electronic control modules CHRYSLER VOYAGER 2003 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 324 of 2177

switch and the heated seat sensor to operate and

control the heated seat elements in the front seat.

The heated seat modules cannot be repaired. If

either of the heated seat modules are damaged or

faulty, the entire module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from the integrated power module.

The module is grounded at all times through the seat

wire harness. Inputs to the module include a resistor

multiplexed heated seat switch request circuit for the

heated seat switch and the heated seat sensor inputs

from the seat cushions of each front seat. In response

to those inputs the heated seat module controls bat-

tery current feeds to the heated seat elements.

When a heated seat switch request signal is

received by the heated seat module and the enable

input is high, the heated seat module energizes the

selected heated seat sensor circuit and the sensor

provides the module with an input indicating the

surface temperature of the selected seat cushion.

The Low heat set point is about 35É C (95É F), and

the High heat set point is about 40É C (104É F). If the

seat cushion surface temperature input is below the

temperature set point for the selected temperature

setting, the heated seat module energizes an N-chan-

nel Field Effect Transistor (N-FET) within the mod-

ule which energizes the heated seat elements in theselected seat cushion and back. When the sensor

input to the module indicates the correct tempera-

ture set point has been achieved, the module de-en-

ergizes the N-FET which de-energizes the heated

seat elements. The heated seat module will continue

to cycle the N-FET as needed to maintain the

selected temperature set point.

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE

If a heated seat heats but one or both indicator

lamps on the heated seat switch fail to operate, test

the heated seat switch. Refer toDiagnosis and

Testing Heated Seat Switchin Heated Seats for

heated seat switch diagnosis and testing procedures.

If the heated seat switch checks OK, proceed as fol-

lows.

(1) Check the heated seat element (Refer to 8 -

ELECTRICAL/HEATED SEATS/HEATED SEAT

ELEMENT - DIAGNOSIS AND TESTING).

(2) Check the heated seat sensor (Refer to 8 -

ELECTRICAL/HEATED SEATS/HEATED SEAT

SENSOR - DIAGNOSIS AND TESTING).

(3) Check the heated seat switch (Refer to 8 -

ELECTRICAL/HEATED SEATS/DRIVER HEATED

SEAT SWITCH - DIAGNOSIS AND TESTING).

NOTE: Refer to Wiring for the location of complete

heated seat system wiring diagrams and connector

pin-out information.

(4) Using a voltmeter, back probe the appropriate

heated seat module connector, do not disconnect.

Check for battery voltage at the appropriate pin cav-

ities. If OK go to Step 5. If not OK, repair the open

or shorted voltage supply circuit as required.

(5) Using a ohmmeter, back probe the appropriate

heated seat module connector, do not disconnect.

Check for proper continuity to ground on the ground

pin cavities. Continuity should be present. If OK

replace the heated seat module with a known good

unit and retest system, if Not OK, Repair the open or

shorted ground circuit as required.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate front seat from the

vehicle (Refer to 23 - BODY/SEATS/SEAT - REMOV-

AL).

(3) Unsnap the module from the seat cushion pan.

(4) Disconnect the module wire harness connec-

tors.

Fig. 7 HEATED SEAT MODULE

1 - HEATED SEAT MODULE

2 - C1 CONNECTOR

3 - C3 CONNECTOR

4 - C1 CONNECTOR

RSELECTRONIC CONTROL MODULES8E-9

HEATED SEAT MODULE (Continued)

ProCarManuals.com

Page 325 of 2177

INSTALLATION

(1) Connect the module wire harness connectors.

(2) Snap the module on the seat cushion pan.

(3) Install the appropriate front seat in the vehicle

(Refer to 23 - BODY/SEATS/SEAT - INSTALLA-

TION).

(4) Connect and isolate the negative battery cable.

MEMORY SEAT/MIRROR

MODULE

DESCRIPTION

Vehicles equipped with the memory seat/mirror

option, utilize a memory module located under the

drivers front seat. This module is basically wired in-

line between the power seat switch and the power

seat track/adjuster motors, or in-line between the

power mirror switch and the power side view mir-

ror(s) motor(s). The MSMM contains a central pro-

cessing unit that communicates with other modules

on the Programmable Communications Interface

(PCI) data bus network.

The Memory Seat/Mirror Module (MSMM) receives

hard wired inputs from the driver power seat switch

and the potentiometers on each of the driver side

power seat track motors, or from the power mirror

switch and the potentiometers on the side view mir-

ror. The MSMM receives messages over the PCI data

bus from the Body Control Module (BCM) (memory

switch status), the Powertrain Control Module (PCM)

(vehicle speed status). The MSMM will prevent the

seat memory recall function from being initiated if

the driver side seat belt is buckled, if the transmis-

sion gear selector lever is not in the Park or Neutral

positions, or if the vehicle is moving.

For diagnosis of the MSMM or the PCI data bus, a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual are recommended. The MSMM cannot

be repaired and, if faulty or damaged, it must be

replaced. Refer toMemory Systemin the Power

Seat or Power Mirror section of this manual for more

information on the memory system option.

OPERATION

When memory system operation is requested

(depressing of the memory switch), a resistor multi-

plexed signal is sent from the memory switch to the

body control module (BCM). The body control module

will then send the appropriate signals out to the

memory/mirror seat module, the memory/mirror seat

module then applies the voltage supply to the power

seat track or side-view mirror if the proper require-

ments are met. The vehicle speed must equal zero

and the transmission must be in park or neutral in

order for the memory system to function.

DIAGNOSIS AND TESTING - MEMORY

SEAT/MIRROR MODULE

Visually inspect the related wiring harness connec-

tors. Look for broken, bent, pushed out, or corroded

terminals. If any of the above conditions are present,

repair as necessary. If not, use a DRB IIItscan tool

and the proper Diagnostic Procedures Manual to test

the memory/mirror seat module. For complete circuit

diagrams, refer toWiring Diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front bucket seat

retaining nuts from under the vehicle (Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(3) Lift the drivers seat up and out of the mount-

ing holes in the floor pan and lay the seat rearward

to access the module located under the seat. It is not

necessary to disconnect the seat electrical, just use

care not to damage the wiring by over-extending.

(4) Disconnect the memory/mirror seat module

electrical connectors. Depress the retaining tab and

pull straight apart.

(5) Remove the module retaining bolts and remove

the module from the bracket.

INSTALLATION

(1) Position and install the module retaining bolts.

(2) Connect the memory/mirror seat module elec-

trical connectors.

(3) Position the drivers seat in the mounting holes

in the floor pan.

(4) Install the driver side front bucket seat retain-

ing nuts from under the vehicle (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION).

(5) Connect the battery negative cable.

POWER LIFTGATE CONTROL

MODULE

DESCRIPTION

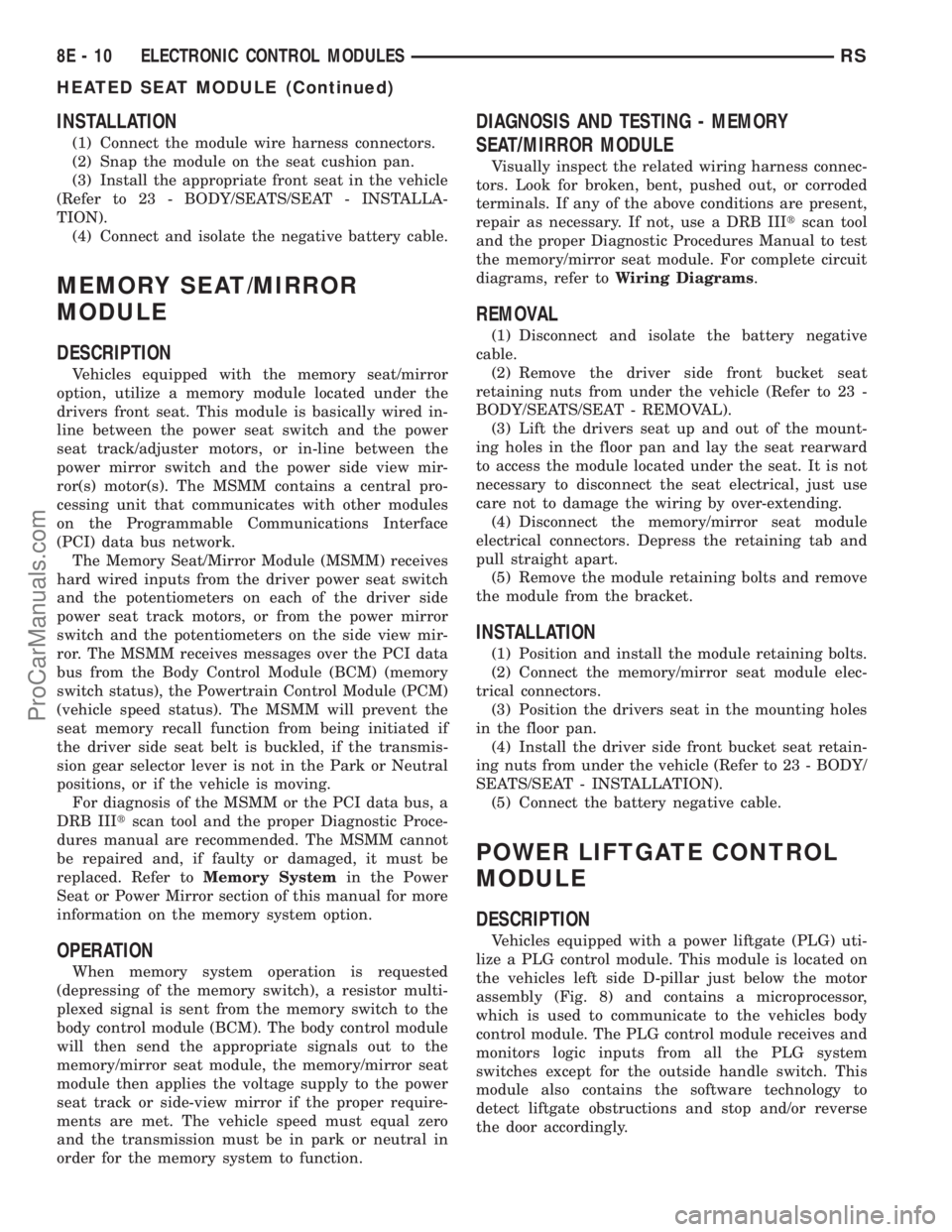

Vehicles equipped with a power liftgate (PLG) uti-

lize a PLG control module. This module is located on

the vehicles left side D-pillar just below the motor

assembly (Fig. 8) and contains a microprocessor,

which is used to communicate to the vehicles body

control module. The PLG control module receives and

monitors logic inputs from all the PLG system

switches except for the outside handle switch. This

module also contains the software technology to

detect liftgate obstructions and stop and/or reverse

the door accordingly.

8E - 10 ELECTRONIC CONTROL MODULESRS

HEATED SEAT MODULE (Continued)

ProCarManuals.com

Page 326 of 2177

OPERATION

The PLG control module contains the electronic cir-

cuitry and software used to control the sequence of

events for the PLG system. This module comunicates

on the PCI bus circuit with the vehicles body control

module to monitor many different inputs and outputs

such as door lock status, transmission gear selector

position and vehicle speed. Refer to PLG system

operation for more information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove left D-pillar trim panel from the vehi-

cle. Refer to Body for the procedure.

(3) Disconnect the wire harness connections from

the PLG motor assembly (Fig. 8).

(4) Remove the screw holding the PLG control

module to the D-pillar (Fig. 8).

(5) Remove the PLG control module from the vehi-

cle.

INSTALLATION

(1) Install the PLG control module on the D-pillar

and install retaining screw. Torque the screw to 14.5

in. lbs.(2) Connect the wire harness connections on the

PLG control module. Be certain to slide connector

locks to the locked position.

(3) Install the D-pillar trim panel on the vehicle.

Refer to the Body section for the procedure.

(4) Connect the negative battery cable.

(5) Using an appropriate scan tool, check any

erase any PLG control module diagnostic trouble

codes.

(6) Verify PLG system operation. Cycle the PLG

through one complete open and close cycle, this will

allow the PLG control module to relearn its cycle

with the new components.

POWERTRAIN CONTROL

MODULE

DESCRIPTION

DESCRIPTION

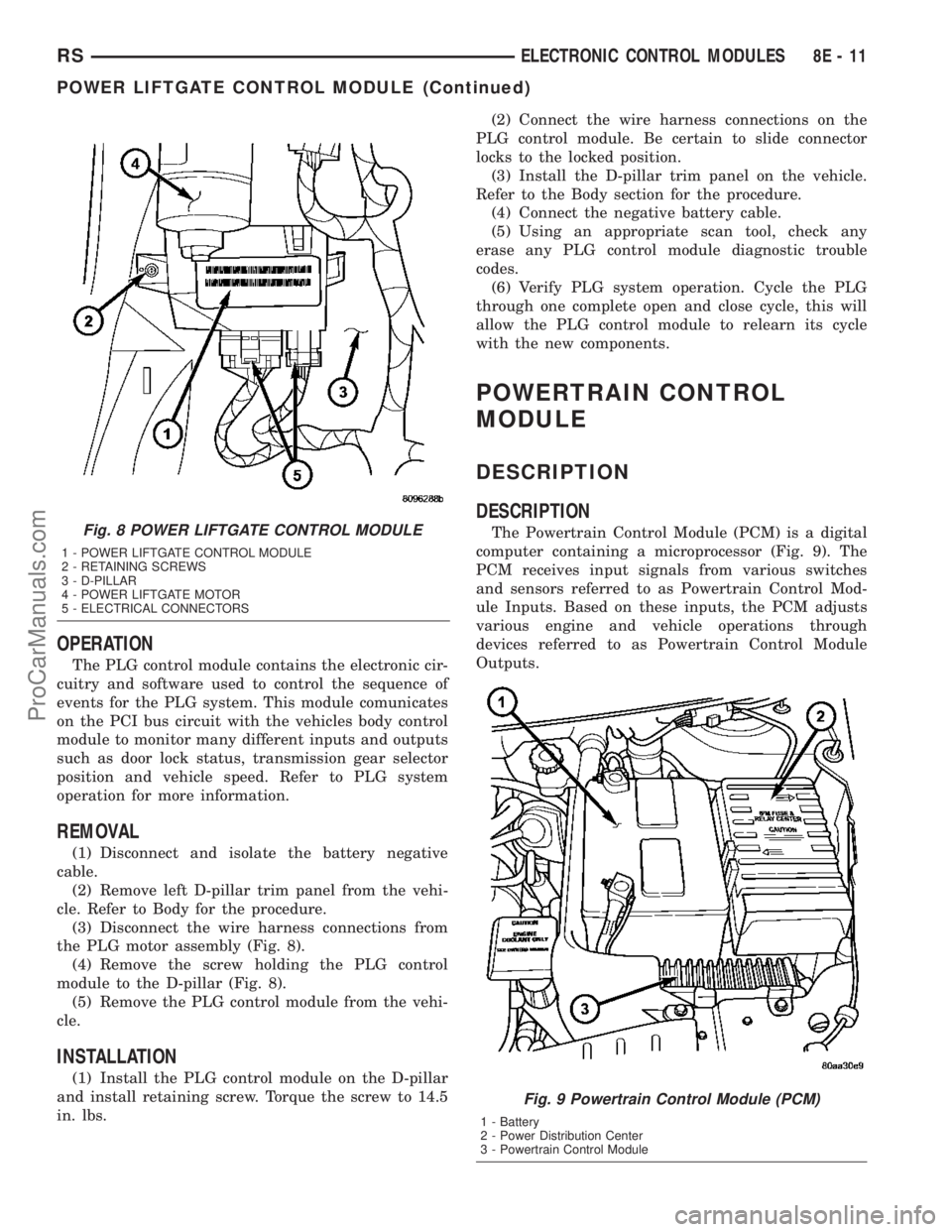

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 9). The

PCM receives input signals from various switches

and sensors referred to as Powertrain Control Mod-

ule Inputs. Based on these inputs, the PCM adjusts

various engine and vehicle operations through

devices referred to as Powertrain Control Module

Outputs.Fig. 8 POWER LIFTGATE CONTROL MODULE

1 - POWER LIFTGATE CONTROL MODULE

2 - RETAINING SCREWS

3 - D-PILLAR

4 - POWER LIFTGATE MOTOR

5 - ELECTRICAL CONNECTORS

Fig. 9 Powertrain Control Module (PCM)

1 - Battery

2 - Power Distribution Center

3 - Powertrain Control Module

RSELECTRONIC CONTROL MODULES8E-11

POWER LIFTGATE CONTROL MODULE (Continued)

ProCarManuals.com

Page 327 of 2177

NOTE: PCM Inputs:

²Air Conditioning Pressure Transducer

²Ambient temperature Sensor

²ASD Relay

²Battery Temperature Sensor (NGC)

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Distance Sensor (from transmission control mod-

ule)

²EGR Position Feedback

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors

²Ignition sense

²Intake Air Temperature Sensor

²Knock Sensor

²Leak Detection Pump Feedback

²Manifold Absolute Pressure (MAP) Sensor

²Park/Neutral

²PCI Bus

²Power Steering Pressure Switch

²Proportional Purge Sense

²SCI Receive

²Speed Control

²Throttle Position Sensor

²Torque Management Input

²Transaxle Control Module (3.3/3.8L Only)

²Transmission Control Relay (Switched B+) (2.4L

Only)

²Transmission Pressure Switches (2.4L Only)

²Transmission Temperature Sensor (2.4L Only)

²Transmission Input Shaft Speed Sensor (2.4L

Only)

²Transmission Output Shaft Speed Sensor (2.4L

Only)

²Transaxle Gear Engagement

²Vehicle Speed

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

²Torque Reduction Request

²Transmission Control Relay (2.4L Only)

²Transmission Solenoids (2.4L Only)

²Vehicle Speed

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

8E - 12 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 328 of 2177

fuel pump and the heating element in each oxygen

sensor.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the engine

coolant temperature sensor, intake air temperature

sensor, manifold absolute pressure sensor and throt-

tle position sensor.

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage in new PCM. Use

the DRBIIItscan tool to change the mileage in the

PCM. Refer to the appropriate Powertrain Diagnostic

Manual and the DRBIIItscan tool.

TRANSMISSION CONTROL (2.4L MODELS ONLY)

CLUTCH VOLUME INDEX (CVI)

An important function of the PCM is to monitor

Clutch Volume Index (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.

The PCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the PCM that represents input shaft rpm. The Out-

put Speed Sensor provides the PCM with output

shaft speed information.

By comparing the two inputs, the PCM can deter-

mine transaxle gear ratio. This is important to the

CVI calculation because the PCM determines CVIs

by monitoring how long it takes for a gear change to

occur (Fig. 10).

Gear ratios can be determined by using the DRB

Scan Tool and reading the Input/Output Speed Sen-

sor values in the ªMonitorsº display. Gear ratio can

be obtained by dividing the Input Speed Sensor value

by the Output Speed Sensor value.

For example, if the input shaft is rotating at 1000

rpm and the output shaft is rotating at 500 rpm,

then the PCM can determine that the gear ratio is

2:1. In direct drive (3rd gear), the gear ratio changesto 1:1. The gear ratio changes as clutches are applied

and released. By monitoring the length of time it

takes for the gear ratio to change following a shift

request, the PCM can determine the volume of fluid

used to apply or release a friction element.

The volume of transmission fluid needed to apply

the friction elements are continuously updated for

adaptive controls. As friction material wears, the vol-

ume of fluid need to apply the element increases.

Certain mechanical problems within the clutch

assemblies (broken return springs, out of position

snap rings, excessive clutch pack clearance, improper

assembly, etc.) can cause inadequate or out-of-range

clutch volumes. Also, defective Input/Output Speed

Sensors and wiring can cause these conditions. The

following chart identifies the appropriate clutch vol-

umes and when they are monitored/updated:

CLUTCH VOLUMES

ClutchWhen Updated

Proper Clutch

Volume

Shift Sequence Oil Temperature Throttle Angle

L/R2-1 or 3-1 coast

downshift>70É <5É 35to83

2/4 1-2 shift

> 110É5 - 54É20 to 77

OD 2-3 shift 48 to 150

UD 4-3 or 4-2 shift > 5É 24 to 70

Fig. 10 Example of CVI Calculation

1 - OUTPUT SPEED SENSOR

2 - OUTPUT SHAFT

3 - CLUTCH PACK

4 - SEPARATOR PLATE

5 - FRICTION DISCS

6 - INPUT SHAFT

7 - INPUT SPEED SENSOR

8 - PISTON AND SEAL

RSELECTRONIC CONTROL MODULES8E-13

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 329 of 2177

SHIFT SCHEDULES

As mentioned earlier, the PCM has programming

that allows it to select a variety of shift schedules.

Shift schedule selection is dependent on the follow-

ing:

²Shift lever position

²Throttle position²Engine load

²Fluid temperature

²Software level

As driving conditions change, the PCM appropri-

ately adjusts the shift schedule. Refer to the follow-

ing chart to determine the appropriate operation

expected, depending on driving conditions.

Schedule Condition Expected Operation

Extreme ColdOil temperature at start-up below

-16É FPark, Reverse, Neutral and 2nd

gear only (prevents shifting which

may fail a clutch with frequent

shifts)

ColdOil temperature at start-up above

-12É F and below 36É F± Delayed 2-3 upshift

(approximately 22-31 mph)

± Delayed 3-4 upshift (45-53 mph)

± Early 4-3 costdown shift

(approximately 30 mph)

± Early 3-2 coastdown shift

(approximately 17 mph)

± High speed 4-2, 3-2, 2-1 kickdown

shifts are prevented

± No EMCC

WarmOil temperature at start-up above

36É F and below 80 degree F± Normal operation (upshift,

kickdowns, and coastdowns)

± No EMCC

HotOil temperature at start-up above

80É F± Normal operation (upshift,

kickdowns, and coastdowns)

± Full EMCC, no PEMCC except to

engage FEMCC (except at closed

throttle at speeds above 70-83 mph)

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F± Delayed 2-3 upshift (25-32 mph)

± Delayed 3-4 upshift (41-48 mph)

± 3rd gear FEMCC from 30-48 mph

± 3rd gear PEMCC from 27-31 mph

Super OverheatOil temperature above 260É F ± All9Overheat9shift schedule

features apply

± 2nd gear PEMCC above 22 mph

± Above 22 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

8E - 14 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 330 of 2177

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module

(PCM).

OPERATION - DATA BUS COMMUNICATION

RECEIVE - PCM INPUT

The PCM uses the SCI communication bus to pre-

form engine diagnostics and flash operations. The

transmission side of the PCM uses the SCI commu-

nication bus to flash new software. However, diagnos-

tics is performed via the vehicles J1850 bus for the

transmission side of the PCM.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as two different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side relays, solenoids, ignition coil or injectors. The

signal ground is used for any input that uses sensor

return for ground, and the ground side of any inter-

nal processing component.

The PCM case is shielded to prevent RFI and EMI.

The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the housing and cover

are also grounded separately from the ground pins.

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM OUTPUT

- SBEC CONTROLLER

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Ambient Temperature sensor

²Battery temperature

²Camshaft Position Sensor (NGC)

²Crankshaft Position Sensor (NGC)

²Electronic Throttle Control (1.6L)²Engine coolant temperature sensor

²Inlet Air Temperature Sensor

²Knock sensor

²Linear EGR solenoid (if equipped)

²Manifold absolute pressure sensor

²Oil Pressure Switch

²Pedal Position Sensor (1.6L)

²Throttle position sensor

²Vehicle Speed Sensor

STANDARD PROCEDURE

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 5 to 8 seconds, lamp

then flashes if once per trip (readiness) monitors

havenotbeen completed until vehicle is started,

then MIL is extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

PCM/TCM has been replaced with a NEW or

replacement unit. Failure to perform this procedure

will result in an inoperative or improperly calibrated

speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The PCM/TCM

must be calibrated to the different combinations of

equipment (final drive and tires) available. Pinion

Factor allows the technician to set the Powertrain/

Transmission Control Module initial setting so that

the speedometer readings will be correct. To properly

RSELECTRONIC CONTROL MODULES8E-15

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 331 of 2177

read and/or reset the Pinion Factor, it is necessary to

use a DRBIIItscan tool.

(1) Plug the DRBIIItscan tool into the diagnostic

connector located under the instrument panel.

(2) Select the Transmission menu.

(3) Select the Miscellaneous menu.

(4) Select Pinion Factor. Then follow the instruc-

tions on the DRBIIItscan tool screen.

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE

The quick learn procedure requires the use of the

DRBIIItscan tool. This program allows the PCM/

TCM to recalibrate itself. This will provide the best

possible transaxle operation.

NOTE: The quick learn procedure should be per-

formed if any of the following procedures are per-

formed:

²Transaxle Assembly Replacement

²Powertrain/Transmission Control Module

Replacement

²Solenoid/Pressure Switch Assembly Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the

DRBIIItindicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

(1) Plug the DRBIIItscan tool into the diagnostic

connector. The connector is located under the instru-

ment panel.

(2) Go to the Transmission screen.

(3) Go to the Miscellaneous screen.

(4) Select Quick Learn Procedure. Follow the

instructions of the DRBIIItto perform the Quick

Learn Procedure.

REMOVAL

REMOVAL - SBEC CONTROLLER

(1) Disconnect the negative battery cable.

(2) Remove the battery shield, refer to the Battery

section for more information.

(3) Remove the 2 upper PCM bracket bolts (Fig.

11).(4) Remove the 2 PCM connectors.

(5) Remove the headlamp, refer to the Lamps sec-

tion for more information.

(6) Remove the lower PCM mounting bolt (Fig. 12).

(7) Remove PCM.

Fig. 11 PCM

1 - Attaching Bolts

Fig. 12 PCM LOWER BOLT

8E - 16 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 332 of 2177

REMOVAL - NGC CONTROLLER

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage and vehicle iden-

tification number (VIN) in the new PCM. Use the

DRBIIItscan tool to change the millage and VIN in

the PCM. If this step is not done a Diagnostic Trou-

ble Code (DTC) may be set. Refer to the appropriate

Powertrain Diagnostic Manual and the DRBIIItscan

tool.

(1) Turn wheels to the left.

(2) Disconnect the negative battery cable.

(3) Raise vehicle and support.

(4) Remove the left front wheel well splash shield

(Fig. 13).

(5) Unlock and disconnect the electrical connectors

(Fig. 14).

(6) Remove 3 screws from PCM to mounting

bracket.

(7) Remove the PCM.

INSTALLATION

INSTALLATION - SBEC CONTROLLER

(1) Install the PCM.

(2) Install the lower PCM mounting bolt. Tighten

bolt.

(3) Install the 2 upper PCM bracket bolts. Tighten

bolt.

(4) Install the headlamp, refer to the Lamps sec-

tion for more information.

(5) Install the 2 PCM connectors.(6) Install the battery shield, refer to the Battery

section for more information.

(7) Connect the negative battery cable.

INSTALLATION

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage and vehicle iden-

tification number (VIN) in the new PCM. Use the

DRBIIItscan tool to change the millage and VIN in

the PCM. If this step is not done a diagnostic trouble

code (DTC) may be set and SKIM must be done or

car will not start if it is a SKIM equipped car. If a

SKIM car you must do a secret key transfer also.

NGC CONTROLLER LOCATION

Fig. 13 SPLASH SHIELD

Fig. 14 NGC CONTROLLER

RSELECTRONIC CONTROL MODULES8E-17

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 333 of 2177

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRBIIItscan tool.

(1) Install PCM module to the mounting bracket.

(2) Install electrical connectors and lock.

(3) Install the splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

(6) Using DRBIIItscan tool, program mileage and

vehicle identification number (VIN) into PCM. Refer

to the DRBIIItscan tool and the appropriate Power-

train Diagnostic Manual.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM retains in memory the ID

numbers of any Sentry Key that is programmed to it.

The maximum number of keys that may be pro-

grammed to each module is eight (8). The SKIM also

communicates over the Programmable Communica-

tion Interface (PCI) data bus with the Powertrain

Control Module (PCM), the Body Control Module

(BCM), the Mechanical Instrument Cluster (MIC),

and the DRB IIItscan tool. The SKIM transmits and

receives RF signals through a tuned antenna

enclosed within a molded plastic ring formation that

is integral to the SKIM housing. When the SKIM is

properly installed on the steering column, the

antenna ring fits snugly around the circumference of

the ignition lock cylinder housing. If this ring is not

mounted properly, communication problems may

arise in the form of transponder-related faults.

For added system security, each SKIM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKIM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKIM for service. The SKIM also stores in its mem-

ory the Vehicle Identification Number (VIN), which itlearns through a bus message from the assembly

plant tester. The SKIS scrambles the information

that is communicated between its components in

order to reduce the possibility of unauthorized SKIM

access and/or disabling.

OPERATION

When the ignition switch is moved to the RUN

position, the Sentry Key Immobilizer Module (SKIM)

transmits an Radio Frequency (RF) signal to the

transponder in the ignition key. The SKIM then

waits for a response RF signal from the transponder

in the key. If the response received identifies the key

as valid, the SKIM sends a9valid key9message to

the Powertrain Control Module (PCM) over the Pro-

grammable Communication Interface (PCI) data bus.

If the response received identifies the key as invalid

or no response is received from the transponder in

the ignition key, the SKIM sends an9invalid key9

message to the PCM. The PCM will enable or disable

engine operation based upon the status of the SKIM

messages. It is important to note that the default

condition in the PCM is9invalid key.9Therefore, if no

response is received by the PCM, the engine will be

immobilized after two (2) seconds of running.

The SKIM also sends indicator light status mes-

sages to the Mechanical Instrument Cluster (MIC) to

operate the light. This is the method used to turn the

light ON solid or to flash it after the indicator light

test is complete to signify a fault in the SKIS. If the

light comes ON and stays ON solid after the indica-

tor light test, this signifies that the SKIM has

detected a system malfunction and/or that the SKIS

has become inoperative. If the SKIM detects an

invalid keyORa key-related fault exists, the indica-

tor light will flash following the indicator light test.

The SKIM may also request an audible chime if the

customer key programming feature is available and

the procedure is being utilized (Refer to 8 - ELEC-

TRICAL/VEHICLE THEFT SECURITY/TRANSPON-

DER KEY - STANDARD PROCEDURE).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Lower Instrument Panel Cover. Refer

to Body, Instrument Panel, Lower Instrument Panel

Cover, Removal.

(3) Remove the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Removal.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the one screws securing the SKIM to

the steering column.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com