engine CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1215 of 2399

(22) Remove engine front mount and bracket from

engine. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - REMOVAL)

(23) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

(24) Remove rear engine mount bracket. (Refer to

9 - ENGINE/ENGINE MOUNTING/REAR MOUNT -

REMOVAL)

(25) Mark flex plate to torque converter and

remove torque converter bolts.

(26) Pinch-off power steering supply hose at pump.

Remove hose from pump.

(27) Remove and set aside the power steering

pump and bracket. Do not disconnect pressure line.

(28) Lower vehicle.

(29) Remove A/C lines at compressor and cap open-

ings.

(30) Remove engine ground straps (strap at engine

right mount and at starter).

(31) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 to be installed under vehicle

(Fig. 8).

(32) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

oil pan rails (Fig. 8). Lower vehicle and position cra-

dle mounts until the engine is resting on mounts.

Tighten mounts to cradle frame. This will keep

mounts from moving when removing or installing

engine and transmission.

(33) Install safety straps around the engine to cra-

dle. Tighten straps and lock.

(34) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(35) Remove engine and transmission mount bolts.

(36) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly with the

dolly to allow for removal around the body.

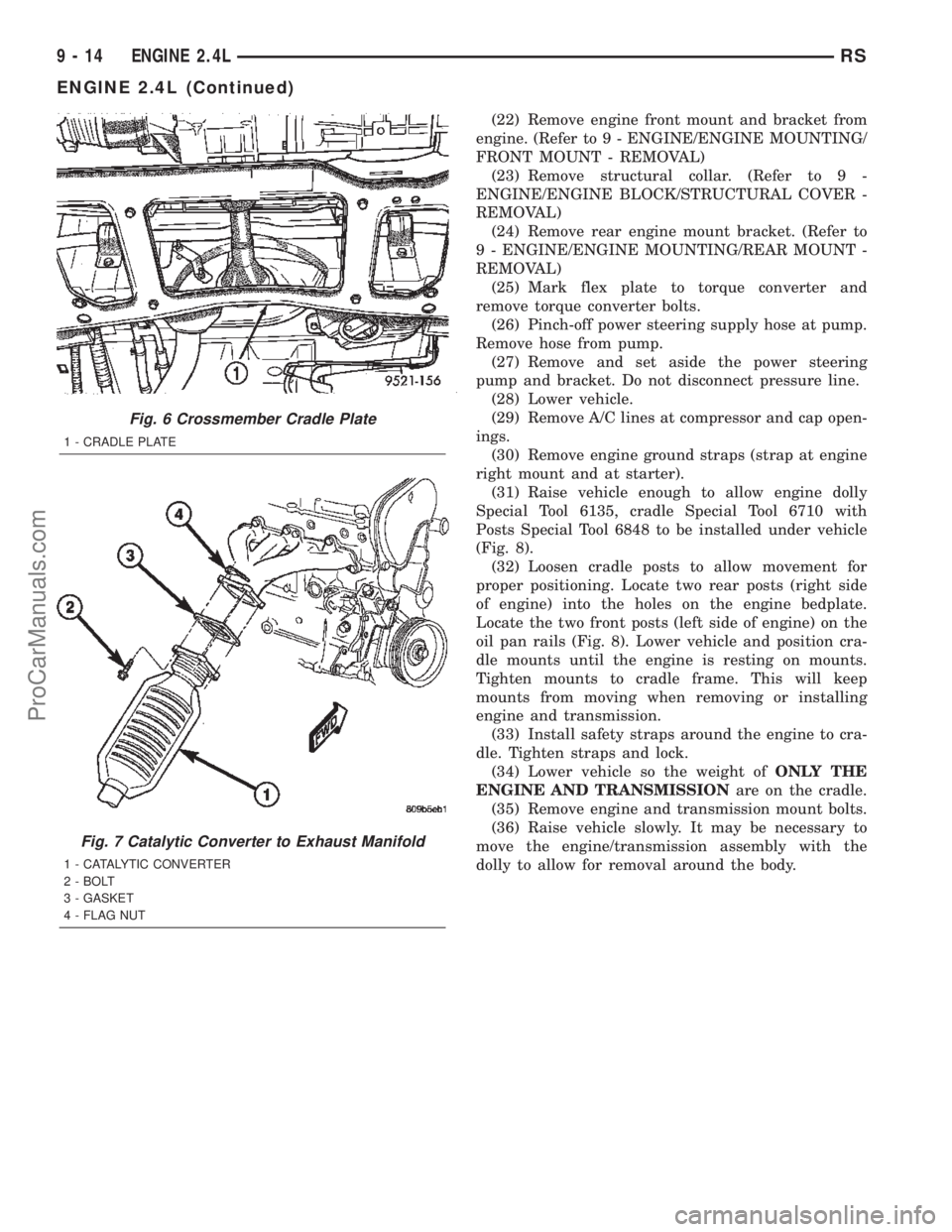

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - CATALYTIC CONVERTER

2 - BOLT

3 - GASKET

4 - FLAG NUT

9 - 14 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1216 of 2399

Fig. 8 Positioning Engine Cradle Support Post Mounts

1 - SPECIAL TOOL POSTS 6848 4 - SPECIAL TOOL 6710 CRADLE

2 - SPECIAL TOOL 6135 DOLLY 5 - SPECIAL TOOL 6848 - POST CONTACT ON PAN RAIL

3 - SPECIAL TOOL POSTS 6848

RSENGINE 2.4L9-15

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1217 of 2399

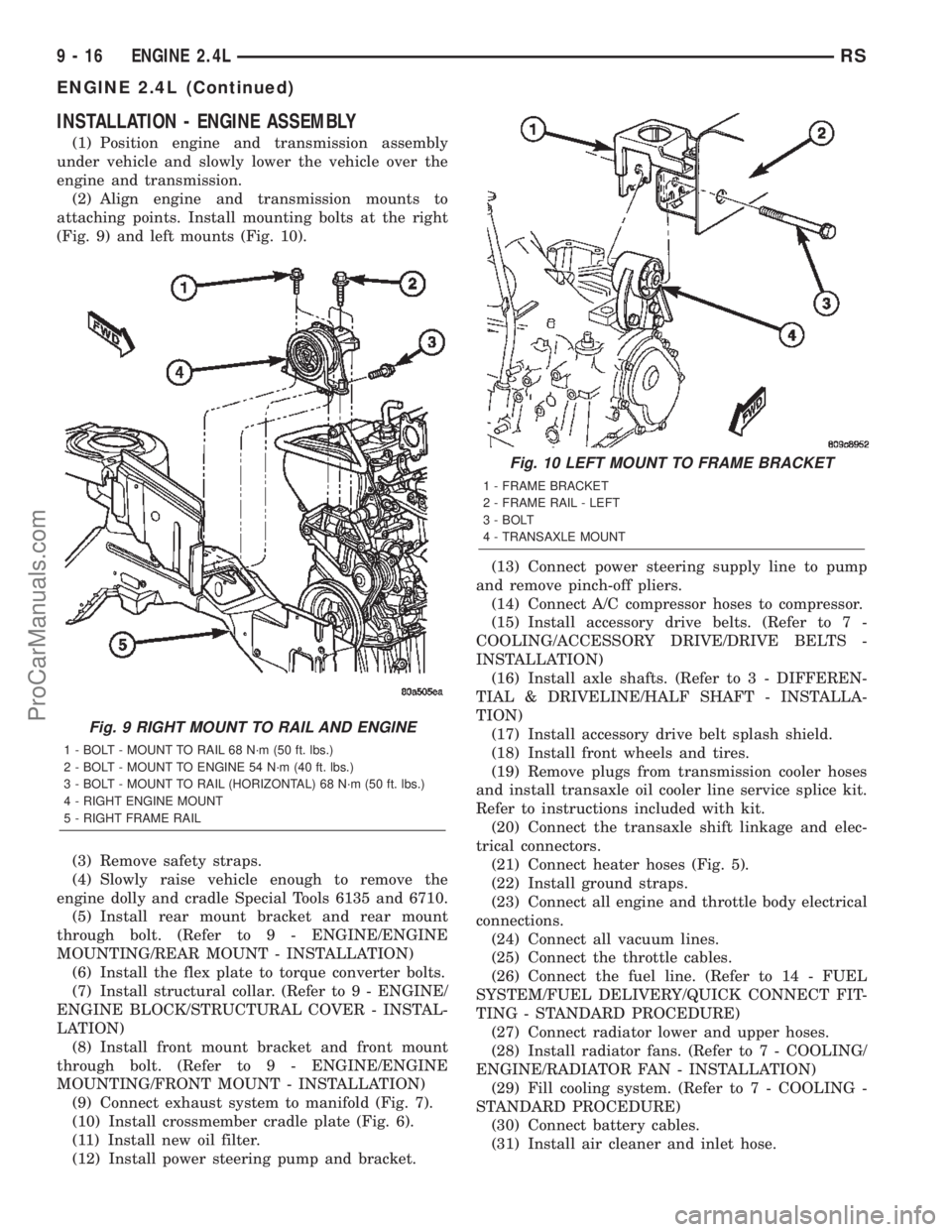

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

(Fig. 9) and left mounts (Fig. 10).

(3) Remove safety straps.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(5) Install rear mount bracket and rear mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/REAR MOUNT - INSTALLATION)

(6) Install the flex plate to torque converter bolts.

(7) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(8) Install front mount bracket and front mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/FRONT MOUNT - INSTALLATION)

(9) Connect exhaust system to manifold (Fig. 7).

(10) Install crossmember cradle plate (Fig. 6).

(11) Install new oil filter.

(12) Install power steering pump and bracket.(13) Connect power steering supply line to pump

and remove pinch-off pliers.

(14) Connect A/C compressor hoses to compressor.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.

(24) Connect all vacuum lines.

(25) Connect the throttle cables.

(26) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(27) Connect radiator lower and upper hoses.

(28) Install radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION)

(29) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(30) Connect battery cables.

(31) Install air cleaner and inlet hose.

Fig. 9 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 10 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

9 - 16 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1218 of 2399

(32) Fill engine crankcase with proper oil to cor-

rect level.

(33) Start engine and run until operating temper-

ature is reached.

(34) Adjust transmission linkage, if necessary.

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE

DESCRIPTION SPECIFICATION

General Specification

Type In-Line OHV, DOHC

Number of Cylinders 4

Displacement 2.4 Liters

(148 cu. in.)

Bore 87.5 mm

(3.445 in.)

Stroke 101.0 mm

(3.976 in.)

Compression Ratio 9.4:1

Firing Order 1-3-4-2

Compression Pressure 690 kPa (Minimum)

(100 psi Minimum)

Max. Variation Between

Cylinders25%

Cylinder Block

Cylinder Bore Diameter 87.4924±87.5076 mm

(3.4446±3.4452 in.)

Out-of-Round (Max.) 0.051 mm

(0.002 in.)

Taper (Max.) 0.051 mm

(0.002 in.)

Pistons

Piston Diameter 87.463±87.481 mm

(3.4434±3.4441 in.)

Clearance @ 14 mm

(9/16 in.) from bottom of

skirt0.024±0.057 mm

(0.0009±0.0022 in.)

Weight 346±356 grams

(12.20±12.56 oz.)

Land Clearance

(Diametrical)0.614±0.664 mm

(0.024±0.026 in.)

Piston Length 66.25 mm

(2.608 in.)

DESCRIPTION SPECIFICATION

Piston Ring Groove

Depth No. 14.640±4.784 mm

(0.182±0.188 in.)

Piston Ring Groove

Depth No. 24.575±4.719 mm

(0.180±0.185 in.)

Piston Ring Groove

Depth No. 34.097±4.236 mm

(0.161±0.166 in.)

Piston Pins

Clearance in Piston 0.005±0.018 mm

(0.0002±0.0008 in.)

Clearance in Connecting

RodInterference

Diameter 21.998±22.003 mm

(0.8660±0.8662 in.)

End Play None

Length 72.75±73.25 mm

(2.864±2.883 in.)

Piston Rings

Ring GapÐTop

Compression Ring0.25±0.51 mm

(0.0098±0.020 in.)

Wear Limit 0.8 mm

(0.031 in.)

Ring GapÐ2nd

Compression Ring0.23±0.48 mm

(0.009±0.018 in.)

Wear Limit 0.8 mm

(0.031 in.)

Ring GapÐOil Control

Steel Rails0.25±0.64 mm

(0.0098±0.025 in.)

Wear Limit 1.0 mm

(0.039 in.)

Ring Side ClearanceÐ

Compression Rings0.030±0.080 mm

(0.0011±0.0031 in.)

Wear Limit 0.10 mm

(0.004 in.)

Ring Side ClearanceÐOil

Ring Pack0.012±0.178 mm

(0.0004±0.0070 in.)

Ring WidthÐ

Compression Rings1.47±1.50 mm

(0.057±0.059 in.)

Ring WidthÐOil Ring

Pack2.72±2.88 mm

(0.107±0.1133 in.)

Connecting Rod

Bearing Clearance 0.025±0.071 mm

(0.0009±0.0027 in.)

RSENGINE 2.4L9-17

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1219 of 2399

DESCRIPTION SPECIFICATION

Wear Limit 0.075 mm

(0.003 in.)

Bore DiameterÐPiston

Pin20.96±20.98 mm

(0.8252±0.8260 in.)

Bore DiameterÐ

Crankshaft End53.007±52.993 mm

(2.0868±2.0863 in.)

Side Clearance 0.13±0.38 mm

(0.005±0.015 in.)

Wear Limit 0.40 mm

(0.016 in.)

WeightÐTotal (Less

Bearing)565.8 grams

(19.96 oz.)

Crankshaft

Connecting Rod Journal

Diameter49.984±50.000 mm

(1.968±1.9685 in.)

Main Bearing Journal

Diameter59.992±60.008 mm

(2.362±2.3625 in.)

Journal Out-of-Round

(Max.)0.0035 mm

(0.0003 in.)

Journal Taper (Max.) 0.007 mm

(0.0001 in.)

End Play 0.09±0.24 mm

(0.0035±0.0094 in.)

Wear Limit 0.38 mm

(0.015 in.)

Main Bearing Diametrical

Clearance0.018±0.062 mm

(0.0007±0.0024 in.)

Hydraulic Lash Adjuster

Body Diameter 15.901±15.913 mm

(0.626±0.6264 in.)

Plunger Travel Minimum

(Dry)3.0 mm

(0.118 in.)

Cylinder Head Camshaft Bearing Bore Diameter

Journals No.1±6 26.020±26.041 mm

(1.024±1.025 in.)

Camshaft

Journal Diameter No. 1±6 25.951±25.970 mm

(1.021±1.022 in.)

Bearing ClearanceÐ

Diametrical0.069±0.071 mm

(0.0027±0.003 in.)

End Play 0.05±0.17 mm

(0.0019±0.0066 in.)DESCRIPTION SPECIFICATION

Lift (Zero Lash)

Intake 8.25 mm

(0.324 in.)

Exhaust 6.60 mm

(0.259 in.)

Intake Valve Timing*

Closes (ABDC) 51É

Opens (BTDC) 1É

Duration 232É

Exhaust Valve Timing*

Closes (ATDC) 7É

Opens (BBDC) 47É

Duration 234É

Valve Overlap 8É

*All readings in crankshaft degrees. Timing points @

4É from top of Ramps.

Cylinder Head

Material Cast Aluminum

Gasket Thickness

(Compressed)0.71 mm

(0.028 in.)

Valve Seat

Angle 44.5±45É

Seat DiameterÐIntake 34.37±34.63 mm

(1.353±1.363 in.)

Seat DiameterÐExhaust 27.06±27.32 mm

(1.065±1.075 in.)

Runout (Max.) 0.05 mm

(0.002 in.)

Valve Seat WidthÐIntake

and Exhaust0.9±1.3 mm

(0.035±0.051 in.)

Service LimitÐIntake 2.0 mm

(0.079 in.)

Service LimitÐExhaust 2.5 mm

(0.098 in.)

Valve Guide

Diameter I.D. 5.975±6.000 mm

(0.235±0.236 in.)

Guide Bore Diameter 11.0±11.02 mm

(0.4330±0.4338 in.)

Guide Height (spring seat

to guide tip)13.25±13.75 mm

(0.521±0.541 in.)

9 - 18 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1220 of 2399

DESCRIPTION SPECIFICATION

Valves

Face AngleÐIntake and

Exhaust44.5Ð45É

Head DiameterÐIntake 34.67±34.93 mm

1.364±1.375 in.)

Head DiameterÐExhaust 28.32±28.52 mm

(1.114±1.122 in.)

Valve Length (Overall)

ÐIntake 112.76±113.32 mm

(4.439±4.461 in.)

ÐExhaust 110.89±111.69 mm

(4.365±4.397 in.)

Valve Stem Diameter

ÐIntake 5.934±5.952 mm

(0.2337±0.2344 in.)

ÐExhaust 5.906±5.924 mm

(0.2326±0.2333 in.)

Valve Margin

Intake 1.2±1.7 mm

(0.047±0.066 in.)

Service Limit 0.95 mm

(1/32 in.)

Exhaust 0.985±1.315 mm

(0.038±0.051 in.)

Service Limit 1.05 mm

(3/64 in.)

Valve Stem Tip Height

Intake 48.04 mm

(1.891 in.)

Exhaust 47.99 mm

(1.889 in.)

Valve Stem to Guide Clearance

Intake 0.048±0.066 mm

(0.0018±0.0025 in.)

Max. Allowable 0.076 mm

(0.003 in.)

Service Limit 0.25 mm

(0.010 in.)

Exhaust 0.0736±0.094 mm

(0.0029±0.0037 in.)

Max. Allowable 0.101 mm

(0.004 in.)DESCRIPTION SPECIFICATION

Service Limit 0.25 mm

(0.010 in.)

Valve Springs

Free Length (Approx.) 48.4 mm

(1.905 in.)

Nominal Force (Valve

Closed)338 N @ 38.0 mm

(75.98 lbs. @ 1.496 in.)

Nominal Force (Valve

Open)607 N @ 29.75 mm

(136 lbs. @ 1.172 in.)

Installed Height 38.00 mm

(1.496 in.)

Number of Coils 7.82

Wire Diameter 3.86 mm

(1.496 in.)

Oil Pump

Clearance Over Rotors

(Max.)0.10 mm

(0.004 in.)

Cover Out-of-Flat (Max.) 0.025 mm

(0.001 in.)

Inner Rotor Thickness

(Min.)9.40 mm

(0.370 in.)

Outer Rotor Thickness

(Min.)9.40 mm

(0.370 in.)

Outer Rotor Clearance

(Max.)0.039 mm

(0.015 in.)

Outer Rotor Diameter

(Min.)79.95 mm

(3.148 in.)

Tip Clearance Between

Rotors (Max.)0.20 mm

(0.008 in.)

Oil Pressure

At Curb Idle Speed* 25 kPa

(4 psi)

At 3000 rpm 170±550 kPa

(25±80 psi)

CAUTION:

*If pressure is ZERO at curb idle, DO NOT run engine

at 3000 rpm.

RSENGINE 2.4L9-19

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1221 of 2399

SPECIFICATIONS - TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Balance Shaft Carrier to

BlockÐBolts54 40 Ð

Balance Shaft Gear

CoverÐDouble Ended

Fastener12 Ð 105

Balance Shaft SprocketÐ

Bolt28 Ð 250

Balance Shaft Chain

TensionerÐBolts12 Ð 105

Balance Shaft Carrier

CoverÐBolts12 Ð 105

Camshaft SprocketÐBolt 101 75 Ð

Connecting Rod

CapÐBolts27 +

1¤4

turn20

+1¤4

turnÐ

Crankshaft Main Bearing

Cap/Bedplate

ÐM8 Bolts 28 250

ÐM11 Bolts 41 +

1¤4

Turn30

+1¤4

TurnÐ

Crankshaft Damper 136 100 Ð

Cylinder HeadÐBolts (Refer to 9 - ENGINE/

CYLINDER HEAD -

INSTALLATION)

Cylinder Head CoverÐ

Bolts12 Ð 105

Flex Plate to Crankshaft 95 70 Ð

Engine Mount Bracket

RightÐBolts61 45 Ð

Engine MountingÐBolts (Refer to 9 ENGINE/

ENGINE MOUNTING)

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Exhaust Manifold to

Cylinder HeadÐBolts19 Ð 170

Exhaust Manifold Heat

ShieldÐBolts12 Ð 105

Intake Manifold - Lower

ÐBolts28 Ð 250

Intake Manifold -

UpperÐBolts28 Ð 250

Oil Filter 12 Ð 105

Oil PanÐBolts 12 Ð 105

Oil Pan DrainÐPlug 27 20 Ð

Oil Pressure Switch 21 Ð 190

Oil Pump to BlockÐBolts 28 Ð 250

Oil Pump Cover

PlateÐBolts12 Ð 105

Oil Pump Pick-up

TubeÐBolt28 20 Ð

Oil Pump Relief

ValveÐCap41 30 Ð

Spark Plugs 18 13 Ð

Structural Collar (Refer to 9 - ENGINE/

ENGINE BLOCK/

STRUCTURAL COVER -

INSTALLATION)

Timing Belt Covers

- Front Covers to Rear

CoverÐBolts7Ð60

- Rear CoverÐM6 Bolts 12 Ð 105

ÐM8 Bolts 28 Ð 250

Timing Belt Tensioner

AssemblyÐBolts61 45 Ð

9 - 20 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1222 of 2399

SPECIAL TOOLS

2.4L ENGINE

Puller 1026

Crankshaft Damper Removal Insert 6827A

Dolly 6135

Cradle 6710A

Post Kit Engine Cradle 6848

Camshaft Sprocket Holder 6847

Camshaft Seal Remover C-4679A

Camshaft Seal Installer MD-998306

Crankshaft Damper/Sprocket Installer 6792

RSENGINE 2.4L9-21

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1223 of 2399

Valve Spring Compressor 8215-A

Adaptor 8436

Valve Spring Compressor MD998772A

Valve Spring Compressor Adapter 6779

Indicator, Cylinder Bore C-119

Connecting Rod Guides 8189

Crankshaft Sprocket Remover 6793

Crankshaft Sprocket Remover Insert C-4685-C2

Front Crankshaft Oil Seal Remover 6771

9 - 22 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1224 of 2399

Front Crankshaft Oil Seal Installer 6780

Oil Pressure Gauge C-3292

Adapter 8406

Rear Crankshaft Oil Seal Installer 6926

Driver Handle C-4171

Balance Shaft Sprocket Installer 6052

Combustion Leak Tester C-3685-A

Pressure Transducer CH7059

Cylinder Compression Pressure Adaptor 8116

DRB IIITwith PEP Module OT-CH6010A

RSENGINE 2.4L9-23

ENGINE 2.4L (Continued)

ProCarManuals.com