. 226 5th Gear Nut Stake

1-STAKE

2 - 5TH GEAR NUT

21 - 386 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

ProCarManuals.com

Page 1944 of 2399

INTERMEDIATE SHAFT

DESCRIPTION

The intermediate shaft assembly (Fig. 227) is part

of the transaxle geartrain, meshes with and is driven

by the input shaft, drives the differential via an inte-

grated pinion gear, and consists of the following com-

ponents:

²Intermediate Mainshaft

²1st Speed Gear

²2nd Speed Gear

²3/4 Cluster Gear

²5th Speed Gear

²Reverse Gear

²1/2 Synchronizer

²5/R Synchronizer

The intermediate shaft is supported by a caged

roller bearing at the front of the transaxle, and a

sealed roller bearing at the rear of the transaxle.

Fig. 227 Intermediate Shaft Assembly

1 - INTERMEDIATE SHAFT 10 - SNAP RING

2 - ROLLER BEARING 11 - SEALED ROLLER BEARING

3 - SNAP RING 12 - THRUST WASHER

4 - NEEDLE BEARING 13 - NEEDLE BEARING

5 - 1ST SPEED GEAR 14 - REVERSE GEAR

6 - SNAP RING 15 - SNAP RING

7 - 2ND SPEED GEAR 16 - 5/R SYNCHRO

8 - 3/4 CLUSTER GEAR 17 - 5TH SPEED GEAR

9 - SNAP RING 18 - 1/2 SYNCHRO

RST850 MANUAL TRANSAXLE21 - 387

ProCarManuals.com

Page 1945 of 2399

DISASSEMBLY

CAUTION: Do not re-use snap rings when servicing

the intermediate shaft assembly. Discard upon dis-

assembly and install new ones provided with avail-

able snap ring service kit.

(1) Install intermediate shaft assembly to arbor

press table with bearing splitter P-334 under the

reverse gear.

(2) Install 8486-4 button to intermediate shaft.

Using arbor press ram, press reverse gear and inter-

mediate roller bearing off of shaft, while holding

remaining assembly with hand (Fig. 228).

(3) Remove reverse gear blocker ring.

(4) Remove reverse gear needle bearing (Fig. 229).

(5) Remove 5/R synchro snap ring (Fig. 230).

Fig. 228 Bearing and Reverse Gear Removal

1 - ARBOR PRESS RAM

2 - ADAPTER 8486-4

3 - SEALED ROLLER BEARING

4 - REVERSE GEAR

5 - BEARING SPLITTER P-334

Fig. 229 Reverse Gear Needle Bearing

1 - NEEDLE BEARING

Fig. 230 5/R Synchro Snap Ring

1 - SNAP RING

21 - 388 T850 MANUAL TRANSAXLERS

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1946 of 2399

(6) Remove 5/R synchro (Fig. 231).

(7) Remove 5th gear blocker ring (Fig. 232).(8) Remove 5th gear (Fig. 233).

(9) Remove 3/4 cluster gear snap ring (Fig. 234).

Fig. 231 5/R Synchronizer

1 - 5/R SYNCHRO ASSEMBLY

Fig. 232 5th Gear Blocker Ring

1 - 5th GEAR BLOCKER RING

Fig. 233 5th Gear

1 - 5th GEAR

Fig. 234 3/4 Cluster Gear Snap Ring

1 - SNAP RING

RST850 MANUAL TRANSAXLE21 - 389

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1947 of 2399

(10) Install shaft assembly into fixture 8483, with

split collar 8483-3 oriented chamfer side up (Fig.

235). Place 8483-2 into position with chamfer side up

(Fig. 236).

(11) Using an arbor press, press intermediate shaft

out of 3/4 cluster gear (Fig. 237).

(12) Remove intermediate shaft from fixture and

remove 3/4 cluster gear from shaft (Fig. 238).

Fig. 235 Fixture 8483

1 - FIXTURE 8483

2 - COLLAR 8483-3

Fig. 236 Loading Intermediate Shaft

1 - FIXTURE 8483

1 - 3/4 CLUSTER GEAR

2 - COLLAR 8483-2

Fig. 237 Press Intermediate Shaft Out of 3/4 Cluster

Gear

1 - ARBOR PRESS RAM

2 - INTERMEDIATE SHAFT

3 - 3/4 CLUSTER GEAR

4 - FIXTURE 8483

Fig. 238 3/4 Cluster Gear

1 - 3/4 CLUSTER GEAR

2 - INTERMEDIATE SHAFT

21 - 390 T850 MANUAL TRANSAXLERS

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1948 of 2399

(13) Remove 2nd gear from shaft (Fig. 239).

(14) Remove 2nd gear reactor ring (Fig. 240).(15) Remove 2nd gear friction cone (Fig. 241).

(16) Remove 2nd Gear outer blocker ring (Fig.

242).

Fig. 239 2nd Gear Removal

1 - 2ND GEAR

2 - INTERMEDIATE SHAFT

Fig. 240 2nd Gear Reactor Ring

1 - 2ND GEAR REACTOR RING

Fig. 241 2nd Gear Friction Cone

1 - 2ND GEAR FRICTION CONE

Fig. 242 2nd Gear Outer Blocker Ring

1 - 2ND GEAR BLOCKER RING

RST850 MANUAL TRANSAXLE21 - 391

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1949 of 2399

(17) Remove 1/2 synchro snap ring (Fig. 243).

(18) Remove 1/2 synchro from shaft (Fig. 244).(19) Remove 1st gear blocker ring (Fig. 245).

(20) Remove 1st gear friction cone (Fig. 246).

Fig. 243 1/2 Synchro Snap Ring

1 - SNAP RING

2 - 1/2 SYNCHRO HUB

Fig. 244 1/2 Synchronizer

1 - 1/2 SYNCHRONIZER

Fig. 245 1st Gear Blocker Ring

1 - 1ST GEAR BLOCKER RING

Fig. 246 1st Gear Friction Cone

1 - 1ST GEAR FRICTION CONE

21 - 392 T850 MANUAL TRANSAXLERS

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1950 of 2399

(21) Remove 1st gear reactor ring (Fig. 247).

(22) Remove 1st gear from shaft (Fig. 248).(23) Remove 1st gear needle bearing (Fig. 249).

(24) Remove intermediate shaft roller bearing

snap ring (Fig. 250).

Fig. 247 1st Gear Reactor Ring

1 - 1ST GEAR REACTOR RING

Fig. 248 1st Gear Removal

1 - 1ST GEAR

Fig. 249 1st Gear Needle Bearing

1 - 1ST GEAR NEEDLE BEARING

Fig. 250 Intermediate Shaft Roller Bearing Snap

Ring

1 - SNAP RING

RST850 MANUAL TRANSAXLE21 - 393

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Trending: tire size, oil capacities, OBD port, wheel, Jack Location, battery replacement, Engine Systems