BCM CHRYSLER VOYAGER 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 555 of 2177

DIAGNOSIS AND TESTING - REAR WIPER

SYSTEM

The rear window wiper system operates in several

modes:

²Continuous wipe

²Intermittent wipe

²Wash

²Wipe after washThe windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. The

DTC(s) can be retrieved using a DRB IIItscan tool.

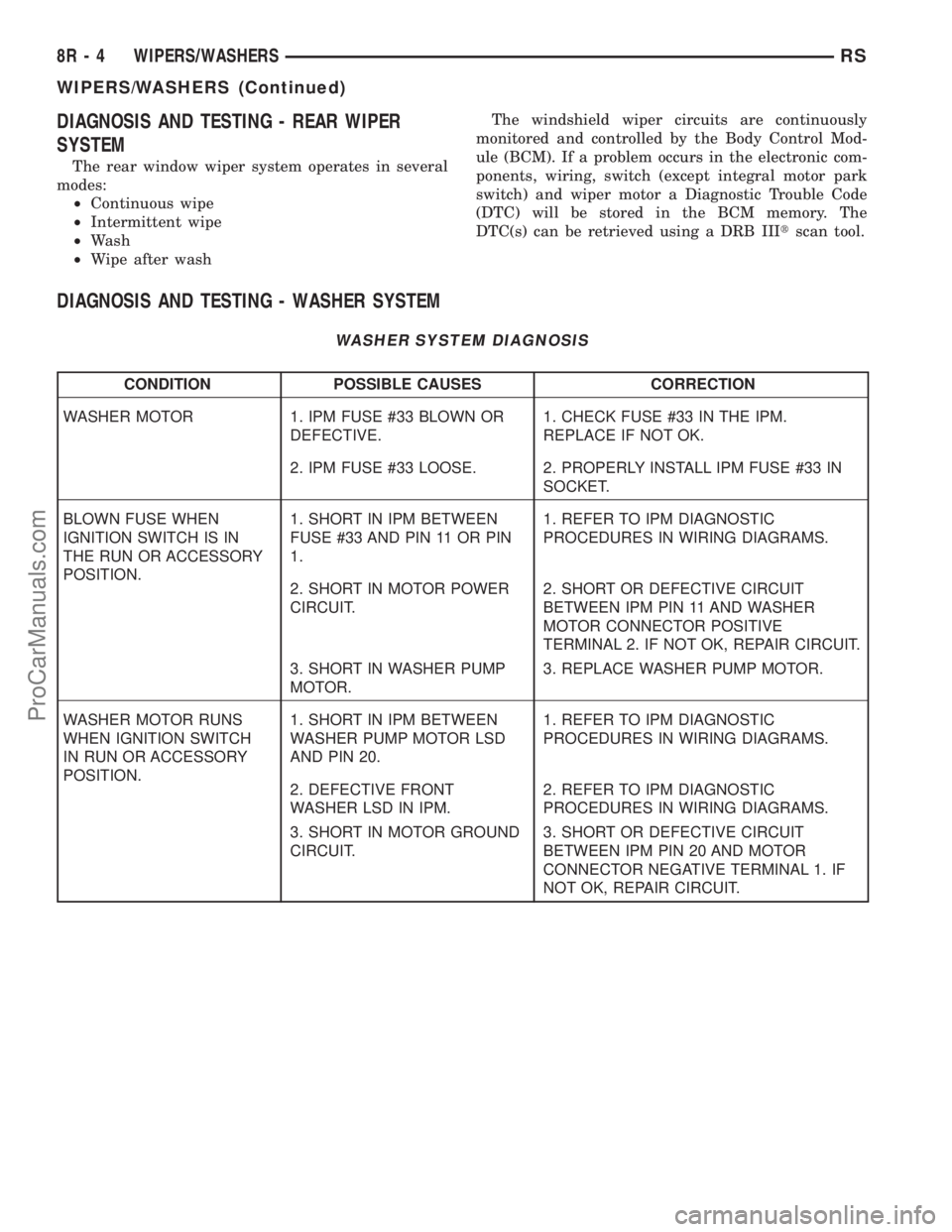

DIAGNOSIS AND TESTING - WASHER SYSTEM

WASHER SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

WASHER MOTOR 1. IPM FUSE #33 BLOWN OR

DEFECTIVE.1. CHECK FUSE #33 IN THE IPM.

REPLACE IF NOT OK.

2. IPM FUSE #33 LOOSE. 2. PROPERLY INSTALL IPM FUSE #33 IN

SOCKET.

BLOWN FUSE WHEN

IGNITION SWITCH IS IN

THE RUN OR ACCESSORY

POSITION.1. SHORT IN IPM BETWEEN

FUSE #33 AND PIN 11 OR PIN

1.1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. SHORT IN MOTOR POWER

CIRCUIT.2. SHORT OR DEFECTIVE CIRCUIT

BETWEEN IPM PIN 11 AND WASHER

MOTOR CONNECTOR POSITIVE

TERMINAL 2. IF NOT OK, REPAIR CIRCUIT.

3. SHORT IN WASHER PUMP

MOTOR.3. REPLACE WASHER PUMP MOTOR.

WASHER MOTOR RUNS

WHEN IGNITION SWITCH

IN RUN OR ACCESSORY

POSITION.1. SHORT IN IPM BETWEEN

WASHER PUMP MOTOR LSD

AND PIN 20.1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. DEFECTIVE FRONT

WASHER LSD IN IPM.2. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

3. SHORT IN MOTOR GROUND

CIRCUIT.3. SHORT OR DEFECTIVE CIRCUIT

BETWEEN IPM PIN 20 AND MOTOR

CONNECTOR NEGATIVE TERMINAL 1. IF

NOT OK, REPAIR CIRCUIT.

8R - 4 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 557 of 2177

CONDITION POSSIBLE CAUSES CORRECTION

COWL GRILLE NOZZLE

WILL NOT FLOW.1. FROZEN NOZZLE. 1. MOVE VEHICLE INTO HEATED AREA TO

ALLOW TIME TO THAW NOZZLE. ASSURE

WASHER FLUID IS PROPERLY BLENDED

FOR AMBIENT OUTSIDE TEMPERATURES.

2. NOZZLE HOSE NOT

FLOWING.2. ASSURE NOZZLE HOSE IS NOT

PINCHED, LOOSE, BROKEN, OR

DISCONNECTED. IF NOT OK, PROPERLY

ROUTE OR REPAIR NOZZLE HOSE.

3. NOZZLE HOSE PLUGGED

BY CONTAMINATION.3. CLEAN NOZZLE HOSE OF

CONTAMINATION. DETERMINE SOURCE

OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

4. NOZZLE PLUGGED BY

CONTAMINATION.4. CLEAN NOZZLE OF CONTAMINATION

OR REPLACE NOZZLE. DETERMINE

SOURCE OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

5. DEFECTIVE WASHER HOSE

CHECK VALVE.5. REPLACE COWL GRILLE PANEL

WASHER HOSE/CHECK VALVE ASSEMBLY.

WASHER FLUID OUTPUT IS

LOW.1. PARTIALLY PINCHED HOSE. 1. ASSURE WASHER HOSE IS NOT

PARTIALLY PINCHED. IF NOT OK,

PROPERLY ROUTE HOSE.

2. REVERSE POLARITY TO

PUMP.2. CHECK FOR CROSSED CIRCUIT TO

PUMP. IF NOT OK, REPAIR CIRCUIT.

3. WORN OUT WASHER PUMP. 3. REPLACE WASHER PUMP.

COWL GRILLE NOZZLE

STREAM OVERSHOOTS

WINDSHIELD.1. NOZZLE NOT SEATED IN

COWL GRILLE.1. ASSURE NOZZLE IS SNAPPED IN

PLACE.

WIPER WILL NOT CYCLE

WHEN WASHER SELECT

SWITCH IS DEPRESSED.1. DEFECTIVE IPM. 1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. DEFECTIVE IPM/BODY

CONTROLLER.2. REFER TO IPM/BODY CONTROLLER

DIAGNOSTIC PROCEDURES IN WIRING

DIAGRAMS.

3. REAR WIPER OUTPUT

SHORT FAULT.3. A GROUND SHORT DETECTED

BETWEEN BCM AND REAR WIPER

MOTOR. CLEAR FAULT. IF IT WON'T

CLEAR, REPAIR SHORT

4. REAR WIPER OUTPUT

OPEN FAULT.4. AN OPEN CIRCUIT DETECTED

BETWEEN BCM AND REAR WIPER

MOTOR. CLEAR FAULT. IF IT WON'T

CLEAR, REPAIR OPEN CIRCUIT.

8R - 6 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 1380 of 2177

opposite preset limit or switch point. The process

then repeats itself in the opposite direction.

Short term fuel correction will keep increasing or

decreasing injector pulse-width based upon the

upstream O2 Sensor input. The maximum range of

authority for short term memory is 25% (+/-) of base

pulse-width. Short term is violated and is lost when

ignition is turned OFF.

Long Term

The second fuel correction program is the long

term adaptive memory. In order to maintain correct

emission throughout all operating ranges of the

engine, a cell structure based on engine rpm and load

(MAP) is used.

Ther number of cells varies upon the driving con-

ditions. Two cells are used only during idle, based

upon TPS and Park/Neutral switch inputs. There

may be two other cells used for deceleration, based

on TPS, engine rpm, and vehicle speed. The other

twelve cells represent a manifold pressure and an

rpm range. Six of the cells are high rpm and the

other six are low rpm. Each of these cells has a spe-

cific MAP voltage range Typical Adaptive Memory

Fuel Cells .As the engine enters one of these cells the PCM

looks at the amount of short term correction being

used. Because the goal is to keep short term at 0 (O2

Sensor switching at 0.5 volt), long term will update

in the same direction as short term correction was

moving to bring the short term back to 0. Once short

term is back at 0, this long term correction factor is

stored in memory.

The values stored in long term adaptive memory

are used for all operating conditions, including open

loop and cold starting. However, the updating of the

long term memory occurs after the engine has

exceeded approximately 170É-190É F, with fuel control

in closed loop and two minutes of engine run time.

This is done to prevent any transitional temperature

or start-up compensations from corrupting long term

fuel correction.

Long term adaptive memory can change the pulse-

width by as much as 25%, which means it can correct

for all of short term. It is possible to have a problem

that would drive long term to 25% and short term to

another 25% for a total change of 50% away from

base pulse-width calculation.

TYPICAL ADAPTIVE MEMORY FUEL CELLS

Open

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

Throttle Idle Decel

Vacuum 20 17 13 9 5 0

Above 1,984

rpm1 3 5 7 9 11 13 Drive 15

Below 1,984

rpm02 4 6 8 1012

Neutral14

MAP volt =0 1.4 2.0 2.6 3.3 3.9

Fuel Correction Diagnostics

There are two fuel correction diagnostic routines:

²Fuel System Rich

²Fuel System Lean

A DTC is set and the MIL is illuminated if the

PCM detects either of these conditions. This is deter-

mined based on total fuel correction, short term

times long term.

PROGRAMMABLE COMMUNICATIONS

INTERFACE (PCI) BUS

DESCRIPTION

The Programmable Communication Interface Mul-

tiplex system (PCI Bus) consist of a single wire. The

Body Control Module (BCM) acts as a splice to con-

nect each module and the Data Link Connector(DLC) together. Each module is wired in parallel to

the data bus through its PCI chip set and uses its

ground as the bus reference. The wiring is a mini-

mum 20 gage wire.

OPERATION

Various modules exchange information through a

communications port called the PCI Bus. The Power-

train Control Module (PCM) transmits the Malfunc-

tion Indicator Lamp (Check Engine) On/Off signal

and engine RPM on the PCI Bus. The PCM receives

the Air Conditioning select input, transaxle gear

position inputs over the PCI Bus. The PCM also

receives the air conditioning evaporator temperature

signal from the PCI Bus.

The following components access or send informa-

tion on the PCI Bus.

RSFUEL INJECTION14-21

FUEL INJECTION (Continued)

ProCarManuals.com

Page 1688 of 2177

SPEED SENSOR - OUTPUT

DESCRIPTION

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

313), sealed with an o-ring (Fig. 314), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

OPERATION

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 315), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

VEHICLE SPEED SIGNAL

The vehicle speed signal is taken from the Output

Speed Sensor. The PCM converts this signal into a

pulse per mile signal and sends the vehicle speed

message across the communication bus to the BCM.

The BCM sends this signal to the Instrument Cluster

to display vehicle speed to the driver. The vehicle

speed signal pulse is roughly 8000 pulses per mile.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Disconnect output speed sensor connector.

(4) Unscrew and remove output speed sensor (Fig.

316).

(5) Inspect speed sensor o-ring (Fig. 317) and

replace if necessary.

Fig. 313 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 314 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 315 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

RS41TE AUTOMATIC TRANSAXLE21 - 241

ProCarManuals.com

Page 1999 of 2177

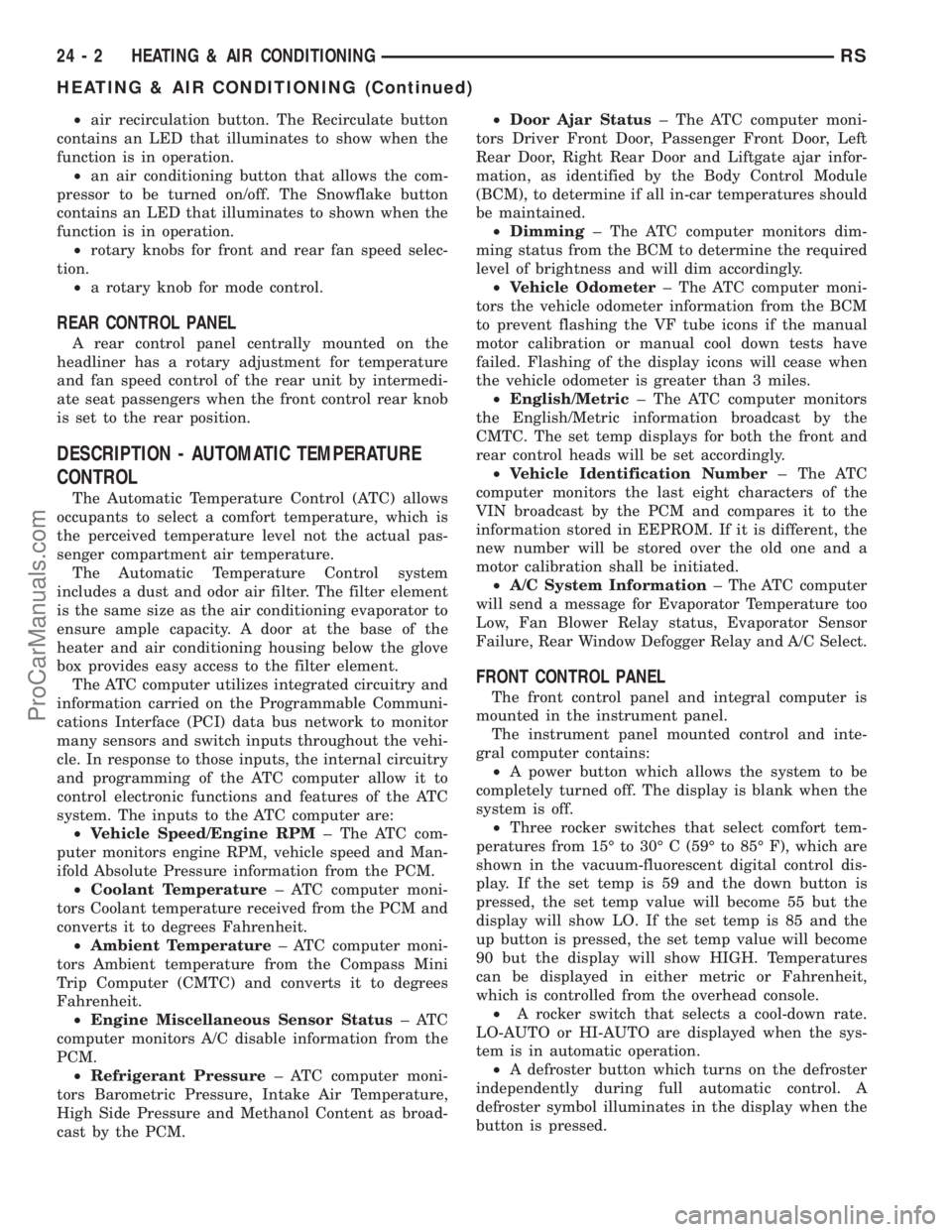

²air recirculation button. The Recirculate button

contains an LED that illuminates to show when the

function is in operation.

²an air conditioning button that allows the com-

pressor to be turned on/off. The Snowflake button

contains an LED that illuminates to shown when the

function is in operation.

²rotary knobs for front and rear fan speed selec-

tion.

²a rotary knob for mode control.

REAR CONTROL PANEL

A rear control panel centrally mounted on the

headliner has a rotary adjustment for temperature

and fan speed control of the rear unit by intermedi-

ate seat passengers when the front control rear knob

is set to the rear position.

DESCRIPTION - AUTOMATIC TEMPERATURE

CONTROL

The Automatic Temperature Control (ATC) allows

occupants to select a comfort temperature, which is

the perceived temperature level not the actual pas-

senger compartment air temperature.

The Automatic Temperature Control system

includes a dust and odor air filter. The filter element

is the same size as the air conditioning evaporator to

ensure ample capacity. A door at the base of the

heater and air conditioning housing below the glove

box provides easy access to the filter element.

The ATC computer utilizes integrated circuitry and

information carried on the Programmable Communi-

cations Interface (PCI) data bus network to monitor

many sensors and switch inputs throughout the vehi-

cle. In response to those inputs, the internal circuitry

and programming of the ATC computer allow it to

control electronic functions and features of the ATC

system. The inputs to the ATC computer are:

²Vehicle Speed/Engine RPM± The ATC com-

puter monitors engine RPM, vehicle speed and Man-

ifold Absolute Pressure information from the PCM.

²Coolant Temperature± ATC computer moni-

tors Coolant temperature received from the PCM and

converts it to degrees Fahrenheit.

²Ambient Temperature± ATC computer moni-

tors Ambient temperature from the Compass Mini

Trip Computer (CMTC) and converts it to degrees

Fahrenheit.

²Engine Miscellaneous Sensor Status±ATC

computer monitors A/C disable information from the

PCM.

²Refrigerant Pressure± ATC computer moni-

tors Barometric Pressure, Intake Air Temperature,

High Side Pressure and Methanol Content as broad-

cast by the PCM.²Door Ajar Status± The ATC computer moni-

tors Driver Front Door, Passenger Front Door, Left

Rear Door, Right Rear Door and Liftgate ajar infor-

mation, as identified by the Body Control Module

(BCM), to determine if all in-car temperatures should

be maintained.

²Dimming± The ATC computer monitors dim-

ming status from the BCM to determine the required

level of brightness and will dim accordingly.

²Vehicle Odometer± The ATC computer moni-

tors the vehicle odometer information from the BCM

to prevent flashing the VF tube icons if the manual

motor calibration or manual cool down tests have

failed. Flashing of the display icons will cease when

the vehicle odometer is greater than 3 miles.

²English/Metric± The ATC computer monitors

the English/Metric information broadcast by the

CMTC. The set temp displays for both the front and

rear control heads will be set accordingly.

²Vehicle Identification Number± The ATC

computer monitors the last eight characters of the

VIN broadcast by the PCM and compares it to the

information stored in EEPROM. If it is different, the

new number will be stored over the old one and a

motor calibration shall be initiated.

²A/C System Information± The ATC computer

will send a message for Evaporator Temperature too

Low, Fan Blower Relay status, Evaporator Sensor

Failure, Rear Window Defogger Relay and A/C Select.

FRONT CONTROL PANEL

The front control panel and integral computer is

mounted in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²A power button which allows the system to be

completely turned off. The display is blank when the

system is off.

²Three rocker switches that select comfort tem-

peratures from 15É to 30É C (59É to 85É F), which are

shown in the vacuum-fluorescent digital control dis-

play. If the set temp is 59 and the down button is

pressed, the set temp value will become 55 but the

display will show LO. If the set temp is 85 and the

up button is pressed, the set temp value will become

90 but the display will show HIGH. Temperatures

can be displayed in either metric or Fahrenheit,

which is controlled from the overhead console.

²A rocker switch that selects a cool-down rate.

LO-AUTO or HI-AUTO are displayed when the sys-

tem is in automatic operation.

²A defroster button which turns on the defroster

independently during full automatic control. A

defroster symbol illuminates in the display when the

button is pressed.

24 - 2 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com