break CHRYSLER VOYAGER 2003 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 2014 of 2177

damaged, the clutch electromagnetic coil unit must

be replaced.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch plate into contact with the clutch pulley and

drives the compressor shaft. When the coil is not

energized, the pulley freewheels on the clutch hub

bearing, which is part of the pulley.

A zener diode is connected in parallel with the

clutch electromagnetic coil. This diode controls the

dissipation of voltage induced into the coil windings

by the collapsing of the electromagnetic fields that

occurs when the compressor clutch is disengaged.

The zener diode dissipates this induced voltage by

regulating a current path to ground. This arrange-

ment serves to protect other circuits and components

from potentially damaging voltage spikes in the vehi-

cle electrical system that might occur if the voltage

induced in the clutch coil windings could not be dis-

sipated.

The compressor clutch engagement is controlled by

several components: the heater-A/C controls in the

passenger compartment, the A/C pressure transducer

on the liquid line, the evaporator temperature sensor

on the expansion valve, the Powertrain Control Mod-

ule (PCM) in the engine compartment, and the com-

pressor clutch relay in the Intelligent Power Module

(IPM). The PCM may delay compressor clutch

engagement for up to thirty seconds. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION - PCM OPERATION).

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPRESSOR

CLUTCH AIR GAP

If a new clutch plate and/or clutch pulley are being

used, the air gap between the clutch plate and clutch

pulley must be checked using the following proce-

dure:

(1) Using feeler gauges, measure the air gap

between the clutch plate and the clutch pulley fric-

tion surfaces.

(2) If the air gap is not between 0.5 and 0.9 mm

(0.020 and 0.035 in.), add or subtract shims until the

desired air gap is obtained.

NOTE: The shims may compress after tightening

the compressor shaft bolt. Check the air gap in four

or more places on the clutch plate to verify that the

air gap is still correct. Spin the clutch pulley before

making the final air gap check.

STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

check that the compressor clutch coil is performing to

specifications. (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS - FRONT/COMPRESSOR

CLUTCH COIL - DIAGNOSIS AND TESTING). If

the clutch coil is performing to specifications, per-

form the compressor clutch break-in procedure. This

procedure (burnishing) will seat the opposing friction

surfaces and provide a higher compressor clutch

torque capability.

(1) Set the heater-A/C controls to the A/C mode,

with the blower switch in the highest speed position.

(2) Start the engine and hold the engine speed at

1500 to 2000 rpm.

(3) Cycle the compressor clutch On and Off about

twenty times (seven seconds On, then seven seconds

Off).

REMOVAL

The refrigerant system can remain fully charged

during compressor clutch, pulley, or coil replacement.

Although the compressor assembly must be removed

from its mounting, the compressor clutch can be ser-

vice with the compressor in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

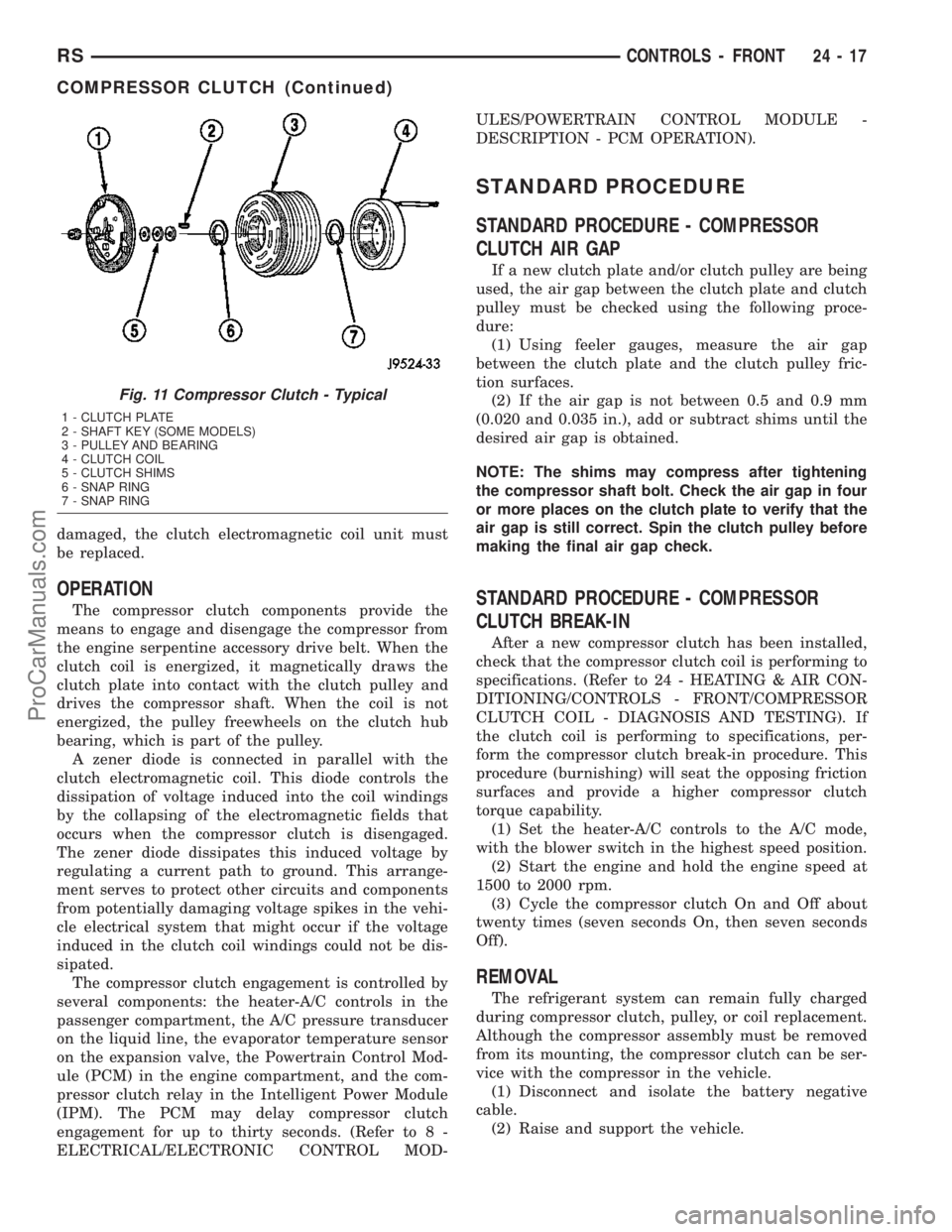

Fig. 11 Compressor Clutch - Typical

1 - CLUTCH PLATE

2 - SHAFT KEY (SOME MODELS)

3 - PULLEY AND BEARING

4 - CLUTCH COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

RSCONTROLS - FRONT24-17

COMPRESSOR CLUTCH (Continued)

ProCarManuals.com

Page 2017 of 2177

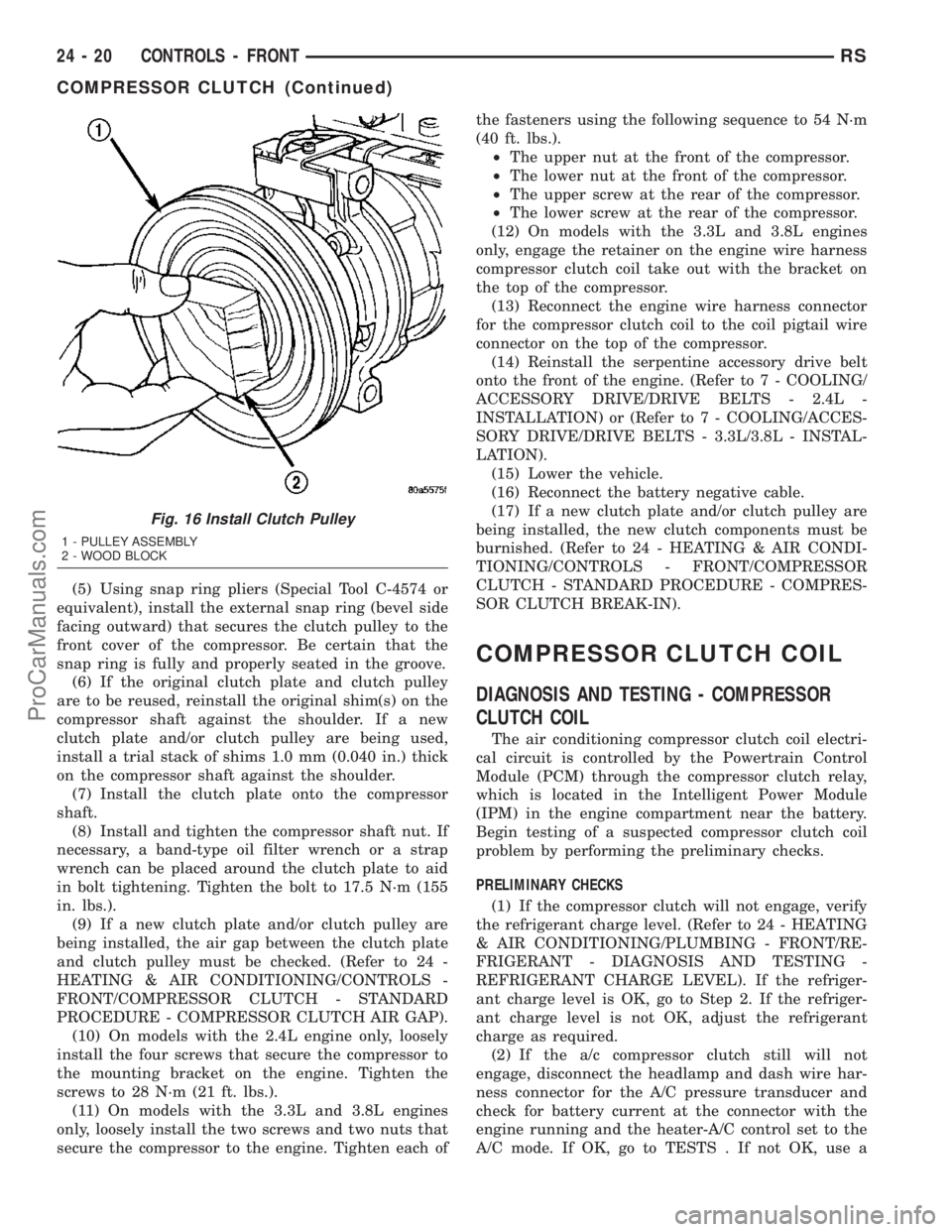

(5) Using snap ring pliers (Special Tool C-4574 or

equivalent), install the external snap ring (bevel side

facing outward) that secures the clutch pulley to the

front cover of the compressor. Be certain that the

snap ring is fully and properly seated in the groove.

(6) If the original clutch plate and clutch pulley

are to be reused, reinstall the original shim(s) on the

compressor shaft against the shoulder. If a new

clutch plate and/or clutch pulley are being used,

install a trial stack of shims 1.0 mm (0.040 in.) thick

on the compressor shaft against the shoulder.

(7) Install the clutch plate onto the compressor

shaft.

(8) Install and tighten the compressor shaft nut. If

necessary, a band-type oil filter wrench or a strap

wrench can be placed around the clutch plate to aid

in bolt tightening. Tighten the bolt to 17.5 N´m (155

in. lbs.).

(9) If a new clutch plate and/or clutch pulley are

being installed, the air gap between the clutch plate

and clutch pulley must be checked. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS -

FRONT/COMPRESSOR CLUTCH - STANDARD

PROCEDURE - COMPRESSOR CLUTCH AIR GAP).

(10) On models with the 2.4L engine only, loosely

install the four screws that secure the compressor to

the mounting bracket on the engine. Tighten the

screws to 28 N´m (21 ft. lbs.).

(11) On models with the 3.3L and 3.8L engines

only, loosely install the two screws and two nuts that

secure the compressor to the engine. Tighten each ofthe fasteners using the following sequence to 54 N´m

(40 ft. lbs.).

²The upper nut at the front of the compressor.

²The lower nut at the front of the compressor.

²The upper screw at the rear of the compressor.

²The lower screw at the rear of the compressor.

(12) On models with the 3.3L and 3.8L engines

only, engage the retainer on the engine wire harness

compressor clutch coil take out with the bracket on

the top of the compressor.

(13) Reconnect the engine wire harness connector

for the compressor clutch coil to the coil pigtail wire

connector on the top of the compressor.

(14) Reinstall the serpentine accessory drive belt

onto the front of the engine. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - 2.4L -

INSTALLATION) or (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - 3.3L/3.8L - INSTAL-

LATION).

(15) Lower the vehicle.

(16) Reconnect the battery negative cable.

(17) If a new clutch plate and/or clutch pulley are

being installed, the new clutch components must be

burnished. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/COMPRESSOR

CLUTCH - STANDARD PROCEDURE - COMPRES-

SOR CLUTCH BREAK-IN).

COMPRESSOR CLUTCH COIL

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

The air conditioning compressor clutch coil electri-

cal circuit is controlled by the Powertrain Control

Module (PCM) through the compressor clutch relay,

which is located in the Intelligent Power Module

(IPM) in the engine compartment near the battery.

Begin testing of a suspected compressor clutch coil

problem by performing the preliminary checks.

PRELIMINARY CHECKS

(1) If the compressor clutch will not engage, verify

the refrigerant charge level. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - FRONT/RE-

FRIGERANT - DIAGNOSIS AND TESTING -

REFRIGERANT CHARGE LEVEL). If the refriger-

ant charge level is OK, go to Step 2. If the refriger-

ant charge level is not OK, adjust the refrigerant

charge as required.

(2) If the a/c compressor clutch still will not

engage, disconnect the headlamp and dash wire har-

ness connector for the A/C pressure transducer and

check for battery current at the connector with the

engine running and the heater-A/C control set to the

A/C mode. If OK, go to TESTS . If not OK, use a

Fig. 16 Install Clutch Pulley

1 - PULLEY ASSEMBLY

2 - WOOD BLOCK

24 - 20 CONTROLS - FRONTRS

COMPRESSOR CLUTCH (Continued)

ProCarManuals.com

Page 2143 of 2177

BODY CONTROL MODULE -

INSTALLATION........................8E-5

BODY CONTROL MODULE - OPERATION . . . 8E-3

BODY CONTROL MODULE - REMOVAL.....8E-4

BODY LUBRICATION, SPECIFICATIONS....23-12

BODY OPENING DIMENSIONS -

SPECIFICATIONS....................23-124

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC.................23-3

BODY SEALING LOCATIONS -

SPECIFICATIONS....................23-127

BODY SIDE MOLDINGS - INSTALLATION . . 23-45

BODY SIDE MOLDINGS - REMOVAL......23-44

BODY, SPECIAL TOOLS................23-13

BOLSTER - INSTALLATION, QUARTER

TRIM..............................23-77

BOLSTER - REMOVAL, QUARTER TRIM . . . 23-77

BOOSTER - DESCRIPTION, POWER

BRAKE..............................5-40

BOOSTER - DIAGNOSIS AND TESTING,

POWER BRAKE.......................5-41

BOOSTER - OPERATION, POWER BRAKE . . . 5-41

BOOT - INNER - INSTALLATION, CV........3-6

BOOT - INNER - REMOVAL, CV...........3-6

BOOT - INNER/OUTER - INSTALLATION,

CV .................................3-17

BOOT - INNER/OUTER - REMOVAL, CV....3-15

BOOT - INSTALLATION, BALL JOINT

SEAL...............................2-11

BOOT - INSTALLATION, GEARSHIFT........21-73

BOOT - OUTER - INSTALLATION, CV......3-10

BOOT - OUTER - REMOVAL, CV..........3-10

BOOT - REMOVAL, BALL JOINT SEAL.....2-11

BOOT - REMOVAL, GEARSHIFT..........21-72

BORE FITTING - STANDARD

PROCEDURE, PISTON TO CYLINDER......9-42

BORE HONING - STANDARD

PROCEDURE, CYLINDER...........9-112,9-35

BOX - INSTALLATION, GLOVE...........23-63

BOX - REMOVAL, GLOVE..............23-63

BOX LAMP SWITCH - INSTALLATION,

GLOVE.............................8L-26

BOX LAMP SWITCH - REMOVAL, GLOVE . . 8L-26

BOX LATCH - INSTALLATION, GLOVE.....23-63

BOX LATCH - REMOVAL, GLOVE.........23-63

BOX LATCH STRIKER - INSTALLATION,

GLOVE.............................23-64

BOX LATCH STRIKER - REMOVAL,

GLOVE.............................23-64

B-PILLAR - INSTALLATION, A-PILLAR-

HEADER, OR........................23-17

B-PILLAR - REMOVAL, A-PILLAR-

HEADER, OR........................23-17

B-PILLAR LOWER TRIM - INSTALLATION . . 23-74

B-PILLAR LOWER TRIM - REMOVAL.....23-73

B-PILLAR SWITCH - DESCRIPTION, LEFT . 8N-32

B-PILLAR SWITCH - DESCRIPTION,

RIGHT.............................8N-32

B-PILLAR SWITCH - INSTALLATION,

LEFT..............................8N-32

B-PILLAR SWITCH - INSTALLATION,

RIGHT.............................8N-32

B-PILLAR SWITCH - OPERATION, LEFT . . . 8N-32

B-PILLAR SWITCH - OPERATION, RIGHT . . 8N-32

B-PILLAR SWITCH - REMOVAL, LEFT....8N-32

B-PILLAR SWITCH - REMOVAL, RIGHT . . . 8N-32

B-PILLAR UPPER TRIM - INSTALLATION

. . 23-74

B-PILLAR UPPER TRIM - REMOVAL

......23-74

BRACKET - 2.4L ENGINE -

INSTALLATION, COMPRESSOR

MOUNTING

.........................24-66

BRACKET - 2.4L ENGINE - REMOVAL,

COMPRESSOR MOUNTING

.............24-65

BRACKET - DESCRIPTION, TRANSVERSE

. . 8N-18

BRACKET - INSTALLATION, TRANSVERSE

. 8N-18

BRACKET - OPERATION, TRANSVERSE

. . . 8N-18

BRACKET - REMOVAL, TRANSVERSE

.....8N-18

BRACKET ASSEMBLY - INSTALLATION,

FLOOR CONSOLE TRAY

................23-82

BRACKET ASSEMBLY - REMOVAL,

FLOOR CONSOLE TRAY

................23-82

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK

...........................8E-5

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK

...........................8E-6

BRAKE - INSTALLATION, LEVER -

PARKING

............................5-65BRAKE - INSTALLATION, SHOES -

PARKING............................5-72

BRAKE - INSTALLATION, SUPPORT

PLATE - DRUM.......................5-56

BRAKE - OPERATION, CONTROLLER

ANTILOCK...........................8E-5

BRAKE - REMOVAL, CONTROLLER

ANTILOCK...........................8E-6

BRAKE - REMOVAL, LEVER - PARKING....5-64

BRAKE - REMOVAL, SHOES - PARKING....5-67

BRAKE - REMOVAL, SUPPORT PLATE -

DRUM..............................5-56

BRAKE AUTOMATIC ADJUSTER -

DIAGNOSIS AND TESTING, DRUM........5-13

BRAKE AUTOMATIC ADJUSTER TENSION

RELEASE - STANDARD PROCEDURE,

PARKING............................5-58

BRAKE AUTOMATIC ADJUSTER TENSION

RESET - STANDARD PROCEDURE,

PARKING............................5-59

BRAKE BLEEDING - STANDARD

PROCEDURE, BASE.....................5-7

BRAKE BOOSTER - DESCRIPTION,

POWER.............................5-40

BRAKE BOOSTER - DIAGNOSIS AND

TESTING, POWER.....................5-41

BRAKE BOOSTER - OPERATION, POWER . . . 5-41

BRAKE CABLE (FRONT) - INSTALLATION,

PARKING............................5-63

BRAKE CABLE (FRONT) - REMOVAL,

PARKING............................5-59

BRAKE CABLE (INTERMEDIATE) -

INSTALLATION, PARKING...............5-63

BRAKE CABLE (INTERMEDIATE) -

REMOVAL, PARKING...................5-60

BRAKE CABLE (LEFT REAR) -

INSTALLATION, PARKING...............5-64

BRAKE CABLE (LEFT REAR) - REMOVAL,

PARKING............................5-62

BRAKE CABLE (RIGHT REAR) -

INSTALLATION, PARKING...............5-63

BRAKE CABLE (RIGHT REAR) -

REMOVAL, PARKING...................5-60

BRAKE CABLES - ADJUSTMENT,

PARKING............................5-64

BRAKE CALIPER - INSTALLATION, REAR

DISC...............................5-30

BRAKE CALIPER - REMOVAL, REAR

DISC...............................5-27

BRAKE CALIPER ADAPTER -

INSTALLATION, FRONT DISC.............5-31

BRAKE CALIPER ADAPTER - REMOVAL,

FRONT DISC.........................5-31

BRAKE CALIPER (DISC/DISC BRAKES) -

INSTALLATION, FRONT DISC.............5-27

BRAKE CALIPER (DISC/DISC BRAKES) -

REMOVAL, FRONT DISC................5-24

BRAKE CALIPER (DISC/DRUM BRAKES) -

INSTALLATION, FRONT DISC.............5-27

BRAKE CALIPER (DISC/DRUM BRAKES) -

REMOVAL, FRONT DISC................5-24

BRAKE CALIPER GUIDE PINS (DISC/

DRUM BRAKES) - INSTALLATION, DISC....5-31

BRAKE CALIPER GUIDE PINS (DISC/

DRUM BRAKES) - REMOVAL, DISC.......5-31

BRAKE FASTENER TORQUE,

SPECIFICATIONS.......................5-9

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-32

BRAKE FLUID LEVEL CHECKING -

STANDARD PROCEDURE................5-32

BRAKE FLUID LEVEL SWITCH -

DESCRIPTION........................5-10

BRAKE FLUID LEVEL SWITCH -

INSTALLATION........................5-11

BRAKE FLUID LEVEL SWITCH -

OPERATION..........................5-10

BRAKE FLUID LEVEL SWITCH -

REMOVAL...........................5-11

BRAKE FLUID, SPECIFICATIONS..........5-33

BRAKE LAMP SWITCH - DESCRIPTION....8L-4

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING

........................8L-5

BRAKE LAMP SWITCH - INSTALLATION

....8L-5

BRAKE LAMP SWITCH - OPERATION

......8L-4

BRAKE LAMP SWITCH - REMOVAL

.......8L-5

BRAKE LEVER AND FRONT CABLE -

INSTALLATION, PARKING

...............5-66BRAKE LEVER AND FRONT CABLE -

REMOVAL, PARKING...................5-65

BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC VARIABLE....5-75

BRAKE PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE................5-77

BRAKE ROTOR - DIAGNOSIS AND

TESTING............................5-51

BRAKE ROTOR - INSTALLATION, FRONT . . . 5-54

BRAKE ROTOR - REMOVAL, FRONT.......5-54

BRAKE ROTOR, EXPORT................5-55

BRAKE ROTOR MACHINING - STANDARD

PROCEDURE.........................5-53

BRAKE ROTOR, SPECIFICATIONS.........5-55

BRAKE SHOE LINING - INSPECTION,

REAR DRUM.........................5-22

BRAKE SHOES - ADJUSTMENT, PARKING . . 5-73

BRAKE SHOES - ADJUSTMENT, REAR

DRUM..............................5-23

BRAKE SHOES - CLEANING, DISC....5-16,5-18

BRAKE SHOES - INSPECTION, DISC . . . 5-16,5-18

BRAKE SHOES - INSTALLATION, REAR

DISC...............................5-19

BRAKE SHOES - INSTALLATION, REAR

DRUM..............................5-22

BRAKE SHOES - REMOVAL, REAR DISC....5-17

BRAKE SHOES - REMOVAL, REAR DRUM . . 5-19

BRAKE SHOES (DISC/DISC BRAKES) -

INSTALLATION, FRONT DISC.............5-16

BRAKE SHOES (DISC/DISC BRAKES) -

REMOVAL, FRONT DISC..................5-14

BRAKE SHOES (DISC/DRUM BRAKES) -

INSTALLATION, FRONT DISC.............5-17

BRAKE SHOES (DISC/DRUM BRAKES) -

REMOVAL, FRONT DISC................5-15

BRAKE SYSTEM - DESCRIPTION,

ANTILOCK...........................5-75

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-4

BRAKE SYSTEM - OPERATION,

ANTILOCK...........................5-76

BRAKE SYSTEM BLEEDING - STANDARD

PROCEDURE, ANTILOCK................5-78

BRAKE SYSTEM (EXPORT) -

DESCRIPTION, ANTILOCK...............5-75

BRAKE SYSTEM, SPECIAL TOOLS - BASE . . 5-10

BRAKE TUBES AND HOSES -

DESCRIPTION........................5-14

BRAKE TUBES AND HOSES -

INSPECTION.........................5-14

BRAKE TUBES AND HOSES - OPERATION . . 5-14

BRAKES - DESCRIPTION, BASE...........5-3

BRAKES - OPERATION, BASE.............5-3

BRAKES (EXPORT) - DESCRIPTION,

BASE................................5-3

BRAKES (EXPORT) - DESCRIPTION, DISC . . 5-13

BRAKES (FRONT) - DESCRIPTION, DISC . . . 5-11

BRAKES (FRONT) - OPERATION, DISC.....5-13

BRAKES (REAR) - DESCRIPTION, DISC

....5-12

BRAKES (REAR) - DESCRIPTION, DRUM

. . . 5-13

BRAKES (REAR) - OPERATION, DISC

......5-13

BRAKE/TRANSMISSION SHIFT

INTERLOCK SOLENOID - DIAGNOSIS

AND TESTING

......................21-235

BREAK-IN - STANDARD PROCEDURE,

COMPRESSOR CLUTCH

...............24-17

BUCKET - INSTALLATION, BUCKET SEAT

BACK - QUAD

.......................23-97

BUCKET - INSTALLATION, SEAT BELT

BUCKLE - FIRST ROW INBOARD -

QUAD

.............................8O-11

BUCKET - REMOVAL, BUCKET SEAT

BACK - QUAD

.......................23-97

BUCKET - REMOVAL, SEAT BELT BUCKLE

- FIRST ROW INBOARD - QUAD

.........8O-11

BUCKET, 50/50 SPLIT, BENCH -

INSTALLATION, SEAT BACK HINGE

COVERS - QUAD

....................23-100

BUCKET, 50/50 SPLIT, BENCH -

INSTALLATION, SEAT CUSHION COVER

- QUAD

............................23-99

BUCKET, 50/50 SPLIT, BENCH -

REMOVAL, SEAT BACK HINGE COVERS

- QUAD

...........................23-100

BUCKET, 50/50 SPLIT, BENCH -

REMOVAL, SEAT CUSHION COVER -

QUAD

..............................23-98

4 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2145 of 2177

CENTER - DESCRIPTION, ELECTRONIC

VEHICLE INFO.......................8M-6

CENTER - DIAGNOSIS AND TESTING,

ELECTRONIC VEHICLE INFORMATION.....8M-7

CENTER - INSTALLATION, ELECTRONIC

VEHICLE INFO.......................8M-9

CENTER - OPERATION, ELECTRONIC

VEHICLE INFO.......................8M-7

CENTER - REMOVAL, ELECTRONIC

VEHICLE INFO.......................8M-9

CENTER BEZEL - INSTALLATION,

INSTRUMENT PANEL..................23-67

CENTER BEZEL - REMOVAL,

INSTRUMENT PANEL..................23-67

CENTER BEZEL OUTLETS -

INSTALLATION.......................24-42

CENTER BEZEL OUTLETS - REMOVAL....24-40

CENTER CONSOLE LAMP SWITCH -

INSTALLATION.......................8L-26

CENTER CONSOLE LAMP SWITCH -

REMOVAL..........................8L-26

CENTER HIGH MOUNTED STOP LAMP -

INSTALLATION........................8L-6

CENTER HIGH MOUNTED STOP LAMP -

REMOVAL...........................8L-6

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION..................8L-7

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL.....................8L-6

CENTER HINGE - INSTALLATION.........23-24

CENTER HINGE - REMOVAL............23-24

CENTER PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC VEHICLE

INFORMATION.......................8M-7

CENTER STRIKER - INSTALLATION.......23-27

CENTER STRIKER - REMOVAL..........23-27

CENTERING - STANDARD PROCEDURE,

CLOCK SPRING.......................8O-4

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY..................Intro.-11

CHAIN AND CAMSHAFT SPROCKET -

INSTALLATION, TIMING................9-157

CHAIN AND CAMSHAFT SPROCKET -

REMOVAL, TIMING...................9-156

CHAIN COVER - INSTALLATION, TIMING . . 9-155

CHAIN COVER - REMOVAL, TIMING......9-153

CHAIN WEAR - STANDARD PROCEDURE,

MEASURING TIMING..................9-153

CHANGE - STANDARD PROCEDURE,

DIFFERENTIAL ASSEMBLY FLUID.........3-40

CHANGE - STANDARD PROCEDURE,

ENGINE OIL AND FILTER...........9-137,9-53

CHANGE - STANDARD PROCEDURE,

OVERRUNNING CLUTCH HOUSING

FLUID..............................3-41

CHANGE - STANDARD PROCEDURE, PTU

FLUID..............................21-5

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-8

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-8

CHANNEL - INSTALLATION, WATER.....23-118

CHANNEL - REMOVAL, WATER.........23-118

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM

...............24-88

CHARGE LEVEL - DIAGNOSIS AND

TESTING, REFRIGERANT SYSTEM

.......24-85

CHARGING - STANDARD PROCEDURE,

CONVENTIONAL BATTERY

..............8F-11

CHARGING - STANDARD PROCEDURE,

SPIRAL PLATE BATTERY

...............8F-10

CHARGING SYSTEM - DESCRIPTION

.....8F-20

CHARGING SYSTEM - OPERATION

.......8F-20

CHARTS - DIAGNOSIS AND TESTING,

STEERING SYSTEM DIAGNOSIS

..........19-3

CHARTS - SPECIFICATIONS, COLOR

CODE

..............................23-83

CHATTER COMPLAINTS - DIAGNOSIS

AND TESTING, CLUTCH

.................6-6

CHECK - DIAGNOSIS AND TESTING,

COOLING SYSTEM FLOW

................7-3

CHECK - DIAGNOSIS AND TESTING,

EXHAUST SYSTEM RESTRICTION

.........11-2

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL

.......................7-5

CHECK - STANDARD PROCEDURE,

ENGINE OIL LEVEL

...................9-137CHECK - STANDARD PROCEDURE, FLUID

LEVEL.............................21-71

CHECK, STANDARD PROCEDURE -

ENGINE OIL LEVEL....................9-53

CHECK, STANDARD PROCEDURE - FLUID

LEVEL AND CONDITION..............21-201

CHECK STRAP - INSTALLATION.........23-15

CHECK STRAP - REMOVAL.............23-15

CHECKING - STANDARD PROCEDURE,

BRAKE FLUID LEVEL...................5-32

CHECKING - STANDARD PROCEDURE,

POWER STEERING FLUID LEVEL........19-44

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE........8F-14

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING..............9-52

CHECKING POWER STEERING BELT

TENSION - STANDARD PROCEDURE.......7-8

CHILD SEAT - INSTALLATION, QUAD.....23-88

CHILD SEAT - REMOVAL, QUAD.........23-88

CHILD SEAT MODULE, BENCH SEAT -

REMOVAL..........................23-86

CHIME SYSTEM - DIAGNOSIS AND

TESTING............................8B-1

CHIME/BUZZER - DESCRIPTION..........8B-1

CHIME/BUZZER - OPERATION............8B-1

CHIME/BUZZER - WARNING.............8B-1

CHIME/THERMISTOR - DESCRIPTION....8N-10

CHIME/THERMISTOR - INSTALLATION....8N-10

CHIME/THERMISTOR - OPERATION......8N-10

CHIME/THERMISTOR - REMOVAL.......8N-10

CHIRP PREFERENCE - STANDARD

PROCEDURE, HORN..................8N-42

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT RESISTANCE TEST -

DIAGNOSIS AND TESTING, FEED........8F-32

CIRCUIT TEST - DIAGNOSIS AND

TESTING, CONTROL..................8F-30

CIRCUIT TEST - DIAGNOSIS AND

TESTING, FEED......................8F-33

CIRCUITS - OPERATION, NON-

MONITORED.........................25-5

CIRCUITS AND VALVES - OPERATION,

HYDRAULIC..........................5-83

CLAMP - STANDARD PROCEDURE,

HOSES..............................14-6

CLAMPS - DESCRIPTION, FUEL

LINES/HOSES........................14-6

CLAMPS - DESCRIPTION, HOSE...........7-1

CLAMPS - OPERATION, HOSE.............7-2

CLEAN, CLEANING...................21-114

CLEARANCE - STANDARD PROCEDURE,

MEASURING CONNECTING ROD

BEARING...........................9-120

CLEARANCE USING PLASTIGAGE -

STANDARD PROCEDURE, MEASURING

BEARING........................9-12,9-84

CLOCK SPRING - DESCRIPTION..........8O-4

CLOCK SPRING - INSTALLATION.........8O-5

CLOCK SPRING - OPERATION...........8O-4

CLOCK SPRING - REMOVAL.............8O-4

CLOCK SPRING CENTERING -

STANDARD PROCEDURE...............8O-4

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT.....8J-1

CLUSTER BEZEL - INSTALLATION

........23-62

CLUSTER BEZEL - REMOVAL

...........23-62

CLUSTER DIAGNOSIS - DIAGNOSIS AND

TESTING

............................8J-2

CLUSTER ILLUMINATION LAMPS -

INSTALLATION

.......................8L-26

CLUSTER ILLUMINATION LAMPS -

REMOVAL

..........................8L-26

CLUSTER LENS - INSTALLATION

........8J-10

CLUSTER LENS - REMOVAL

............8J-10

CLUTCH - DESCRIPTION

.................6-1

CLUTCH - DESCRIPTION, BI-

DIRECTIONAL OVERRUNNING

...........3-34

CLUTCH - DESCRIPTION, COMPRESSOR

. . 24-16

CLUTCH - OPERATION, BI-DIRECTIONAL

OVERRUNNING

.......................3-36

CLUTCH - OPERATION, COMPRESSOR

....24-17

CLUTCH AIR GAP - STANDARD

PROCEDURE, COMPRESSOR

...........24-17CLUTCH AIR PRESSURE TESTS -

DIAGNOSIS AND TESTING............21-122

CLUTCH ASSEMBLY - ASSEMBLY, INPUT . 21-216

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-208

CLUTCH ASSY - 2.4L GAS -

INSTALLATION, MODULAR..............6-11

CLUTCH ASSY - 2.4L GAS - REMOVAL,

MODULAR...........................6-11

CLUTCH BREAK-IN - STANDARD

PROCEDURE, COMPRESSOR...........24-17

CLUTCH CHATTER COMPLAINTS -

DIAGNOSIS AND TESTING...............6-6

CLUTCH COIL - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-20

CLUTCH COVER AND DISC RUNOUT -

DIAGNOSIS AND TESTING...............6-6

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - INSTALLATION...............6-12

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - REMOVAL...................6-11

CLUTCH HOUSING FLUID CHANGE -

STANDARD PROCEDURE,

OVERRUNNING.......................3-41

CLUTCH PEDAL INTERLOCK SWITCH -

INSTALLATION........................6-14

CLUTCH PEDAL INTERLOCK SWITCH -

REMOVAL...........................6-13

CLUTCH PEDAL UPSTOP SWITCH -

INSTALLATION........................6-16

CLUTCH PEDAL UPSTOP SWITCH -

REMOVAL...........................6-15

CLUTCH RELAY - DESCRIPTION,

COMPRESSOR........................24-21

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-22

CLUTCH RELAY - INSTALLATION,

COMPRESSOR.......................24-22

CLUTCH RELAY - OPERATION,

COMPRESSOR.......................24-21

CLUTCH RELAY - REMOVAL,

COMPRESSOR.......................24-22

CLUTCH RELEASE LEVER AND BEARING

- INSTALLATION.......................6-7

CLUTCH RELEASE LEVER AND BEARING

- REMOVAL...........................6-6

CLUTCH SYSTEM - DIAGNOSIS AND

TESTING.............................6-3

CLUTCH/COIL - INSPECTION,

COMPRESSOR.......................24-18

CLUTCHES - DESCRIPTION, DRIVING....21-190

CLUTCHES - DESCRIPTION, HOLDING . . . 21-207

CLUTCHES - OPERATION, DRIVING.....21-190

CLUTCHES - OPERATION, HOLDING.....21-207

COAT/CLEARCOAT FINISH -

DESCRIPTION, BASE..................23-84

CODE - DESCRIPTION, PAINT...........23-84

CODE CHARTS - SPECIFICATIONS,

COLOR.............................23-83

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER..............8M-11

CODES - STANDARD PROCEDURE,

OBTAINING DIAGNOSTIC TROUBLE......8E-15

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER..............8M-11

COIL - DESCRIPTION, IGNITION

..........8I-6

COIL - DIAGNOSIS AND TESTING,

COMPRESSOR CLUTCH

...............24-20

COIL - OPERATION, IGNITION

............8I-6

COLLAR - INSTALLATION, STRUCTURAL

. . . 9-48

COLLAR - REMOVAL, STRUCTURAL

.......9-47

COLOR CODE CHARTS -

SPECIFICATIONS

.....................23-83

COLUMN - DESCRIPTION, STEERING

.....19-10

COLUMN - DIAGNOSIS AND TESTING,

STEERING

..........................19-12

COLUMN COVER - INSTALLATION,

LOWER STEERING

...................23-69

COLUMN COVER - INSTALLATION, OVER

STEERING

..........................23-69

COLUMN COVER - REMOVAL, LOWER

STEERING

..........................23-69

COLUMN COVER - REMOVAL, OVER

STEERING

..........................23-69

COLUMN COVER BACKING PLATE -

INSTALLATION, STEERING

.............23-69

6 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2146 of 2177

COLUMN COVER BACKING PLATE -

REMOVAL, STEERING.................23-69

COLUMN TORQUE, SPECIFICATIONS.....19-14

COMBUSTION PRESSURE LEAKAGE

TEST - DIAGNOSIS AND TESTING,

CYLINDER........................9-83,9-9

COMMON PROBLEM CAUSES -

DIAGNOSIS AND TESTING.............21-30

COMMUNICATION RECEIVE - PCM INPUT

- OPERATION, DATA BUS..............8E-15

COMMUNICATIONS INTERFACE (PCI)

BUS, OPERATION - PROGRAMMABLE....14-21

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING.............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-5

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-9

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-10

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-10

COMPLAINTS - DIAGNOSIS AND

TESTING, CLUTCH CHATTER..............6-6

COMPRESSION PRESSURE TEST -

DIAGNOSIS AND TESTING, CYLINDER . . 9-83,9-9

COMPRESSOR - 2.4/3.3/3.8L ENGINES -

REMOVAL............................24-64

COMPRESSOR - DESCRIPTION, A/C......24-63

COMPRESSOR - INSTALLATION.........24-65

COMPRESSOR - OPERATION, A/C........24-63

COMPRESSOR CLUTCH - DESCRIPTION . . 24-16

COMPRESSOR CLUTCH - OPERATION....24-17

COMPRESSOR CLUTCH AIR GAP -

STANDARD PROCEDURE...............24-17

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-17

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-20

COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-21

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING.............24-22

COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-22

COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-21

COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-22

COMPRESSOR CLUTCH/COIL -

INSPECTION........................24-18

COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE - INSTALLATION...........24-66

COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE - REMOVAL..............24-65

COMPRESSOR NOISE DIAGNOSIS -

DIAGNOSIS AND TESTING.............24-63

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-9

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP

.................8M-10

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP

.........................8M-10

COMPUTER - OPERATION, COMPASS/

MINI-TRIP

..........................8M-9

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP

.........................8M-10

CONCENTRATION TESTING - DIAGNOSIS

AND TESTING, COOLANT

...............7-19

CONDENSER - DESCRIPTION

...........24-66

CONDENSER - INSTALLATION

...........24-67

CONDENSER - OPERATION

.............24-66

CONDENSER - REMOVAL

..............24-66

CONDITION CHECK, STANDARD

PROCEDURE - FLUID LEVEL

...........21-201

CONDITIONING LINES - INSTALLATION,

REAR AIR

.........................24-105

CONDITIONING LINES - REMOVAL, REAR

AIR

..............................24-104

CONNECTING ROD - DESCRIPTION,

PISTON

........................9-116,9-42CONNECTING ROD - INSTALLATION,

PISTON.............................9-44

CONNECTING ROD - REMOVAL, PISTON . . . 9-43

CONNECTING ROD BEARING

CLEARANCE - STANDARD

PROCEDURE, MEASURING.............9-120

CONNECTING ROD, FITTING.............9-45

CONNECTING RODS - STANDARD

PROCEDURE, FITTING.................9-116

CONNECTOR - DESCRIPTION, DATA LINK . . 8E-6

CONNECTOR - INSTALLATION.......8W-01-11

CONNECTOR - OPERATION, DATA LINK....8E-7

CONNECTOR - REMOVAL...........8W-01-11

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD....8M-1

CONSOLE - DIAGNOSIS AND TESTING,

OVERHEAD..........................8M-2

CONSOLE - INSTALLATION, LOWER......23-68

CONSOLE - OPERATION, OVERHEAD......8M-2

CONSOLE - REMOVAL, LOWER..........23-68

CONSOLE - REMOVAL, OVERHEAD.......8M-6

CONSOLE LAMP SWITCH -

INSTALLATION, CENTER...............8L-26

CONSOLE LAMP SWITCH - REMOVAL,

CENTER............................8L-26

CONSOLE, SPECIAL TOOLS - OVERHEAD . . 8M-6

CONSOLE TRAY - BRACKET ASSEMBLY -

INSTALLATION, FLOOR................23-82

CONSOLE TRAY - BRACKET ASSEMBLY -

REMOVAL, FLOOR....................23-82

CONSOLE TRAY - INSTALLATION, FLOOR . . 23-81

CONSOLE TRAY - REMOVAL, FLOOR.....23-81

CONTAINER - DESCRIPTION, COOLANT

RECOVERY..........................7-19

CONTAINER - INSTALLATION, COOLANT

RECOVERY..........................7-20

CONTAINER - OPERATION, COOLANT

RECOVERY..........................7-19

CONTAINER - REMOVAL, COOLANT

RECOVERY..........................7-20

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-32

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTROL (4 SPEED EATX ONLY) -

OPERATION, INTERACTIVE SPEED........8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-12

CONTROL ARM - INSPECTION, LOWER....2-14

CONTROL ARM - INSTALLATION, LOWER . . 2-15

CONTROL ARM - OPERATION, LOWER.....2-12

CONTROL ARM - REMOVAL, LOWER......2-12

CONTROL ARM (REAR BUSHING -

HYDRO) - ASSEMBLY, LOWER...........2-14

CONTROL ARM (REAR BUSHING -

HYDRO) - DISASSEMBLY, LOWER........2-14

CONTROL ARM (REAR BUSHING -

STANDARD) - ASSEMBLY, LOWER........2-14

CONTROL ARM (REAR BUSHING -

STANDARD) - DISASSEMBLY, LOWER.....2-13

CONTROL CABLE - INSTALLATION,

THROTTLE..........................14-35

CONTROL CABLE - REMOVAL,

THROTTLE..........................14-35

CONTROL CALIBRATION - STANDARD

PROCEDURE, HEATER-A/C..............24-8

CONTROL CIRCUIT TEST - DIAGNOSIS

AND TESTING.......................8F-30

CONTROL INFORMATION LABEL -

DESCRIPTION, VEHICLE EMISSION.......25-1

CONTROL MODULE - DESCRIPTION,

BODY...............................8E-3

CONTROL MODULE - DESCRIPTION,

FRONT..............................8E-7

CONTROL MODULE - DESCRIPTION,

POWER LIFTGATE....................8E-10

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG

.................8O-17

CONTROL MODULE - DESCRIPTION,

SLIDING DOOR

......................8E-19

CONTROL MODULE - DESCRIPTION,

TRANSMISSION

......................8E-20

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT

......................8E-7

CONTROL MODULE - INSTALLATION,

BODY

...............................8E-5CONTROL MODULE - INSTALLATION,

FRONT..............................8E-8

CONTROL MODULE - INSTALLATION,

POWER LIFTGATE....................8E-11

CONTROL MODULE - INSTALLATION,

SIDE IMPACT AIRBAG.................8O-17

CONTROL MODULE - INSTALLATION,

SLIDING DOOR......................8E-20

CONTROL MODULE - OPERATION, BODY . . . 8E-3

CONTROL MODULE - OPERATION,

FRONT..............................8E-7

CONTROL MODULE - OPERATION,

POWER LIFTGATE....................8E-11

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-17

CONTROL MODULE - OPERATION,

SLIDING DOOR......................8E-19

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-20

CONTROL MODULE - REMOVAL, BODY....8E-4

CONTROL MODULE - REMOVAL, FRONT . . . 8E-8

CONTROL MODULE - REMOVAL, POWER

LIFTGATE...........................8E-11

CONTROL MODULE - REMOVAL, SIDE

IMPACT AIRBAG.....................8O-17

CONTROL MODULE - REMOVAL,

SLIDING DOOR......................8E-19

CONTROL MOTOR - DESCRIPTION, IDLE

AIR ...............................14-28

CONTROL MOTOR - INSTALLATION, IDLE

AIR ...............................14-29

CONTROL MOTOR - OPERATION, IDLE

AIR.................................14-28

CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-29

CONTROL RELAY - DESCRIPTION,

TRANSMISSION.....................21-247

CONTROL RELAY - OPERATION,

TRANSMISSION.....................21-248

CONTROL SWITCH - DIAGNOSIS AND

TESTING, TRACTION...................5-82

CONTROL SYSTEM - DESCRIPTION,

TRACTION...........................5-76

CONTROL SYSTEM - OPERATION,

EVAPORATION.......................25-10

CONTROL SYSTEM - OPERATION,

TRACTION...........................5-77

CONTROLLER - DESCRIPTION,

OCCUPANT RESTRAINT................8O-7

CONTROLLER - INSTALLATION,

OCCUPANT RESTRAINT................8O-7

CONTROLLER - INSTALLATION, SBEC....8E-17

CONTROLLER - OPERATION, 8-VOLT

SUPPLY - PCM OUTPUT - SBEC.........8E-15

CONTROLLER - OPERATION, OCCUPANT

RESTRAINT..........................8O-7

CONTROLLER - REMOVAL, NGC.........8E-17

CONTROLLER - REMOVAL, OCCUPANT

RESTRAINT..........................8O-7

CONTROLLER - REMOVAL, SBEC........8E-16

CONTROLLER ANTILOCK BRAKE -

DESCRIPTION........................8E-5

CONTROLLER ANTILOCK BRAKE -

INSTALLATION........................8E-6

CONTROLLER ANTILOCK BRAKE -

OPERATION..........................8E-5

CONTROLLER ANTILOCK BRAKE -

REMOVAL...........................8E-6

CONVENTIONAL BATTERY CHARGING -

STANDARD PROCEDURE...............8F-11

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-4

CONVERTER - DESCRIPTION, TORQUE . . . 21-242

CONVERTER - INSPECTION, CATALYTIC....11-5

CONVERTER - INSTALLATION, CATALYTIC . . 11-6

CONVERTER - INSTALLATION, TORQUE . . 21-247

CONVERTER - OPERATION, CATALYTIC....11-4

CONVERTER - OPERATION, TORQUE....21-245

CONVERTER - REMOVAL, CATALYTIC......11-5

CONVERTER - REMOVAL, TORQUE......21-247

CONVERTER HOUSING FLUID LEAKAGE -

DIAGNOSIS AND TESTING, TORQUE.....21-123

COOL DOWN TEST - DIAGNOSIS AND

TESTING, A/C

........................24-4

COOLANT - DESCRIPTION, ENGINE

.......7-19

COOLANT - DESCRIPTION, ENGINE

........0-3

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL

...................7-5

COOLANT CONCENTRATION TESTING -

DIAGNOSIS AND TESTING

..............7-19

RSINDEX7

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com