battery location CHRYSLER VOYAGER 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 329 of 2399

(9) Disconnect the wire connectors from the back

of the radio.

INSTALLATION

(1) Connect wire harness to back of radio.

(2) Install bolt holding ground strap to the radio (if

equipped).

(3) Connect antenna cable to back of radio.

(4) Position radio into instrument panel.

(5) Install screws holding radio to instrument

panel.

(6) Install center instrument panel trim.

(7) Install trim panel above cupholder.

(8) Install cupholder.

(9) Connect battery negative cable.

RADIO NOISE SUPPRESSION

COMPONENTS

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.

When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radionoise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.

Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

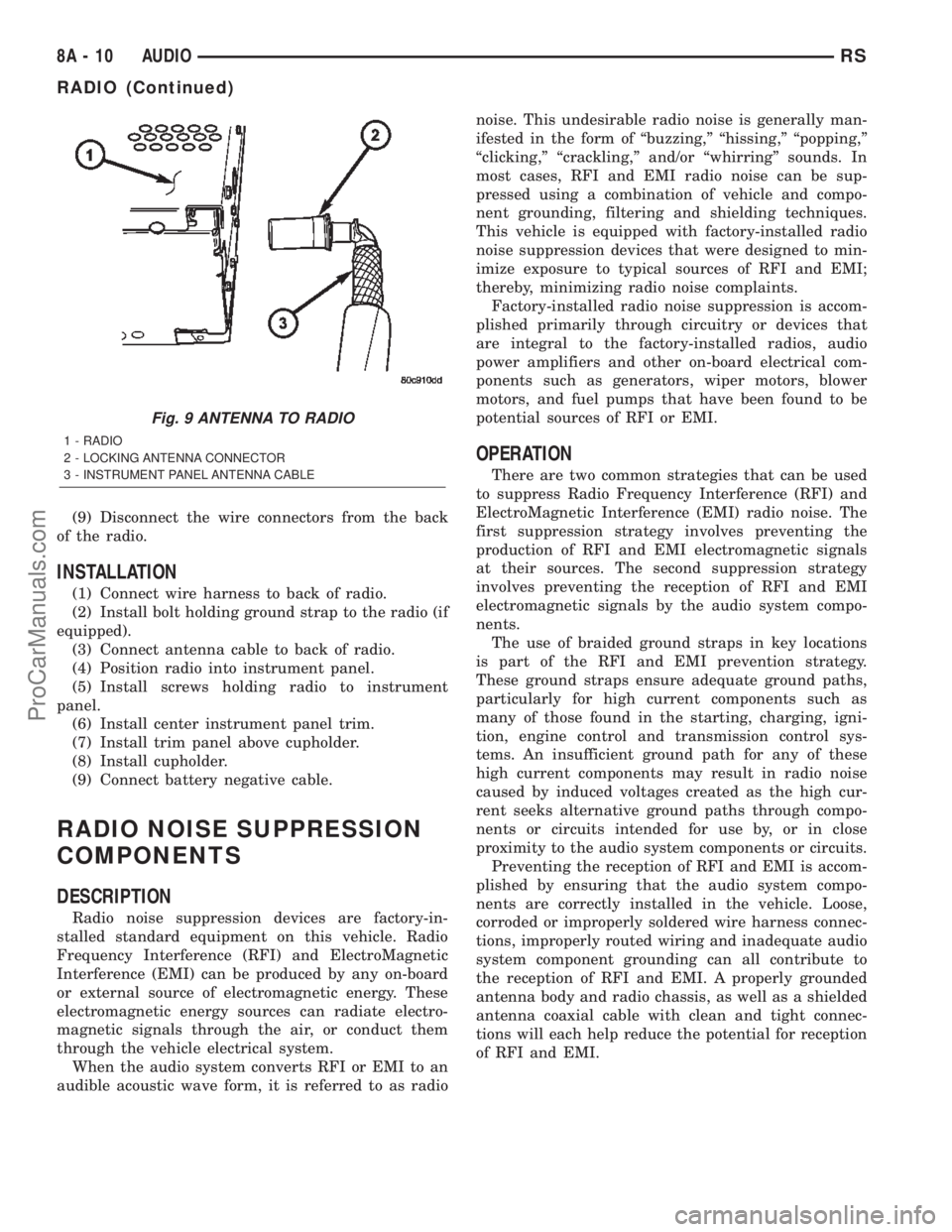

Fig. 9 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

8A - 10 AUDIORS

RADIO (Continued)

ProCarManuals.com

Page 330 of 2399

REMOTE SWITCHES

DESCRIPTION

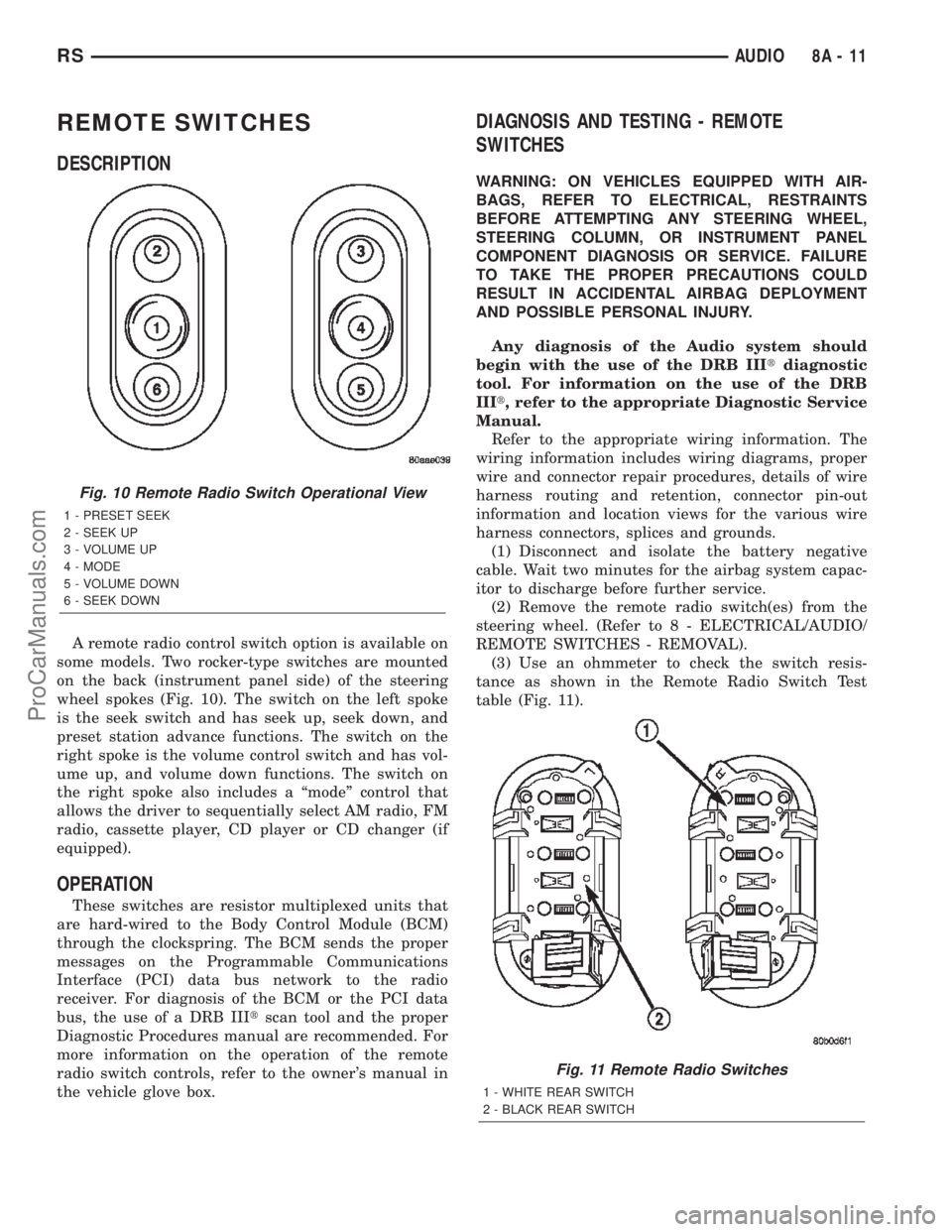

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 10). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended. For

more information on the operation of the remote

radio switch controls, refer to the owner's manual in

the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the airbag system capac-

itor to discharge before further service.

(2) Remove the remote radio switch(es) from the

steering wheel. (Refer to 8 - ELECTRICAL/AUDIO/

REMOTE SWITCHES - REMOVAL).

(3) Use an ohmmeter to check the switch resis-

tance as shown in the Remote Radio Switch Test

table (Fig. 11).

Fig. 10 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

Fig. 11 Remote Radio Switches

1 - WHITE REAR SWITCH

2 - BLACK REAR SWITCH

RSAUDIO8A-11

ProCarManuals.com

Page 332 of 2399

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) If all speakers are inoperative, check the radio

fuses in the junction block. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 3.

(3) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. Remove the radio receiver.

(4) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

(5) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector. Repeat the check between

the speaker return (-) circuit cavities of the radio

receiver wire harness connector and the speaker wire

harness connector. In each case, there should be con-

tinuity. If OK, replace the faulty speaker. If not OK,

repair the open speaker feed (+) and/or return (-) cir-

cuits(s) as required.

REMOVAL

D-PILLAR SPEAKER

(1)Disconnect and isolate the battery negative cable.

(2) Remove rear header trim (right side speaker).

(3) Remove jack cover (left side speaker).

(4) Remove liftgate scuff plate.

(5) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).(6) Partially remove quarter trim panel to access

the D-pillar speaker.

(7) Slide the speaker from the retainer (Fig. 12).

(8) Disconnect the wire harness connector from the

speaker.

FRONT DOOR SPEAKER

(1)Disconnect and isolate the battery negative cable.

(2)Remove the front door trim panel. (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the speaker mounting screws (Fig. 13).

(4) Disconnect wire harness connector and remove

speaker from door.

Fig. 12 D-PILLAR SPEAKER

1 - SPEAKER

2 - RETAINER

3 - TRIM PANEL

Fig. 13 DOOR SPEAKER

1 - SPEAKER

2 - WIRE HARNESS CONNECTOR

RSAUDIO8A-13

SPEAKER (Continued)

ProCarManuals.com

Page 335 of 2399

(a) BCM has two battery feeds at pin 1 and pin

5 of the 6±way connector.

(b) Pin 5 of the (BX2) 32 way connector of the

BCM for ignition feed.

(c) Check voltage (PX2) connector, pin 34 for 12v.

(d) If voltage OK, go to step Step 3

(e) If NO voltage repair as necessary. Refer to

the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

(3) Check driver's seat belt buckle switch input

(form ORC) for a closed circuit when not buckled. If

input not seen, look for open in wiring or switch. The

switch is grounded when belt is not buckled.

(4) Verify PCI data bus communication between

ORC and BCM.

NO FASTEN SEAT BELT LAMP WHEN IGNITION

SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage at the clus-

ter conncctor:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

FASTEN SEAT BELT LAMP OR TONE CONTINUES

FOR MORE THAN 10 SECONDS AFTER SEAT

BELTS ARE FASTENED AND DRIVER'S DOOR IS

CLOSED.

Refer to the proper Body Diagnostic Procedures

manual.

NO TONE WHEN PARK OR HEADLAMPS ARE ON

AND DRIVER'S DOOR IS OPEN.

Make sure ignition is in lock position with the key

removed.

(1) Check the BCM DTC's and BCM sensors to

verify the door is open. Repair as necessary.

(2) Actuate Chime (BCM actuates).

(3) Inspect BCM connectors and wires for proper

connection.

(4) Measure with a voltmeter the voltage (12v) on

BCM connector (PX2) pin 34 with harness connected.

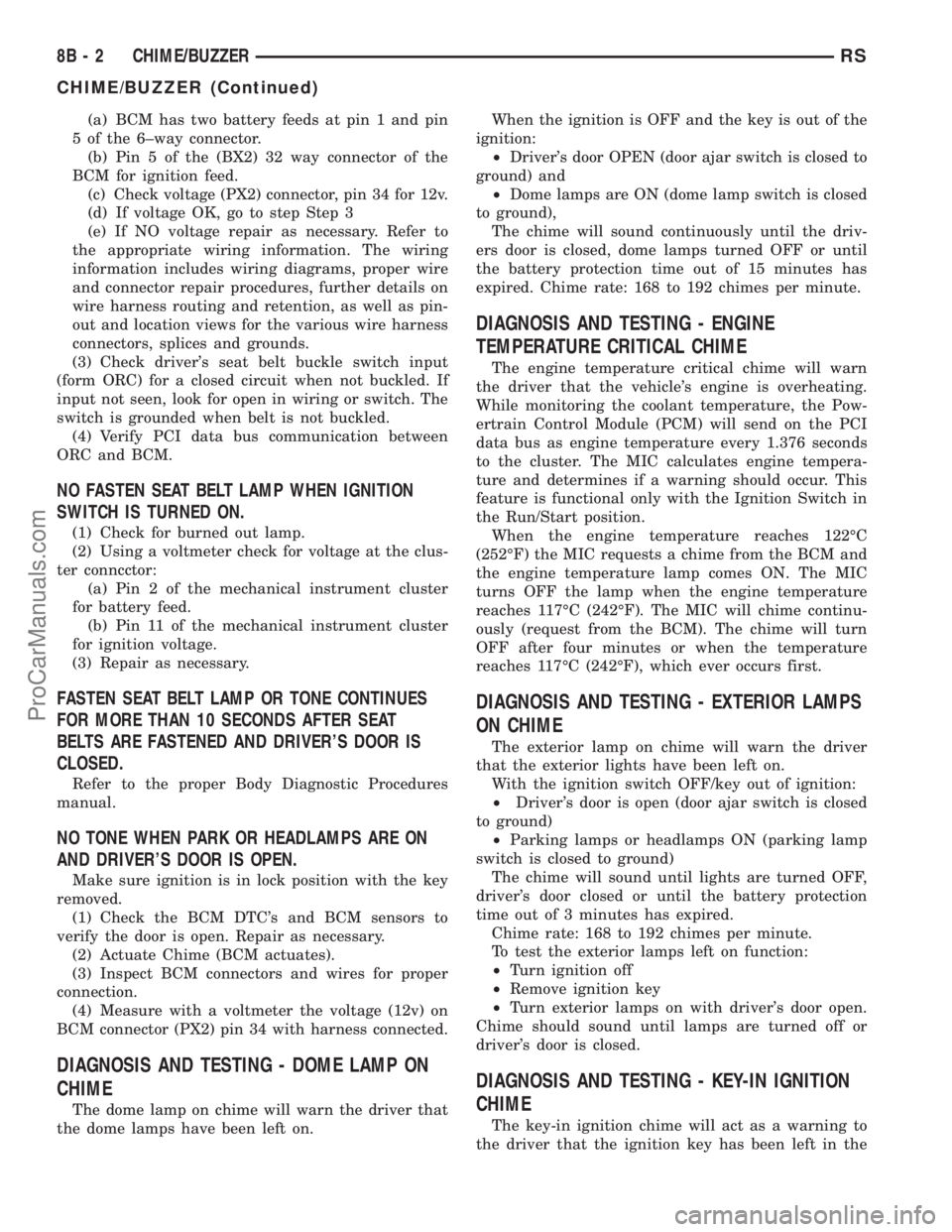

DIAGNOSIS AND TESTING - DOME LAMP ON

CHIME

The dome lamp on chime will warn the driver that

the dome lamps have been left on.When the ignition is OFF and the key is out of the

ignition:

²Driver's door OPEN (door ajar switch is closed to

ground) and

²Dome lamps are ON (dome lamp switch is closed

to ground),

The chime will sound continuously until the driv-

ers door is closed, dome lamps turned OFF or until

the battery protection time out of 15 minutes has

expired. Chime rate: 168 to 192 chimes per minute.

DIAGNOSIS AND TESTING - ENGINE

TEMPERATURE CRITICAL CHIME

The engine temperature critical chime will warn

the driver that the vehicle's engine is overheating.

While monitoring the coolant temperature, the Pow-

ertrain Control Module (PCM) will send on the PCI

data bus as engine temperature every 1.376 seconds

to the cluster. The MIC calculates engine tempera-

ture and determines if a warning should occur. This

feature is functional only with the Ignition Switch in

the Run/Start position.

When the engine temperature reaches 122ÉC

(252ÉF) the MIC requests a chime from the BCM and

the engine temperature lamp comes ON. The MIC

turns OFF the lamp when the engine temperature

reaches 117ÉC (242ÉF). The MIC will chime continu-

ously (request from the BCM). The chime will turn

OFF after four minutes or when the temperature

reaches 117ÉC (242ÉF), which ever occurs first.

DIAGNOSIS AND TESTING - EXTERIOR LAMPS

ON CHIME

The exterior lamp on chime will warn the driver

that the exterior lights have been left on.

With the ignition switch OFF/key out of ignition:

²Driver's door is open (door ajar switch is closed

to ground)

²Parking lamps or headlamps ON (parking lamp

switch is closed to ground)

The chime will sound until lights are turned OFF,

driver's door closed or until the battery protection

time out of 3 minutes has expired.

Chime rate: 168 to 192 chimes per minute.

To test the exterior lamps left on function:

²Turn ignition off

²Remove ignition key

²Turn exterior lamps on with driver's door open.

Chime should sound until lamps are turned off or

driver's door is closed.

DIAGNOSIS AND TESTING - KEY-IN IGNITION

CHIME

The key-in ignition chime will act as a warning to

the driver that the ignition key has been left in the

8B - 2 CHIME/BUZZERRS

CHIME/BUZZER (Continued)

ProCarManuals.com

Page 346 of 2399

(4) Install the battery in the vehicle. Refer to the

procedure in Battery Systems.

(5) Connect the positive and negative battery

cables.

(6) Using the DRB IIIt, under ªFRONT CON-

TROL MODULEº then ªMISCº program the EQ

curve of the radio into the Front Control Module.

Refer to the appropriate diagnostic manual.

NOTE: If the vehicle is not equipped with Name

Brand Speakers (Infinity, etc.) or Headlamp Washers

the DRB IIITmust be used to Disable the appropri-

ate relays in the Intelligent Power Module Assembly.

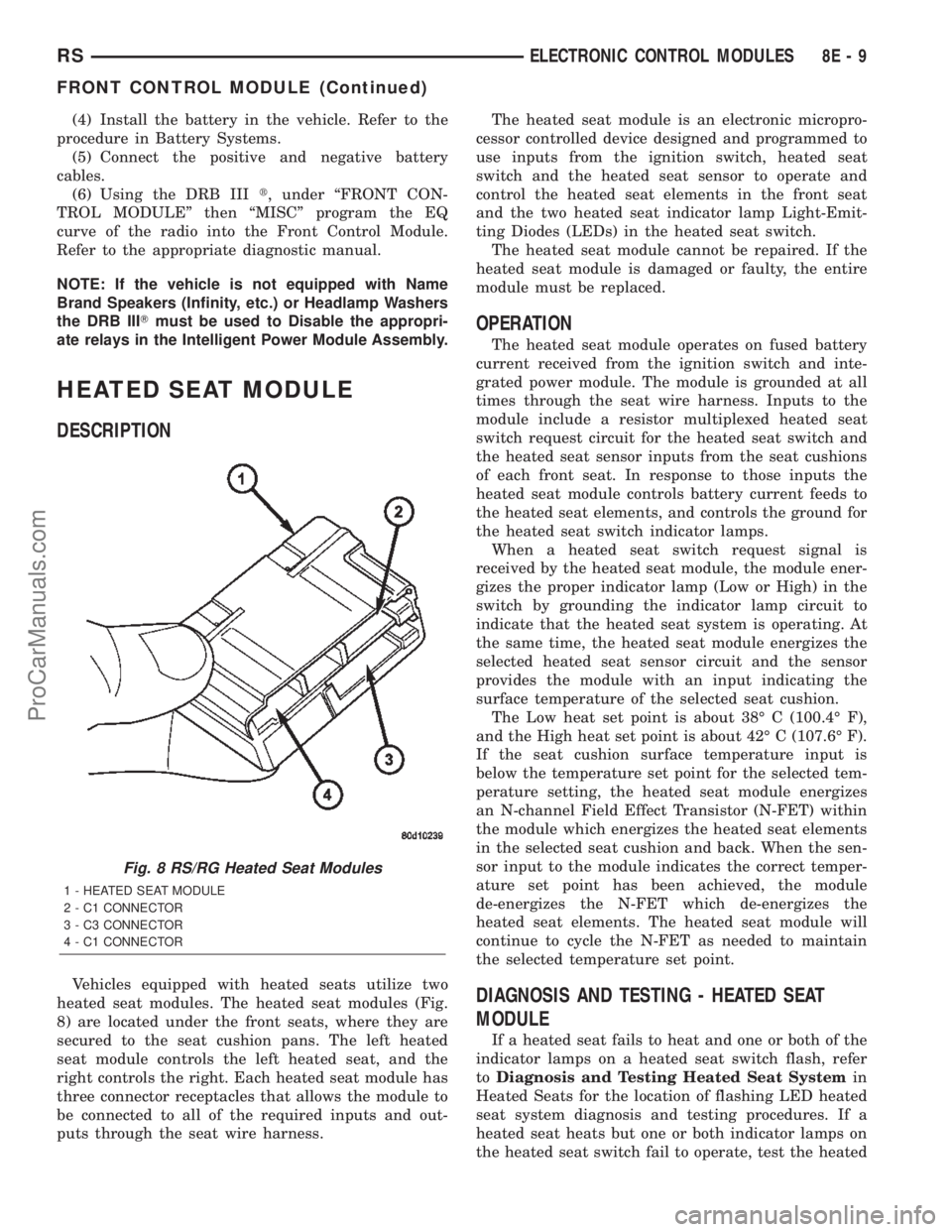

HEATED SEAT MODULE

DESCRIPTION

Vehicles equipped with heated seats utilize two

heated seat modules. The heated seat modules (Fig.

8) are located under the front seats, where they are

secured to the seat cushion pans. The left heated

seat module controls the left heated seat, and the

right controls the right. Each heated seat module has

three connector receptacles that allows the module to

be connected to all of the required inputs and out-

puts through the seat wire harness.The heated seat module is an electronic micropro-

cessor controlled device designed and programmed to

use inputs from the ignition switch, heated seat

switch and the heated seat sensor to operate and

control the heated seat elements in the front seat

and the two heated seat indicator lamp Light-Emit-

ting Diodes (LEDs) in the heated seat switch.

The heated seat module cannot be repaired. If the

heated seat module is damaged or faulty, the entire

module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from the ignition switch and inte-

grated power module. The module is grounded at all

times through the seat wire harness. Inputs to the

module include a resistor multiplexed heated seat

switch request circuit for the heated seat switch and

the heated seat sensor inputs from the seat cushions

of each front seat. In response to those inputs the

heated seat module controls battery current feeds to

the heated seat elements, and controls the ground for

the heated seat switch indicator lamps.

When a heated seat switch request signal is

received by the heated seat module, the module ener-

gizes the proper indicator lamp (Low or High) in the

switch by grounding the indicator lamp circuit to

indicate that the heated seat system is operating. At

the same time, the heated seat module energizes the

selected heated seat sensor circuit and the sensor

provides the module with an input indicating the

surface temperature of the selected seat cushion.

The Low heat set point is about 38É C (100.4É F),

and the High heat set point is about 42É C (107.6É F).

If the seat cushion surface temperature input is

below the temperature set point for the selected tem-

perature setting, the heated seat module energizes

an N-channel Field Effect Transistor (N-FET) within

the module which energizes the heated seat elements

in the selected seat cushion and back. When the sen-

sor input to the module indicates the correct temper-

ature set point has been achieved, the module

de-energizes the N-FET which de-energizes the

heated seat elements. The heated seat module will

continue to cycle the N-FET as needed to maintain

the selected temperature set point.

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE

If a heated seat fails to heat and one or both of the

indicator lamps on a heated seat switch flash, refer

toDiagnosis and Testing Heated Seat Systemin

Heated Seats for the location of flashing LED heated

seat system diagnosis and testing procedures. If a

heated seat heats but one or both indicator lamps on

the heated seat switch fail to operate, test the heated

Fig. 8 RS/RG Heated Seat Modules

1 - HEATED SEAT MODULE

2 - C1 CONNECTOR

3 - C3 CONNECTOR

4 - C1 CONNECTOR

RSELECTRONIC CONTROL MODULES8E-9

FRONT CONTROL MODULE (Continued)

ProCarManuals.com

Page 347 of 2399

seat switch. Refer toDiagnosis and Testing

Heated Seat Switchin Heated Seats for heated

seat switch diagnosis and testing procedures. If the

heated seat switch checks OK, proceed as follows.

(1) Check the heated seat element (Refer to 8 -

ELECTRICAL/HEATED SEATS/HEATED SEAT

ELEMENT - DIAGNOSIS AND TESTING).

(2) Check the heated seat sensor (Refer to 8 -

ELECTRICAL/HEATED SEATS/HEATED SEAT

SENSOR - DIAGNOSIS AND TESTING).

(3) Check the heated seat switch (Refer to 8 -

ELECTRICAL/HEATED SEATS/DRIVER HEATED

SEAT SWITCH - DIAGNOSIS AND TESTING).

NOTE: Refer to Wiring for the location of complete

heated seat system wiring diagrams and connector

pin-out information.

(4) Using a voltmeter, backprobe the appropriate

heated seat module connector, do not disconnect.

Check for voltage at the appropriate pin cavities. 12v

should be present. If OK go to Step 5, if Not, Repair

the open or shorted voltage supply circuit as

required.

(5) Using a ohmmeter, backprobe the appropriate

heated seat module connector, do not disconnect.

Check for proper continuity to ground on the ground

pin cavities. Continuity should be present. If OK

replace the heated seat module with a known good

unit and retest system, if Not OK, Repair the open or

shorted ground circuit as required.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate front seat from the

vehicle (Refer to 23 - BODY/SEATS/SEAT - REMOV-

AL).

(3) Unsnap the module from the seat cushion pan.

(4) Disconnect the module wire harness connec-

tors.

INSTALLATION

(1) Connect the module wire harness connectors.

(2) Snap the module on the seat cushion pan.

(3) Install the appropriate front seat in the vehicle

(Refer to 23 - BODY/SEATS/SEAT - INSTALLA-

TION).

(4) Connect and isolate the negative battery cable.

POWER LIFTGATE MODULE

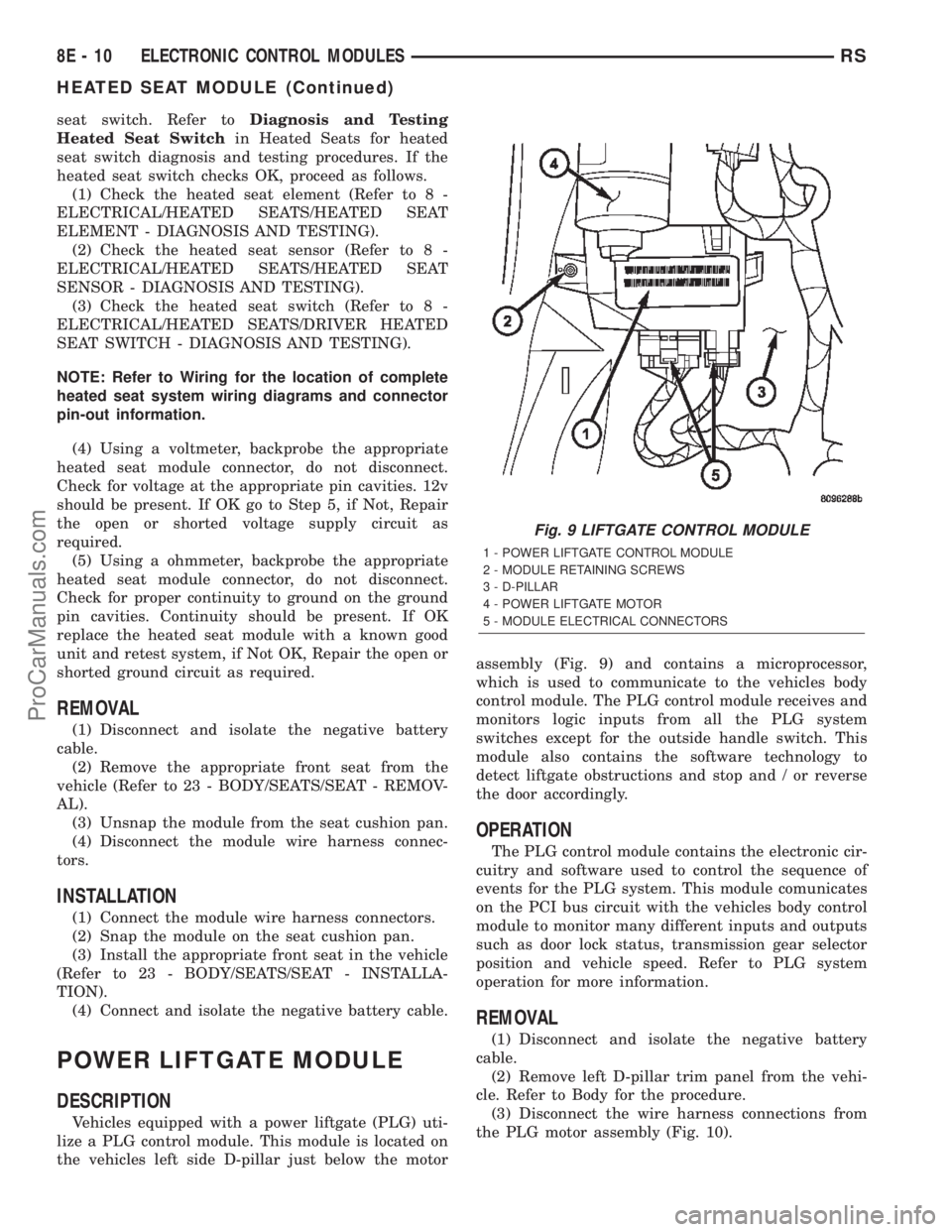

DESCRIPTION

Vehicles equipped with a power liftgate (PLG) uti-

lize a PLG control module. This module is located on

the vehicles left side D-pillar just below the motorassembly (Fig. 9) and contains a microprocessor,

which is used to communicate to the vehicles body

control module. The PLG control module receives and

monitors logic inputs from all the PLG system

switches except for the outside handle switch. This

module also contains the software technology to

detect liftgate obstructions and stop and / or reverse

the door accordingly.

OPERATION

The PLG control module contains the electronic cir-

cuitry and software used to control the sequence of

events for the PLG system. This module comunicates

on the PCI bus circuit with the vehicles body control

module to monitor many different inputs and outputs

such as door lock status, transmission gear selector

position and vehicle speed. Refer to PLG system

operation for more information.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove left D-pillar trim panel from the vehi-

cle. Refer to Body for the procedure.

(3) Disconnect the wire harness connections from

the PLG motor assembly (Fig. 10).

Fig. 9 LIFTGATE CONTROL MODULE

1 - POWER LIFTGATE CONTROL MODULE

2 - MODULE RETAINING SCREWS

3 - D-PILLAR

4 - POWER LIFTGATE MOTOR

5 - MODULE ELECTRICAL CONNECTORS

8E - 10 ELECTRONIC CONTROL MODULESRS

HEATED SEAT MODULE (Continued)

ProCarManuals.com

Page 361 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed control

servo power control circuit. (SBECII: ext relay).

P1684 Battery Loss In The Last 50 Starts The battery has been disconnected within the last 50 starts.

P1685 Skim Invalid Key The engine controller has received an invalid key from the

SKIM.

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

P1687 No MIC BUS Message No CCD/J1850 messages received from the Mechanical

Instrument Cluster (MIC) module.

P1693 DTC Detected in Companion Module A fault has been generated in the companion engine control

module.

P1694 Fault In Companion Module No CCD/J1850 messages received from the powertrain

control module-Aisin transmission.

P1695 No CCD/J1850 Message From Body

Control ModuleNo CCD/J1850 messages received from the body control

module.

P1696 (M) PCM Failure EEPROM Write Denied Unsuccessful attempt to write to an EEPROM location by the

control module.

P1697 (M) PCM Failure SRI Mile Not Stored Unsuccessful attempt to update Service Reminder Indicator

(SRI or EMR) mileage in the control module EEPROM.

P1698 (M) No CCD/J1850 Message From TCM No CCD/J1850 messages received from the electronic

transmission control module (EATX) or the Aisin transmission

controller.

P1719 Skip Shift Solenoid Circuit An open or shorted condition detected in the transmission

2-3 gear lock-out solenoid control circuit.

P1740 TCC or O/D Solenoid Performance Rationality error detected in either the torque convertor

clutch or solenoid or overdrive solenoid system.

P1756 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear. (Mid Pressure Malfunction)

P1757 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear (Zero Pressure Malfunction)

P1762 Gov Press Sen Offset Volts Too Low

or HighThe Governor Pressure Sensor input is greater than a

calibration limit or is less than a calibration limit for 3

consecutive park/neutral calibrations.

P1763 Governor Pressure Sensor Volts Too

HiThe Governor Pressure Sensor input is above an acceptable

voltage level.

P1764 Governor Pressure Sensor Volts Too

LowThe Governor Pressure Sensor input is below an acceptable

voltage level.

P1765 Trans 12 Volt Supply Relay CTRL

CircuitAn open or shorted condition is detected in the Transmission

Relay control circuit. This relay supplies power to the TCC

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch.

8E - 24 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 365 of 2399

TRANSMISSION CONTROL

MODULE

DESCRIPTION

The Transmission Control Module (TCM) is located

behind the left fender and is fastened with three

screws to three clips in the left frame rail forward of

the suspension (Fig. 14).

OPERATION

The TCM is the controlling unit for all electronic

operations of the transaxle. The TCM receives infor-

mation regarding vehicle operation from both direct

and indirect inputs, and selects the operational mode

of the transaxle. Direct inputs are hardwired to, and

used specifically by the TCM. Indirect inputs origi-

nate from other components/modules, and are shared

with the TCM via the J1850 communication bus.Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor (CKP)

²Transmission Range Sensor (TRS)

²Pressure Switches (L/R, 2/4, OD)

²Transmission Temperature Sensor (Integral to

TRS)

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

Some examples ofindirect inputsto the TCM are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Speed Control ON/OFF Switch

²Engine Coolant Temperature

²Ambient/Battery Temperature

²Brake Switch Status

²DRB Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids (LR/CC, 2/4, OD and UD)

²Vehicle Speed (to PCM)

²Torque Reduction Request (to PCM)

An example of a TCMindirect outputis:

²Transmission Temperature (to PCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indices

(CVI)

²

Storing and selecting appropriate Shift Schedules

²System self-diagnostics

²Diagnostic capabilities (with DRB scan tool)

Fig. 14 Transmission Control Module (TCM)

Location

1 - TRANSMISSION CONTROL MODULE (TCM)

8E - 28 ELECTRONIC CONTROL MODULESRS

ProCarManuals.com

Page 368 of 2399

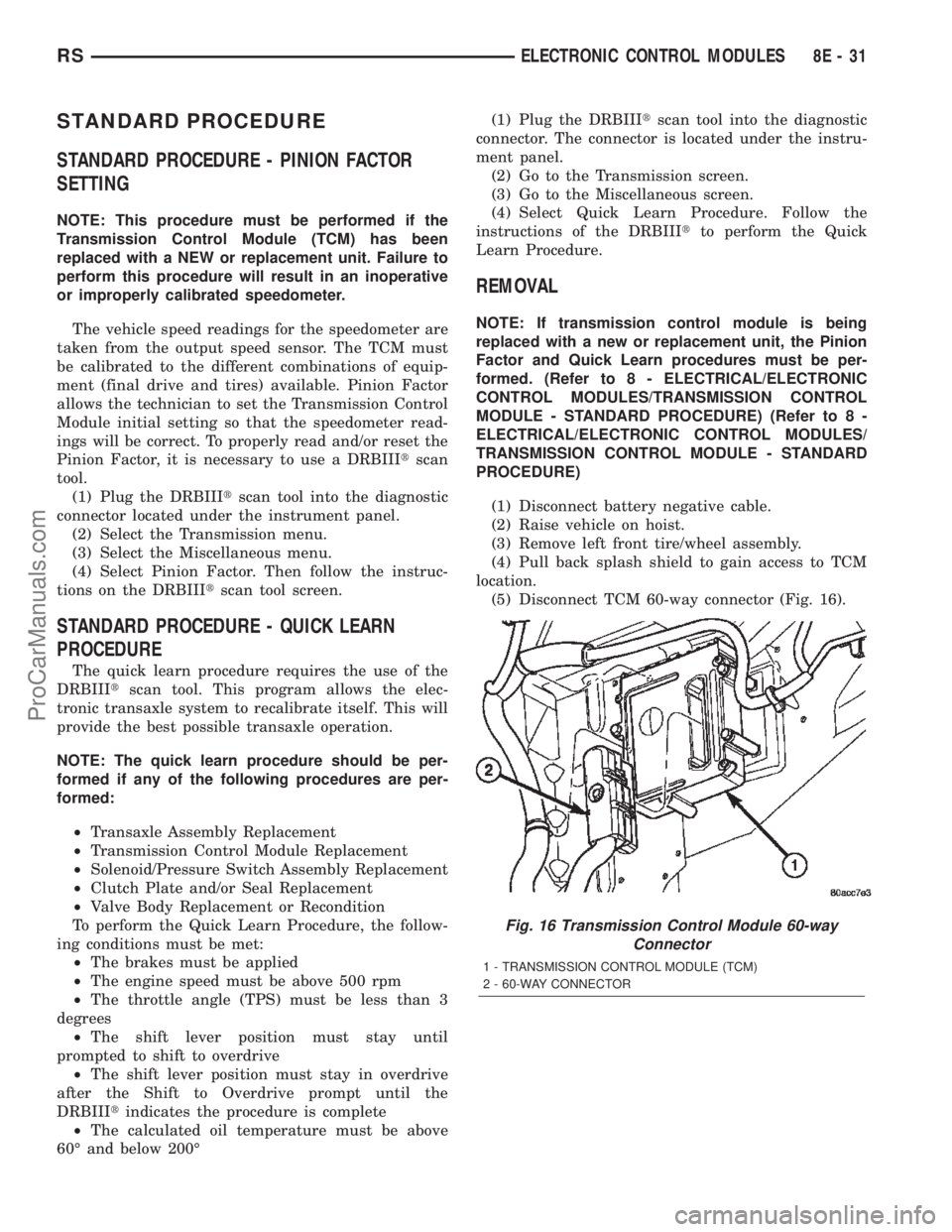

STANDARD PROCEDURE

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

Transmission Control Module (TCM) has been

replaced with a NEW or replacement unit. Failure to

perform this procedure will result in an inoperative

or improperly calibrated speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The TCM must

be calibrated to the different combinations of equip-

ment (final drive and tires) available. Pinion Factor

allows the technician to set the Transmission Control

Module initial setting so that the speedometer read-

ings will be correct. To properly read and/or reset the

Pinion Factor, it is necessary to use a DRBIIItscan

tool.

(1) Plug the DRBIIItscan tool into the diagnostic

connector located under the instrument panel.

(2) Select the Transmission menu.

(3) Select the Miscellaneous menu.

(4) Select Pinion Factor. Then follow the instruc-

tions on the DRBIIItscan tool screen.

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE

The quick learn procedure requires the use of the

DRBIIItscan tool. This program allows the elec-

tronic transaxle system to recalibrate itself. This will

provide the best possible transaxle operation.

NOTE: The quick learn procedure should be per-

formed if any of the following procedures are per-

formed:

²Transaxle Assembly Replacement

²Transmission Control Module Replacement

²Solenoid/Pressure Switch Assembly Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the

DRBIIItindicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É(1) Plug the DRBIIItscan tool into the diagnostic

connector. The connector is located under the instru-

ment panel.

(2) Go to the Transmission screen.

(3) Go to the Miscellaneous screen.

(4) Select Quick Learn Procedure. Follow the

instructions of the DRBIIItto perform the Quick

Learn Procedure.

REMOVAL

NOTE: If transmission control module is being

replaced with a new or replacement unit, the Pinion

Factor and Quick Learn procedures must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE) (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE)

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Remove left front tire/wheel assembly.

(4) Pull back splash shield to gain access to TCM

location.

(5) Disconnect TCM 60-way connector (Fig. 16).

Fig. 16 Transmission Control Module 60-way

Connector

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60-WAY CONNECTOR

RSELECTRONIC CONTROL MODULES8E-31

ProCarManuals.com

Page 372 of 2399

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ENGINE CONTROL MODULE

DESCRIPTION..........................1

OPERATION............................1

STANDARD PROCEDURE - PCM/ECM/SKIM

PROGRAMMING - DIESEL...............2REMOVAL.............................4

INSTALLATION..........................4

ENGINE CONTROL MODULE

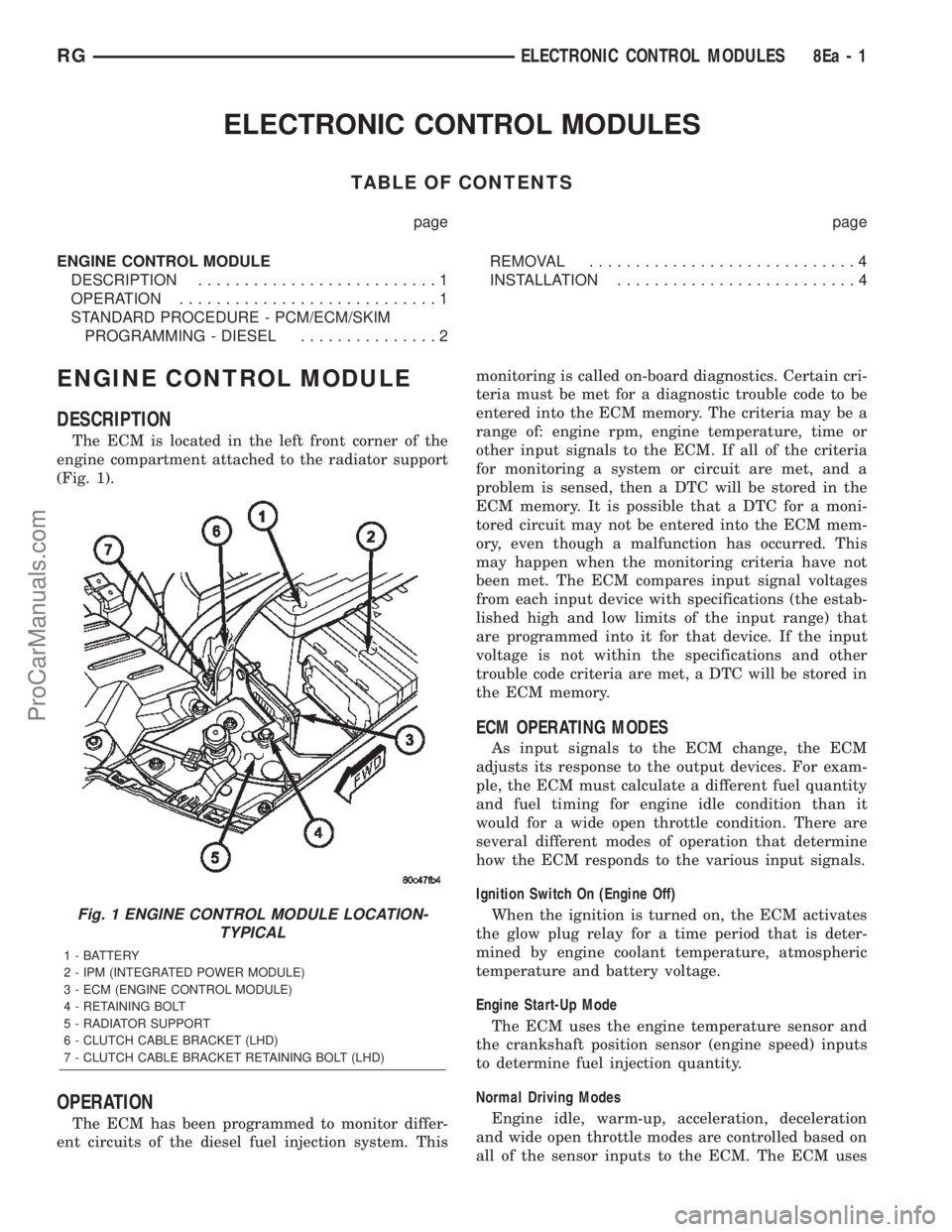

DESCRIPTION

The ECM is located in the left front corner of the

engine compartment attached to the radiator support

(Fig. 1).

OPERATION

The ECM has been programmed to monitor differ-

ent circuits of the diesel fuel injection system. Thismonitoring is called on-board diagnostics. Certain cri-

teria must be met for a diagnostic trouble code to be

entered into the ECM memory. The criteria may be a

range of: engine rpm, engine temperature, time or

other input signals to the ECM. If all of the criteria

for monitoring a system or circuit are met, and a

problem is sensed, then a DTC will be stored in the

ECM memory. It is possible that a DTC for a moni-

tored circuit may not be entered into the ECM mem-

ory, even though a malfunction has occurred. This

may happen when the monitoring criteria have not

been met. The ECM compares input signal voltages

from each input device with specifications (the estab-

lished high and low limits of the input range) that

are programmed into it for that device. If the input

voltage is not within the specifications and other

trouble code criteria are met, a DTC will be stored in

the ECM memory.

ECM OPERATING MODES

As input signals to the ECM change, the ECM

adjusts its response to the output devices. For exam-

ple, the ECM must calculate a different fuel quantity

and fuel timing for engine idle condition than it

would for a wide open throttle condition. There are

several different modes of operation that determine

how the ECM responds to the various input signals.

Ignition Switch On (Engine Off)

When the ignition is turned on, the ECM activates

the glow plug relay for a time period that is deter-

mined by engine coolant temperature, atmospheric

temperature and battery voltage.

Engine Start-Up Mode

The ECM uses the engine temperature sensor and

the crankshaft position sensor (engine speed) inputs

to determine fuel injection quantity.

Normal Driving Modes

Engine idle, warm-up, acceleration, deceleration

and wide open throttle modes are controlled based on

all of the sensor inputs to the ECM. The ECM uses

Fig. 1 ENGINE CONTROL MODULE LOCATION-

TYPICAL

1 - BATTERY

2 - IPM (INTEGRATED POWER MODULE)

3 - ECM (ENGINE CONTROL MODULE)

4 - RETAINING BOLT

5 - RADIATOR SUPPORT

6 - CLUTCH CABLE BRACKET (LHD)

7 - CLUTCH CABLE BRACKET RETAINING BOLT (LHD)

RGELECTRONIC CONTROL MODULES8Ea-1

ProCarManuals.com