engine CHRYSLER VOYAGER 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 191 of 2177

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4 or 5 strokes).

(2) Remove negative battery cable terminal from

battery.

(3) Remove positive battery cable terminal from

battery.

(4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray.

(6) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray.

(7) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray.

(8) If vehicle is equipped with speed control:

(a) Disconnect wiring harness connector from

the speed control servo.

(b) Remove the two servo mounting nuts.(c) Lay speed control servo off to the side, out of

the way.

(9) If the vehicle is equipped with the 2.5L diesel

engine, remove the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

REMOVAL)

(10) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 63).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(11) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the booster.

(12) Remove two nuts attaching master cylinder to

power brake booster (Fig. 64).

(13) Slide master cylinder straight out of power

brake booster. Lay master cylinder with primary and

secondary tubes to the side, out of the way.

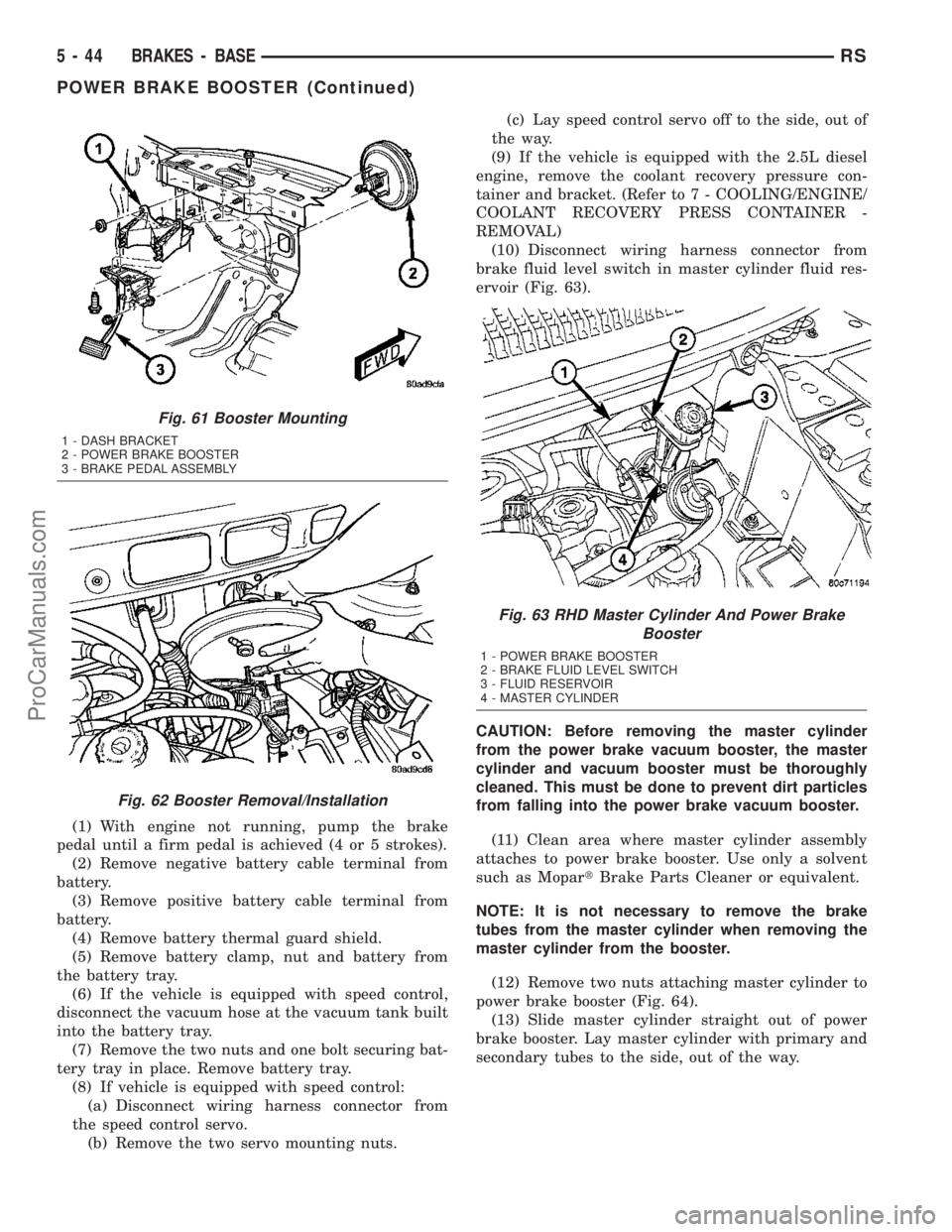

Fig. 61 Booster Mounting

1 - DASH BRACKET

2 - POWER BRAKE BOOSTER

3 - BRAKE PEDAL ASSEMBLY

Fig. 62 Booster Removal/Installation

Fig. 63 RHD Master Cylinder And Power Brake

Booster

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

5 - 44 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 192 of 2177

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

(14) Disconnect vacuum hose from check valve

located on booster.DO NOT REMOVE CHECK

VALVE FROM POWER BRAKE BOOSTER.

(15) Under the instrument panel, remove booster

input rod trim cover.

(16) Locate the booster input rod to brake pedal

torque shaft connection under the instrument panel.

Position a small screwdriver between the center tang

on the retaining clip (Fig. 65).

(17) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal torque shaft

pin.Discard retaining clip. It is not to be

reused. Replace only with a new retaining clip

when assembling.

(18) Remove booster input rod from pedal torque

shaft pin.

(19) Remove the three easily accessed mounting

nuts attaching power brake booster to dash panel

and loosen fourth (Fig. 66). As fourth nut is loosened,

push the booster forward periodically until the nut

can be completely removed.

(20) Slide power brake booster forward and remove

through engine compartment (Fig. 67).

CAUTION: Do not attempt to disassemble the power

brake vacuum booster. It is serviced ONLY as a

complete assembly.

Fig. 64 RHD Master Cylinder Mounting

1 - PRIMARY BRAKE TUBE NUT

2 - SECONDARY BRAKE TUBE NUT

3 - MASTER CYLINDER MOUNTING NUTS

Fig. 65 Booster Input Rod Pin Retaining Clip

(Typical)

1 - BRAKE PEDAL

2 - INPUT ROD

3 - SCREWDRIVER

4 - RETAINING CLIP

5 - BRAKE PEDAL PIN

Fig. 66 Booster, Torque Shaft And Pedal Mounting

1 - PEDAL MOUNTING NUT

2 - BRAKE PEDAL ASSEMBLY

3 - PEDAL MOUNTING NUT

4 - PEDAL TORQUE SHAFT

5 - BOOSTER MOUNTING NUT

6 - BOOSTER BRACKET

7 - POWER BRAKE BOOSTER

8 - BOOSTER BRACKET MOUNTING NUT

RSBRAKES - BASE5-45

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 194 of 2177

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(16) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(17) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(18) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing. Securely tighten hose clamp at air cleaner hous-

ing and throttle body.

(19) Secure the engine coolant filler neck to the

battery tray with its mounting screw.

(20) Install the battery, clamp and mounting nut.

(21) Install the positive battery cable on the bat-

tery.

(22) Install the negative battery cable on the bat-

tery.

(23) Install the battery thermal guard shield.

(24) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(25) Road test vehicle to ensure operation of the

brakes.

INSTALLATION - RHD

(1) Position power brake booster on dash panel

using the reverse procedure of its removal (Fig. 67).

(2) Below instrument panel, first install the two

upper nuts mounting the booster to the dash panel,

drawing it into place, then install the two lower

mounting nuts. Tighten the mounting nuts to a

torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod.CAUTION: When installing the brake pedal torque

shaft pin on the power brake booster input rod, do

not re-use the old retaining clip.

(4) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 70).

(5) Install booster input rod trim cover.

(6) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder, do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

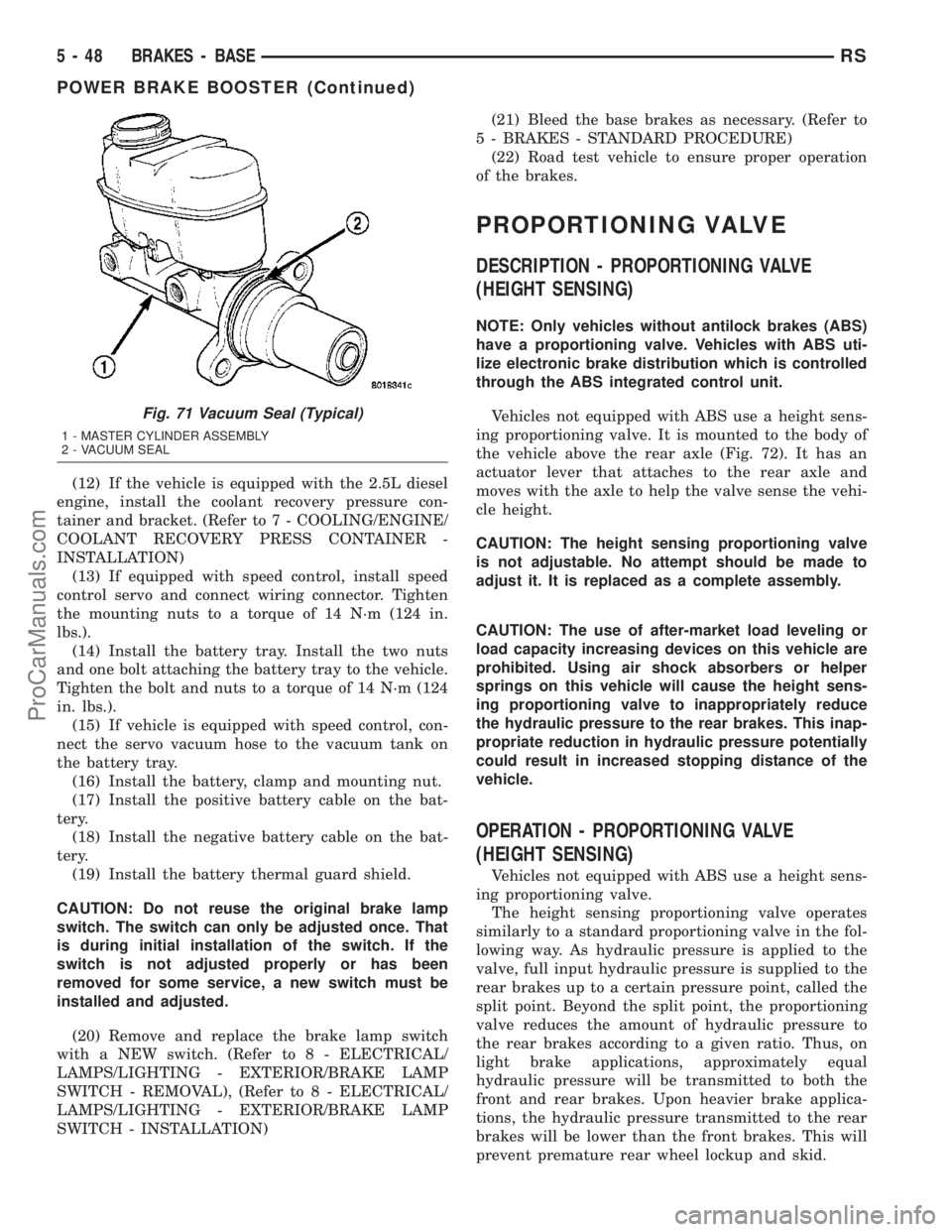

(8) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 71).

(9) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(10) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 64). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(11) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 63).

Fig. 69 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

Fig. 70 Retaining Pin Installed On Brake Pedal Pin

(Typical)

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

RSBRAKES - BASE5-47

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 195 of 2177

(12) If the vehicle is equipped with the 2.5L diesel

engine, install the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

INSTALLATION)

(13) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(14) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(15) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(16) Install the battery, clamp and mounting nut.

(17) Install the positive battery cable on the bat-

tery.

(18) Install the negative battery cable on the bat-

tery.

(19) Install the battery thermal guard shield.

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(20) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)(21) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(22) Road test vehicle to ensure proper operation

of the brakes.

PROPORTIONING VALVE

DESCRIPTION - PROPORTIONING VALVE

(HEIGHT SENSING)

NOTE: Only vehicles without antilock brakes (ABS)

have a proportioning valve. Vehicles with ABS uti-

lize electronic brake distribution which is controlled

through the ABS integrated control unit.

Vehicles not equipped with ABS use a height sens-

ing proportioning valve. It is mounted to the body of

the vehicle above the rear axle (Fig. 72). It has an

actuator lever that attaches to the rear axle and

moves with the axle to help the valve sense the vehi-

cle height.

CAUTION: The height sensing proportioning valve

is not adjustable. No attempt should be made to

adjust it. It is replaced as a complete assembly.

CAUTION: The use of after-market load leveling or

load capacity increasing devices on this vehicle are

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-

propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

OPERATION - PROPORTIONING VALVE

(HEIGHT SENSING)

Vehicles not equipped with ABS use a height sens-

ing proportioning valve.

The height sensing proportioning valve operates

similarly to a standard proportioning valve in the fol-

lowing way. As hydraulic pressure is applied to the

valve, full input hydraulic pressure is supplied to the

rear brakes up to a certain pressure point, called the

split point. Beyond the split point, the proportioning

valve reduces the amount of hydraulic pressure to

the rear brakes according to a given ratio. Thus, on

light brake applications, approximately equal

hydraulic pressure will be transmitted to both the

front and rear brakes. Upon heavier brake applica-

tions, the hydraulic pressure transmitted to the rear

brakes will be lower than the front brakes. This will

prevent premature rear wheel lockup and skid.

Fig. 71 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

5 - 48 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 237 of 2177

(Fig. 12). The ICU is located below the master cylin-

der in the engine compartment (Fig. 13).

Two different ICU's (HCU and CAB) are used on

this vehicle depending on whether or not the vehicle

is equipped with traction control. The HCU on a

vehicle equipped with traction control has a valve

block that is approximately one inch longer than a

HCU on a vehicle that is equipped with ABS only.

The ABS-only ICU consists of the following compo-

nents: the CAB, eight (build/decay) solenoid valves

(four inlet valves and four outlet valves), valve block,

fluid accumulators, a pump, and an electric motor.

The ABS-with traction control ICU consists of the

following components: the CAB, eight (build/decay)solenoid valves (four inlet valves and four outlet

valves), two traction control (ASR) valves, two

hydraulic shuttle valves, valve block, fluid accumula-

tors, a pump, and an electric motor.

The replaceable components of the ICU are the

HCU and the CAB. No attempt should be made to

service any individual components of the HCU or

CAB. For information on the CAB, (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/CONTROLLER ANTILOCK BRAKE -

DESCRIPTION).

OPERATION

For information of the ICU, refer to these individ-

ual components of the ICU:

²CONTROLLER ANTILOCK BRAKE (CAB)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/CONTROLLER ANTILOCK

BRAKE - OPERATION)

²HYDRAULIC CONTROL UNIT (HCU) (Refer to

5 - BRAKES - ABS/HYDRAULIC/MECHANICAL/

HCU (HYDRAULIC CONTROL UNIT) - OPERA-

TION)

For information on the ICU's hydraulic circuits,

refer to HYDRAULIC CIRCUITS AND VALVE

OPERATION. (Refer to 5 - BRAKES - ABS/HY-

DRAULIC/MECHANICAL - OPERATION)

REMOVAL

REMOVAL - LHD

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Remove the battery shield.

(3) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(4) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(5) Remove the screw securing the engine coolant

filler neck to the battery tray.

(6) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(7) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder once the

brake tubes are removed from the HCU.

CAUTION: Do not apply a 12±volt power source to

any terminals of the 24-way CAB connector when

disconnected.

(8) Disconnect the wiring harness connector from

the speed control servo.

(9) Remove the speed control servo mounting nuts

and move the servo out of the way.

Fig. 12 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 13 ICU LOCATION IN VEHICLE

1 - POWER BRAKE BOOSTER

2 - MASTER CYLINDER

3 - ICU

5 - 90 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 238 of 2177

(10) Disconnect the 24±way connector from the

CAB. To disconnect the 24±way connector, grasp the

lock on the 24±way connector and pull it as far up as

possible. This will unlock the 24±way connector from

the socket on the CAB.

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. This

must be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.

(11) Thoroughly clean all surfaces of the ICU and

brake tube nuts. Use only a solvent such as Mopart

Brake Parts Cleaner or equivalent to clean the ICU.

(12) Remove the brake tubes (4) from the outlet

ports on the HCU (Fig. 14).

(13) Remove the primary and secondary brake

tubes from the inlet ports on the HCU (Fig. 14).

(14) Center and prop the steering wheel.

(15) Remove the pinch bolt and disconnect the

steering shaft coupling.

(16) If equipped, remove the two clips securing

silencer to dash seal (Fig. 15). Remove silencer.

(17) Remove the three screws securing the dash

seal (Fig. 15). Remove seal.

(18) Remove the 3 bolts attaching the ICU to its

mounting bracket (Fig. 16).

(19) Remove ICU from the vehicle through engine

compartment.

(20) If required, to separating the CAB from the

HCU, (Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/ICU (INTEGRATED CONTROL UNIT) -

DISASSEMBLY).

REMOVAL - RHD

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION)

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

Fig. 14 Brake Tube Nuts At ICU

1 - PRIMARY BRAKE TUBE

2 - SECONDARY BRAKE TUBE

3 - CHASSIS BRAKE TUBES

Fig. 15 Lower Coupling And Dash Seal

1 - COUPLING

2 - DASH SEAL

3 - SILENCER

4 - MOUNTING SCREWS

5 - RETAINING CLIPS

6 - DASH

Fig. 16 ICU Mounting Bolts

1 - ICU MOUNTING BOLTS

2 - COUPLER

RSBRAKES - ABS5-91

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 244 of 2177

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CLUTCH

SYSTEM.............................3

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT.......................6

DIAGNOSIS AND TESTING - CLUTCH

COVER AND DISC RUNOUT..............6

DIAGNOSIS AND TESTING - CLUTCH

CHATTER COMPLAINTS.................6

SPECIAL TOOLS - T850 TRANSAXLE........6

CLUTCH RELEASE LEVER AND BEARING

REMOVAL.............................6

INSTALLATION..........................7

MASTER CYLINDER - RHD

REMOVAL.............................8

INSTALLATION..........................9

MASTER CYLINDER - LHD

REMOVAL.............................9INSTALLATION.........................10

MODULAR CLUTCH ASSY - 2.4L GAS

REMOVAL.............................11

INSTALLATION.........................11

SLAVE CYLINDER

REMOVAL.............................11

INSTALLATION.........................11

CLUTCH DISC AND PRESSURE PLATE - 2.5L TD

REMOVAL.............................11

INSTALLATION.........................12

FLYWHEEL

REMOVAL.............................12

INSTALLATION.........................12

CLUTCH PEDAL INTERLOCK SWITCH

REMOVAL.............................13

INSTALLATION.........................14

CLUTCH PEDAL UPSTOP SWITCH

REMOVAL.............................15

INSTALLATION.........................16

CLUTCH

DESCRIPTION

CLUTCH COMPONENTS

Models equipped with a 2.4L Gas engine utilize a

modular clutch assembly (Fig. 1). The modular clutch

consists of a single, dry-type clutch disc, a diaphragm

style clutch cover, and an integrated flywheel. The

clutch cover (pressure plate) is riveted to the fly-

wheel, and therefore can only be serviced as an

assembly.

Models equipped with the 2.5L Turbo Diesel engine

utilize a conventional clutch system (Fig. 2). This

system consists of a flywheel, clutch disc, and clutch

cover (pressure plate), which is fastened to the fly-

wheel, capturing the clutch disc within. Each compo-

nent is individually serviceable, however it ishighly

recommended that the clutch cover and disc be

replaced as a set.

Fig. 1 Modular Clutch AssemblyÐ2.4L Gas Engines

1 - MODULAR CLUTCH ASSEMBLY

RSCLUTCH6-1

ProCarManuals.com

Page 245 of 2177

Fig. 2 Clutch Disc and Pressure PlateÐ2.5L TD Engines

1 - FLYWHEEL

2 - DISC

3 - PRESSURE PLATE

6 - 2 CLUTCHRS

CLUTCH (Continued)

ProCarManuals.com

Page 246 of 2177

RELEASE SYSTEM

All models utilize a hydraulic clutch release sys-

tem, conisting of a clutch master cylinder attached to

the clutch pedal (Fig. 3), and a slave cylinder fas-

tened to the transaxle which operates the clutch

release lever (Fig. 4). When the driver depresses the

clutch pedal, the master cylinder pushrod travels

through the cylinder bore, displacing fluid through

the master cylinder plumbing. This fluid displace-

ment forces the slave cylinder piston to travel, forc-

ing the clutch release bearing into the clutch

diaphragm spring via the release lever and leverage

(Fig. 5). This releases the clamping force on the

clutch disc, allowing the engine crankshaft to rotate

independently from the transaxle input shaft.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CLUTCH SYSTEM

Clutch problem diagnosis will generally require a

road test to determine the type of fault. Component

inspection will then determine the problem after road

testing.

Drive the vehicle at normal speeds during road

test. Shift the transaxle through all gear ranges and

observe clutch action. If chatter, grab, slip, or

improper release is experienced, remove and inspectthe clutch components. If the problem is noise or

hard shifting, further diagnosis may be needed. The

transaxle or other driveline components may actually

be at fault.

Fig. 3 Clutch Master Cylinder - Typical

1 - CLUTCH PEDAL

2 - BUSHING

3 - GROMMET

4 - MASTER CYLINDER

5-STOP

Fig. 4 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

Fig. 5 Release Bearing and Lever

1 - RELEASE LEVER

2 - RELEASE BEARING

RSCLUTCH6-3

CLUTCH (Continued)

ProCarManuals.com

Page 247 of 2177

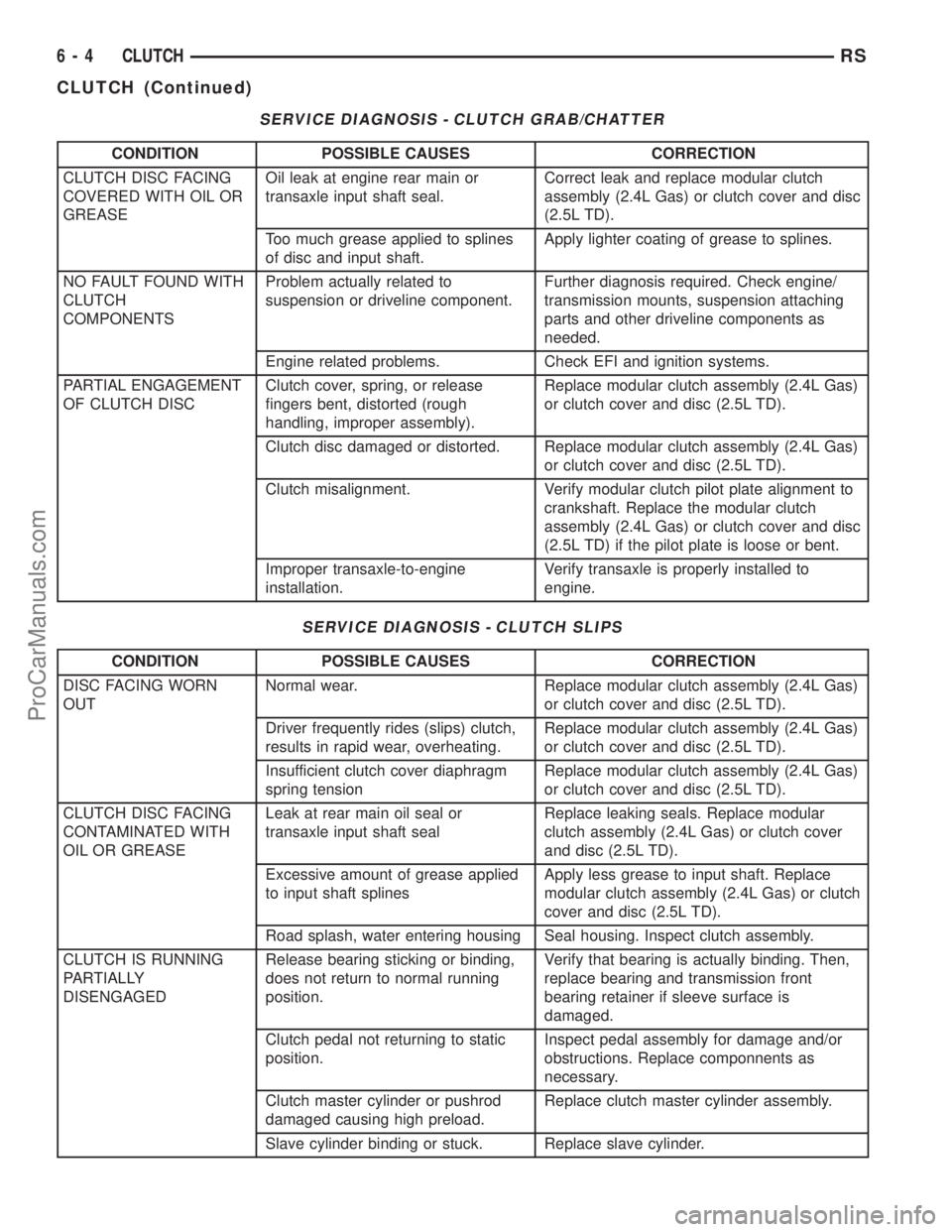

SERVICE DIAGNOSIS - CLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACING

COVERED WITH OIL OR

GREASEOil leak at engine rear main or

transaxle input shaft seal.Correct leak and replace modular clutch

assembly (2.4L Gas) or clutch cover and disc

(2.5L TD).

Too much grease applied to splines

of disc and input shaft.Apply lighter coating of grease to splines.

NO FAULT FOUND WITH

CLUTCH

COMPONENTSProblem actually related to

suspension or driveline component.Further diagnosis required. Check engine/

transmission mounts, suspension attaching

parts and other driveline components as

needed.

Engine related problems. Check EFI and ignition systems.

PARTIAL ENGAGEMENT

OF CLUTCH DISCClutch cover, spring, or release

fingers bent, distorted (rough

handling, improper assembly).Replace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

Clutch disc damaged or distorted. Replace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

Clutch misalignment. Verify modular clutch pilot plate alignment to

crankshaft. Replace the modular clutch

assembly (2.4L Gas) or clutch cover and disc

(2.5L TD) if the pilot plate is loose or bent.

Improper transaxle-to-engine

installation.Verify transaxle is properly installed to

engine.

SERVICE DIAGNOSIS - CLUTCH SLIPS

CONDITION POSSIBLE CAUSES CORRECTION

DISC FACING WORN

OUTNormal wear. Replace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

Driver frequently rides (slips) clutch,

results in rapid wear, overheating.Replace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

Insufficient clutch cover diaphragm

spring tensionReplace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

CLUTCH DISC FACING

CONTAMINATED WITH

OIL OR GREASELeak at rear main oil seal or

transaxle input shaft sealReplace leaking seals. Replace modular

clutch assembly (2.4L Gas) or clutch cover

and disc (2.5L TD).

Excessive amount of grease applied

to input shaft splinesApply less grease to input shaft. Replace

modular clutch assembly (2.4L Gas) or clutch

cover and disc (2.5L TD).

Road splash, water entering housing Seal housing. Inspect clutch assembly.

CLUTCH IS RUNNING

PARTIALLY

DISENGAGEDRelease bearing sticking or binding,

does not return to normal running

position.Verify that bearing is actually binding. Then,

replace bearing and transmission front

bearing retainer if sleeve surface is

damaged.

Clutch pedal not returning to static

position.Inspect pedal assembly for damage and/or

obstructions. Replace componnents as

necessary.

Clutch master cylinder or pushrod

damaged causing high preload.Replace clutch master cylinder assembly.

Slave cylinder binding or stuck. Replace slave cylinder.

6 - 4 CLUTCHRS

CLUTCH (Continued)

ProCarManuals.com