wiper fluid CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 179 of 2399

(4) Using vacuum line pliers, close off the vacuum

supply hose near the booster, but before the vacuum

gauge, then observe the vacuum gauge.

If the vacuum drop exceeds 1.0 inch Hg (3.3 kPa)

in one minute, repeat the above steps to confirm the

reading. The vacuum loss should be less than 1.0

inch Hg in one minute time span. If the loss is more

than 1.0 inch Hg, replace the power brake booster. If

it is not, continue on with this test.

(5) Remove the pliers from the hose temporarily.

(6) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.

Do not move the pedal once the pressure is applied

or the test results may vary.

(7) Have an assistant reattach the vacuum line

pliers to the vacuum supply hose.

(8) Allow 5 seconds for stabilization, then observe

the vacuum gauge.

If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective.

(9) Remove the pliers and vacuum gauge.

REMOVAL

REMOVAL - LHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove negative battery cable terminal from

battery.

(3) Remove positive battery cable terminal from

battery.

(4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray.

(6) Remove screw securing engine coolant filler

tube to battery tray.

(7) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray.

(8) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray.

(9) If vehicle is equipped with speed control:(a) Disconnect wiring harness connector from

the speed control servo.

(b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(10) Remove the wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL)

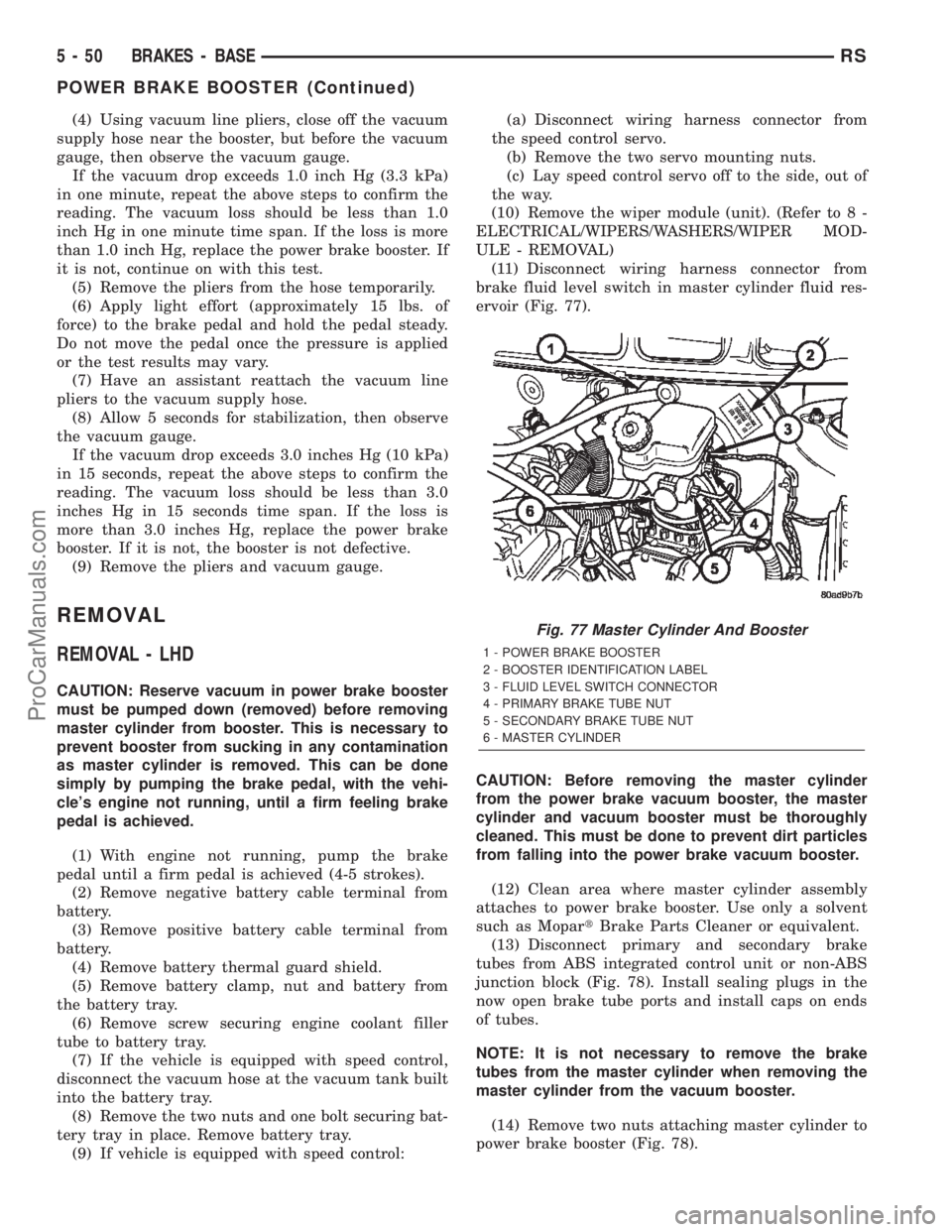

(11) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 77).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(12) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.

(13) Disconnect primary and secondary brake

tubes from ABS integrated control unit or non-ABS

junction block (Fig. 78). Install sealing plugs in the

now open brake tube ports and install caps on ends

of tubes.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(14) Remove two nuts attaching master cylinder to

power brake booster (Fig. 78).

Fig. 77 Master Cylinder And Booster

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

5 - 50 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 184 of 2399

(12) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 77).

(13) Connect primary and secondary brake tubes

to ABS ICU or non-ABS junction block (Fig. 78).

Tighten the tube nuts to 17 N´m (145 in lbs.).

(14) Install wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION)

(15) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(16) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(17) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(18) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing. Securely tighten hose clamp at air cleaner hous-

ing and throttle body.

(19) Secure the engine coolant filler neck to the

battery tray with its mounting screw.

(20) Install the battery, clamp and mounting nut.

(21) Install the positive battery cable on the bat-

tery.

(22) Install the negative battery cable on the bat-

tery.

(23) Install the battery thermal guard shield.

(24) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(25) Road test vehicle to ensure operation of the

brakes.

INSTALLATION - RHD

(1) Position power brake booster on dash panel

using the reverse procedure of its removal (Fig. 86).

(2) Below instrument panel, first install the two

upper nuts mounting the booster to the dash panel,

drawing it into place, then install the two lower

mounting nuts. Tighten the mounting nuts to a

torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod.

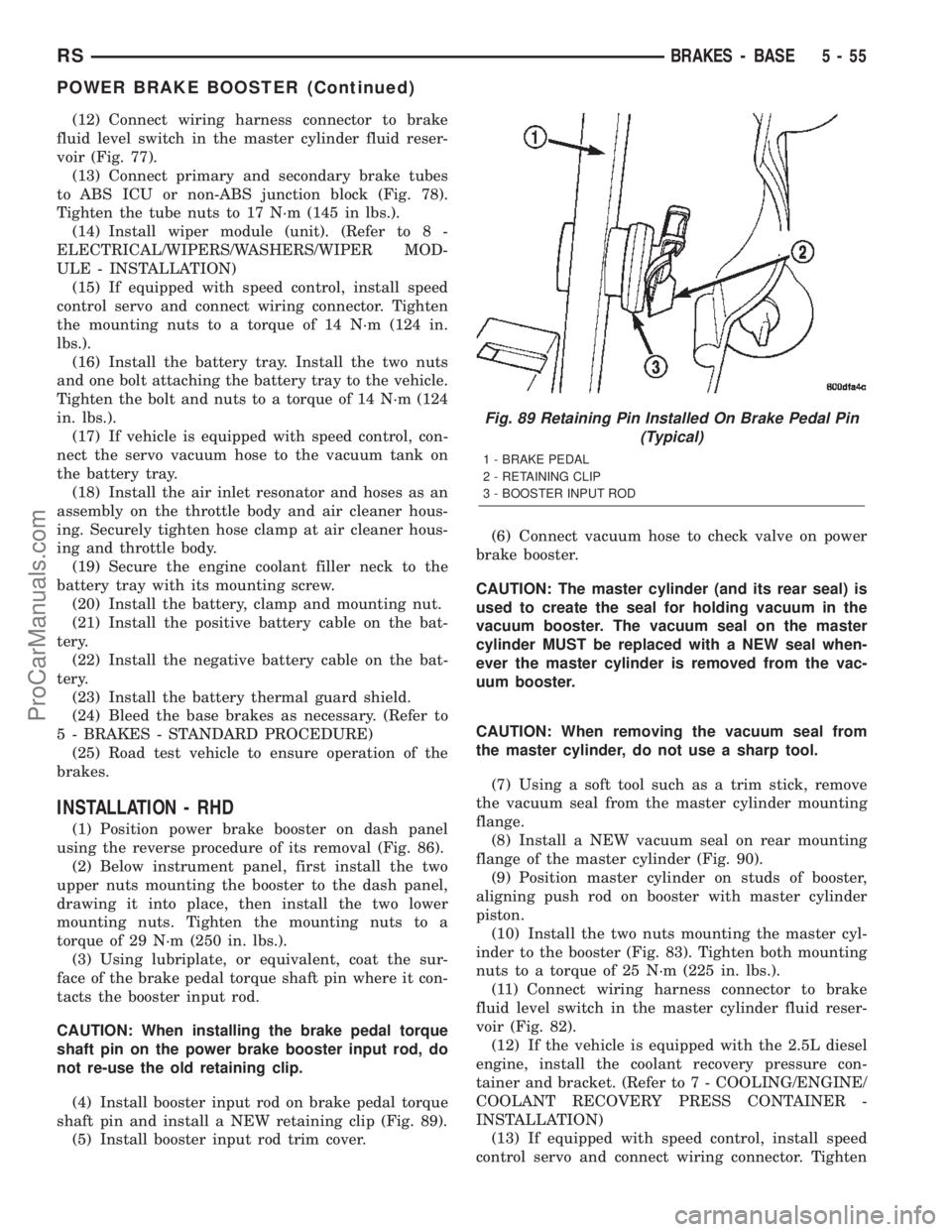

CAUTION: When installing the brake pedal torque

shaft pin on the power brake booster input rod, do

not re-use the old retaining clip.

(4) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 89).

(5) Install booster input rod trim cover.(6) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder, do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(8) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 90).

(9) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(10) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 83). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(11) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 82).

(12) If the vehicle is equipped with the 2.5L diesel

engine, install the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

INSTALLATION)

(13) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

Fig. 89 Retaining Pin Installed On Brake Pedal Pin

(Typical)

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

RSBRAKES - BASE5-55

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 345 of 2399

²Back-Up switch

²Brake Fluid Level

²B+ Connection Detection

²Engine Crank Signal (Diesel Engine Vehicles)

²Horn Input

²Ignition Switch Start Only

²Ignition Switch Run and Start Only

²Stop Lamp Sense

²Washer Fluid Level

²Windshield Wiper Park

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The Front Control Module (FCM) is a printed cir-

cuit board based module with a on-board micro-pro-

cessor. The FCM interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus. In order to

obtain conclusive testing the PCI data bus and all of

the electronic modules that provide inputs to, or

receive outputs from the FCM must be checked. All

PCI communication faults must be resolved prior to

further diagnosing any front control module related

issues.

The FCM was designed to be diagnosed with an

appropriate diagnostic scan tool, such as the DRB

IIIt. The most reliable, efficient, and accurate means

to diagnose the front control module requires the use

of a DRB IIItscan tool and the proper Body Diag-

nostic Procedures manual.

Before any testing of the FCM is attempted, the

battery should be fully charged and all wire harness

and ground connections inspected around the affected

areas on the vehicle.

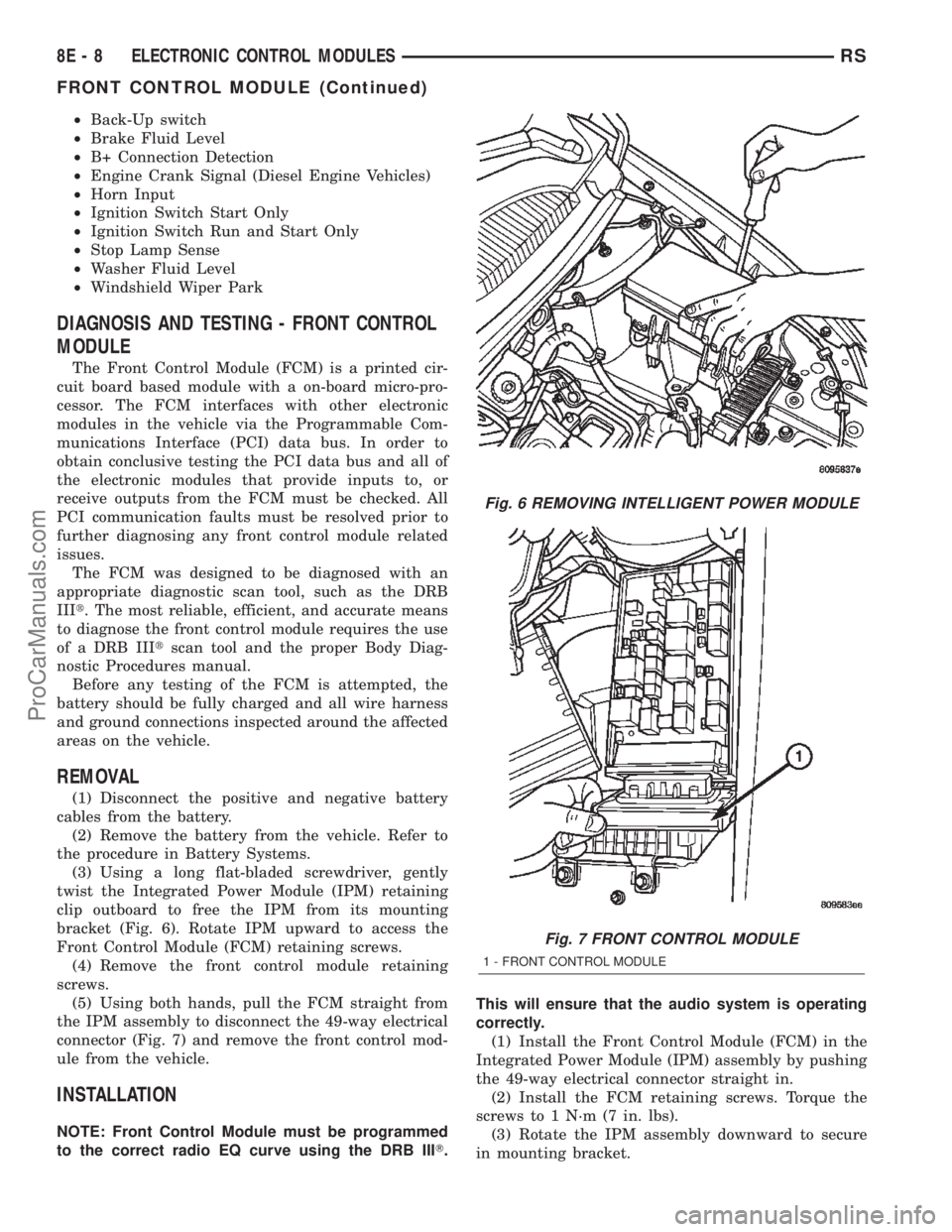

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Remove the battery from the vehicle. Refer to

the procedure in Battery Systems.

(3) Using a long flat-bladed screwdriver, gently

twist the Integrated Power Module (IPM) retaining

clip outboard to free the IPM from its mounting

bracket (Fig. 6). Rotate IPM upward to access the

Front Control Module (FCM) retaining screws.

(4) Remove the front control module retaining

screws.

(5) Using both hands, pull the FCM straight from

the IPM assembly to disconnect the 49-way electrical

connector (Fig. 7) and remove the front control mod-

ule from the vehicle.

INSTALLATION

NOTE: Front Control Module must be programmed

to the correct radio EQ curve using the DRB IIIT.This will ensure that the audio system is operating

correctly.

(1) Install the Front Control Module (FCM) in the

Integrated Power Module (IPM) assembly by pushing

the 49-way electrical connector straight in.

(2) Install the FCM retaining screws. Torque the

screws to 1 N´m (7 in. lbs).

(3) Rotate the IPM assembly downward to secure

in mounting bracket.

Fig. 6 REMOVING INTELLIGENT POWER MODULE

Fig. 7 FRONT CONTROL MODULE

1 - FRONT CONTROL MODULE

8E - 8 ELECTRONIC CONTROL MODULESRS

FRONT CONTROL MODULE (Continued)

ProCarManuals.com

Page 638 of 2399

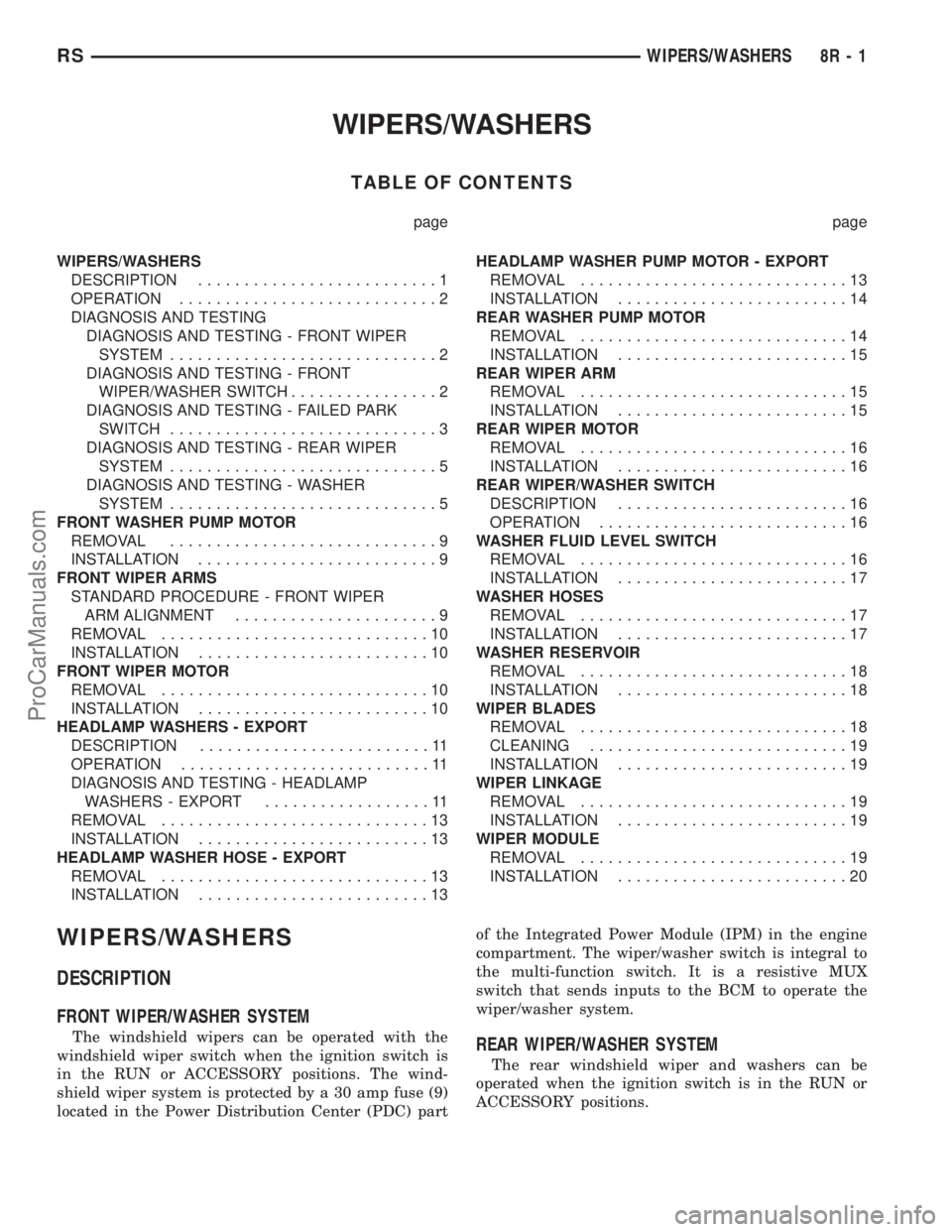

WIPERS/WASHERS

TABLE OF CONTENTS

page page

WIPERS/WASHERS

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT WIPER

SYSTEM.............................2

DIAGNOSIS AND TESTING - FRONT

WIPER/WASHER SWITCH................2

DIAGNOSIS AND TESTING - FAILED PARK

SWITCH.............................3

DIAGNOSIS AND TESTING - REAR WIPER

SYSTEM.............................5

DIAGNOSIS AND TESTING - WASHER

SYSTEM.............................5

FRONT WASHER PUMP MOTOR

REMOVAL.............................9

INSTALLATION..........................9

FRONT WIPER ARMS

STANDARD PROCEDURE - FRONT WIPER

ARM ALIGNMENT......................9

REMOVAL.............................10

INSTALLATION.........................10

FRONT WIPER MOTOR

REMOVAL.............................10

INSTALLATION.........................10

HEADLAMP WASHERS - EXPORT

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - HEADLAMP

WASHERS - EXPORT..................11

REMOVAL.............................13

INSTALLATION.........................13

HEADLAMP WASHER HOSE - EXPORT

REMOVAL.............................13

INSTALLATION.........................13HEADLAMP WASHER PUMP MOTOR - EXPORT

REMOVAL.............................13

INSTALLATION.........................14

REAR WASHER PUMP MOTOR

REMOVAL.............................14

INSTALLATION.........................15

REAR WIPER ARM

REMOVAL.............................15

INSTALLATION.........................15

REAR WIPER MOTOR

REMOVAL.............................16

INSTALLATION.........................16

REAR WIPER/WASHER SWITCH

DESCRIPTION.........................16

OPERATION...........................16

WASHER FLUID LEVEL SWITCH

REMOVAL.............................16

INSTALLATION.........................17

WASHER HOSES

REMOVAL.............................17

INSTALLATION.........................17

WASHER RESERVOIR

REMOVAL.............................18

INSTALLATION.........................18

WIPER BLADES

REMOVAL.............................18

CLEANING............................19

INSTALLATION.........................19

WIPER LINKAGE

REMOVAL.............................19

INSTALLATION.........................19

WIPER MODULE

REMOVAL.............................19

INSTALLATION.........................20

WIPERS/WASHERS

DESCRIPTION

FRONT WIPER/WASHER SYSTEM

The windshield wipers can be operated with the

windshield wiper switch when the ignition switch is

in the RUN or ACCESSORY positions. The wind-

shield wiper system is protected by a 30 amp fuse (9)

located in the Power Distribution Center (PDC) partof the Integrated Power Module (IPM) in the engine

compartment. The wiper/washer switch is integral to

the multi-function switch. It is a resistive MUX

switch that sends inputs to the BCM to operate the

wiper/washer system.REAR WIPER/WASHER SYSTEM

The rear windshield wiper and washers can be

operated when the ignition switch is in the RUN or

ACCESSORY positions.

RSWIPERS/WASHERS8R-1

ProCarManuals.com

Page 643 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

WASHER SYSTEM WILL

NOT FLOW WASHER

FLUID.1. NO WASHER FLUID IN

RESERVOIR.1. FILL WASHER RESERVOIR.

2. IPM FUSE #33 BLOWN. 2. SHORT OR DEFECTIVE CIRCUIT

BETWEEN IPM PIN 11 AND WASHER

PUMP MOTOR CONNECTOR POSITIVE

TERMINAL 2. INTERNAL SHORT IN IPM. IF

NOT OK, REPAIR CIRCUIT OR REFER TO

IPM DIAGNOSTIC PROCEDURES IN

WIRING DIAGRAMS.

3. WASHER HOSE NOT

FLOWING WASHER FLUID.3. ASSURE WASHER HOSE IS NOT

PINCHED, LOOSE, BROKEN OR

DISCONNECTED. IF NOT OK, PROPERLY

ROUTE OR REPAIR WASHER HOSE.

4. MOTOR CONNECTOR

LOOSE.4. PROPERLY SEAT AND LOCK

CONNECTOR TO MOTOR.

5. MOTOR CONNECTOR

TERMINALS BENT.5. REPAIR TERMINALS AND PROPERLY

SEAT CONNECTOR TO MOTOR.

6. OPEN CIRCUIT TO OR

FROM WASHER SELECT

SWITCH.6. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM BODY CONTROLLER PIN

27 AND WASHER SELECT SWITCH PIN 4,

OR OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM BODY CONTROLLER PIN

22 AND WASHER SELECT SWITCH PIN 2.

IF NOT OK, REPAIR CIRCUIT.

7. OPEN OR DEFECTIVE

WASHER SELECT SWITCH.7. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/MULTI-FUNCTION

SWITCH - DIAGNOSIS AND TESTING).

8. OPEN POWER CIRCUIT TO

MOTOR.8. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM CONNECTOR TERMINAL 11

AND WASHER MOTOR CONNECTOR

POSITIVE TERMINAL 2. INTERNAL OPEN

IN IPM. IF NOT OK, REPAIR CIRCUIT OR

REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

9. OPEN OR DEFECTIVE

MOTOR GROUND CIRCUIT.9. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM CONNECTOR TERMINAL

20 AND WASHER MOTOR CONNECTOR

NEGATIVE TERMINAL 1. INTERNAL OPEN

IN IPM. IF NOT OK, REPAIR CIRCUIT OR

REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

10. OPEN CIRCUIT IN MOTOR. 10. CHECK FOR OPEN CIRCUIT IN MOTOR

BETWEEN POSITIVE TERMINAL 2 AND

NEGATIVE TERMINAL 1. IF NOT OK,

REPLACE WASHER MOTOR.

11. SEIZED MOTOR BEARINGS. 11. APPLY DIRECT BATTERY VOLTAGE TO

MOTOR TERMINALS. IF MOTOR DOES

NOT RUN, REPLACE MOTOR.

8R - 6 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 644 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

COWL GRILLE NOZZLE

WILL NOT FLOW.1. FROZEN NOZZLE. 1. MOVE VEHICLE INTO HEATED AREA TO

ALLOW TIME TO THAW NOZZLE. ASSURE

WASHER FLUID IS PROPERLY BLENDED

FOR AMBIENT OUTSIDE TEMPERATURES.

2. NOZZLE HOSE NOT

FLOWING.2. ASSURE NOZZLE HOSE IS NOT

PINCHED, LOOSE, BROKEN, OR

DISCONNECTED. IF NOT OK, PROPERLY

ROUTE OR REPAIR NOZZLE HOSE.

3. NOZZLE HOSE PLUGGED

BY CONTAMINATION.3. CLEAN NOZZLE HOSE OF

CONTAMINATION. DETERMINE SOURCE

OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

4. NOZZLE PLUGGED BY

CONTAMINATION.4. CLEAN NOZZLE OF CONTAMINATION

OR REPLACE NOZZLE. DETERMINE

SOURCE OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

5. DEFECTIVE WASHER HOSE

CHECK VALVE.5. REPLACE COWL GRILLE PANEL

WASHER HOSE/CHECK VALVE ASSEMBLY.

WASHER FLUID OUTPUT IS

LOW.1. PARTIALLY PINCHED HOSE. 1. ASSURE WASHER HOSE IS NOT

PARTIALLY PINCHED. IF NOT OK,

PROPERLY ROUTE HOSE.

2. REVERSE POLARITY TO

PUMP.2. CHECK FOR CROSSED CIRCUIT TO

PUMP. IF NOT OK, REPAIR CIRCUIT.

3. WORN OUT WASHER PUMP. 3. REPLACE WASHER PUMP.

COWL GRILLE NOZZLE

STREAM OVERSHOOTS

WINDSHIELD.1. NOZZLE NOT SEATED IN

COWL GRILLE.1. ASSURE NOZZLE IS SNAPPED IN

PLACE.

2. NOZZLE JET(S) OUT OF

ADJUSTMENT.2. ADJUST NOZZLE JET(S) USING A

SAFETY PIN.

WIPER WILL NOT CYCLE

WHEN WASHER SELECT

SWITCH IS DEPRESSED.1. DEFECTIVE IPM. 1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. DEFECTIVE IPM/BODY

CONTROLLER.2. REFER TO IPM/BODY CONTROLLER

DIAGNOSTIC PROCEDURES IN WIRING

DIAGRAMS.

WASHER OPERATES

INTERMITTENTLY.1. INTERMITTENT MOTOR

GROUND.INTERMITTENT GROUND BETWEEN

MOTOR CONNECTOR TERMINAL 1 AND

IPM PIN 20.

2. INTERMITTENT OPEN IN

WASHER SELECT SWITCH.2. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/MULTI-FUNCTION

SWITCH - DIAGNOSIS AND TESTING).

3. DEFECTIVE WASHER

MOTOR.3. REPLACE WASHER MOTOR.

RSWIPERS/WASHERS8R-7

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 645 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

LOW WASHER FLUID

LEVEL INDICATOR

INOPERATIVE.1. LOOSE FLUID LEVEL

SENSOR CONNECTOR.1. PROPERLY SEAT CONNECTOR TO LOW

FLUID LEVEL SENSOR AND LOCK.

2. OPEN POWER CIRCUIT TO

FLUID LEVEL SENSOR.2. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM CONNECTOR TERMINAL 7

AND THE LOW FLUID LEVEL SENSOR

CONNECTOR TERMINAL 2. IF NOT OK,

REPAIR CIRCUIT.

3. OPEN GROUND CIRCUIT. 3. OPEN OR DEFECTIVE CIRCUIT

BETWEEN FLUID LEVEL SENSOR

CONNECTOR TERMINAL 1 AND FLOOR

GROUND 1.

4. DEFECTIVE IPM. 4. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

5. FLUID LEVEL SENSOR

SWITCH OPEN OR

DEFECTIVE.5. APPLY OHMMETER TO THE SWITCH

TERMINALS TO CHECK FOR COMPLETE

CIRCUIT. CYCLE SWITCH FLOAT BACK

AND FORTH BY FILLING AND DEPLETING

RESERVOIR OF WASHER FLUID TO

CHECK FOR PROPER SWITCH FUNCTION.

IF NOT OK, REPLACE LOW FLUID LEVEL

SENSOR SWITCH.

LEAKING WASHER FLUID. 1. PUMP OR SENSOR

GROMMET DEFECTIVE.1. PROPERLY SEAT PUMP OR SENSOR IN

GROMMET. IF NOT OK, REPLACE PUMP

OR SENSOR GROMMET.

2. LEAKING WASHER PUMP. 2. REPLACE WASHER PUMP.

3. LEAKING FLUID LEVEL

SENSOR.3. REPLACE FLUID LEVEL SENSOR.

4. LEAKING OR DEFECTIVE

RESERVOIR BODY.4. REPLACE RESERVOIR BODY.

8R - 8 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 646 of 2399

FRONT WASHER PUMP

MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the washer hose at the in-line con-

nector forward of the cowl grille so that the in-line

connector remains with the washer hose from the

fresh air plenum.

(4) Disconnect the washer hose from the hose clip

located on the front fender side shield.

(5) Remove the filler tube screw.

(6) Hoist and support vehicle on hoist or jack

stands.

(7) Remove the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - REMOVAL).

(8) Disconnect the left right front wheelhouse

splash shield and move aside (Refer to 23 - BODY/

EXTERIOR/WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(9) Drain washer fluid from the reservoir and into

a suitable clean container. This can be done by dis-

connecting the windshield washer hose from the

front (outboard) washer pump and allowing the

washer fluid to drain into a container through a tem-

porary jumper hose connected to the front washer

pump.

(10) Disconnect the electrical body harness connec-

tors to the washer pump motors and the fluid level

sensor. Slide the red lock on the connector to the

release position, then, depress the black tab and pull

the connector off the pump or sensor.

(11) Remove the two reservoir mounting screws.

(12) Disconnect the reservoir from the body mount

by raising the reservoir upward slightly and then

down so that the reservoir filler neck and front

washer hose pull through the opening in the front

fender side shield.

(13) Remove pump from reservoir by pulling pump

upper retention tab away from reservoir cavity and

then lifting pump up from mounting grommet. Do

not damage reservoir/pump sealing surface or punc-

ture reservoir during removal.

(14) Remove pump grommet and discard.

INSTALLATION

(1) Use new grommet when installing a new pump

assembly.

(2) Assure pump upper retention tab is pressed

into reservoir slot and that pump is rotated flatagainst the reservoir and that pump connector is fac-

ing up in the fully seated position. Assure the pump

is aligned to and fully seated in the reservoir cavity.

(3) Push filler neck and front washer hose through

the opening in the front fender side shield. Connect

the reservoir to the body mount by lowering the res-

ervoir down.

(4) Install the two reservoir mounting screws.

Torque screws to 8.5 - 11.3 N´m (75 - 100 in. lbs.).

(5) Connect the electrical body harness connectors

to the washer pump motors and the fluid level sen-

sor. Slide the red lock on the connector to the closed

or locked position.

(6) Assure that washer hose is properly routed to

prevent pinching and possible inoperative washers.

(7) Connect the left right front wheelhouse splash

shield and move aside (Refer to 23 - BODY/EXTERI-

OR/WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(8) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(9) lower vehicle from hoist or jack stands.

(10) Install the filler tube screw. Torque screw to

8.5 - 11.3 N´m (75 - 100 in. lbs.).

(11) Connect the washer hose to the hose clip

located on the front fender side shield.

(12) Connect the washer hose at the in-line con-

nector forward of the cowl grille.

(13) Install the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(14) Connect the battery negative cable.

(15) Verify system operation.

FRONT WIPER ARMS

STANDARD PROCEDURE - FRONT WIPER ARM

ALIGNMENT

(1) Verify wiper blade element condition and wiper

arm spring tension. Run wipers in low speed mode

while applying water to the windshield. Observe the

wiper blade that is chattering or skipping across the

windshield. If the wiper element is not rolling over

when the wiper direction reverses, align the wiper

arm. The extension bar portion of the wiper arm

must be twisted in the proper direction to allow the

wiper element to roll over when the direction

reverses.

(2) Place two small adjustable wrenches placed 50

mm (2 in.) apart on the wiper arm extension rod.

(3) Twist the extension rod slightly in the opposite

direction that the element is laying on the wind-

shield while holding the wrench closest to the pivot

stationary.

RSWIPERS/WASHERS8R-9

ProCarManuals.com

Page 648 of 2399

HEADLAMP WASHERS -

EXPORT

DESCRIPTION

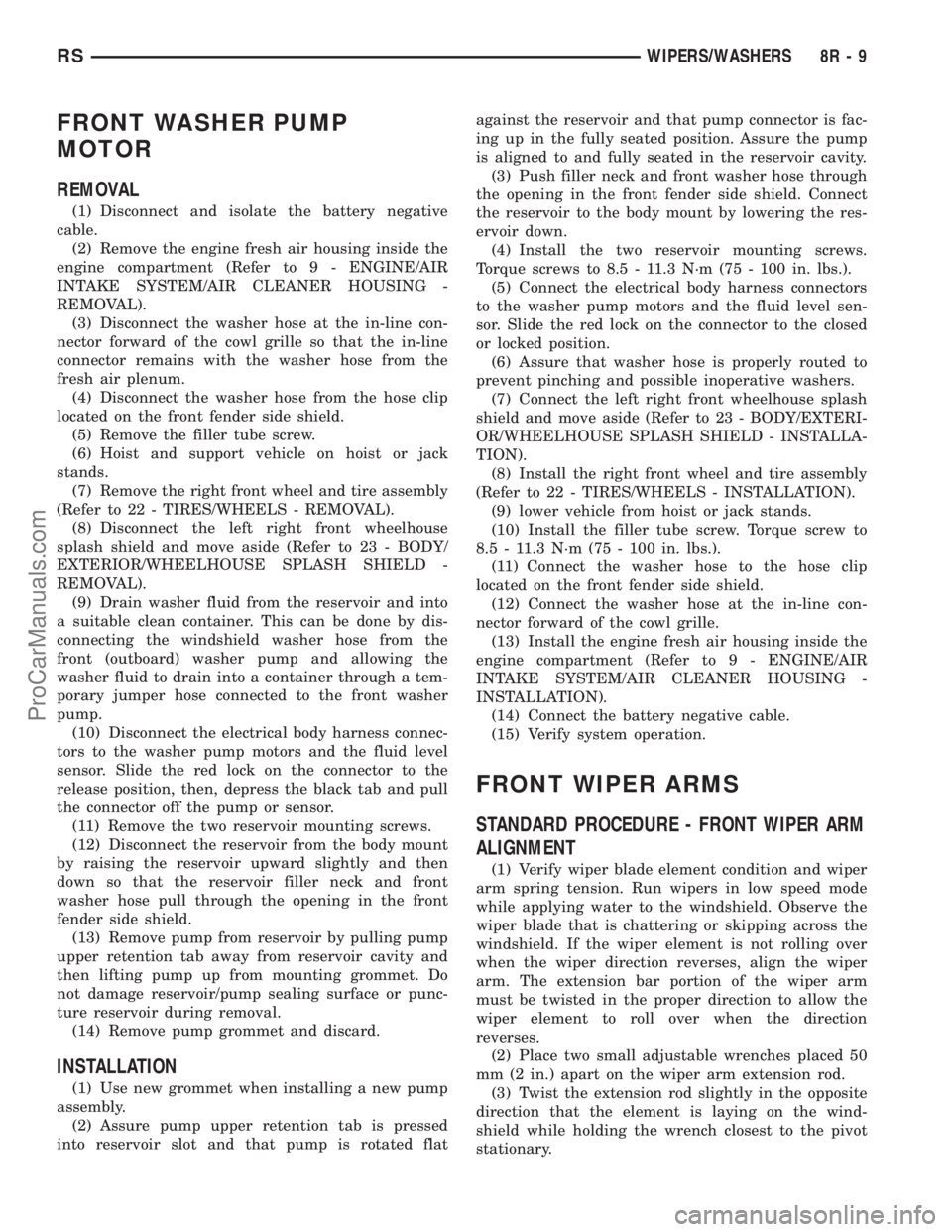

The headlamp washers (Fig. 3) work in conjunction

with the windshield washers. The headlamp washers

are enabled with the headlamps ON and the wind-

shield washers activated. With the windshield wash-

ers activated, the headlamp washers will spray twice

for a predetermined amount of time.

OPERATION

The headlamp washer system utilizes a separate

high pressure pump that is attached to the wind-

shield washer reservoir. The headlamp washer pump

feeds nozzles that are mounted in the front fascia of

the vehicle. The nozzle bodies have a telescopic

action that will extend the nozzles in front of the

headlamp assembly. These nozzles spray the head-

lamps when the system is activated.

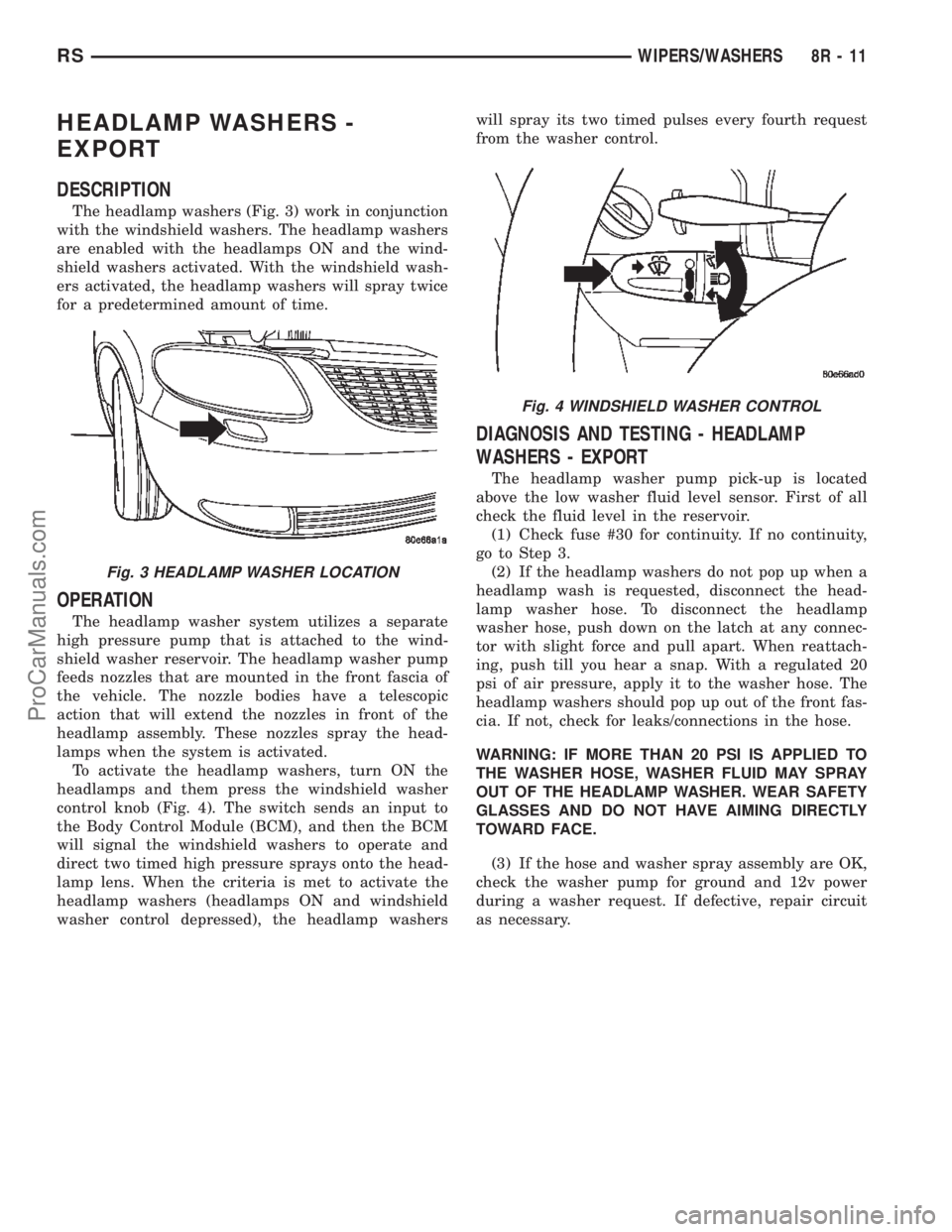

To activate the headlamp washers, turn ON the

headlamps and them press the windshield washer

control knob (Fig. 4). The switch sends an input to

the Body Control Module (BCM), and then the BCM

will signal the windshield washers to operate and

direct two timed high pressure sprays onto the head-

lamp lens. When the criteria is met to activate the

headlamp washers (headlamps ON and windshield

washer control depressed), the headlamp washerswill spray its two timed pulses every fourth request

from the washer control.

DIAGNOSIS AND TESTING - HEADLAMP

WASHERS - EXPORT

The headlamp washer pump pick-up is located

above the low washer fluid level sensor. First of all

check the fluid level in the reservoir.

(1) Check fuse #30 for continuity. If no continuity,

go to Step 3.

(2) If the headlamp washers do not pop up when a

headlamp wash is requested, disconnect the head-

lamp washer hose. To disconnect the headlamp

washer hose, push down on the latch at any connec-

tor with slight force and pull apart. When reattach-

ing, push till you hear a snap. With a regulated 20

psi of air pressure, apply it to the washer hose. The

headlamp washers should pop up out of the front fas-

cia. If not, check for leaks/connections in the hose.

WARNING: IF MORE THAN 20 PSI IS APPLIED TO

THE WASHER HOSE, WASHER FLUID MAY SPRAY

OUT OF THE HEADLAMP WASHER. WEAR SAFETY

GLASSES AND DO NOT HAVE AIMING DIRECTLY

TOWARD FACE.

(3) If the hose and washer spray assembly are OK,

check the washer pump for ground and 12v power

during a washer request. If defective, repair circuit

as necessary.

Fig. 3 HEADLAMP WASHER LOCATION

Fig. 4 WINDSHIELD WASHER CONTROL

RSWIPERS/WASHERS8R-11

ProCarManuals.com

Page 649 of 2399

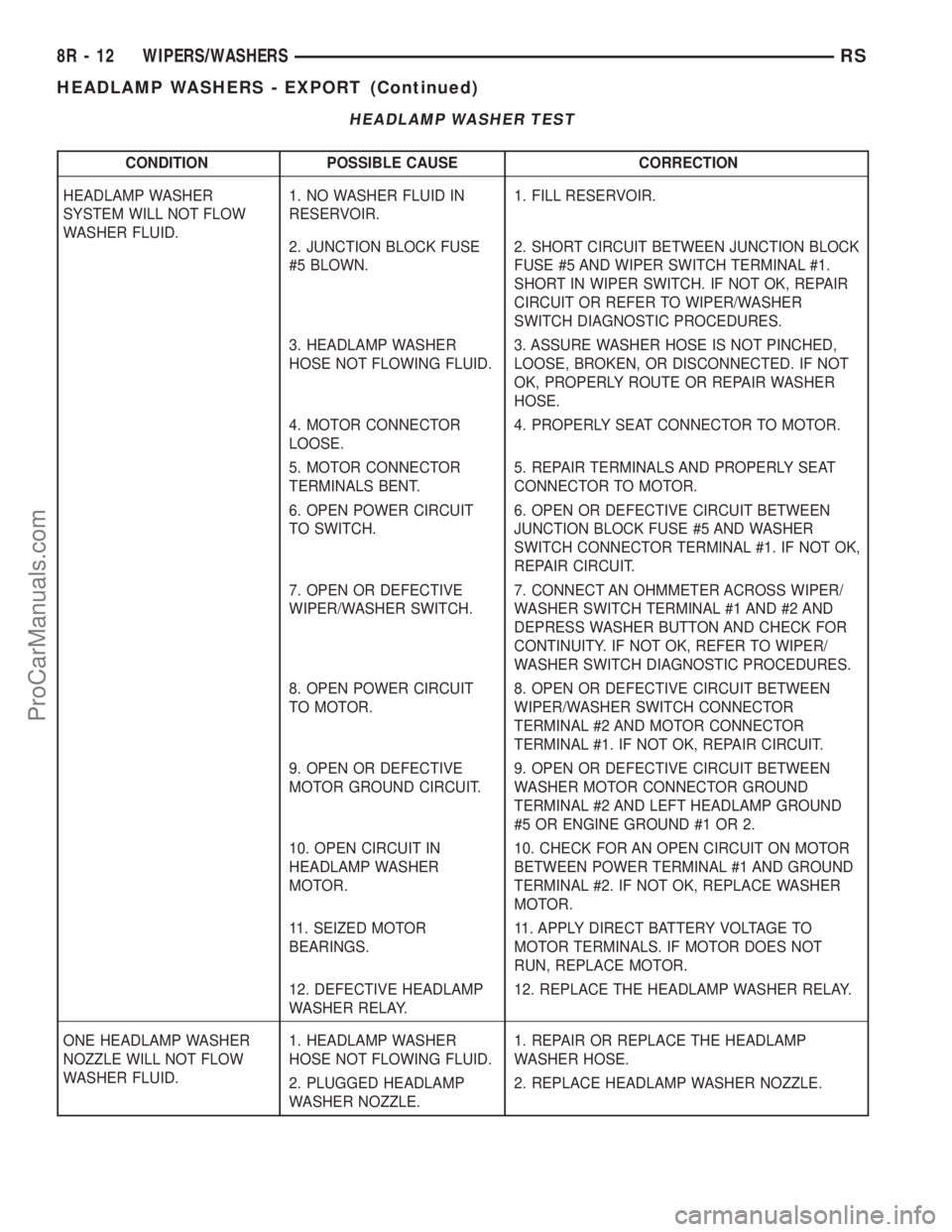

HEADLAMP WASHER TEST

CONDITION POSSIBLE CAUSE CORRECTION

HEADLAMP WASHER

SYSTEM WILL NOT FLOW

WASHER FLUID.1. NO WASHER FLUID IN

RESERVOIR.1. FILL RESERVOIR.

2. JUNCTION BLOCK FUSE

#5 BLOWN.2. SHORT CIRCUIT BETWEEN JUNCTION BLOCK

FUSE #5 AND WIPER SWITCH TERMINAL #1.

SHORT IN WIPER SWITCH. IF NOT OK, REPAIR

CIRCUIT OR REFER TO WIPER/WASHER

SWITCH DIAGNOSTIC PROCEDURES.

3. HEADLAMP WASHER

HOSE NOT FLOWING FLUID.3. ASSURE WASHER HOSE IS NOT PINCHED,

LOOSE, BROKEN, OR DISCONNECTED. IF NOT

OK, PROPERLY ROUTE OR REPAIR WASHER

HOSE.

4. MOTOR CONNECTOR

LOOSE.4. PROPERLY SEAT CONNECTOR TO MOTOR.

5. MOTOR CONNECTOR

TERMINALS BENT.5. REPAIR TERMINALS AND PROPERLY SEAT

CONNECTOR TO MOTOR.

6. OPEN POWER CIRCUIT

TO SWITCH.6. OPEN OR DEFECTIVE CIRCUIT BETWEEN

JUNCTION BLOCK FUSE #5 AND WASHER

SWITCH CONNECTOR TERMINAL #1. IF NOT OK,

REPAIR CIRCUIT.

7. OPEN OR DEFECTIVE

WIPER/WASHER SWITCH.7. CONNECT AN OHMMETER ACROSS WIPER/

WASHER SWITCH TERMINAL #1 AND #2 AND

DEPRESS WASHER BUTTON AND CHECK FOR

CONTINUITY. IF NOT OK, REFER TO WIPER/

WASHER SWITCH DIAGNOSTIC PROCEDURES.

8. OPEN POWER CIRCUIT

TO MOTOR.8. OPEN OR DEFECTIVE CIRCUIT BETWEEN

WIPER/WASHER SWITCH CONNECTOR

TERMINAL #2 AND MOTOR CONNECTOR

TERMINAL #1. IF NOT OK, REPAIR CIRCUIT.

9. OPEN OR DEFECTIVE

MOTOR GROUND CIRCUIT.9. OPEN OR DEFECTIVE CIRCUIT BETWEEN

WASHER MOTOR CONNECTOR GROUND

TERMINAL #2 AND LEFT HEADLAMP GROUND

#5 OR ENGINE GROUND #1 OR 2.

10. OPEN CIRCUIT IN

HEADLAMP WASHER

MOTOR.10. CHECK FOR AN OPEN CIRCUIT ON MOTOR

BETWEEN POWER TERMINAL #1 AND GROUND

TERMINAL #2. IF NOT OK, REPLACE WASHER

MOTOR.

11. SEIZED MOTOR

BEARINGS.11. APPLY DIRECT BATTERY VOLTAGE TO

MOTOR TERMINALS. IF MOTOR DOES NOT

RUN, REPLACE MOTOR.

12. DEFECTIVE HEADLAMP

WASHER RELAY.12. REPLACE THE HEADLAMP WASHER RELAY.

ONE HEADLAMP WASHER

NOZZLE WILL NOT FLOW

WASHER FLUID.1. HEADLAMP WASHER

HOSE NOT FLOWING FLUID.1. REPAIR OR REPLACE THE HEADLAMP

WASHER HOSE.

2. PLUGGED HEADLAMP

WASHER NOZZLE.2. REPLACE HEADLAMP WASHER NOZZLE.

8R - 12 WIPERS/WASHERSRS

HEADLAMP WASHERS - EXPORT (Continued)

ProCarManuals.com