air filter CHRYSLER VOYAGER 2003 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 36 of 2177

Kilometers 149 000 154 000 158 000 160 000 163 000 168 000

(Miles) (93,000) (96,000) (99,000) (100,000) (102,000) (105,000)

Change engine oil and engine

oil filter.XXX X X

Inspect the brake linings. X

Inspect the engine air cleaner

filter, replace if necessary. *X XXX X

Replace theengine air

cleaner filter*X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.X

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Inspect engine accessory

drive belts on 3.3 liter

engines, replace if necessary.

³X

Change the automatic

transmission fluid and fliter.X

Change the manual

transmission fluid.X

Change the All Wheel Drive

(AWD) power transfer unit,

overrunning clutch and rear

carrier fluid. (See note at the

end of this chart)X

Flush and replace the engine

coolant at 60 months or

100,000 miles.X

Replace the air conditioning

filter.X

RSMAINTENANCE SCHEDULES0a-5

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 37 of 2177

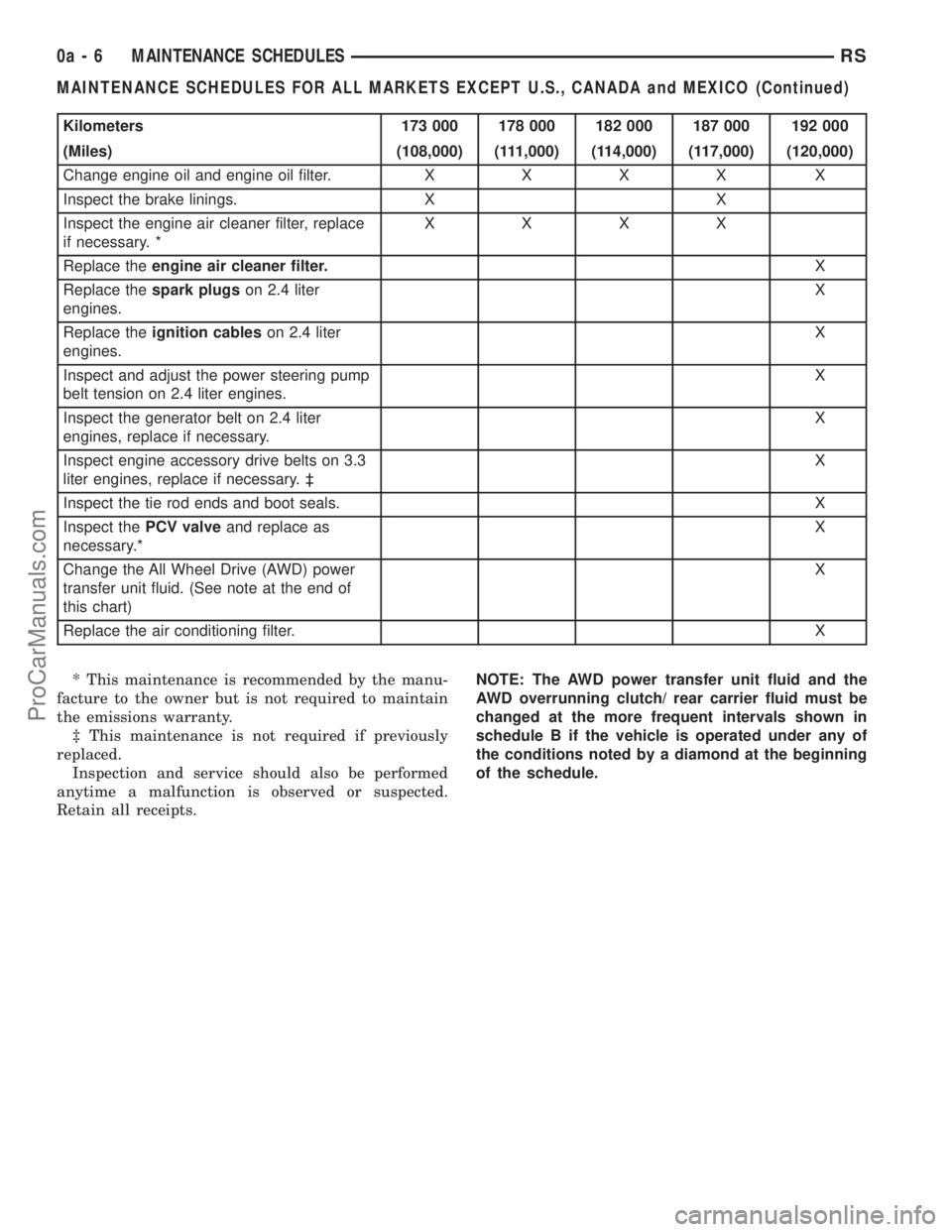

Kilometers 173 000 178 000 182 000 187 000 192 000

(Miles) (108,000) (111,000) (114,000) (117,000) (120,000)

Change engine oil and engine oil filter.XXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX

Replace theengine air cleaner filter.X

Replace thespark plugson 2.4 liter

engines.X

Replace theignition cableson 2.4 liter

engines.X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect engine accessory drive belts on 3.3

liter engines, replace if necessary. ³X

Inspect the tie rod ends and boot seals. X

Inspect thePCV valveand replace as

necessary.*X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Replace the air conditioning filter.X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.NOTE: The AWD power transfer unit fluid and the

AWD overrunning clutch/ rear carrier fluid must be

changed at the more frequent intervals shown in

schedule B if the vehicle is operated under any of

the conditions noted by a diamond at the beginning

of the schedule.

0a - 6 MAINTENANCE SCHEDULESRS

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 38 of 2177

![CHRYSLER VOYAGER 2003 User Guide SCHEDULE ªAº

Kilometers 12 000 24 000 36 000 48 000 60 000 72 000

(Miles) (7,500) (15,000) (22,500 (30,000) (37,500) (45,000)

[Months] [6] [12] [18] [24] [30] [36]

Change engine oil and engine oil

f CHRYSLER VOYAGER 2003 User Guide SCHEDULE ªAº

Kilometers 12 000 24 000 36 000 48 000 60 000 72 000

(Miles) (7,500) (15,000) (22,500 (30,000) (37,500) (45,000)

[Months] [6] [12] [18] [24] [30] [36]

Change engine oil and engine oil

f](/img/25/56869/w960_56869-37.png)

SCHEDULE ªAº

Kilometers 12 000 24 000 36 000 48 000 60 000 72 000

(Miles) (7,500) (15,000) (22,500 (30,000) (37,500) (45,000)

[Months] [6] [12] [18] [24] [30] [36]

Change engine oil and engine oil

filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter,

replace if necessary. *XXX X X

Replace theengine air cleaner

filter.X

Replace thespark plugson 2.4 liter

engines.X

Inspect the tie rod ends and boot

seals.X

Replace the air conditioning filter. X X X

Kilometers 84 000 96 000 108 000 120 000 132 000 144 000

(Miles) (52,500) (60,000) (67,500) (75,000) (82,500) (90,000)

[Months] [42] [48] [54] [60] [66] [72]

Change engine oil and engine oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter,

replace if necessary. *X XXX

Replace theengine air cleaner filter.XX

Replace thespark plugson 2.4 liter

engines.XX

Replace theignition cableson 2.4 liter

engines.X

Inspect and adjust the power steering

pump belt tension on 2.4 liter engines.XX

Inspect the tie rod ends and boot seals. X X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.XX

Check thePCV valveand replace, if

necessary.*XX

Inspect the serpentine drive belt on 3.3

liter engines, replace if necessary. ³XX X

Flush and replace the engine coolant at

60 months, regardless of mileage.X

Replace the air conditioning filter. X X X

RSMAINTENANCE SCHEDULES0a-7

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 39 of 2177

![CHRYSLER VOYAGER 2003 User Guide Kilometers 156 000 160 000 168 000 180 000 192 000

(Miles) (97,500) (100,000) (105,000) (112,500) (120,000)

[Months] [78] [84] [90] [96]

Change engine oil and engine oil filter. X X X X

Inspect the br CHRYSLER VOYAGER 2003 User Guide Kilometers 156 000 160 000 168 000 180 000 192 000

(Miles) (97,500) (100,000) (105,000) (112,500) (120,000)

[Months] [78] [84] [90] [96]

Change engine oil and engine oil filter. X X X X

Inspect the br](/img/25/56869/w960_56869-38.png)

Kilometers 156 000 160 000 168 000 180 000 192 000

(Miles) (97,500) (100,000) (105,000) (112,500) (120,000)

[Months] [78] [84] [90] [96]

Change engine oil and engine oil filter. X X X X

Inspect the brake linings. X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX

Replace theengine air cleaner filter.X

Replace thespark plugson 2.4 liter

engines.X

Replace theignition cableson 2.4 liter

engines.X

Inspect the tie rod ends and boot seals. X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.XX

Inspect the generator belt on 2.4 liter

engines, replace if necessary.XX

Check and replace thePCV valve,if

necessary.*X

Inspect the serpentine drive belt on 3.3 liter

engines, replace if necessary. ³XX

Replace thespark plugs3.3 liter engines. X

Replace theignition cables3.3 liter

engines.X

Flush and replace the engine coolant at

100,000 miles, if not done at 60 months.X

Replace theengine timing belton 2.4 liter

engines only.X

Replace the air conditioning filter. X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

0a - 8 MAINTENANCE SCHEDULESRS

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 41 of 2177

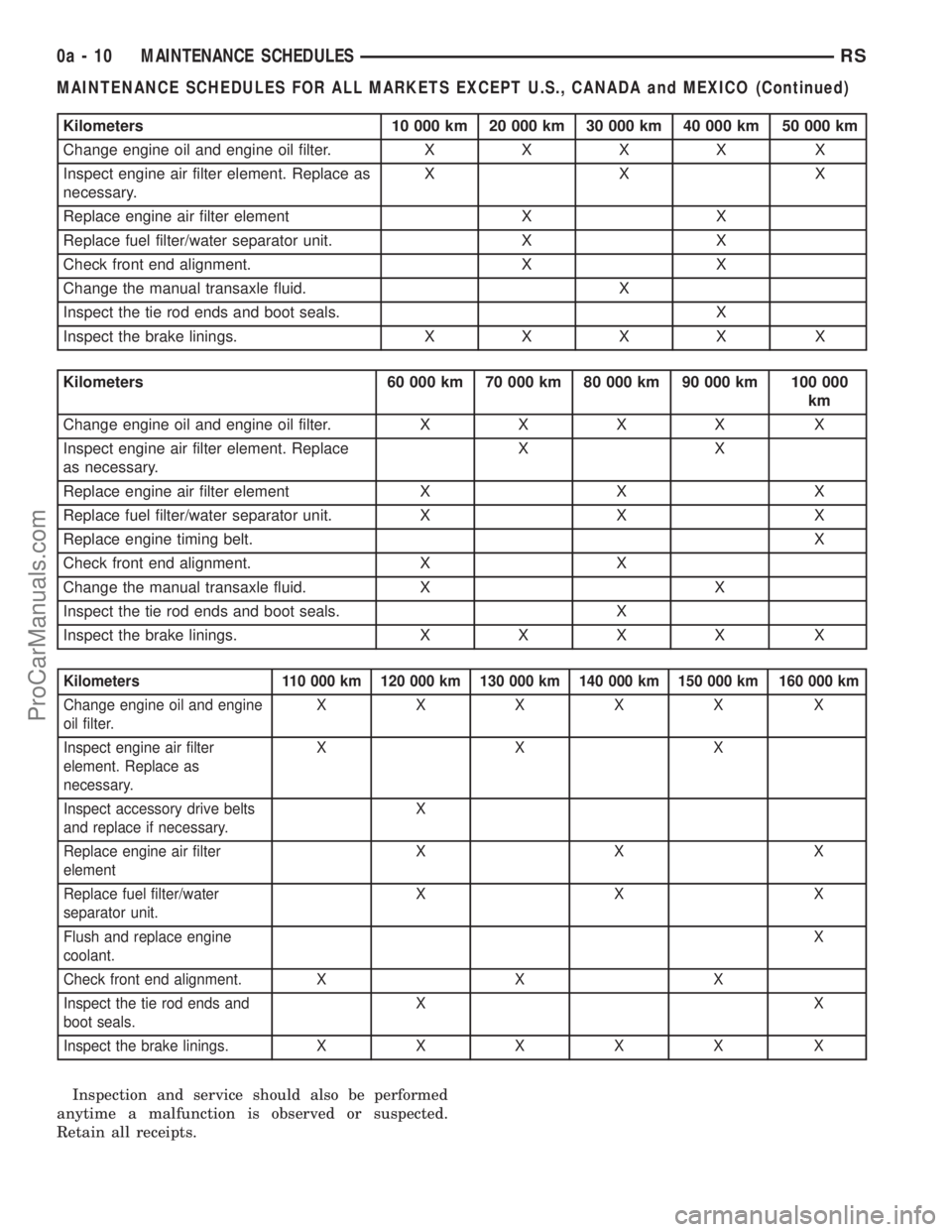

Kilometers 10 000 km 20 000 km 30 000 km 40 000 km 50 000 km

Change engine oil and engine oil filter.XXXX X

Inspect engine air filter element. Replace as

necessary.XX X

Replace engine air filter element X X

Replace fuel filter/water separator unit. X X

Check front end alignment. X X

Change the manual transaxle fluid. X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings.XXXX X

Kilometers 60 000 km 70 000 km 80 000 km 90 000 km 100 000

km

Change engine oil and engine oil filter.XXXX X

Inspect engine air filter element. Replace

as necessary.XX

Replace engine air filter element X X X

Replace fuel filter/water separator unit. X X X

Replace engine timing belt.X

Check front end alignment. X X

Change the manual transaxle fluid. X X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings.XXXX X

Kilometers 110 000 km 120 000 km 130 000 km 140 000 km 150 000 km 160 000 km

Change engine oil and engine

oil filter.XXXXX X

Inspect engine air filter

element. Replace as

necessary.XXX

Inspect accessory drive belts

and replace if necessary.X

Replace engine air filter

elementXX X

Replace fuel filter/water

separator unit.XX X

Flush and replace engine

coolant.X

Check front end alignment. X X X

Inspect the tie rod ends and

boot seals.XX

Inspect the brake linings.XXXXX X

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

0a - 10 MAINTENANCE SCHEDULESRS

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 42 of 2177

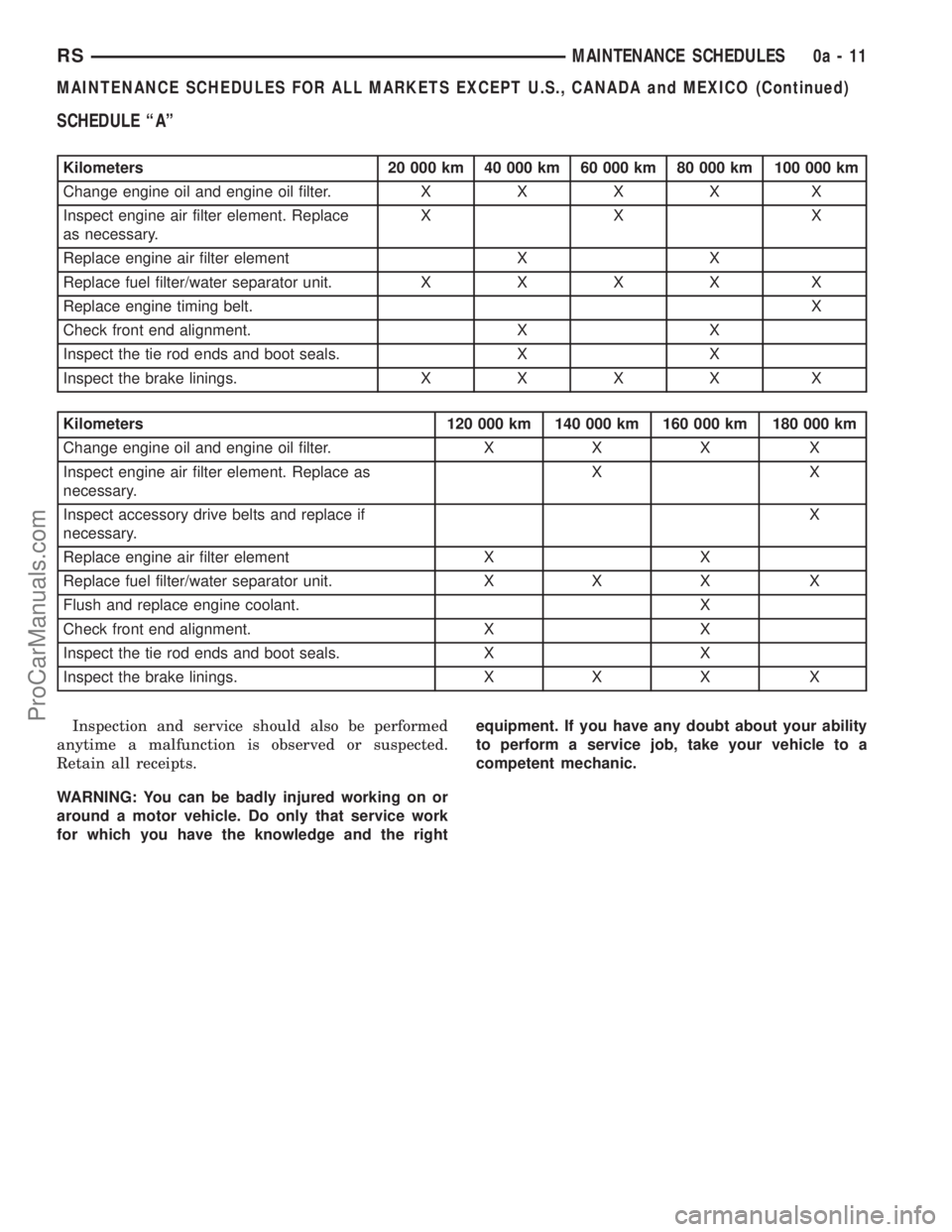

SCHEDULE ªAº

Kilometers 20 000 km 40 000 km 60 000 km 80 000 km 100 000 km

Change engine oil and engine oil filter.XXXX X

Inspect engine air filter element. Replace

as necessary.XX X

Replace engine air filter element X X

Replace fuel filter/water separator unit.XXXX X

Replace engine timing belt.X

Check front end alignment. X X

Inspect the tie rod ends and boot seals. X X

Inspect the brake linings.XXXX X

Kilometers 120 000 km 140 000 km 160 000 km 180 000 km

Change engine oil and engine oil filter. X X X X

Inspect engine air filter element. Replace as

necessary.XX

Inspect accessory drive belts and replace if

necessary.X

Replace engine air filter element X X

Replace fuel filter/water separator unit. X X X X

Flush and replace engine coolant. X

Check front end alignment. X X

Inspect the tie rod ends and boot seals. X X

Inspect the brake linings. X X X X

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the rightequipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

RSMAINTENANCE SCHEDULES0a-11

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 308 of 2177

to Step 6. If not OK, repair the open circuit as

required.

(6) Turn the ignition switch to the OFF position.

Check for battery voltage at the fused B(+) circuit

cavity of the radio wire harness connector. If OK,

replace the faulty radio. If not OK, repair the open

circuit to the Ignition-Off Draw (IOD) fuse as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cup holder.

(3) Remove trim panel above cupholder by pulling

straight out.

(4) Remove center instrument panel trim panel.

(5) Remove screws holding radio to instrument

panel.

(6) Pull radio rearward to gain access to the back

of radio (Fig. 10).

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(7) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

11).

(8) Disconnect the wire connectors from the back

of the radio.

INSTALLATION

(1) Connect wire harness to back of radio.

(2) Connect antenna cable to back of radio.

(3) Position radio into instrument panel.

(4) Install screws holding radio to instrument

panel.(5) Install center instrument panel trim.

(6) Install trim panel above cupholder.

(7) Install cupholder.

(8) Connect battery negative cable.

RADIO NOISE SUPPRESSION

COMPONENTS

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.

When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radio

noise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.

Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

Fig. 10 RADIO

1 - RADIO

2 - CD-PLAYER

Fig. 11 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

RSAUDIO8A-11

RADIO (Continued)

ProCarManuals.com

Page 406 of 2177

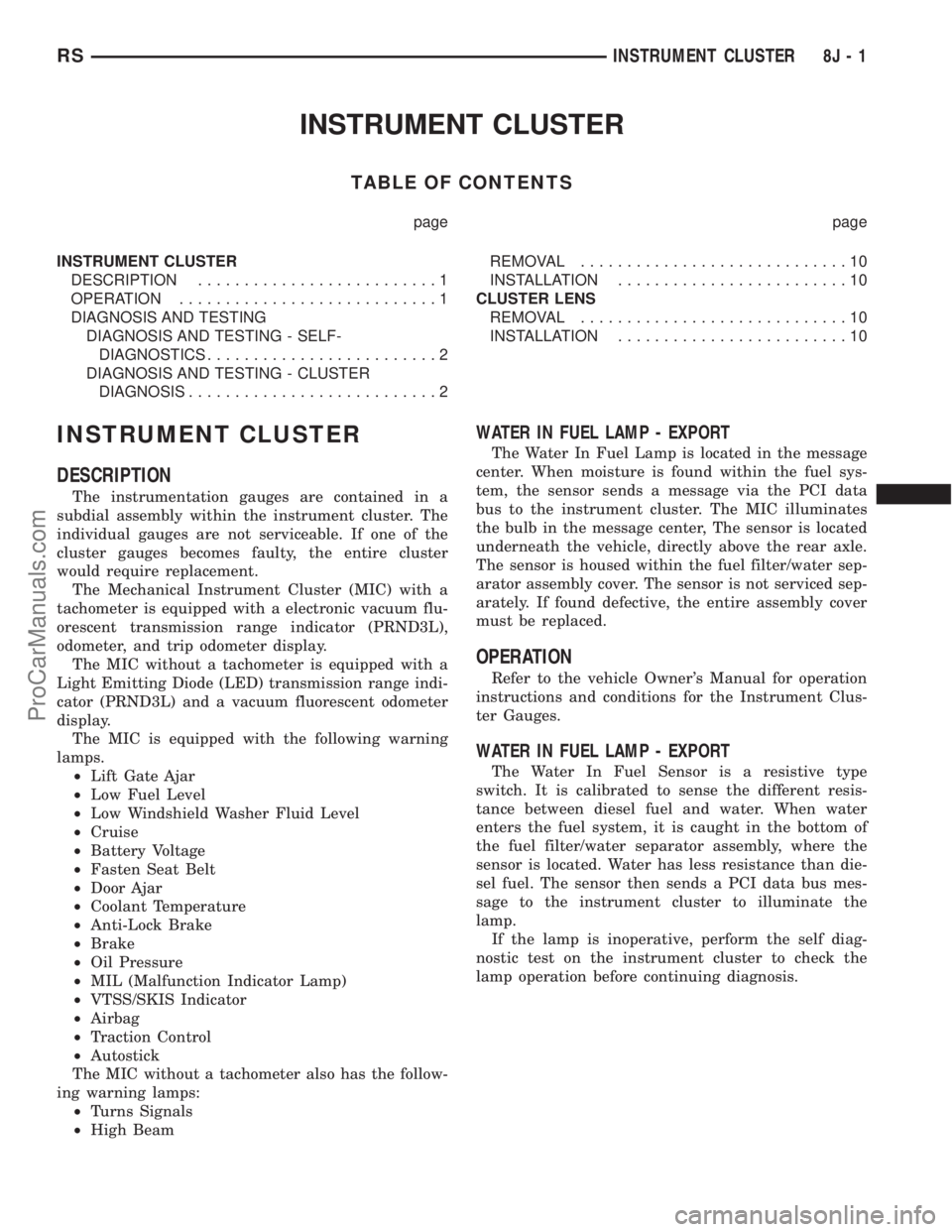

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS.........................2

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS...........................2REMOVAL.............................10

INSTALLATION.........................10

CLUSTER LENS

REMOVAL.............................10

INSTALLATION.........................10

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The Mechanical Instrument Cluster (MIC) with a

tachometer is equipped with a electronic vacuum flu-

orescent transmission range indicator (PRND3L),

odometer, and trip odometer display.

The MIC without a tachometer is equipped with a

Light Emitting Diode (LED) transmission range indi-

cator (PRND3L) and a vacuum fluorescent odometer

display.

The MIC is equipped with the following warning

lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Oil Pressure

²MIL (Malfunction Indicator Lamp)

²VTSS/SKIS Indicator

²Airbag

²Traction Control

²Autostick

The MIC without a tachometer also has the follow-

ing warning lamps:

²Turns Signals

²High Beam

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Lamp is located in the message

center. When moisture is found within the fuel sys-

tem, the sensor sends a message via the PCI data

bus to the instrument cluster. The MIC illuminates

the bulb in the message center, The sensor is located

underneath the vehicle, directly above the rear axle.

The sensor is housed within the fuel filter/water sep-

arator assembly cover. The sensor is not serviced sep-

arately. If found defective, the entire assembly cover

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Sensor is a resistive type

switch. It is calibrated to sense the different resis-

tance between diesel fuel and water. When water

enters the fuel system, it is caught in the bottom of

the fuel filter/water separator assembly, where the

sensor is located. Water has less resistance than die-

sel fuel. The sensor then sends a PCI data bus mes-

sage to the instrument cluster to illuminate the

lamp.

If the lamp is inoperative, perform the self diag-

nostic test on the instrument cluster to check the

lamp operation before continuing diagnosis.

RSINSTRUMENT CLUSTER8J-1

ProCarManuals.com

Page 1183 of 2177

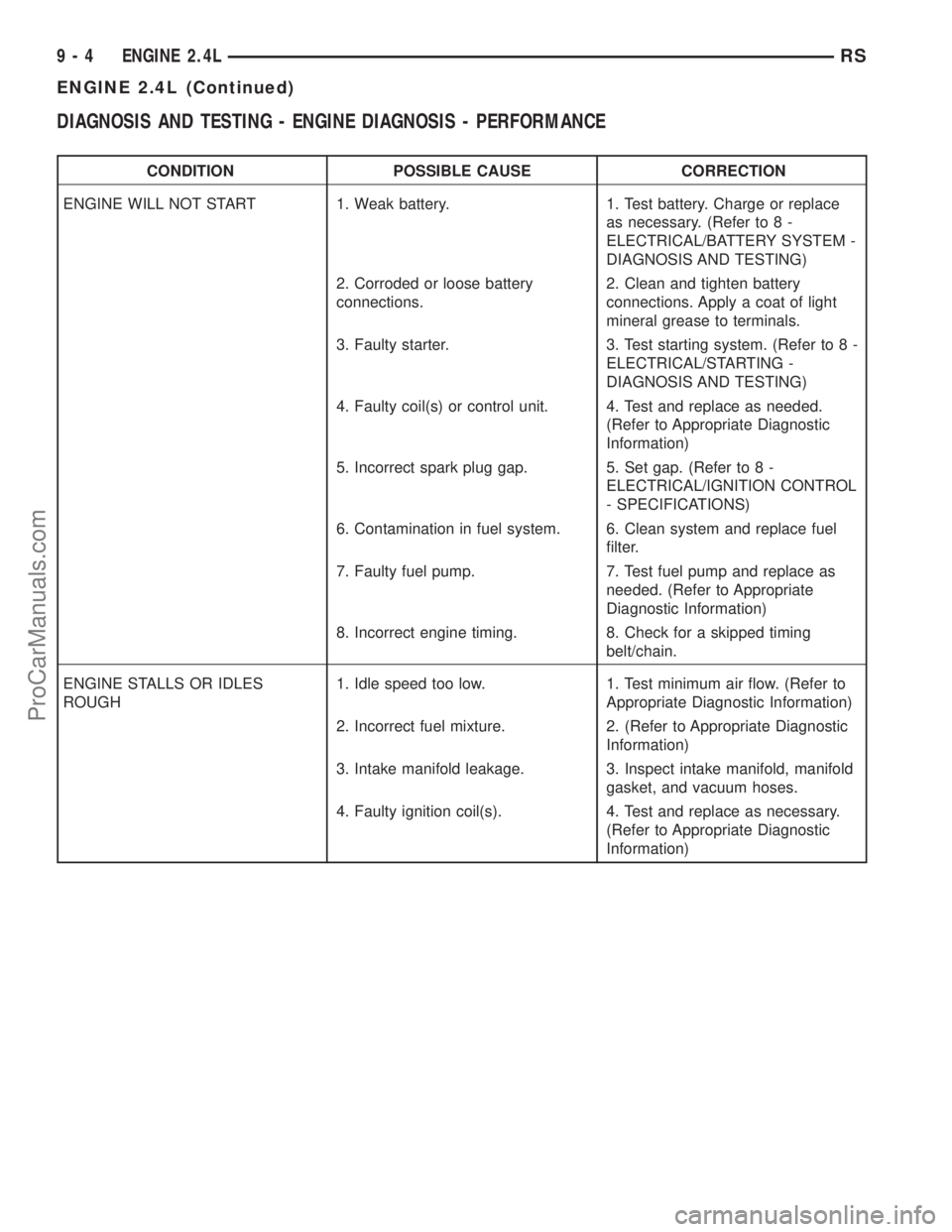

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery. 1. Test battery. Charge or replace

as necessary. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM -

DIAGNOSIS AND TESTING)

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Faulty starter. 3. Test starting system. (Refer to 8 -

ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Faulty coil(s) or control unit. 4. Test and replace as needed.

(Refer to Appropriate Diagnostic

Information)

5. Incorrect spark plug gap. 5. Set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL

- SPECIFICATIONS)

6. Contamination in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump. 7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Incorrect engine timing. 8. Check for a skipped timing

belt/chain.

ENGINE STALLS OR IDLES

ROUGH1. Idle speed too low. 1. Test minimum air flow. (Refer to

Appropriate Diagnostic Information)

2. Incorrect fuel mixture. 2. (Refer to Appropriate Diagnostic

Information)

3. Intake manifold leakage. 3. Inspect intake manifold, manifold

gasket, and vacuum hoses.

4. Faulty ignition coil(s). 4. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

9 - 4 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1185 of 2177

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

4. Low oil pressure. 4. Check and correct engine oil

pressure problem.

5. Dirt in hydraulic lifters/lash

adjusters.5. Replace hydraulic lifters/lash

adjusters.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn hydraulic lifters/lash

adjusters.7. Replace hydraulic lifters/lash

adjusters.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Connecting rod journal

out-of-round.6. Replace crankshaft or grind

surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

9 - 6 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com