door lock CHRYSLER VOYAGER 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 542 of 2399

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM.................. 1

POWER SLIDING DOOR SYSTEM............ 18

POWER LOCKS........................... 39POWER MIRRORS........................ 46

POWER SEAT SYSTEM..................... 51

POWER WINDOWS........................ 64

POWER LIFTGATE SYSTEM

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM

DESCRIPTION..........................2

OPERATION............................3

DIAGNOSIS AND TESTING - POWER

LIFTGATE SYSTEM.....................4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIFTGATE

ADJUSTMENT.........................8

STANDARD PROCEDURE - POWER

LIFTGATE LEARN CYCLE................9

PINCH SENSOR

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION..........................9

FULL OPEN SWITCH

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................10

LIFTGATE MOTOR

DESCRIPTION.........................10

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

ENGAGE ACTUATOR

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................12

INSTALLATION.........................12TRANSVERSE BRACKET

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................13

INSTALLATION.........................13

LIFT GEAR & LINK ROD

DESCRIPTION.........................13

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

LATCH

DESCRIPTION.........................14

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................15

LATCH ACTUATOR

DESCRIPTION.........................15

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................16

EXTERIOR HANDLE SWITCH

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

CHIME/THERMISTOR

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

RSPOWER SYSTEMS8N-1

ProCarManuals.com

Page 556 of 2399

OPERATION

On the power cinch/release latch, the latch

mounted actuator provides the torque required to

close the power liftgate from the secondary to the pri-

mary closed and latched position. On the power

cinch/release latch and the power release only latch,

the actuator releases the liftgate from the primary

closed and latched position to the fully unlatched and

movable position.

REMOVAL

(1) Open the hood, disconnect and isolate the neg-

ative battery cable.

(2) Open the liftgate and remove the liftgate trim

panel. Refer to Body for the procedure.

(3) Disconnect the power latch electrical connector

(Fig. 12).

(4) Remove the power latch retaining bolts.

(5) Disconnect the liftgate lock cylinder link rod

from the key cylinder or latch assembly. To discon-

nect from latch, rotate the plastic retaining clip 90 É

to unsnap clip from linkrod. Then pull link rod

straight out of latch arm.

INSTALLATION

(1) Connect the liftgate lock cylinder link rod on

the cinch latch assembly. Rotate the plastic retaining

clip 90 É to lock retaining clip on linkrod.

(2) Connect the link rod on the lock cylinder.

(3) Install the power latch retaining bolts. Torque

to 10 N´m (90 in. lbs.).

(4) Connect the power latch electrical connector

and secure push pin retainers.

(5) Connect the negative battery cable.

(6) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the power latch.

(7) Verify power liftgate system and power cinch /

release latch operation. Cycle the power liftgate

through one complete open and close cycle, this will

allow the power liftgate control module to relearn its

cycle with the new components.

(8) Verify power liftgate manual operation. Using

liftgate key rotate the lock cylinder to verify door

operation. Pull door open using exterior liftgate han-

dle / switch.

(9) Install the liftgate trim panel. Refer to Body for

the procedure.

LATCH ACTUATOR

DESCRIPTION

Vehicles equipped with a power liftgate utilize a

power cinch latch or power release latch (Fig. 13).

The power cinch and/or power release is made possi-ble by a latch actuator attached to the leading edge

of the power latch assembly. This 12 volt latch actua-

tor contains a small drive gear that meshes with the

latch assemblies internal gears to perform the power

cinch close / power release operations. Refer to the

Latch assembly for more information.

The power cinch/release actuator is serviceable

component. Consult your MoparŸ parts catalog for

specific part numbers.

OPERATION

During a power close cycle, the power cinch actua-

tor provides the torque required to close the power

liftgate from the secondary to the primary closed and

latched position. During a power open cycle, the

power release actuator releases the liftgate from the

primary closed and latched position to the fully

unlatched and movable position.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Open the liftgate and remove the lower liftgate

trim panel. Refer to Body for the procedure.

(3) Disconnect the power latch electrical connector

(Fig. 13).

(4) Remove the three latch retaining bolts.

Fig. 13 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

RSPOWER LIFTGATE SYSTEM8N-15

LATCH (Continued)

ProCarManuals.com

Page 559 of 2399

POWER SLIDING DOOR SYSTEM

TABLE OF CONTENTS

page page

POWER SLIDING DOOR SYSTEM

DESCRIPTION.........................18

OPERATION...........................20

DIAGNOSIS AND TESTING - POWER SLIDING

DOOR SYSTEM.......................21

STANDARD PROCEDURE

STANDARD PROCEDURE - WELLNUT

REPLACEMENT.......................27

STANDARD PROCEDURE - POWER DOOR

LEARN CYCLE.......................27

STANDARD PROCEDURE - SLIDING DOOR

ADJUSTMENT........................27

LATCH

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................29

SLIDING DOOR MOTOR

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................30

FULL OPEN SWITCH

DESCRIPTION.........................30

OPERATION...........................30

LEFT B-PILLAR SWITCH

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................31

INSTALLATION.........................31RIGHT B-PILLAR SWITCH

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................31

INSTALLATION.........................31

LOWER DRIVE UNIT

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................32

INSTALLATION.........................32

LOWER DRIVE UNIT TRACK & RACK

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

WIRING HARNESS

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................35

FLEX DRIVE

DESCRIPTION.........................35

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................36

SLIDING DOOR MODULE

DESCRIPTION.........................37

OPERATION...........................37

REMOVAL.............................38

INSTALLATION.........................38

POWER SLIDING DOOR

SYSTEM

DESCRIPTION

Some vehicles are equipped with a power opening

and closing sliding door system (Fig. 1). Depending

on how the vehicle is ordered it may be equipped

with only a right side power door or right and left

side power doors. This power sliding door system is a

complex system consisting of many components.

Some of these components are the door motor, latch

assembly, sliding door control module, lower drive

unit, flex drive assembly, wire harness and track,

lower drive unit track and rack assembly, full open

switch, B-pillar switch, overhead console switch, key

fob switches (Fig. 2), pawl switch, ratchet switch and

child lockout and handle switches.Each power side door has its own door control mod-

ule, located in the center of the door behind the door

trim panel. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/DOOR CONTROL

MODULE - DESCRIPTION) The power side door

motor is located in the front portion of the door, on

the inner door panel sheet metal. The latch assembly

is located in the rear of the power side door, near the

body line. The lower drive unit is attached to the

lower door hinge. The flex drive assembly connects

the door motor to the lower drive unit. The wire har-

ness and track and the lower drive unit track are vis-

ible with the door open in the lower door sill area.

The power side door full open switch is located under

the lower drive unit and is part of the hold open

latch assembly. The pawl, ratchet, handle and child

lockout switches are all located on the power side

door latch assembly. The B-pillar switch, as it will be

8N - 18 POWER SLIDING DOOR SYSTEMRS

ProCarManuals.com

Page 560 of 2399

referred to, is an open and close command switch

located on the vehicles interior body side B-pillar

trim. The overhead console switch, is an open and

close command switch located in the vehicle's over-

head console. More detailed information can be found

on these components later in this section.

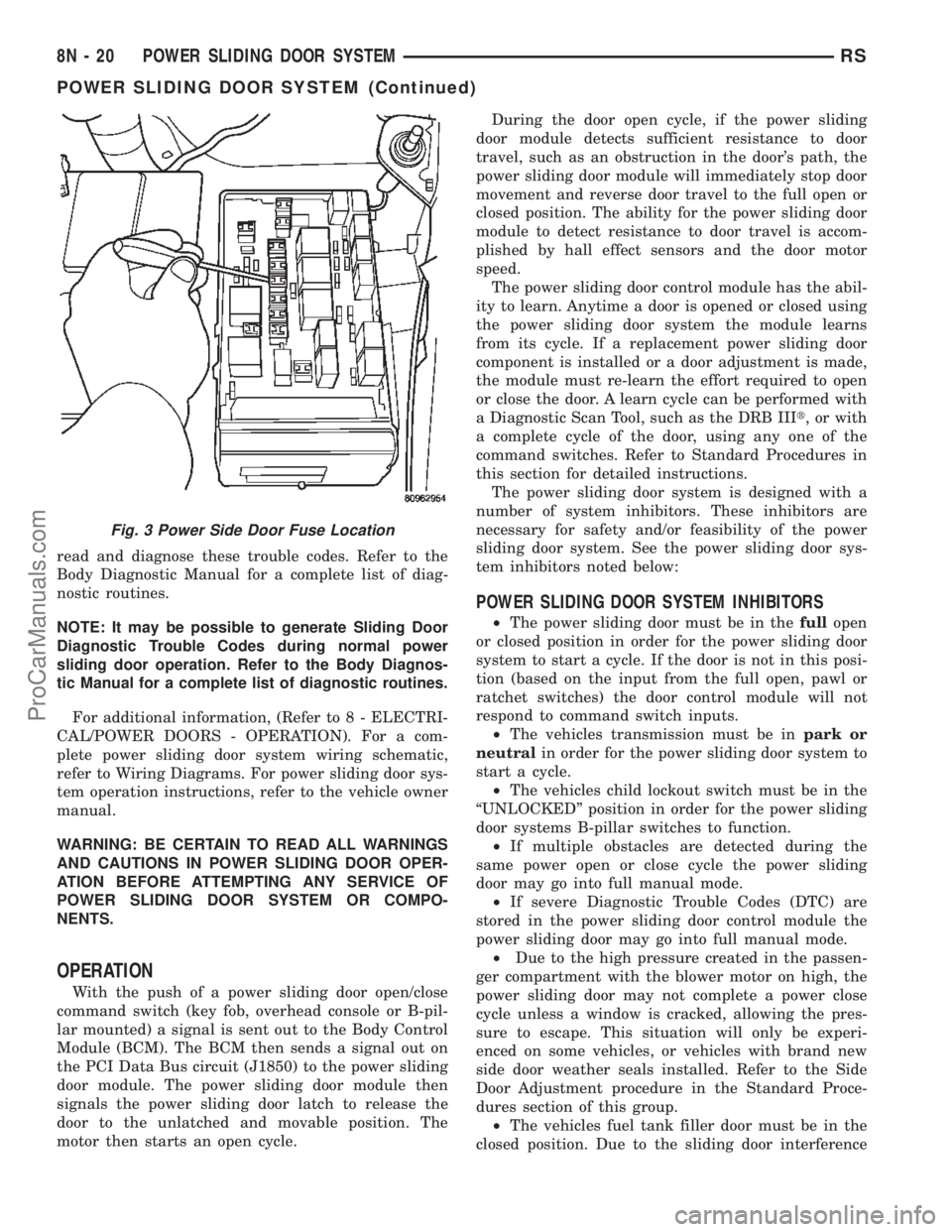

Safety is of the utmost concern with the power

sliding door system. Software technology has enabled

the power sliding door control module to detect resis-

tance to door travel. This allows the power sliding

door to stop and reverse direction any time an

obstruction is felt or any of the command switches

are operated (while closing only). Battery voltage is

supplied to the power sliding door system through a

40 amp fuse, located in the Intelligent Power Module

(IPM) assembly (Fig. 3). The child lockout switch pre-

vents children from opening or actuating the power

sliding door system when desired. In the unlikely

event that the power sliding door system develops a

fault, the power sliding door can still be operated

manually from the interior or exterior door handle,

just like a standard manual sliding door.

The power sliding door control module communi-

cates on the J1850 PCI Data Bus Circuit. Therefore,

the power sliding door control module can generate

and store its own diagnostic trouble codes (DTC). A

diagnostic scan tool, such as the DRB IIItis used to

Fig. 1 Power Sliding Door Introduction

Fig. 2 Key Fob

1 - Left Sliding Door Switch

2 - Right Sliding Door Switch

3 - Liftgate Switch

RSPOWER SLIDING DOOR SYSTEM8N-19

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 561 of 2399

read and diagnose these trouble codes. Refer to the

Body Diagnostic Manual for a complete list of diag-

nostic routines.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). For a com-

plete power sliding door system wiring schematic,

refer to Wiring Diagrams. For power sliding door sys-

tem operation instructions, refer to the vehicle owner

manual.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the PCI Data Bus circuit (J1850) to the power sliding

door module. The power sliding door module then

signals the power sliding door latch to release the

door to the unlatched and movable position. The

motor then starts an open cycle.During the door open cycle, if the power sliding

door module detects sufficient resistance to door

travel, such as an obstruction in the door's path, the

power sliding door module will immediately stop door

movement and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors and the door motor

speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a Diagnostic Scan Tool, such as the DRB IIIt, or with

a complete cycle of the door, using any one of the

command switches. Refer to Standard Procedures in

this section for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. See the power sliding door sys-

tem inhibitors noted below:

POWER SLIDING DOOR SYSTEM INHIBITORS

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The vehicles transmission must be inpark or

neutralin order for the power sliding door system to

start a cycle.

²The vehicles child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

²If multiple obstacles are detected during the

same power open or close cycle the power sliding

door may go into full manual mode.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power sliding door control module the

power sliding door may go into full manual mode.

²Due to the high pressure created in the passen-

ger compartment with the blower motor on high, the

power sliding door may not complete a power close

cycle unless a window is cracked, allowing the pres-

sure to escape. This situation will only be experi-

enced on some vehicles, or vehicles with brand new

side door weather seals installed. Refer to the Side

Door Adjustment procedure in the Standard Proce-

dures section of this group.

²The vehicles fuel tank filler door must be in the

closed position. Due to the sliding door interference

Fig. 3 Power Side Door Fuse Location

8N - 20 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 562 of 2399

with the open fuel tank filler door, mechanical link-

age prevents the side door from opening and striking

the fuel door. Refer to the Body section of this man-

ual for detailed information on the fuel door lockout

feature.

POWER SLIDING DOOR SYSTEM WARNINGS

WARNING: ALWAYS DISCONNECT THE NEGATIVE

BATTERY CABLE BEFORE ATTEMPTING ANY

POWER SLIDING DOOR SYSTEM SERVICE.

WARNING: EXTREME CARE MUST BE TAKEN TO

PREVENT OBJECTS FROM ENTERING THE DOORS

PATH ONCE THE DOOR REACHES THE CINCH

MOTOR CONTACT (APPROXIMATELY 1 INCH

BEFORE FULLY CLOSED).

WARNING: NEVER ATTEMPT TO ENTER OR EXIT

THE VEHICLE WHILE THE POWER SLIDING DOOR

IS IN MOTION. YOU COULD DAMAGE THE POWER

SLIDING DOOR SYSTEM OR COMPONENTS

AND/OR CAUSE PERSONAL INJURY.

WARNING: NEVER ATTEMPT TO DRIVE AWAY WITH

THE POWER SLIDING DOOR IN MOTION. YOU

COULD DAMAGE THE POWER SLIDING DOOR SYS-

TEM OR COMPONENTS AND/OR CAUSE PER-

SONAL INJURY.

WARNING: NEVER PLACE OBJECTS IN THE

POWER SLIDING DOOR WHEN CINCHING CLOSED.

YOU COULD DAMAGE THE VEHICLE, POWER SLID-ING DOOR SYSTEM OR COMPONENTS AND/OR

CAUSE PERSONAL INJURY.

DIAGNOSIS AND TESTING - POWER SLIDING

DOOR SYSTEM

The power opening and closing power sliding door

system is a complex system containing many compo-

nents and modules. In order to obtain conclusive

testing, the Programmable Communications Interface

(J1850) data bus network and all of the electronic

modules that provide inputs to, or receive outputs

from the power sliding door system must be checked.

The power sliding door system was designed to be

diagnosed with an appropriate diagnostic scan tool,

such as the DRB IIIt. The most reliable, efficient,

and accurate means to diagnose the power sliding

door system requires the use of a DRB IIItscan tool

and the proper Body Diagnostic Procedures manual.

The DRB IIItcan be used to observe various switch

statuses throughout the power sliding door system to

help the technician diagnose a defective switch or

component. The DRB IIItcan also be used to actuate

various components throughout the power sliding

door system to help the technician diagnose a defec-

tive component.

Before any testing of the power sliding door system

is attempted, the battery should be fully charged, all

built-in power sliding door system inhibitors read

and understood (Refer to 8 - ELECTRICAL/POWER

DOORS - OPERATION) and all wire harness and

ground connections inspected around the affected

areas on the vehicle.

The following are quick reference diagnostic tables

to help when diagnosing and testing the power slid-

ing door system.

RSPOWER SLIDING DOOR SYSTEM8N-21

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 565 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

Low battery voltage Charge battery

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of drive assembly Remove lower drive unit and check for no

drive condition

No latching in primary

and/or secondary positionsFailure of inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Failure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Door seal force too high Inspect seals for damage, mis-assembly,

foreign matter. Refer to Door adjustment in

the Body section of the service manual for

specifications

Failure of drive assembly Remove lower drive unit and check for no

drive condition

Failure of striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Latch will not fully release

from primary positionFailure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of fuel filler door lockout

mechanismCheck operation of fuel filler door lockout

mechanism. Refer to the Body section for

information

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of striker Striker misaligned or loose

8N - 24 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 569 of 2399

Use a known good vehicle for side door comparison

data. Refer to the Side Door Adjustment procedure in

the Body section of the service manual for detailed

instructions.

LATCH

DESCRIPTION

Vehicles equipped with a power side door or doors

utilize a power latch. One power latch is used for

each power door. The latch is located on the trailing

edge of the side door assembly (Fig. 5). This power

latch assembly is comprised of many different compo-

nents which have the ability to perform the power

cinch, release, lock, unlock and safety related opera-

tions. These components are the door latch, lock/un-

lock actuator, cinch/release actuator and child

lockout, pawl, ratchet and handle switches. The pawl

and ratchet switches are used to indicate the primary

and secondary latched positions. The cinch latch also

provides a connection point for the interior handle,

exterior handle and hold open latch cables.

The power latch is a replaceable component. Con-

sult your Mopar parts catalog for specific part num-

bers.

OPERATION

The power latch performs the same operation as a

full manual door latch as well as power cinch,

release, lock and unlock operations. The power latch

mounted actuator cinches the door closed and latches

it in its primary latched position. During a power

close cycle, the power cinch actuator will not operate

until the side door has reached its secondary latch

position (determined by pawl and ratchet switches).

During a power open cycle, the power release actua-

tor will stop once the side door has moved from pri-

mary latch position.

The power latch uses inputs from the lock/unlock

actuator, power side door control module and child

lockout, pawl, ratchet and handle switches to provide

safe power cinch and release operations. Refer to

Power Side Door Operation for additional informa-

tion.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate side door trim panel.

Refer to the Body section for the procedure.

(3) Remove the weather shield if necessary. Refer

to the Body section for the procedure.

(4) Open the side door all the way and remove the

door latch retaining bolts (Fig. 6).

Fig. 5 Removing/Installing Power Latch in Sliding

Door

1 - Power Latch Assembly

Fig. 6 Removing Latch Retaining Bolts

1 - Latch Retaining Bolts

2 - Side Door

8N - 28 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 570 of 2399

(5) Partially close the door and pull the latch

assembly out of the side door inner panel.

(6) Disconnect all electrical connectors leading to

the latch assembly.

(7) Disconnect the inside and outside handle cables

from the latch assembly. Refer to the Body Section of

the service manual for the procedure.

(8) Disconnect the hold open latch cable from the

latch assembly. Refer to the Body Section of the ser-

vice manual for the procedure.

(9) Disconnect lock actuator link rod from the

latch assembly.

(10) Remove the latch assembly from the vehicle.

INSTALLATION

(1) Position the latch assembly in the vehicle. Be

certain all latch mounted components are installed

on the replacement latch assembly. If not, transfer

components from the old latch to the new latch

assembly.

(2) Connect the lock actuator link rod on the latch

assembly.

(3) Connect the hold open latch cable on the latch

assembly. Refer to the procedure in this section for

detailed instructions.

(4) Connect the inside and outside handle cables

on the latch assembly. Refer to the procedure in the

Body section for detailed instructions.

(5) Connect all electrical connectors leading to the

latch assembly.

(6) With assistance from another person, position

the side door and install the door latch retaining

bolts. Torque to 10 - 12 N´m (100 in. lbs.).

(7) Install the weathershield if necessary. Refer to

the procedure in the Body section for detailed

instructions.

(8) Install the appropriate side door trim panel.

Refer to the procedure in the Body section for

detailed instructions.

(9) Connect the negative battery cable.

SLIDING DOOR MOTOR

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a door motor assembly. The door motor is located in

the center of the side door (Fig. 7) and is comprised

of three parts. The three parts of the door motor

assembly are the motor, gear reduction and clutch

assembly. The door motor assembly provides the

power and torque to move the sliding door from the

open/closed position to full closed/open position, after

the power latching mechanism has released.

Special wellnuts and screws are used in the side

door inner panel to retain the door motor to the doorpanel. Refer to Standard Procedures in this section

for additional wellnut information.

The door motor is replaced as a complete assembly,

which includes the DC motor, gear reduction and

clutch assemblies. Consult your Mopar parts catalog

for specific part numbers.

OPERATION

With the push of a Power Side Door (PSD) com-

mand switch, the PSD control module will signal the

latch assembly to release the door from its primary

locked position. The drive motor will then take over

to provide the power to open the door to its full open

or closed position. The gear reduction portion of the

motor assembly reduces the speed of the motor from

5800 to 260 rpm and also increases the torque to the

lower drive unit. The clutch portion of the motor

assembly engages the motor to drive the door under

power and disengages it so the door can be moved

easily under manual operation.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

Fig. 7 Side Door Components

1 - Sliding Door Control Module

2 - Module Retaining Screw

3 - Module Electrical Connectors

4 - Door Motor Assembly

5 - Flex Drive Assembly

6 - Door Motor Retaining Fasteners

7 - Door Motor Electrical Connector

RSPOWER SLIDING DOOR SYSTEM8N-29

LATCH (Continued)

ProCarManuals.com

Page 571 of 2399

(2) Remove the door trim panel from the appropri-

ate side door. Refer to the Body section for the pro-

cedure.

(3) Remove water shield as necessary to gain

access to motor assembly.

(4) Remove retaining clip holding flex drive assem-

bly to the motor (Fig. 8). Pull flex drive cable straight

out of the motor assembly.

(5) Disconnect door motor electrical connector.

(6) Remove the 4 screws holding the motor to the

inner door panel.

(7) Remove the motor assembly from the vehicle.

INSTALLATION

(1) Position the motor assembly on the door inner

panel.

(2) Install the 4 screws holding the motor to the

inner door panel. Torque to 35 in. lbs.

(3) Install the flex shaft by lining up the square

shaped drive shaft with corresponding hole in motor

drive unit and push straight in.

(4) Install the E-clip to secure flex-shaft.

(5) Connect the negative battery cable.

(6) Install the weather shield. Refer to the Body

section of the service manual for the procedure.

(7) Install the door trim panel on the side door.

Refer to Body for the procedure.

FULL OPEN SWITCH

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a full open switch. This switch is located in the hold

open latch (Fig. 9) under the side door lower hinge.

When the power side door module receives a ground

signal input from the full open switch, and as long as

the cinching latch actuator is not in power mode or

the handle switch is open, the signal indicates that

the door is at the full open position.

The full open switch is incorporated into the hold

open latch. If the full open switch proves faulty, the

entire hold open latch assembly must be replaced.

OPERATION

The full open switch is triggered by a pawl lever in

the hold open latch. When the full open switch is

closed (circuit to ground) the ratchet has engaged on

the hold open striker and the pawl lever has engaged

on the ratchet, locking the latch from opening and

holding the door in the full open position.

Fig. 8 Flex Drive Retaining Clip

1 - Flex Drive Cable Retaining Clip

2 - Flex Drive Cable

3 - Side Door Motor Assembly

Fig. 9 Full Open Switch Position & Orientation

1 - Hold Open Latch Assembly

2 - Hold Open Latch Cable

3 - Full Open Switch

8N - 30 POWER SLIDING DOOR SYSTEMRS

SLIDING DOOR MOTOR (Continued)

ProCarManuals.com