seat adjustment CHRYSLER VOYAGER 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 76 of 2177

NOTE: If equipped with antilock brakes, make sure

wheel speed sensor stays clean and dry as it is

installed into the hub and bearing cap.

(4) If the vehicle is equipped with antilock brakes,

perform the following:

(a) If metal sensor retaining clip is not in the

neutral installed position on hub and bearing cap,

install from the bottom, if necessary, and push clip

upward until it snaps into position.

(b) Install wheel speed sensor head into rear of

hub and bearing aligning index tab with the notch

in the top of the mounting hole. Push the sensor in

until it snaps into place on the metal retaining

clip.

(c) Install secondary (yellow) retaining clip over

wheel speed sensor head and engage the tabs on

each side (Fig. 8).

(5) Install brake drum or disc brake rotor and

brake caliper. (Refer to 5 - BRAKES/HYDRAULIC/

MECHANICAL/DRUM - INSTALLATION)(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTOR -

INSTALLATION)

(6) Install wheel and tire (Refer to 22 - TIRES/

WHEELS - INSTALLATION). Tighten the wheel

nuts in the proper sequence to a torque of 135 N´m

(100 ft. lbs.).

(7) Adjust the rear brakes as necessary. (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - ADJUSTMENTS)

(8) Lower vehicle.

(9) Road test vehicle to ensure proper operation of

brakes.

ALL-WHEEL-DRIVE VEHICLES

(1) Install hub/bearing on end of axle. (Fig. 12).

(2) Install the hub/bearing mounting bolts. In a

progressive crisscross pattern, tighten the 4 hub/

bearing mounting bolts (Fig. 13) until the disc brake

caliper adapter and hub/bearing are squarely seated

against the axle. Then tighten the hub/bearing

mounting bolts to a torque of 129 N´m (95 ft. lbs.).

(3) Install driveshaft in hub/bearing and on output

shaft of rear drive line module. Driveshaft is

installed by first sliding the outer joint of the drive-

shaft into the hub/bearing and then compressing the

Fig. 11 Hub/Bearing Removal From Caliper Adapter

1 - SPECIAL TOOL 8214-1

2 - PARK BRAKE CABLE

3 - DISC BRAKE CALIPER ADAPTER

4 - HUB/BEARING

Fig. 12 Hub/Bearing Removal And Installation

1 - PARK BRAKE BRAKE SHOE

2 - HUB/BEARING

3 - PARK BRAKE BRAKE SHOE

Fig. 13 Hub/Bearing Mounting Bolts

1 - HUB/BEARING

2 - AXLE

3 - MOUNTING BOLTS

4 - CALIPER ADAPTER

RSREAR SUSPENSION2-33

HUB / BEARING (Continued)

ProCarManuals.com

Page 205 of 2177

nects the front parking brake cable to the left rear

and intermediate cable. The intermediate cable is

connected to the right rear cable using a parking

brake cable connector.

On vehicles equipped with rear drum brakes, the

rear service brakes also act as the vehicle's parking

brakes.

Vehicles equipped with rear disc brakes use a

small duo-servo brake assembly mounted to the each

rear disc brake caliper adapter as the parking brake.

The inside of the brake rotor (hat section of drum-in-

hat style brake rotor) is used as the parking brake

drum.

DESCRIPTION - EXPORT

The parking brake system on this vehicle features

a hand-operated parking brake lever. The lever is

located between the two front seats and requires a

special front cable.

OPERATION

The automatic-adjusting feature in the foot oper-

ated parking brake lever continuously applies mini-

mal tension to the parking brake cables when the

parking brake lever is in the released position to

keep them in adjustment at all times. Due to this

feature, the parking brake cables require no periodic

adjustment.

When the parking brake lever is applied, the

cables are pulled, thus applying the brake shoes

(rear drum brakes) or parking brake shoes (rear disc

brakes) at each rear wheel.

The brake shoes are mechanically operated by an

internal lever and strut connected to the rear park-

ing brake cables.

An equalizer bracket is used at the rear end of the

front parking brake cable to distribute tension

equally to each parking brake cable.

STANDARD PROCEDURE

STANDARD PROCEDURE - PARKING BRAKE

AUTOMATIC ADJUSTER TENSION RELEASE

The parking brake lever (pedal) mechanism used

in this vehicle is designed so that the automatic

adjuster is not required to be locked out when servic-

ing the parking brake lever (pedal) or the parking

brake cables.

This parking brake lever (pedal) mechanism is

designed so that the adjuster mechanism will rotate

only half a turn when the tension is released from

the parking brake cable. This eliminates the require-

ment to lock out the automatic adjuster when servic-

ing the parking brake lever (pedal) mechanism and

cables.Use the following procedure to release the tension

from the parking brake cables and the automatic

adjuster in the parking brake lever (pedal) mecha-

nism.

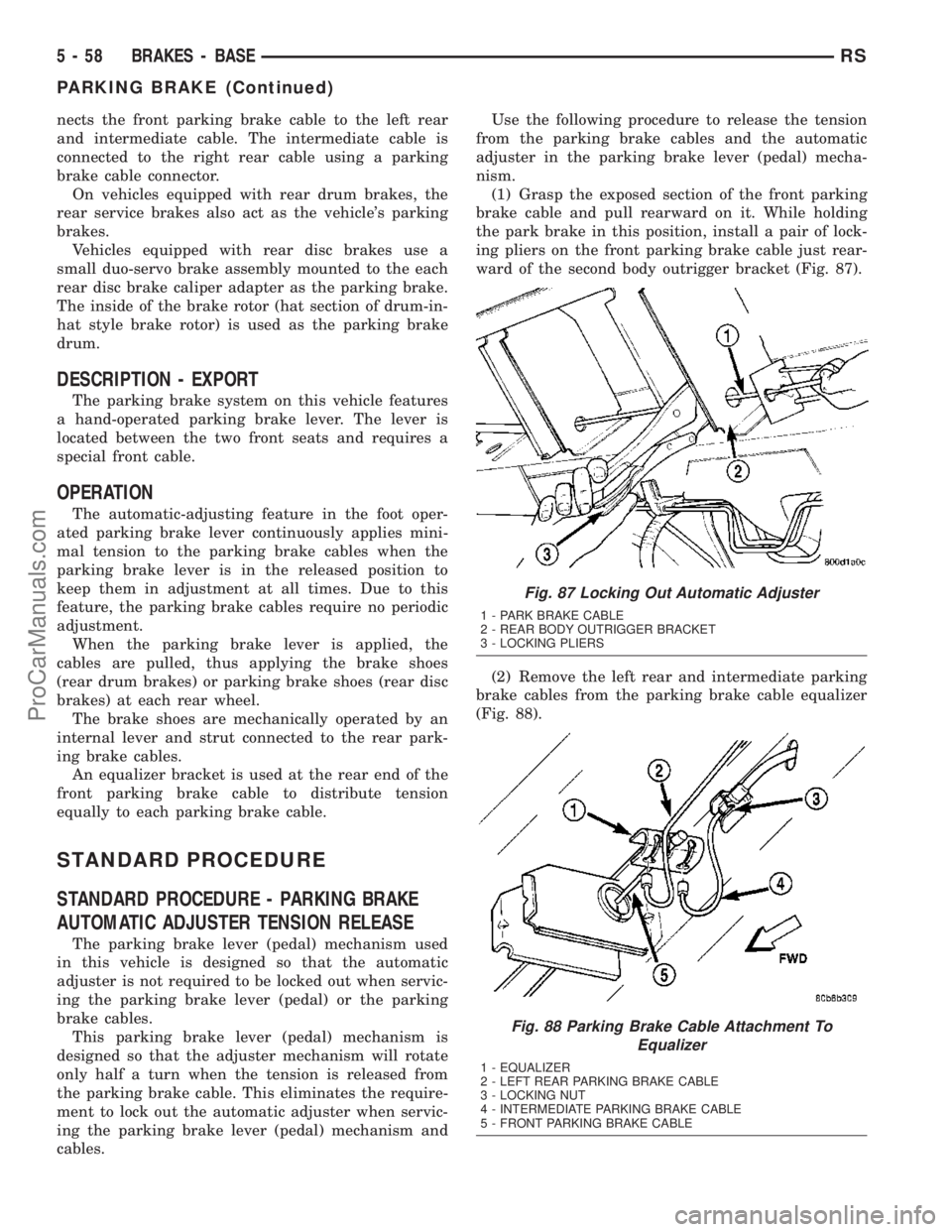

(1) Grasp the exposed section of the front parking

brake cable and pull rearward on it. While holding

the park brake in this position, install a pair of lock-

ing pliers on the front parking brake cable just rear-

ward of the second body outrigger bracket (Fig. 87).

(2) Remove the left rear and intermediate parking

brake cables from the parking brake cable equalizer

(Fig. 88).

Fig. 87 Locking Out Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

Fig. 88 Parking Brake Cable Attachment To

Equalizer

1 - EQUALIZER

2 - LEFT REAR PARKING BRAKE CABLE

3 - LOCKING NUT

4 - INTERMEDIATE PARKING BRAKE CABLE

5 - FRONT PARKING BRAKE CABLE

5 - 58 BRAKES - BASERS

PARKING BRAKE (Continued)

ProCarManuals.com

Page 211 of 2177

INSTALLATION - PARKING BRAKE CABLE

(LEFT REAR)

(1) Install the rear parking brake cable in the

brake support plate. Insert cable housing retainer

into brake support plate making certain that cable

housing retainer fingers lock the housing and

retainer firmly into place.

(2) Attach the parking brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(4) Insert cable housing retainer into body outrig-

ger bracket making certain that cable housing

retainer fingers lock the housing firmly into place.

(5) Connect rear parking brake cable to the equal-

izer bracket (Fig. 99).

(6) Install brake drum, and wheel and tire assem-

bly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Apply and release park brake pedal 1 time.

This will seat the park brake cables.

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE CABLES

The park brake cables on this vehicle have an

automatic self adjuster built into the park brake

pedal mechanism. When the foot operated park brake

pedal is in its released (upward most) position, a

clock spring automatically adjusts the park brake

cables. The park brake cables are adjusted (ten-

sioned) just enough to remove all the slack from the

cables. The automatic adjuster system will not over

adjust the cables causing rear brake drag.

Due to the automatic adjust feature of the park

brake pedal, adjustment of the parking brake cables

on these vehicles relies on proper drum brake and

park brake shoe adjustment. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/DRUM - ADJUST-

MENTS) and (Refer to 5 - BRAKES/PARKING

BRAKE/SHOES - ADJUSTMENTS).

When the park brake pedal is applied the self

adjuster is by-passed and the pedal operates nor-

mally to engage the park brakes.

When a service procedure needs to be performed on

the park brake pedal or the park brake cables, the

automatic self adjuster can be manually locked out

by the service technician.

CABLES - PARKING BRAKE

(EXPORT)

REMOVAL - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - REMOVAL)

INSTALLATION - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - INSTALLATION)

LEVER - PARKING BRAKE

REMOVAL

(1) Manually release the automatic self-adjusting

mechanism tension of the parking brake lever (pedal)

assembly. (Refer to 5 - BRAKES/PARKING BRAKE -

STANDARD PROCEDURE).

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(3) Remove sill scuff plate from left door sill.

(4) Remove the left side kick panel.

(5) Remove the silencer panel under the instru-

ment panel.

(6) Remove the steering column cover from the

lower instrument panel.

(7) Remove the reinforcement from the lower

instrument panel.

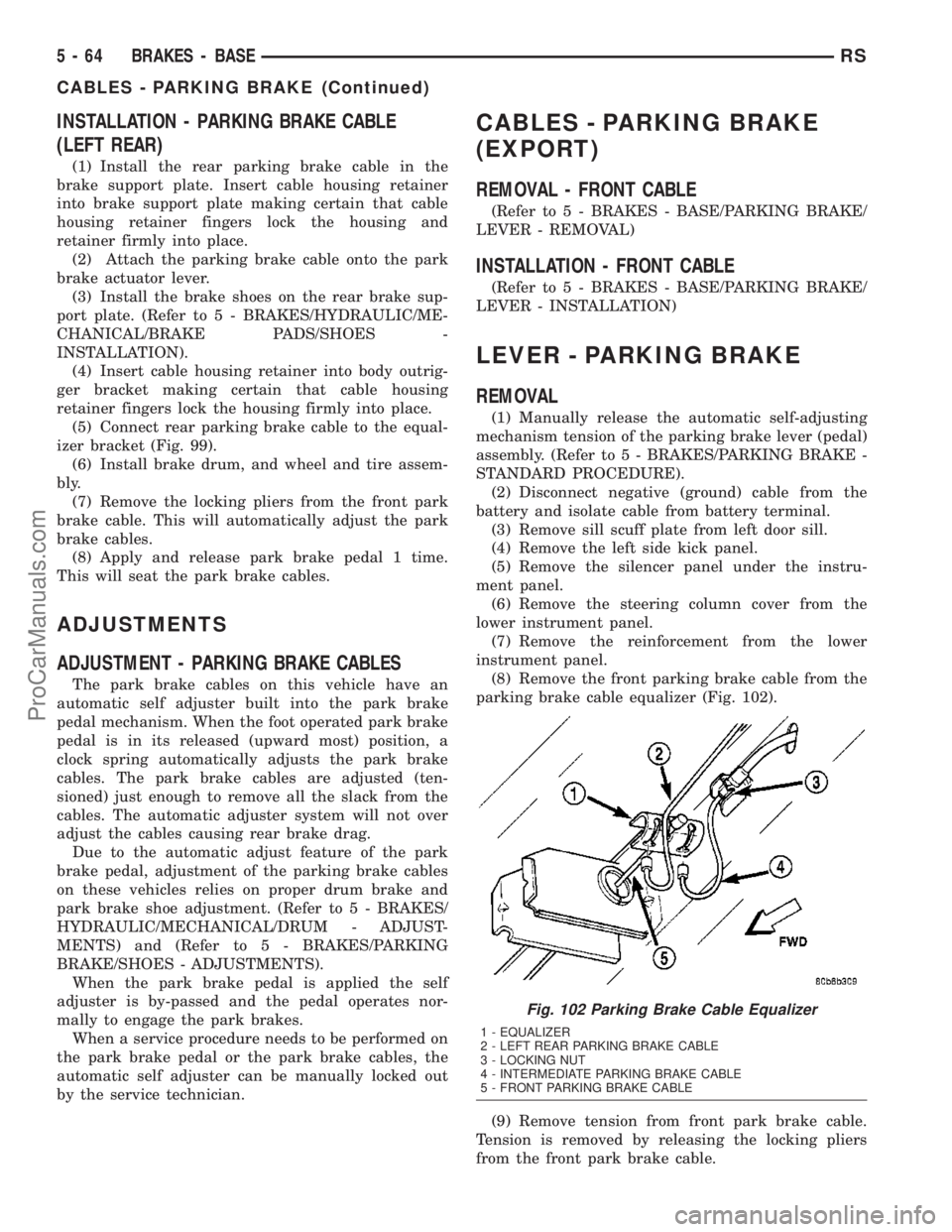

(8) Remove the front parking brake cable from the

parking brake cable equalizer (Fig. 102).

(9) Remove tension from front park brake cable.

Tension is removed by releasing the locking pliers

from the front park brake cable.

Fig. 102 Parking Brake Cable Equalizer

1 - EQUALIZER

2 - LEFT REAR PARKING BRAKE CABLE

3 - LOCKING NUT

4 - INTERMEDIATE PARKING BRAKE CABLE

5 - FRONT PARKING BRAKE CABLE

5 - 64 BRAKES - BASERS

CABLES - PARKING BRAKE (Continued)

ProCarManuals.com

Page 220 of 2177

(13) AWD only - Install the wheel speed sensor on

the hub/bearing and adapter. Install the wheel speed

sensor attaching bolt (Fig. 115). Tighten the wheel

speed sensor attaching bolt to a torque of 12 N´m

(105 in. lbs).

(14) FWD only - Install the wheel speed sensor in

the following fashion:

(a) If metal wheel speed sensor retaining clip is

not in the neutral installed position on hub and

bearing cap, install from the bottom, if necessary,

and push clip upward until it snaps into position.

(b) Install wheel speed sensor head into rear of

hub and bearing aligning index tab with the notch

in the top of the mounting hole. Push the sensor in

until it snaps into place on the metal retaining

clip.

(c) Install secondary (yellow) retaining clip over

wheel speed sensor head and engage the tabs on

each side.

(15) Install the park brake cable into its mounting

hole in the adapter.Be sure all the locking tabs

on the park brake cable retainer are expanded

out to ensure the cable will not pull out of the

adapter.

(16) Install the end of the park brake cable on the

park brake actuator lever (Fig. 113).

(17) Attach park brake cable to adapter using

mounting bolt.

(18) Remove the locking pliers (Fig. 109) from the

front park brake cable.

(19) Adjust the park brake drum-in-hat brake

shoes. (Refer to 5 - BRAKES/PARKING BRAKE/

SHOES - ADJUSTMENTS).

(20) Install the rotor on the hub/bearing.

(21) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 111).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(22) Install the caliper guide pin bolts (Fig. 110).

Tighten the guide pin bolts to a torque of 35 N´m (26

ft. lbs.).

(23) AWD only - Clean all foreign material off the

threads of the outer C/V joint stub shaft. Install the

washer and hub nut (Fig. 108) on the stub shaft of

the outer C/V joint.

(24) AWD only - Set the parking brake.

(25) AWD only - Tighten the hub nut to a torque of

244 N´m (180 ft. lbs.).

(26) AWD only - Install the spring washer (Fig.

107) on the stub shaft of the outer C/V joint.

(27) AWD only - Install the nut retainer and cotter

pin (Fig. 106) on the stub shaft of the outer C/V joint.(28) Install the wheel and tire assembly. Tighten

the wheel mounting stud nuts in proper sequence

until all nuts are torqued to half specification. Then

repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

(29) Lower vehicle.

(30) Fully apply and release the park brake pedal

one time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

(31) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES

CAUTION: Before adjusting the park brake shoes be

sure that the park brake pedal is in the fully

released position. If park brake pedal is not in the

fully released position, the park brake shoes can

not be accurately adjusted.

(1) Raise vehicle.

(2) Remove tire and wheel.

(3) Remove disc brake caliper from caliper adapter

(Fig. 128). (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - REMOVAL).

(4) Remove rotor from hub/bearing.

Fig. 128 Disc Brake Caliper

1 - DISC BRAKE CALIPER

2 - ADAPTER

3 - AXLE

4 - GUIDE PIN BOLTS

5 - DRIVESHAFT (AWD MODELS ONLY)

RSBRAKES - BASE5-73

SHOES - PARKING BRAKE (Continued)

ProCarManuals.com

Page 421 of 2177

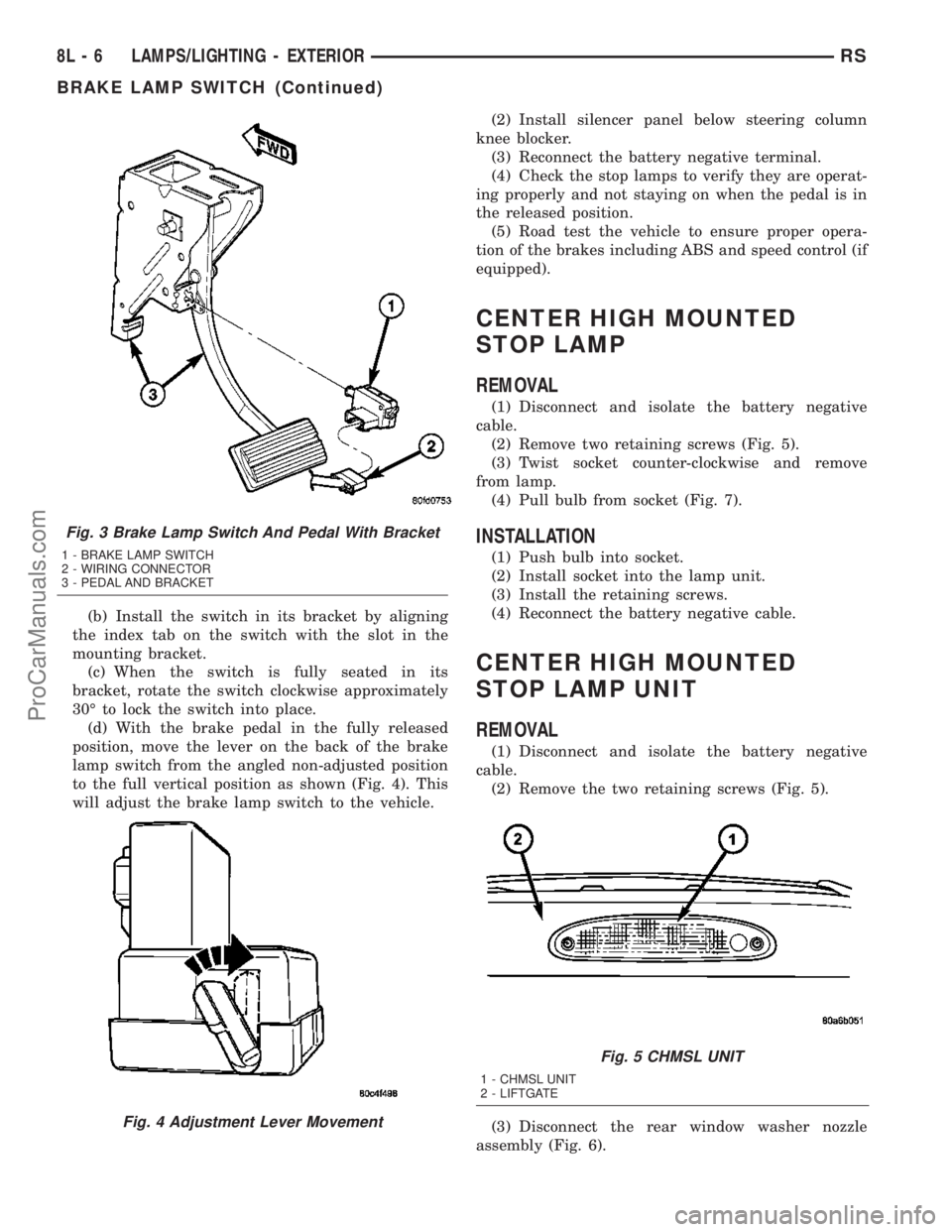

(b) Install the switch in its bracket by aligning

the index tab on the switch with the slot in the

mounting bracket.

(c) When the switch is fully seated in its

bracket, rotate the switch clockwise approximately

30É to lock the switch into place.

(d) With the brake pedal in the fully released

position, move the lever on the back of the brake

lamp switch from the angled non-adjusted position

to the full vertical position as shown (Fig. 4). This

will adjust the brake lamp switch to the vehicle.(2) Install silencer panel below steering column

knee blocker.

(3) Reconnect the battery negative terminal.

(4) Check the stop lamps to verify they are operat-

ing properly and not staying on when the pedal is in

the released position.

(5) Road test the vehicle to ensure proper opera-

tion of the brakes including ABS and speed control (if

equipped).

CENTER HIGH MOUNTED

STOP LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two retaining screws (Fig. 5).

(3) Twist socket counter-clockwise and remove

from lamp.

(4) Pull bulb from socket (Fig. 7).

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into the lamp unit.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two retaining screws (Fig. 5).

(3) Disconnect the rear window washer nozzle

assembly (Fig. 6).

Fig. 3 Brake Lamp Switch And Pedal With Bracket

1 - BRAKE LAMP SWITCH

2 - WIRING CONNECTOR

3 - PEDAL AND BRACKET

Fig. 4 Adjustment Lever Movement

Fig. 5 CHMSL UNIT

1 - CHMSL UNIT

2 - LIFTGATE

8L - 6 LAMPS/LIGHTING - EXTERIORRS

BRAKE LAMP SWITCH (Continued)

ProCarManuals.com

Page 456 of 2177

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM.................. 1

POWER SLIDING DOOR SYSTEM............ 19

POWER LOCKS........................... 38POWER MIRRORS........................ 45

POWER SEAT SYSTEM..................... 50

POWER WINDOWS........................ 62

POWER LIFTGATE SYSTEM

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM

DESCRIPTION..........................2

OPERATION............................3

DIAGNOSIS AND TESTING - POWER

LIFTGATE SYSTEM.....................4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIFTGATE

ADJUSTMENT.........................9

STANDARD PROCEDURE - POWER

LIFTGATE LEARN CYCLE................9

SPECIFICATIONS

SPECIFICATIONS TABLE................9

CHIME/THERMISTOR

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................10

ENGAGE ACTUATOR

DESCRIPTION.........................10

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

EXTERIOR HANDLE SWITCH

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................12

FULL OPEN SWITCH

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................13INSTALLATION.........................13

LATCH

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................14

LATCH ACTUATOR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

LIFTGATE MOTOR

DESCRIPTION.........................15

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................15

LIFT GEAR & LINK ROD

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

PINCH SENSOR

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

TRANSVERSE BRACKET

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................18

INSTALLATION.........................18

RSPOWER SYSTEMS8N-1

ProCarManuals.com

Page 513 of 2177

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Install the switch knobs on the switch control

levers, if equipped.

(7) Reconnect the battery negative cable.

DRIVER POWER SEAT TRACK

DESCRIPTION

The eight-way driver side power seat option

includes a electrically operated power seat track

located under the driver side front seat. The front

power seat track on the driver side of the vehicle also

provides the mounting location for the Memory Seat/

Mirror Module (MSMM). The power seat circuit

breakers are mounted on the rear of the driver side

power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

pan to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit.

The power seat track unit includes four reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the four power seat

track motors used on models equipped with the

optional memory system incorporates a position

potentiometer integral to the motor assembly, which

electronically monitors the motor position. This

enables the memory system to function by referenc-

ing the motor positions programmed into the memory

seat/mirror module.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. A third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

The forth motor is the recliner adjustment motor,

which moves the seat back in the forward and rear-

ward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any componentin this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When the driver side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the driver side power seat switch to move

all three power seat track adjusters in each direction.

The power seat track adjusters should move in each

of the selected directions. If a power seat track

adjuster fails to operate in only one direction, move

the adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Diagnosis and Testing Power Seat Switchin this

section. If the power seat track adjuster fails to oper-

ate in more than one direction, perform the following

tests. For complete circuit diagrams, refer toWiring

Diagrams.

8N - 58 POWER SEAT SYSTEMRS

PASSENGER SEAT SWITCH (Continued)

ProCarManuals.com

Page 514 of 2177

TESTING POWER SEAT TRACK MOTORS

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Test the power seat switch. Refer toDiagnosis

and Testing Power Seat Switchin this section. If

the switch tests OK, test the circuits of the power

seat wire harness between the inoperative power seat

track adjuster motor and the power seat switch for

shorts or opens. If the circuits check OK, replace the

faulty power seat track unit. If the circuits are not

OK, repair the power seat wire harness as required.

REMOVAL

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the appropriate seat from the vehicle

and place it on a clean work surface(Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(2) If the vehicle is so equipped, remove the Mem-

ory Seat/Mirror Module (MSMM) retaining screws.

(3) If the vehicle is so equipped, disconnect the

MSMM electrical connectors and remove the MSMM

from the power seat track.

(4) Remove the rear fabric blocker trim panel from

the rear of the front seat.(5) Remove the seat side cover and power seat

switch as an assembly (Refer to 23 - BODY/SEATS/

SEAT CUSHION SIDE COVERS - REMOVAL).

(6) Disconnect all electrical connectors connecting

the power seat track to the seat assembly.

(7) Pull the seat back trim cover up slightly to

access and remove the two seat back frame mounting

bolts and also remove two seat back recliner bolts.

(8) Remove four seat track mounting bolts from

the seat cushion pan.

(9) Remove the power seat track from the seat.

INSTALLATION

(1) Position the seat cushion on the seat track.

(2) Install the four seat track retaining bolts in the

seat cushion pan. Torque the bolts to 28.5 N´m.

(3) Position the seat back and install the two seat

back frame mounting bolts and the two seat back

recliner bolts. Torque the bolts to 55 N´m.

(4) Route and connect the electrical connectors

between the power seat track and the seat assembly.

(5) Install the seat side cover and power seat

switch as an assembly (Refer to 23 - BODY/SEATS/

SEAT CUSHION SIDE COVERS - INSTALLATION).

(6) Install the rear fabric blocker trim panel on the

rear of the front seat.

(7) If the vehicle is so equipped, position the Mem-

ory Seat/Mirror Module (MSMM) and connect the

MSMM electrical connectors.

(8) Install the MSMM retaining screws.

(9) Install the seat assembly in the vehicle (Refer

to 23 - BODY/SEATS/SEAT - INSTALLATION).

PASSENGER POWER SEAT

TRACK

DESCRIPTION

The four-way passenger side power seat option

includes a electrically operated power seat track unit

located under the passenger side front seat. The

power seat circuit breaker is mounted on the rear of

the power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

frame to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit.

The passenger side power seat track unit includes

two reversible electric motors that are secured to the

upper half of the track unit. Each motor moves the

seat adjuster through a combination of worm-drive

gearboxes and screw-type drive units. The horizontal

adjustment motor moves the seat track in the for-

RSPOWER SEAT SYSTEM8N-59

DRIVER POWER SEAT TRACK (Continued)

ProCarManuals.com

Page 1245 of 2177

ting notch and spring tang should remain aligned

after lock nut is torqued.

(6) Remove allen wrench and torque wrench.

NOTE: Repositioning the crankshaft to the TDC

position must be done only during the CLOCKWISE

rotation movement. If TDC is missed, rotate a fur-

ther two revolutions until TDC is achieved. DO NOT

rotate crankshaft counterclockwise as this will

make verification of proper tensioner setting impos-

sible.

(7) Rotate the crankshaft CLOCKWISE two com-

plete revolutions manually for seating of the belt,

until the crankshaft is repositioned at the TDC posi-

tion. Verify that the camshaft and crankshaft timing

marks are in proper position (Fig. 124).

Fig. 121 Camshaft Sprocket Alignment

1 - CAMSHAFT SPROCKET-EXHAUST

2 - CAMSHAFT SPROCKET-INTAKE

3 - 1/2 NOTCH LOCATION

Fig. 122 Timing Belt Installation

1 - CAMSHAFT TIMING MARKS 1/2 NOTCH LOCATION

2 - CRANKSHAFT AT TDC

3 - INSTALL BELT IN THIS DIRECTION

4 - ROTATE CAMSHAFT SPROCKET TO TAKE UP BELT SLACK

Fig. 123 Timing Belt Tension Adjustment

1 - ALIGN SETTING NOTCH WITH SPRING TANG

2 - TOP PLATE

3 - 6mm ALLEN WRENCH

4 - LOCK BOLT

5 - SETTING NOTCH

6 - SPRING TANG

9 - 66 ENGINE 2.4LRS

TIMING BELT AND SPROCKET(S) (Continued)

ProCarManuals.com

Page 1646 of 2177

(17) Apply a bead of MopartSilicone Rubber

Adhesive Sealant to differential cover and install to

case (Fig. 205).

(18) Install and torque cover-to-case bolts to 19

N´m (165 in. lbs.) (Fig. 206).

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING

PRELOAD

NOTE: Perform all differential bearing preload mea-

surements with the transfer shaft and gear

removed.

DIFFERENTIAL BEARING PRELOAD ADJUSTMENT

USING EXISTING SHIM

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up.

(2) Install Tool L-4436A into the differential and

onto the pinion mate shaft (Fig. 207).

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.

(4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential

(Fig. 208).The turning torque should be

between 5 and 18 inch-pounds.

Fig. 205 Install Differential Cover

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL COVER

Fig. 206 Differential Cover Bolts

1 - DIFFERENTIAL COVER BOLTS

2 - DIFFERENTIAL COVER

Fig. 207 Tool L-4436 and Torque Wrench

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

3 - DIFFERENTIAL BEARING RETAINER

Fig. 208 Checking Differential Bearings Turning

Torque

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

RS41TE AUTOMATIC TRANSAXLE21 - 199

FINAL DRIVE (Continued)

ProCarManuals.com