Tire rotation CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 219 of 2399

(1) Connect the front wheel speed sensor cable to

the vehicle wiring harness connector. Be sure speed

sensor cable connector is fully seated and locked into

vehicle wiring harness connector.

(2) Install the bolts attaching the routing clamps

to the body of the vehicle. Tighten the bolts to a

torque of 14 N´m (125 in. lbs.).

(3) Insert speed sensor cable grommets into inter-

mediate bracket on strut.

(4) Install the wheel speed sensor head mounting

bolt (Fig. 1). Tighten the bolt to a torque of 13 N´m

(115 in. lbs.)

(5) Install the wheel and tire assembly on vehicle.

(6) Lower vehicle.

(7) Road test vehicle to ensure proper operation of

the base and ABS brake systems.

REAR WHEEL SPEED SENSOR

-AWD

REMOVAL

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

CAUTION: When disconnecting speed sensor cable

from vehicle wiring harness be careful not to dam-

age pins on the electrical connectors. Also, inspect

connectors for any signs of previous damage.(2) Remove grommet from floor pan of vehicle and

disconnect speed sensor cable connector from vehicle

wiring harness.

CAUTION: When removing rear wheel speed sensor

cable from routing clips, be sure not to damage the

routing clips. Routing clips that are molded onto

the brake hose will require replacement of the brake

hose if damaged during removal or installation of

the speed sensor cable.

(3) Carefully remove speed sensor cable from

press-in routing clips along brake hose and tubing.

(4) Remove bolt securing wheel speed sensor cable

metal clip to rear of axle. Remove metal clip from

cable if necessary.

CAUTION: If speed sensor head has seized due to

corrosion, do not use pliers on speed sensor head

in an attempt to remove it. Use a hammer and a

punch and tap mounting flange edge side-to-side,

rocking the sensor until free.

(5) Remove wheel speed sensor head attaching

bolt.

(6) Remove wheel speed sensor head from the axle,

and remove sensor from vehicle.

INSTALLATION

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers as indicated may

result in contact with moving parts or over-exten-

sion of cables, resulting in an open circuit.

(1) Install wheel speed sensor head in axle flange.

CAUTION: Prior to installing the speed sensor head

attaching bolt, the plastic anti-rotation pin must be

fully seated into the bearing flange.

(2) Install wheel speed sensor head attaching bolt.

Tighten bolt to a torque 10 N´m (90 in. lbs.).

(3) Check the air gap between the face of the

wheel speed sensor and the top surface of the tone

wheel. (Refer to 5 - BRAKES - SPECIFICATIONS)

CAUTION: When installing wheel speed sensor

cable in the routing clips on rear brake flex hose,

be sure not to damage the routing clips. Routing

clips are molded onto the hose and will require

replacement of the brake hose if damaged.

(4) Install speed sensor cable under leaf spring

onto brake hose and tubing utilizing routing clips to

secure it in place.

Fig. 1 Front Wheel Speed Sensor Attaching Bolt

1 - MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - DRIVESHAFT

4 - TONE WHEEL

5 - STEERING KNUCKLE

5 - 90 BRAKES - ABSRS

FRONT WHEEL SPEED SENSOR (Continued)

ProCarManuals.com

Page 612 of 2399

(6) Refer to the proper Body Diagnostic Procedures

manual if any diagnostic codes are found in Step 4 or

Step 5.

(7) Erase stored diagnostic codes if there are no

active diagnostic codes. If problems remain, diagnos-

tic codes will not erase. Refer to the Proper Body

Diagnostic Procedures Manual to diagnose the prob-

lem.If airbag warning lamp either fails to light,

or goes on and stays on, there is a system mal-

function. Refer to the proper Body Diagnostic

Procedures manual to diagnose the problem.

CLOCK SPRING

DESCRIPTION

The clock spring is screwed to a plastic mounting

platform on the steering column behind the steering

wheel. The clock spring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the drivers airbag.

OPERATION

This assembly consists of a flat ribbon like electri-

cally conductive tape which winds and unwinds with

the steering wheel rotation. The clock spring cannot

be repaired. If the clock spring is faulty, damaged, or

if the airbag has been deployed, the clock spring

must be replaced.

STANDARD PROCEDURE - CLOCK SPRING

CENTERING

If the rotating tape (wire coil) in the clock spring is

not positioned properly with the steering wheel and

the front wheels, the clock spring may fail. The fol-

lowing procedure MUST BE USED to center the

clock spring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

(1) Adjust the steering wheel so that the tires are

in a straight ahead position.

(2) Remove Driver Airbag from steering wheel.

(3) Disconnect wire connectors from back of airbag.

(4) Remove steering wheel.

(5) Rotate the clock spring rotor clockwise until

the rotor stops. Do not apply excessive force.

(6) From the end of travel, rotate the rotor two

turns counterclockwise until the wires end up at the

top.

(7) Install steering wheel and airbag.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood. Disconnect

and isolate the battery negative cable.

(3) Remove driver airbag from steering wheel.

(4) Disconnect wire connectors from back of driver

airbag.

(5) Disconnect the 2±way connector from remote

radio control harness and the 4-way connector from

the speed control/horn harness.

(6) Remove steering wheel.

(7) Remove steering column shrouds.

(8) Disconnect 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(9) Remove clock spring from housing assembly by

removing the two retaining screws retaining the

clock spring.

INSTALLATION

(1) Position the clock spring into the housing.

Install the two retaining screws to clock spring.

(2) Connect the 4-way and 6-way harness between

the clock spring and the instrument panel.

(3) Install the steering wheel. Refer to Steering,

Column, Steering Wheel, Installation.

(4) Connect the harness connector to the driver

airbag.

(5) Connect the remote radio control harness and

the speed control/horn harness.

(6) Install the driver airbag into the steering

wheel.

(7) Install the steering column upper and lower

shrouds.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

DRIVER AIRBAG

DESCRIPTION

The Driver Airbag is located in the center of the

steering wheel. The most visible part of the airbag is

the cover/horn switch.

OPERATION

The Driver Airbag cover contains the horn switch,

inflator device, and a fabric bag. The airbag cover/

horn switch is serviced separately from the inflator

and bag components.

RSRESTRAINTS8O-3

RESTRAINTS (Continued)

ProCarManuals.com

Page 1879 of 2399

(11) Raise vehicle on hoist.

(12) Remove front wheel/tires and halfshafts.

(13) Remove underbody splash shield.

(14) Drain transaxle fluid into suitable container.

(15) Remove front harness retainer and secure

harness out of way.

(16) Using Tool 6638A, disconnect clutch hydrau-

lic circuit quick connect (located on slave cylinder

tube). Remove clutch slave cylinder by depressing

towards case and rotating counter-clockwise 60É,

while lifting anti-rotation tab out of case slot with

screwdriver (Fig. 21).

(17) Remove engine left mount bracket (Fig. 22).

(18) Remove starter motor (Fig. 23).

(19) Disconnect back-up lamp switch connector.

(20) Position screw jack and wood block to engine

oil pan.

(21) Remove transmission upper mount through-

bolt from left frame rail.

(22) Lower engine/transaxle assembly on screw

jack.

Fig. 21 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 22 Left Mount Bracket Removal/Installation

1 - BOLT (2)

2 - MOUNT BRACKET

3 - BOLT (2)

Fig. 23 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

21 - 322 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1898 of 2399

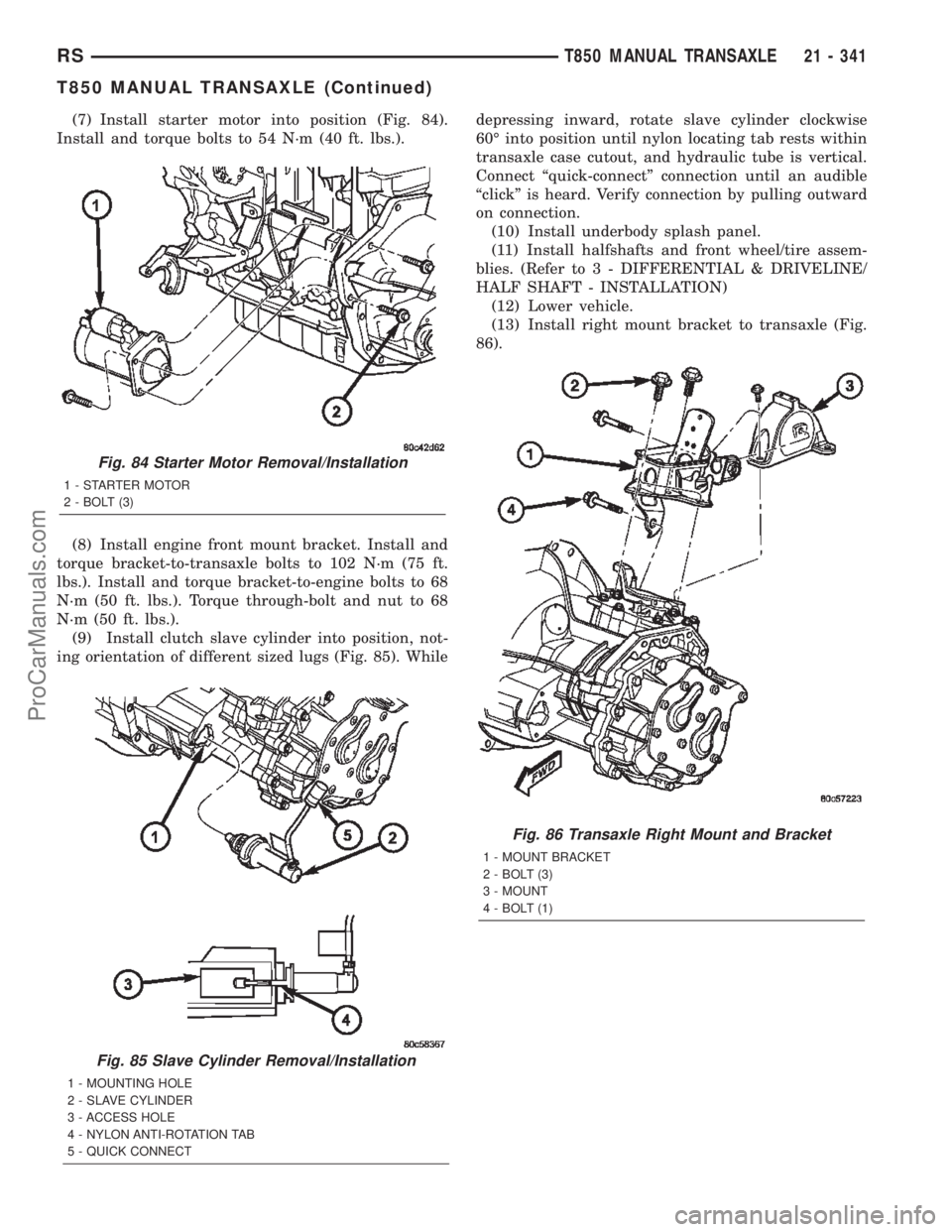

(7) Install starter motor into position (Fig. 84).

Install and torque bolts to 54 N´m (40 ft. lbs.).

(8) Install engine front mount bracket. Install and

torque bracket-to-transaxle bolts to 102 N´m (75 ft.

lbs.). Install and torque bracket-to-engine bolts to 68

N´m (50 ft. lbs.). Torque through-bolt and nut to 68

N´m (50 ft. lbs.).

(9) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs (Fig. 85). Whiledepressing inward, rotate slave cylinder clockwise

60É into position until nylon locating tab rests within

transaxle case cutout, and hydraulic tube is vertical.

Connect ªquick-connectº connection until an audible

ªclickº is heard. Verify connection by pulling outward

on connection.

(10) Install underbody splash panel.

(11) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(12) Lower vehicle.

(13) Install right mount bracket to transaxle (Fig.

86).

Fig. 85 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 84 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

Fig. 86 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

RST850 MANUAL TRANSAXLE21 - 341

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1962 of 2399

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL VIBRATION.....................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................5

STANDARD PROCEDURE - TIRE AND

WHEEL MATCH MOUNTING..............5

STANDARD PROCEDURE - TIRE AND

WHEEL ROTATION.....................7

REMOVAL

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)....................7

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL).......................7

INSTALLATION

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (ALUMINUM WHEEL)..........8

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (STEEL WHEEL)..............8

TIRE PRESSURE MONITORING (TPM)

DESCRIPTION..........................9

OPERATION............................9

SENSOR - TPM

DESCRIPTION.........................10

OPERATION...........................10

CAUTION.............................10

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR............................10

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN....................10

REMOVAL.............................11

INSTALLATION.........................11

TIRES

DESCRIPTION

DESCRIPTION - TIRE..................13

DESCRIPTION - RADIAL-PLY TIRES.......13DESCRIPTION - REPLACEMENT TIRES....14

DESCRIPTION - SPARE TIRE

(TEMPORARY).......................14

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE NOISE . . . 14

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD...............................14

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS..........................14

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS.........................14

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE INFLATION

PRESSURES.........................14

STANDARD PROCEDURE - TIRE

PRESSURE FOR HIGH SPEED

OPERATION.........................17

STANDARD PROCEDURE - TIRE LEAK

REPAIRING..........................17

CLEANING - TIRES.....................17

WHEELS

DESCRIPTION - WHEEL..................17

DIAGNOSIS AND TESTING - WHEEL

INSPECTION.........................18

CLEANING - ALUMINUM WHEEL CARE......18

SPECIFICATIONS

WHEEL.............................19

WHEEL COVER

DESCRIPTION.........................19

REMOVAL.............................19

INSTALLATION.........................19

WHEEL MOUNTING STUDS - FRONT

REMOVAL.............................20

INSTALLATION.........................21

WHEEL MOUNTING STUDS - REAR

REMOVAL.............................21

INSTALLATION.........................22

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

VIBRATION

Tire and wheel imbalance, runout and force varia-

tion can cause vehicles to exhibit steering wheel

vibration.

VISUAL INSPECTION

Visual inspection of the vehicle is recommended

prior to road testing or performing any other proce-

dure. Raise vehicle on a suitable hoist. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

RSTIRES/WHEELS22-1

ProCarManuals.com

Page 1968 of 2399

STANDARD PROCEDURE - TIRE AND WHEEL

ROTATION

NON-DIRECTIONAL TREAD PATTERN TIRES

Tires on the front and rear axles operate at differ-

ent loads and perform different functions. For these

reasons, they wear at unequal rates, and tend to

develop irregular wear patterns. These effects can be

reduced by timely rotation of tires. The benefits of

rotation are especially worthwhile. Rotation will

increase tread life, help to maintain mud, snow, and

wet traction levels, and contribute to a smooth, quiet

ride.

The suggested rotation method is the forward-cross

tire rotation method (Fig. 11). This method takes

advantage of current tire industry practice which

allows rotation of radial-ply tires. Other rotation

methods may be used, but may not have all the ben-

efits of the recommended method.

NOTE: Only the 4 tire rotation method may be used

if the vehicle is equipped with a low mileage or tem-

porary spare tire.

DIRECTIONAL TREAD PATTERN TIRES

Some vehicles are fitted with special high-perfor-

mance tires having a directional tread pattern. These

tires are designed to improve traction on wet pave-

ment. To obtain the full benefits of this design, the

tires must be installed so that they rotate in the cor-

rect direction. This is indicated by arrows on the tire

sidewalls.When wheels and tires are being installed, extra

care is needed to ensure that this direction of rota-

tion is maintained.

Refer to Owner's Manual for rotation schedule.

REMOVAL

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

(2) Remove the 5 wheel mounting nuts from the

studs.

(3) Remove the tire and wheel from the hub.

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

(2) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 12).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

Fig. 10 Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - WHEEL WEIGHT

Fig. 11 Forward-Cross Tire Rotation Method

RSTIRES/WHEELS22-7

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 1971 of 2399

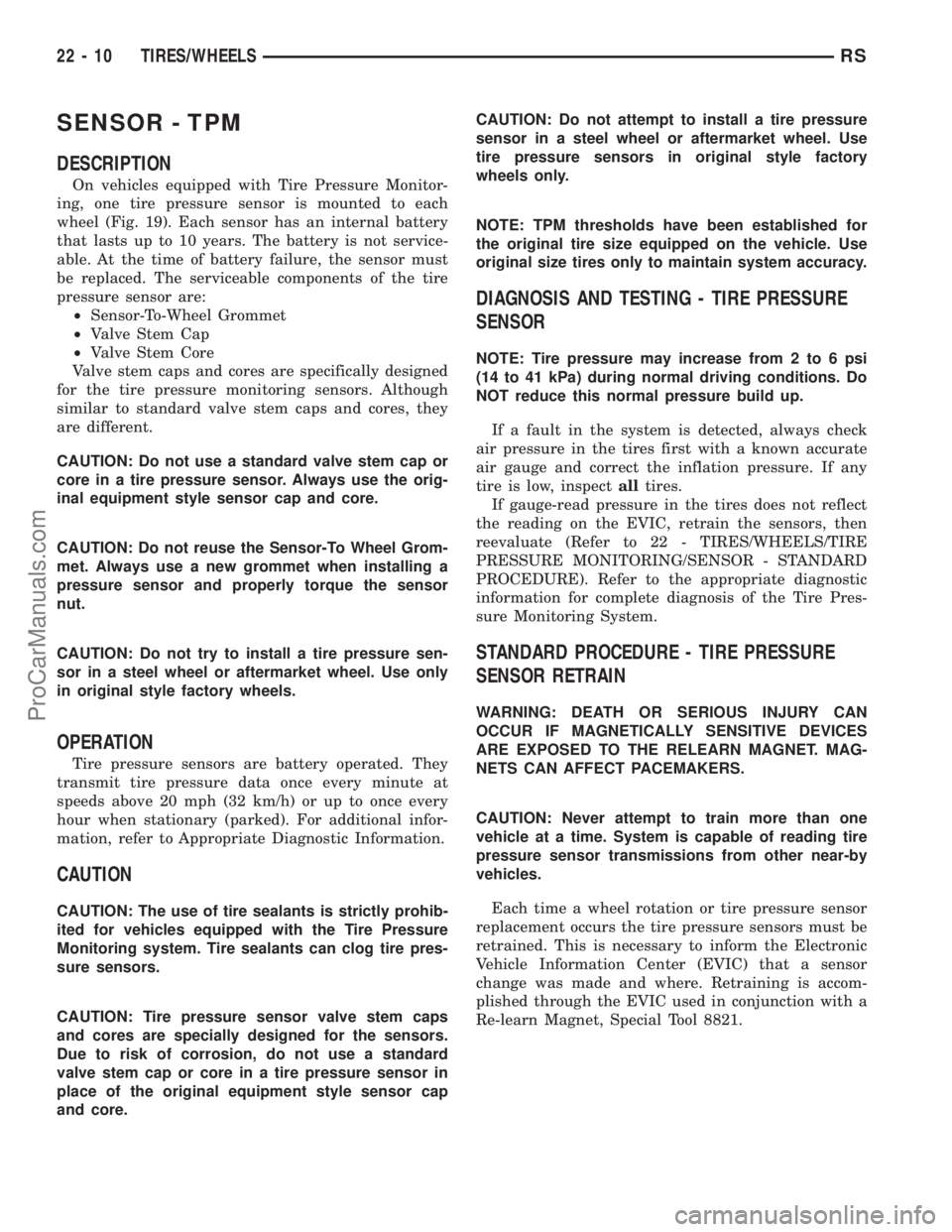

SENSOR - TPM

DESCRIPTION

On vehicles equipped with Tire Pressure Monitor-

ing, one tire pressure sensor is mounted to each

wheel (Fig. 19). Each sensor has an internal battery

that lasts up to 10 years. The battery is not service-

able. At the time of battery failure, the sensor must

be replaced. The serviceable components of the tire

pressure sensor are:

²Sensor-To-Wheel Grommet

²Valve Stem Cap

²Valve Stem Core

Valve stem caps and cores are specifically designed

for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they

are different.

CAUTION: Do not use a standard valve stem cap or

core in a tire pressure sensor. Always use the orig-

inal equipment style sensor cap and core.

CAUTION: Do not reuse the Sensor-To Wheel Grom-

met. Always use a new grommet when installing a

pressure sensor and properly torque the sensor

nut.

CAUTION: Do not try to install a tire pressure sen-

sor in a steel wheel or aftermarket wheel. Use only

in original style factory wheels.

OPERATION

Tire pressure sensors are battery operated. They

transmit tire pressure data once every minute at

speeds above 20 mph (32 km/h) or up to once every

hour when stationary (parked). For additional infor-

mation, refer to Appropriate Diagnostic Information.

CAUTION

CAUTION: The use of tire sealants is strictly prohib-

ited for vehicles equipped with the Tire Pressure

Monitoring system. Tire sealants can clog tire pres-

sure sensors.

CAUTION: Tire pressure sensor valve stem caps

and cores are specially designed for the sensors.

Due to risk of corrosion, do not use a standard

valve stem cap or core in a tire pressure sensor in

place of the original equipment style sensor cap

and core.CAUTION: Do not attempt to install a tire pressure

sensor in a steel wheel or aftermarket wheel. Use

tire pressure sensors in original style factory

wheels only.

NOTE: TPM thresholds have been established for

the original tire size equipped on the vehicle. Use

original size tires only to maintain system accuracy.

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR

NOTE: Tire pressure may increase from 2 to 6 psi

(14 to 41 kPa) during normal driving conditions. Do

NOT reduce this normal pressure build up.

If a fault in the system is detected, always check

air pressure in the tires first with a known accurate

air gauge and correct the inflation pressure. If any

tire is low, inspectalltires.

If gauge-read pressure in the tires does not reflect

the reading on the EVIC, retrain the sensors, then

reevaluate (Refer to 22 - TIRES/WHEELS/TIRE

PRESSURE MONITORING/SENSOR - STANDARD

PROCEDURE). Refer to the appropriate diagnostic

information for complete diagnosis of the Tire Pres-

sure Monitoring System.

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN

WARNING: DEATH OR SERIOUS INJURY CAN

OCCUR IF MAGNETICALLY SENSITIVE DEVICES

ARE EXPOSED TO THE RELEARN MAGNET. MAG-

NETS CAN AFFECT PACEMAKERS.

CAUTION: Never attempt to train more than one

vehicle at a time. System is capable of reading tire

pressure sensor transmissions from other near-by

vehicles.

Each time a wheel rotation or tire pressure sensor

replacement occurs the tire pressure sensors must be

retrained. This is necessary to inform the Electronic

Vehicle Information Center (EVIC) that a sensor

change was made and where. Retraining is accom-

plished through the EVIC used in conjunction with a

Re-learn Magnet, Special Tool 8821.

22 - 10 TIRES/WHEELSRS

ProCarManuals.com

Page 1974 of 2399

(6) Retrain tire pressure sensors. (Refer to 22 -

TIRES/WHEELS/TIRE PRESSURE MONITORING/

SENSOR - STANDARD PROCEDURE)

TIRES

DESCRIPTION

DESCRIPTION - TIRE

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

²Operating vehicle with over or under inflated

tire pressuresRadial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

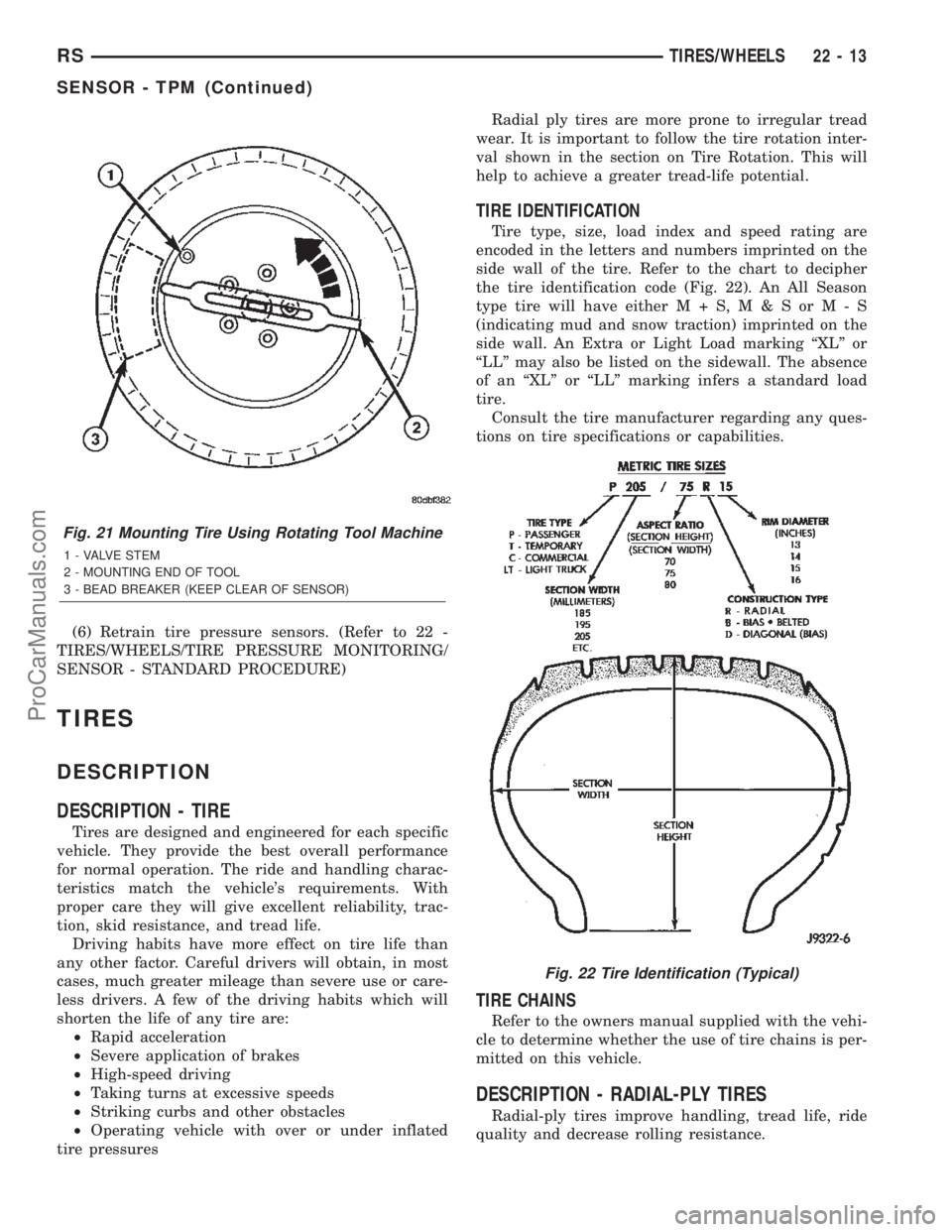

TIRE IDENTIFICATION

Tire type, size, load index and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 22). An All Season

type tire will have eitherM+S,M&SorM-S

(indicating mud and snow traction) imprinted on the

side wall. An Extra or Light Load marking ªXLº or

ªLLº may also be listed on the sidewall. The absence

of an ªXLº or ªLLº marking infers a standard load

tire.

Consult the tire manufacturer regarding any ques-

tions on tire specifications or capabilities.

TIRE CHAINS

Refer to the owners manual supplied with the vehi-

cle to determine whether the use of tire chains is per-

mitted on this vehicle.

DESCRIPTION - RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, ride

quality and decrease rolling resistance.

Fig. 21 Mounting Tire Using Rotating Tool Machine

1 - VALVE STEM

2 - MOUNTING END OF TOOL

3 - BEAD BREAKER (KEEP CLEAR OF SENSOR)

Fig. 22 Tire Identification (Typical)

RSTIRES/WHEELS22-13

SENSOR - TPM (Continued)

ProCarManuals.com