mirror CHRYSLER VOYAGER 2003 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 1418 of 2177

SHROUD - UPPER

REMOVAL

(1) Remove the two shroud-to-shroud mounting

screws from the lower shroud (Fig. 32).

(2) Unsnap the upper shroud from the lower on

the left side as follows:

(a) Hook a finger on the left hand around the

rear of the shrouds at the seam (Fig. 33), near the

snap points.

(b) Grasp the upper shroud at the rear using the

right hand (Fig. 33).

(c) As the left hand's hooked finger is pulled out-

ward against the seam, pull the upper shroud

upward using the right hand, disconnecting the

shroud snaps.

(3) Unsnap the upper shroud from the lower on

the right side as follows:

(a) Hook a finger on the right hand around the

rear of the shrouds at the seam (Fig. 34), near the

snap points.

(b) Grasp the upper shroud at the rear using the

left hand (Fig. 34).

(c) As the right hand's hooked finger is pulled

outward against the seam, pull the upper shroud

upward using the left hand, disconnecting the

shroud snaps.

(4) Lift the upper shroud straight up off the steer-

ing column. If vehicle is equipped with traction con-

trol, disconnect wiring connector at traction control

switch pig tail. If vehicle is equipped with power fold-

away mirrors (Export), disconnect wiring connector

at mirror switch pig tail. Remove upper shroud.

(5) If vehicle is equipped with traction control,

remove traction control switch from shroud.

(6) If vehicle is equipped with power foldaway mir-

rors (Export), remove power fold-away switch from

upper shroud.

INSTALLATION

(1) If the vehicle is equipped with power foldaway

mirrors (Export), install the power fold-away switch

in the upper shroud.

(2) If vehicle is equipped with traction control,

install the traction control switch in the upper

shroud.

(3) Place the upper shroud over the lower shroud,

aligning the snap clips and alignment tabs. If the

vehicle is equipped with traction control, connect the

wiring connector at the traction control switch pig

tail before lining the shrouds up to one another.

(4) Snap the upper shroud to the lower shroud.

Once snapped into place, verify there are no gaps

between the two mating surfaces of the shrouds.(5) Install the two shroud-to-shroud mounting

screws (Fig. 32). Tighten the screws to 2 N´m (17 in.

lbs.) torque.

(6) Ensure that the shrouds are snug and fit is

acceptable.

STEERING WHEEL

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS - WARNING).

(1) Adjust the steering wheel so that the tires are

in thestraight-aheadposition.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the two bolts from the rear of the

steering wheel attaching the driver airbag. Lift the

airbag from the steering wheel.

(4) Disconnect airbag squib wiring connectors from

the airbag and the horn/speed control switch pigtail

connector from the clockspring (Fig. 35). If the steer-

ing wheel is equipped with remote radio controls, dis-

connect the connector from the clockspring (Fig. 36).

Properly store the driver airbag out of the way.

(Refer to 8 - ELECTRICAL/RESTRAINTS - WARN-

ING)

(5) Remove the steering wheel retaining nut from

the steering column shaft (Fig. 36).

(6) Remove the steering wheel damper from the

steering wheel (Fig. 36).

Fig. 35 Airbag Wiring Connections

1 - AIRBAG FEED SQUIB CONNECTORS

2 - DRIVER AIRBAG

3 - HORN/SPEED CONTROL CONNECTOR

4 - CLOCKSPRING

RSCOLUMN19-23

ProCarManuals.com

Page 1735 of 2177

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations (Refer to LUBRI-

CATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehicle

in a brightly lit area. From inside the darkened lug-

gage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage com-

partment. If light is visible through a normally sealed

location, water could enter through the opening.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 2 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1745 of 2177

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Luggage rack crossbar fasteners 4 Ð 35

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Side view mirror bolts 10 Ð 85

Sliding door center hinge adjusting bolt 15 Ð 130

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track guide to seat riser 3.5 Ð 31

Sunroof opening panel to lifter arm screws 5 44

Sunroof opening panel motor screws 4 35

Sunroof trough bracket to roof bolts 6 53

Sunroof trough to trough bracket bolts 6 53

Sunroof trough bracket bolts 6 53

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a com-

ponent, any excess oil or grease should be removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

23 - 12 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1777 of 2177

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL.............................44

INSTALLATION.........................45

COWL GRILLE

REMOVAL.............................49

INSTALLATION.........................50

EXTERIOR NAME PLATES - TAPE ATTACHED

REMOVAL.............................50

INSTALLATION.........................50

EXTERIOR NAME PLATES - ADHESIVE

ATTACHED

REMOVAL.............................50

INSTALLATION.........................50

FRONT FENDER

REMOVAL.............................51

INSTALLATION.........................51

FUEL FILL DOOR

REMOVAL.............................51

INSTALLATION.........................51

FUEL FILL DOOR BLOCKER LATCH

REMOVAL.............................52

INSTALLATION.........................52

FUEL FILL DOOR BLOCKER LATCH STRIKER

REMOVAL.............................52

INSTALLATION.........................52

FUEL FILL DOOR BLOCKER LOCKOUT LINK

REMOVAL.............................52INSTALLATION.........................53

GRILLE OPENING REINFORCEMENT

REMOVAL.............................53

INSTALLATION.........................53

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL.............................54

INSTALLATION.........................54

LUGGAGE RACK RISER

REMOVAL.............................54

INSTALLATION.........................55

LUGGAGE RACK CROSSBAR

REMOVAL.............................55

INSTALLATION.........................56

REAR QUARTER PANEL/FENDER AIR

EXHAUSTER

DESCRIPTION.........................56

REMOVAL.............................56

INSTALLATION.........................57

ROOF JOINT MOLDING

REMOVAL.............................57

INSTALLATION.........................57

SIDE VIEW MIRROR

REMOVAL.............................57

INSTALLATION.........................57

SIDE VIEW MIRROR GLASS

REMOVAL.............................58

INSTALLATION.........................58

BODY SIDE MOLDINGS

REMOVAL

Refer to (Fig. 1), (Fig. 2), (Fig. 3), (Fig. 4) or (Fig.

5)for proper location of fasteners holding the molding

to the wheelhouse lip and rocker panels.

(1) Warm the affected stick on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.

(2) If equipped, remove pop rivets holding molding

edge to wheelhouse lip.(3) Pull stick on molding from painted surface.

(4) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Disc, or equivalent, to

clean adhesive residue from painted surfaces. These

products are available from automotive paint suppli-

ers. Refer to instructions supplied with the specific

product for proper usage.

23 - 44 EXTERIORRS

ProCarManuals.com

Page 1790 of 2177

INSTALLATION

SHORT WHEELBASE

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 19).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the rear fascia onto the body. (Refer

to 13 - FRAMES & BUMPERS/BUMPERS/REAR

FASCIA - INSTALLATION).

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is installed using the same procedure used to

install the air exhauster onto the short wheelbase

model. Refer to SHORT WHEELBASE.

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 20).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the quarter trim panel onto the inside

of the left or right quarter inner panel. (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- INSTALLATION) or (Refer to 23 - BODY/INTERI-

OR/LEFT QUARTER TRIM PANEL - INSTALLA-

TION).

ROOF JOINT MOLDING

REMOVAL

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-

cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) Warm the affected stick-on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.

(2) Pull stick-on molding from painted surface.

(3) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Discs, or equivalent, to

clean adhesive residue from painted surfaces. The

adhesive removal discs are available from automotive

paint suppliers. Refer to instructions supplied with

the discs for proper usage.

INSTALLATION

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-

cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) If molding is to be reused;

(a) Remove tape residue from molding.

(b) Clean back of molding with MopartSuper

Kleen solvent, or equivalent.

(c) Wipe molding dry with lint free cloth.

(d) Apply new body side molding (two sided

adhesive) tape to back of molding.

(2) Clean body surface with MopartSuper Kleen

solvent, or equivalent. Wipe surface dry with lint free

cloth.

(3) Remove protective cover from tape on back of

molding.

(4) Apply molding to body from front of vehicle to

rear.

(5) Using a roller tool, roll molding onto body

panel with enough force to assure adhesion and not

bend roof panels.

SIDE VIEW MIRROR

REMOVAL

(1) Using a trim stick C-4755 or equivalent, lift up

the end of the instrument panel top pad enough to

gain access to the mirror electrical connector, if

equipped. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/INSTRUMENT PANEL TOP COVER -

REMOVAL)

(2) Disconnect the electrical connector, if equipped.

(3) Using a trim stick or equivalent, remove the

trim cover (Fig. 21).

(4) Remove the bolts.

(5) Remove the mirror from the pillar.

INSTALLATION

(1) Route the mirror wire harness, if equipped,

through the a-pillar and place side view mirror in

position on vehicle (Fig. 21).

(2) Install the bolts and tighten to 10 N´m (85 in.

lbs.).

(3) Install the mirror trim cover.

(4) Connect the electrical connector, if equipped.

(5) Install the instrument panel top cover, if

equipped with the electric mirror. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

RSEXTERIOR23-57

REAR QUARTER PANEL/FENDER AIR EXHAUSTER (Continued)

ProCarManuals.com

Page 1791 of 2177

SIDE VIEW MIRROR GLASS

REMOVAL

WARNING: ALWAYS WEAR EYE AND HAND PRO-

TECTION WHEN SERVICING THE MIRROR ASSEM-

BLY. FAILURE TO OBSERVE THESE WARNINGS

MAY RESULT IN PERSONAL INJURY FROM BRO-

KEN GLASS.

(1) Carefully pull/pry the broken glass holder from

the mirror assembly.

(2) Disconnect the heated mirror electrical connec-

tors from the terminals on the mirror glass holder, if

equipped.

INSTALLATION

CAUTION: It is important to make sure the motor is

square to the glass holder (attaching fingers) prior

to glass holder attachment, otherwise the glass

holder could be installed incorrectly causing poor

retention and possible repeat failure.

(1) Position the new mirror glass holder to the

mirror assembly.

NOTE: Position the mirror glass holder so that the

moisture drain hole on the mirror glass holder

assembly is facing downward.

(2) Align the mirror glass holder's attaching fin-

gers to the mirror motor housing.

NOTE: Ensure that the protective rubber cover of

the mirror motor housing is positioned correctly

around the bottom of the fingers area.

(3) Using one hand, firmly press the mirror glass

holder assembly into place while at the same time

supporting the housing assembly from the backside

with the other hand.

NOTE: Pressure must be applied equally over the

center portion of the mirror to engage the mirror

glass holder's attaching fingers to the correspond-

ing fingers on the housing assembly. One or more

clicks may be heard when finger engagement takes

place.

(4) Verify retention of the mirror glass holder

assembly by gently pulling outward on the mirror

glass holder.

Fig. 21 SIDE VIEW MIRROR

1 - MIRROR

2 - MIRROR TRIM COVER

3 - A-PILLAR

4 - BOLTS

23 - 58 EXTERIORRS

SIDE VIEW MIRROR (Continued)

ProCarManuals.com

Page 1797 of 2177

GLOVE BOX LATCH STRIKER

REMOVAL

(1) Open glove box door.

(2) Remove screws holding lock striker to instru-

ment panel.

(3) Remove glove box latch striker.

INSTALLATION

(1) Install the glove box latch striker.

(2) Install the screws holding latch striker to

instrument panel.

(3) Close glove box door.

INSTRUMENT PANEL

ASSEMBLY

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower console:

(a) Remove six retaining screws.

(b) Pull rearward and disconnect the auxiliary

power outlet.

(c) Remove lower console from vehicle.

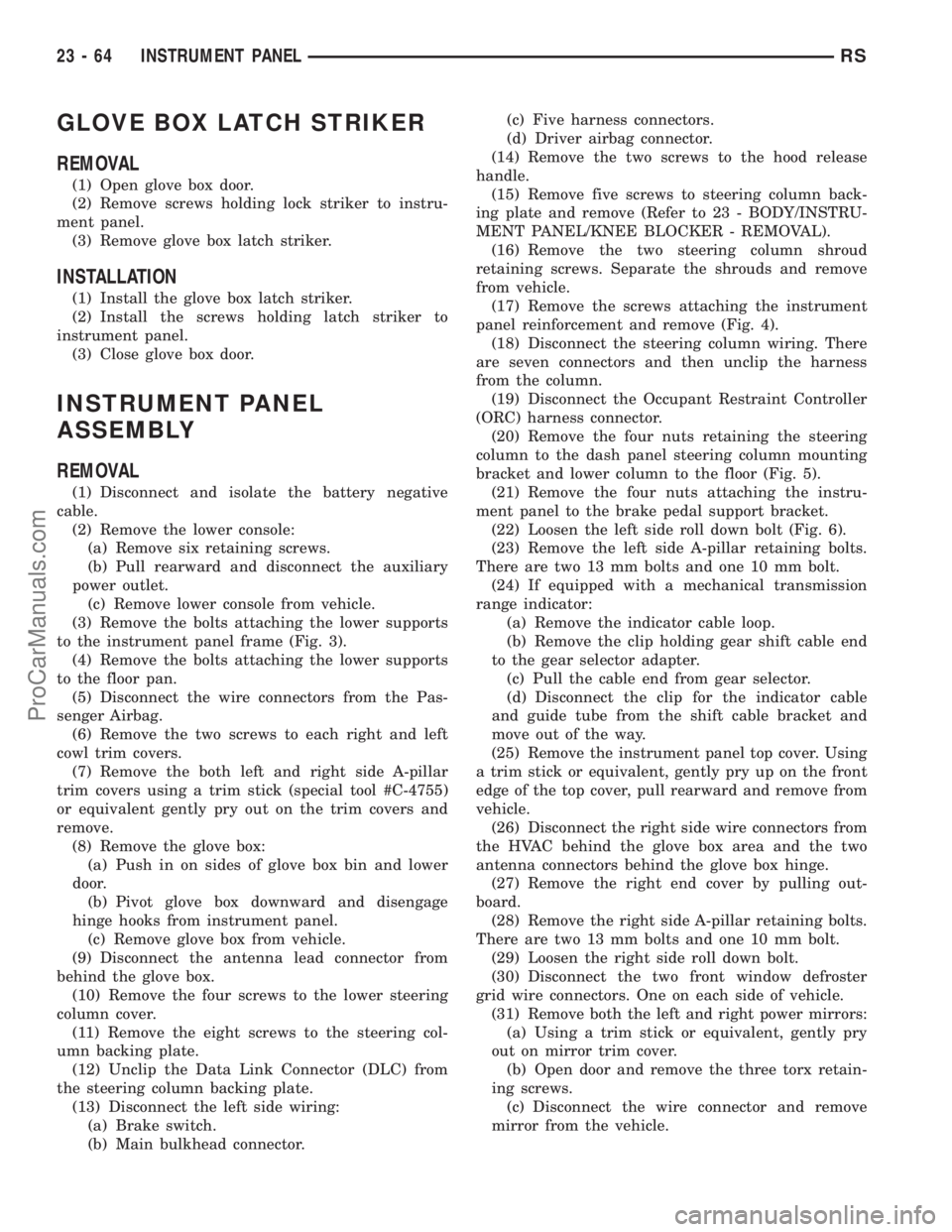

(3) Remove the bolts attaching the lower supports

to the instrument panel frame (Fig. 3).

(4) Remove the bolts attaching the lower supports

to the floor pan.

(5) Disconnect the wire connectors from the Pas-

senger Airbag.

(6) Remove the two screws to each right and left

cowl trim covers.

(7) Remove the both left and right side A-pillar

trim covers using a trim stick (special tool #C-4755)

or equivalent gently pry out on the trim covers and

remove.

(8) Remove the glove box:

(a) Push in on sides of glove box bin and lower

door.

(b) Pivot glove box downward and disengage

hinge hooks from instrument panel.

(c) Remove glove box from vehicle.

(9) Disconnect the antenna lead connector from

behind the glove box.

(10) Remove the four screws to the lower steering

column cover.

(11) Remove the eight screws to the steering col-

umn backing plate.

(12) Unclip the Data Link Connector (DLC) from

the steering column backing plate.

(13) Disconnect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.(c) Five harness connectors.

(d) Driver airbag connector.

(14) Remove the two screws to the hood release

handle.

(15) Remove five screws to steering column back-

ing plate and remove (Refer to 23 - BODY/INSTRU-

MENT PANEL/KNEE BLOCKER - REMOVAL).

(16) Remove the two steering column shroud

retaining screws. Separate the shrouds and remove

from vehicle.

(17) Remove the screws attaching the instrument

panel reinforcement and remove (Fig. 4).

(18) Disconnect the steering column wiring. There

are seven connectors and then unclip the harness

from the column.

(19) Disconnect the Occupant Restraint Controller

(ORC) harness connector.

(20) Remove the four nuts retaining the steering

column to the dash panel steering column mounting

bracket and lower column to the floor (Fig. 5).

(21) Remove the four nuts attaching the instru-

ment panel to the brake pedal support bracket.

(22) Loosen the left side roll down bolt (Fig. 6).

(23) Remove the left side A-pillar retaining bolts.

There are two 13 mm bolts and one 10 mm bolt.

(24) If equipped with a mechanical transmission

range indicator:

(a) Remove the indicator cable loop.

(b) Remove the clip holding gear shift cable end

to the gear selector adapter.

(c) Pull the cable end from gear selector.

(d) Disconnect the clip for the indicator cable

and guide tube from the shift cable bracket and

move out of the way.

(25) Remove the instrument panel top cover. Using

a trim stick or equivalent, gently pry up on the front

edge of the top cover, pull rearward and remove from

vehicle.

(26) Disconnect the right side wire connectors from

the HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

(27) Remove the right end cover by pulling out-

board.

(28) Remove the right side A-pillar retaining bolts.

There are two 13 mm bolts and one 10 mm bolt.

(29) Loosen the right side roll down bolt.

(30) Disconnect the two front window defroster

grid wire connectors. One on each side of vehicle.

(31) Remove both the left and right power mirrors:

(a) Using a trim stick or equivalent, gently pry

out on mirror trim cover.

(b) Open door and remove the three torx retain-

ing screws.

(c) Disconnect the wire connector and remove

mirror from the vehicle.

23 - 64 INSTRUMENT PANELRS

ProCarManuals.com

Page 1798 of 2177

(32) Feed power mirror wire harness inboard

through the A-pillar.

(33) Remove the bolts attaching the instrument

panel frame to the dash panel below windshield

opening.

(34) With the help of an assistant remove the

instrument panel from vehicle. Lift the instrument

panel up off the HVAC so you won't damage the seal-

ing surface of the distribution duct.

If the instrument panel is being replaced, transfer

all parts to the new instrument panel assembly.

INSTALLATION

(1) With the help of an assistant place the instru-

ment panel into vehicle on roll down bolts. As youroll the instrument panel up, lift the instrument

panel up so the duct work does not bind or bend and

you can set it down on the HVAC housing to get the

proper seal at the distribution duct. Get one bolt

started in the dash panel.

(2) Install the left and right side A-pillar retaining

bolts. There are two 13 mm bolts and one 10 mm

bolt. The 10 mm bolts need to be installed first to

insure proper positioning of the Instrument panel in

the vehicle. Start the right side 10 mm bolt first (Fig.

6).

(3) Feed power mirror wire harness outboard

through the A-pillar.

(4) Install both the left and right power mirrors:

(a) Connect the wire connector and install the

mirror onto the vehicle.

(b) Install the three torx retaining screws.

(c) Using a firm push, snap the mirror trim

cover into place.

(5) Connect the two front window defroster grid

wire connectors. One on each side of vehicle.

(6) Tighten the right side roll down bolt.

(7) Install the right end cover. Position over retain-

ing slots and firmly snap into place.

(8) Connect the right side wire connectors to the

HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

(9) Install the bolts attaching the instrument

panel frame to the dash panel below windshield

opening.

(10) Install the instrument panel top cover. Slide

the front edge of the top cover toward dash panel,

and firmly snap down the rear edge of the to cover to

engage clips.

Fig. 3 INSTRUMENT PANEL CENTER STACK RIGHT

& LEFT REINFORCEMENTS

1 - INSTRUMENT PANEL

2 - CENTER STACK RIGHT & LEFT REINFORCEMENT

Fig. 4 INSTRUMENT PANEL LOWER

REINFORCEMENT

1 - LOWER RIGHT REINFORCEMENT

2 - STEERING WHEEL ASSEMBLY

Fig. 5 STEERING COLUMN MOUNTING BRACKET

1 - INSTRUMENT PANEL

2 - INSTRUMENT PANEL STEERING BRACKET

3 - DASH PANEL REINFORCEMENT

4 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

RSINSTRUMENT PANEL23-65

INSTRUMENT PANEL ASSEMBLY (Continued)

ProCarManuals.com

Page 1805 of 2177

INTERIOR

TABLE OF CONTENTS

page page

A-PILLAR LOWER EXTENSION TRIM

REMOVAL.............................73

INSTALLATION.........................73

A-PILLAR TRIM

REMOVAL.............................73

INSTALLATION.........................73

ASSIST HANDLE

REMOVAL.............................73

INSTALLATION.........................73

B-PILLAR LOWER TRIM

REMOVAL.............................73

INSTALLATION.........................74

B-PILLAR UPPER TRIM

REMOVAL.............................74

INSTALLATION.........................74

CARPETS AND FLOOR MATS

REMOVAL.............................74

INSTALLATION.........................75

COWL TRIM

REMOVAL.............................75

INSTALLATION.........................75

C-PILLAR TRIM

REMOVAL.............................75

INSTALLATION.........................76

DOOR SILL TRIM PLATE

REMOVAL.............................76

INSTALLATION.........................76

HEADLINER

REMOVAL.............................76

INSTALLATION.........................76

LEFT D-PILLAR TRIM PANEL

REMOVAL.............................77

INSTALLATION.........................77

LIFTGATE SILL PLATE

REMOVAL.............................77

INSTALLATION.........................77

QUARTER TRIM BOLSTER

REMOVAL.............................77INSTALLATION.........................77

RIGHT QUARTER TRIM PANEL

REMOVAL.............................78

INSTALLATION.........................78

LEFT QUARTER TRIM PANEL

REMOVAL.............................78

INSTALLATION.........................78

REAR HEADER TRIM

REMOVAL.............................79

INSTALLATION.........................79

REAR HVAC LOUVER

REMOVAL.............................79

INSTALLATION.........................79

REAR VIEW MIRROR

REMOVAL.............................79

INSTALLATION.........................80

RIGHT D-PILLAR TRIM PANEL

REMOVAL.............................80

INSTALLATION.........................80

SLIDING DOOR SILL PLATE

REMOVAL.............................80

INSTALLATION.........................80

SUN VISOR

REMOVAL.............................81

INSTALLATION.........................81

SUN VISOR SUPPORT

REMOVAL.............................81

INSTALLATION.........................81

FLOOR CONSOLE TRAY

REMOVAL.............................81

INSTALLATION.........................81

FLOOR CONSOLE TRAY - BRACKET

ASSEMBLY

REMOVAL.............................82

INSTALLATION.........................82

23 - 72 INTERIORRS

ProCarManuals.com

Page 1809 of 2177

INSTALLATION

(1) Place upper C-pillar trim in position on vehicle

(Fig. 6).

(2) Engage hidden clips attaching trim to upper

C-pillar.

(3) Install screw attaching C-pillar trim panel to

C-pillar.

(4) Install seat belt turning loop onto height

adjuster. Tighten all seat belt bolts to 39 N´m (29 ft.

lbs.) torque.

(5) Install quarter trim panel.

DOOR SILL TRIM PLATE

REMOVAL

(1) Using trim stick (C-4755), disengage hidden

clips holding door sill plate from door sill.

(2) Remove sill plate from vehicle (Fig. 7).

INSTALLATION

(1) Place sill plate in position on vehicle (Fig. 7).

(2) Align interlock tabs at front and rear to mating

trim.

(3) Engage hidden clips to hold door sill plate to

door sill.

HEADLINER

REMOVAL

(1) Remove sun visors and vanity mirrors.

(2) Remove sun visor center supports.

(3) If equipped, remove coat hooks.

(4) If equipped, remove roof rail modules.

(5) Remove A-pillar trim covers.

(6) Remove B-pillar upper trim covers.

(7) Remove C-pillar upper trim covers.

(8) Remove D-pillar trim covers.

(9) Remove liftgate opening header trim.

(10) If equipped, remove overhead console screw.

(11) If equipped, remove reading lamp.

(12) Remove dome lamp.

(13) Remove push in locking fasteners attaching

headlining to rear roof header and roof bows (Fig. 8).

(14) Remove wiring connections.

(15) Remove headlining from roof.

(16) Extract headlining through liftgate opening.

INSTALLATION

(1) Insert headlining through liftgate opening.

(2) Place headlining in position on roof.

(3) Connect wire connectors.

(4) Install left sun visor support.

(5) Install push in locking fasteners attaching

headlining to rear roof header and bows (Fig. 8).

(6) Install right sun visor support.

(7) Install sun visors and vanity mirrors.

(8) If equipped, install roof rail modules.

(9) If equipped, install coat hooks.

(10) Install dome lamp.

(11) If equipped, install reading lamp.

(12) If equipped, install overhead console.

Fig. 6 C-PILLAR

1 - C-PILLAR TRIM PANEL

2 - C-PILLAR

Fig. 7 DOOR SILL PLATE

1 - CLIPS

2 - SLIDING DOOR SILL TRIM PLATE

3 - FRONT DOOR SILL TRIM PLATE

23 - 76 INTERIORRS

C-PILLAR TRIM (Continued)

ProCarManuals.com