Power system CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 553 of 2585

OPERATION - TURN SIGNAL SYSTEM

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Multi-function switch

²Body Control Module

²Integrated Power Module (IPM)

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 1.0 mile and a speed of 15

mph, with the turn signal ON.

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

To test turn signal, headlamp beam select and opti-

cal horn portion of the multi-function switch:

(1) Remove the multi-function switch, refer to

Electrical, Lamps/Lighting - Exterior, Multi-Function

Switch, Removal, and Installation.

(2) Using an ohmmeter check the resistance read-

ings between multi-function switch pins. Refer to

Wiring Diagrams for proper pin numbers and the

MULTI-FUNCTION SWITCH RESISTANCE table.

MULTI-FUNCTION SWITCH RESISTANCE

SWITCH

POSITIONPIN NUMBER RESISTANCE

LEFT 2 AND 3 2.7V 5%

RIGHT 2 AND 3 1KV 5%

OPTICAL

HORN2 AND 4 1.7KV 5%

HI BEAM 2 AND 4 2.32KV 5%

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove upper and lower steering column

shrouds. Refer to Steering, Column, Shroud,

Removal.

(3) Disconnect wire connector from back of multi-

function switch.

(4) Remove screws holding multi-function switch to

steering column adapter collar.

(5) Remove the multi-function switch.

INSTALLATION

(1) Position the switch on to the steering column.

(2) Install the two retaining screws.(3) Connect the wire harness connector.

(4) Install the upper and lower steering column

shrouds. Refer to Steering, Column, Shroud, Installa-

tion.

(5) Connect the battery negative cable.

PARK/TURN SIGNAL LAMP

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove headlamp retaining screws.

(3) Twist socket counter - clockwise and remove

(Fig. 21).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Twist socket into headlamp.

(3) Install headlamp retaining screws.

(4) Reconnect battery negative cable.

TAIL LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the tail lamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Squeeze the tabs on the bulb socket and

remove from tail lamp unit (Fig. 22).

(4) Pull bulb from lamp socket.

Fig. 21 PARK/TURN SIGNAL LAMP

1 - PARK/TURN SIGNAL LAMP

2 - LAMP SOCKET

8L - 18 LAMPS/LIGHTING - EXTERIORRS

MULTI-FUNCTION SWITCH (Continued)

Page 560 of 2585

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT.........3

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT.......................3

STANDARD PROCEDURE - COMPASS

CALIBRATION.........................3

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING......................4

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................5

REMOVAL - OVERHEAD CONSOLE..........6

INSTALLATION..........................6

SPECIAL TOOLS

OVERHEAD CONSOLE..................6

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION..........................6

OPERATION............................7

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER.........7

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING.......................7

REMOVAL.............................9INSTALLATION..........................9

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER.................10

REMOVAL.............................10

INSTALLATION.........................10

UNIVERSAL TRANSMITTER

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER.......................10

STANDARD PROCEDURE

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES.................11

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES.................11

REMOVAL.............................11

AMBIENT TEMP SENSOR

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR...............12

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT........12

REMOVAL.............................12

INSTALLATION.........................12

OVERHEAD CONSOLE

DESCRIPTION

Three overhead consoles are available on RS/RG

models. These are the Electronic Vehicle Information

Center (EVIC), Compass Mini-Trip Computer

(CMTC) or a Compass Temperature Computer (CT).

All consoles are equipped with two reading/courtesy

lamps and if the vehicle is equipped with a power

liftgate or power sliding door(s) the overhead console

will also include command switches for these fea-

tures. The overhead console is mounted with one

screw and two snap clips to a molded plastic retainer

bracket located above the headliner.

DESCRIPTION - COMPASS

All the available overhead consoles on this model

include Compass information. While in the compass/temperature mode, the compass will display the

direction in which the vehicle is pointed using the

eight major compass headings (Examples: north is N,

northeast is NE). The self-calibrating compass unit

requires no adjusting in normal use. The only cali-

bration that may prove necessary is to drive the vehi-

cle in three complete circles at 5 to 8 kilometers-per-

hour (3 to 5 miles-per-hour), on level ground, in not

less than forty-eight seconds. This will reorient the

compass unit to its vehicle.

The compass unit also will compensate for magne-

tism the body of the vehicle may acquire during nor-

mal use. However, avoid placing anything magnetic

directly on the roof of the vehicle. Magnetic mounts

for an antenna, a repair order hat, or a funeral pro-

cession flag can exceed the compensating ability of

the compass unit if placed on the roof panel. Mag-

netic bit drivers used on the fasteners that hold the

overhead console assembly to the roof header can

RSMESSAGE SYSTEMS8M-1

Page 561 of 2585

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this section may be

required to restore proper compass operation.

DESCRIPTION - TEMPERATURE

All the available overhead consoles on this model

include Temperature information. The temperature

displays the outside ambient temperature in whole

degrees. The temperature display can be toggled

from Fahrenheit to Celsius by selecting the desired

U.S./Metric option from the customer programmable

features. The displayed temperature is not an instant

reading of conditions, but an average temperature. It

may take the temperature display several minutes to

respond to a major temperature change, such as driv-

ing out of a heated garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the electronic control modules (CT, CMTC, EVIC)

memory. When the ignition switch is turned to the

On position again, the electronic module will display

the memory temperature for one minute; then update

the display to the current average temperature read-

ing within five minutes.

The temperature function is supported by an ambi-

ent temperature sensor. The sensor is mounted out-

side the passenger compartment near the front and

center of the vehicle, and is hard wired to the Front

Control Module (FCM). The FCM sends temperature

status messages to the module over the J1850 PCI

data bus circuit.

Following are general descriptions of the major

components used in the overhead console. Refer to

Wiring Diagrams for complete circuit schematics.

OPERATION

Refer to the vehicle Owner's Manual for specific

operation of each overhead console and its systems.

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE

If the problem with the overhead console is an

inaccurate or scrambled display, refer toSelf-Diag-

nostic Testbelow. If the problem with the overhead

console is incorrect Vacuum Fluorescent Display

(VFD) dimming levels, use a DRB IIItscan tool and

the proper Diagnostic Procedures manual to test for

the correct dimming message inputs being received

from the Body Control Module (BCM) or Front Con-

trol Module (FCM) over the J1850 Programmable

Communications Interface (PCI) data bus circuit. If

the problem is a no-display condition, use the follow-

ing procedures. For complete circuit diagrams, refer

toOverhead Consolein the Wiring Diagrams sec-

tion of the service manual.(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the integrated power module. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit to the

fused B(+) fuse in the integrated power module as

required.

(3) Check the fused ignition switch output (run/

start) fuse in the integrated power module. If OK, go

to Step 4. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the integrated power mod-

ule. If OK, go to Step 5. If not OK, repair the open

fused ignition switch output (run/start) circuit to the

ignition switch as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavity of the roof wire

harness connector for the electronics module and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the electronics mod-

ule. If OK, go to Step 7. If not OK, repair the open

fused B(+) circuit to the fused B(+) fuse in the inte-

grated power module as required.

(7)

Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the electronics module. If OK, refer

toSelf-Diagnostic Test

later this group for further

diagnosis of the electronics module and the J1850

PCI data bus circuit. If not OK, repair the open fused

ignition switch output (run/start) circuit to the fuse

in the integrated power module as required.

SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

electronics module is operating properly, and that all

the J1850 PCI data bus messages are being received

for initial operation. Initiate the self-diagnostic test

as follows:

(1) With the ignition switch in the Off position, on

Electronic Vehicle Information Center (EVIC) and

Compass Mini-Trip Computer (CMTC) equipped vehi-

cles simultaneously depress and hold theSTEP and

the RESET buttons. On Compass Temperature

Module (CT) equipped vehicles depress theC/T and

the US/M push buttons.

8M - 2 MESSAGE SYSTEMSRS

OVERHEAD CONSOLE (Continued)

Page 562 of 2585

(2) Turn the ignition switch to the On position.

(3)

Following completion of these tests, the electron-

ics module will display one of the following messages:

a.Pass Self Test (EVIC only), PASS (CT,

CMTC)- The electronics module is working properly.

b.Failed Self Test (EVIC only), FAIL (CT,

CMTC)- The electronics module has an internal fail-

ure. The electronics module is faulty and must be

replaced.

c.Failed J1850 Communication (EVIC only),

BUS (CT, CMTC)- The electronics module is not

receiving proper message input through the J1850

PCI data bus circuit. This can result from one or

more faulty electronic modules in the vehicle, or from

a faulty PCI data bus. The use of a DRB IIItscan

tool and the proper Diagnostic Procedures manual

are required for further diagnosis.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Stan-

dard Procedures section of this group.

NOTE: If the compass reading displays dashes, and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Standard Procedures section

of this group.

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable remote terminal from the remote bat-

tery post.

(2) Remove the reading/courtesy lamp lens. Using

a trim stick, gently pry the forward edge of the read-

ing/courtesy lamp lens outward.

(3) Remove the reading/courtesy lamp socket from

the overhead console. Rotate the reading/courtesy

lamp socket one quarter turn counter clockwise.

(4) Remove the lamp and socket assembly.

(5) Reverse the above procedure to install.

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

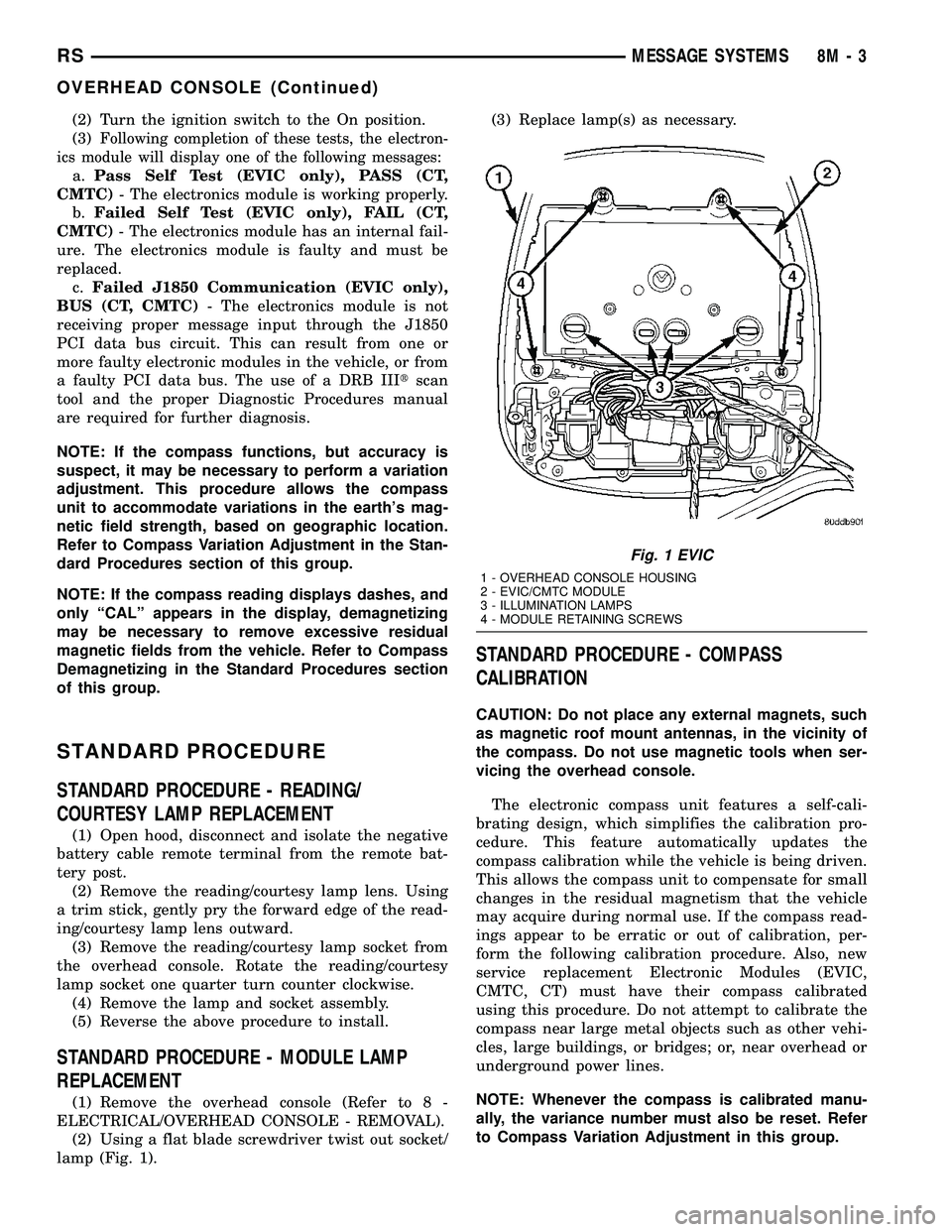

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 1).(3) Replace lamp(s) as necessary.

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.

The electronic compass unit features a self-cali-

brating design, which simplifies the calibration pro-

cedure. This feature automatically updates the

compass calibration while the vehicle is being driven.

This allows the compass unit to compensate for small

changes in the residual magnetism that the vehicle

may acquire during normal use. If the compass read-

ings appear to be erratic or out of calibration, per-

form the following calibration procedure. Also, new

service replacement Electronic Modules (EVIC,

CMTC, CT) must have their compass calibrated

using this procedure. Do not attempt to calibrate the

compass near large metal objects such as other vehi-

cles, large buildings, or bridges; or, near overhead or

underground power lines.

NOTE: Whenever the compass is calibrated manu-

ally, the variance number must also be reset. Refer

to Compass Variation Adjustment in this group.

Fig. 1 EVIC

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC/CMTC MODULE

3 - ILLUMINATION LAMPS

4 - MODULE RETAINING SCREWS

RSMESSAGE SYSTEMS8M-3

OVERHEAD CONSOLE (Continued)

Page 563 of 2585

Calibrate the compass manually as follows:

(1) Turn the ignition switch to the On position. If

the compass/thermometer data is not currently being

displayed, momentarily depress and release the C/T

push button to reach the compass/thermometer dis-

play.

(2) On Electronic Vehicle Information Center

(EVIC) and Compass Mini-Trip Computer (CMTC)

equipped vehicles depress the Reset push button and

hold the button down until ªCALº appears in the dis-

play. This takes about ten seconds, and appears

about five seconds after ªVAR = XXº is displayed. On

Compass Temperature Module (CT) equipped vehicles

depress the C/T push button and US/M push button

down until ªCALº appears in the display. This takes

about ten seconds, and appears about five seconds

after ªVAR = XXº is displayed.

(3) Release the push button(s).

(4) Drive the vehicle on a level surface, away from

large metal objects and power lines, through three or

more complete circles at between five and eight kilo-

meters-per-hour (three and five miles-per-hour) in

not less than 48 seconds. The ªCALº message will

disappear from the display to indicate that the com-

pass is now calibrated.

NOTE: If the ªCALº message remains in the display,

either there is excessive magnetism near the com-

pass, or the unit is faulty. Repeat the calibration

procedure one more time.

NOTE: If the wrong direction is still indicated in the

compass display, the area selected for calibration

may be too close to a strong magnetic field. Repeat

the calibration procedure in another location.

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING

A degaussing tool (Special Tool 6029) is used to

demagnetize, or degauss, the overhead console for-

ward mounting screw and the roof panel above the

overhead console. Equivalent units must be rated as

continuous duty for 110/115 volts and 60 Hz. They

must also have a field strength of over 350 gauss at 7

millimeters (0.25 inch) beyond the tip of the probe.

To demagnetize the roof panel and the overhead

console forward mounting screw, proceed as follows:

(1) Be certain that the ignition switch is in the Off

position, before you begin the demagnetizing proce-

dure.

(2) Connect the degaussing tool (Fig. 2) to an elec-

trical outlet, while keeping the tool at least 61 centi-

meters (2 feet) away from the compass unit.(3) Slowly approach the head of the overhead con-

sole forward mounting screw with the degaussing

tool connected.

(4) Contact the head of the screw with the plastic

coated tip of the degaussing tool for about two sec-

onds.

(5) With the degaussing tool still energized, slowly

back it away from the screw. When the tip of the tool

is at least 61 centimeters (2 feet) from the screw

head, disconnect the tool.

(6) Place a piece of paper approximately 22 by 28

centimeters (8.5 by 11 inches), oriented on the vehicle

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 3). The pur-

pose of the paper is to protect the roof panel from

scratches, and to define the area to be demagnetized.

Fig. 2 Degaussing Tool 6029

Fig. 3 Roof Demagnetizing Pattern

8M - 4 MESSAGE SYSTEMSRS

OVERHEAD CONSOLE (Continued)

Page 568 of 2585

with the optional Auto Headlamps. The options

include Yes and No. The default is No. When Yes is

selected, the headlamps will turn on automatically

when the windshield wipers are turned on. The head-

lamps will turn off when the wipers are turned off,

as long as the headlamp switch is in the Auto or Off

positions. When No is selected, the headlamps will

only turn on if manually selected or if the Auto mode

is selected and the outside ambient light levels dic-

tate that they should be on.

²RETRAIN TIRE SENSORS?- This program-

mable feature only applies to vehicles equipped with

the optional Tire Pressure Monitoring System. The

options include Yes and No. The default is No. When

Yes is selected, and the menu button is depressed the

EVIC will enter the training mode, starting with the

left front tire.

²POWER ACCESSORY DELAY?- The options

include Yes and No. The default is Yes. When No is

selected, the accessory powered components will turn

off automatically when the ignition key is turned off.

When Yes is selected, the accessory powered compo-

nents will remain on for 45 seconds when the igni-

tion key is turned off.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove overhead console. Refer to Overhead

Console Removal and Installation in this section(Re-

fer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

(3) Remove the ten screws holding the EVIC mod-

ule in the overhead console.

(4) Remove EVIC module from console assembly.

NOTE: If the EVIC module is being replaced, the tire

pressure monitoring system (if equipped) must be

retrained. Refer to the Tires/Wheels section of this

manual for detailed instructions.

INSTALLATION

(1) Position the EVIC module in the overhead con-

sole.

(2) Install the ten screws holding the EVIC module

in the overhead console.

(3) Install the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION).

(4) Connect the battery negative cable.

NOTE: If the EVIC module is being replaced, the tire

pressure monitoring system (if equipped) must be

retrained. Refer to the Tires/Wheels section of this

manual for detailed instructions.NOTE: If a new EVIC module has been installed, the

compass will have to be calibrated and the variance

set. Refer to compass variation adjustment and

compass calibration in standard procedures.

COMPASS/MINI-TRIP

COMPUTER

DESCRIPTION

The Compass Mini-Trip Computer (CMTC) and

Compass Temperature (CT) computer are modules

located in the overhead console. Vehicles are

equipped with either the CMTC or the CT computers

not both. The CMTC is different in the fact that it is

equipped with the mini-trip feature. The CMTC, CT

consists of a electronic control module with a vacuum

fluorescent display (VFD) and function switches. The

CMTC, CT consists of a electronic module that dis-

plays compass, trip computer (CMTC only), and tem-

perature features. Actuating the STEP push button

(CMTC only) will cause the CMTC to change mode of

operation when ignition is ON. Actuating the STEP

push button (CMTC only) will cause the CMTC to

change mode of operation when ignition is ON.

Example:

²Average miles per gallon (ECO)

²Distance to empty (DTE)

²Instant miles per gallon (ECO)

²Trip odometer (ODO)

²Elapsed time (ET)

²Off

Actuating the C/T push button will cause the

CMTC, CT to change to Compass/Temperature dis-

play.

OPERATION

The Compass Mini-Trip Computer (CMTC), Com-

pass Temperature (CT) module in the overhead con-

sole has buttons used to select various functions. The

CMTC, CT selector buttons will not operate until the

ignition is in the RUN position.

When the ignition switch is first turned to the

RUN position the CMTC, CT display;

²Blanks momentarily

²All segments of the VFD will light for one sec-

ond

²Blanks momentarily

²Returns to the last mode setting selected before

the ignition was last switched OFF.

RSMESSAGE SYSTEMS8M-9

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 570 of 2585

Transmitter and the EVIC module are inoperative,

refer toElectronic Vehicle Information Center

Diagnosis and Testingin this group for further

diagnosis. For complete circuit diagrams, refer to

Wiring Diagrams. (Fig. 5) as described below:

(1) Turn the Radio Frequency (RF) Detector ON. A

ªchirpº will sound and the green power LED will

light. If the green LED does not light, replace the

battery.

(2) Hold the RF detector within one inch of the

TRAINED universal transmitter and press any of the

transmitters buttons.

(3) The red signal detection LEDs will light and

the tool will beep if a radio signal is detected. Repeat

this test three times.

STANDARD PROCEDURE

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES

(1) Turn off the engine.

(2) Erase the codes by pressing the two outside

buttons. Release the buttons when the display con-

firms the operation (about 20 seconds).

(3) Choose one of the three buttons to train. Place

the hand-held transmitter within one inch of the uni-

versal transmitter and push the buttons on both

transmitters.(4) Release both buttons. Your universal transmit-

ter is now ªtrainedº. To train the other buttons,

repeat Step 3 and Step 4. Be sure to keep your hand-

held transmitter in case you need to retrain the uni-

versal transmitter.

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES

To erase the universal transmitter codes, simply

hold down the two outside buttons until the display

confirms the operation.

NOTE: Individual channels cannot be erased. Eras-

ing the transmitter codes will erase ALL pro-

grammed codes.

REMOVAL

(1) For universal transmitter removal and installa-

tion procedure, (Refer to 8 - ELECTRICAL/OVER-

HEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - REMOVAL and INSTALLATION).

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the over-

head console through ambient temperature messages

received from the Front Control Module (FCM) over

the Programmable Communications Interface (PCI)

J1850 data bus circuit. The FCM receives a hard

wired input from the ambient temperature sensor.

The ambient temperature sensor is a variable resis-

tor mounted to a bracket that is secured with a screw

to the right side of the headlamp mounting module

grille opening, behind the radiator grille and in front

of the engine compartment.

For more information on the Front Control Module

refer to the Electronic Control Modules section of this

manual. For complete circuit diagrams, refer to the

appropriate wiring information. The ambient temper-

ature sensor cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the Front Control Module. The resis-

tance in the sensor changes as temperature changes,

changing the temperature sensor signal circuit volt-

age to the Front Control Module. Based upon the

resistance in the sensor, the Front Control Module

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The Front Control Module

Fig. 5 RADIO FREQUENCY DETECTOR

1 - SIGNAL DETECTION LED'S

2 - POWER LED

3 - ON/OFF SWITCH

4 - 9V BATTERY

RSMESSAGE SYSTEMS8M-11

UNIVERSAL TRANSMITTER (Continued)

Page 572 of 2585

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM.................. 1

POWER SLIDING DOOR SYSTEM............ 19

POWER LOCKS........................... 38POWER MIRRORS........................ 45

POWER SEAT SYSTEM..................... 50

POWER WINDOWS........................ 62

POWER LIFTGATE SYSTEM

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM

DESCRIPTION..........................2

OPERATION............................3

DIAGNOSIS AND TESTING - POWER

LIFTGATE SYSTEM.....................4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIFTGATE

ADJUSTMENT.........................9

STANDARD PROCEDURE - POWER

LIFTGATE LEARN CYCLE................9

SPECIFICATIONS

SPECIFICATIONS TABLE................9

CHIME/THERMISTOR

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................10

ENGAGE ACTUATOR

DESCRIPTION.........................10

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

EXTERIOR HANDLE SWITCH

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................12

FULL OPEN SWITCH

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................13INSTALLATION.........................13

LATCH

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................14

LATCH ACTUATOR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

LIFTGATE MOTOR

DESCRIPTION.........................15

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................15

LIFT GEAR & LINK ROD

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

PINCH SENSOR

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

TRANSVERSE BRACKET

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................18

INSTALLATION.........................18

RSPOWER SYSTEMS8N-1

Page 573 of 2585

POWER LIFTGATE SYSTEM

DESCRIPTION

Some vehicles are equipped with an automatic

opening and closing power liftgate system (Fig. 1).

This power liftgate system is a complex system con-

sisting of many components. Some of these compo-

nents are the liftgate gear motor assembly, latch

assembly, lift gear and rod, liftgate control module,

chime/thermistor, full open switch, engage actuator,

pinch sensor, liftgate handle switch, overhead console

switch, key fob switches (Fig. 2), pawl switch and

ratchet switch.

The power liftgate system has its own door control

module, located on the vehicles left body D-pillar

behind the trim panel. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/DOOR CON-

TROL MODULE - DESCRIPTION) The power

liftgate gear motor assembly is located just above the

control module. The latch assembly is located in the

bottom center of the power liftgate, below the exte-

rior liftgate handle switch. The power liftgate full

open switch, engage actuator, lift gear and rod are

part of the liftgate gear motor assembly. The pawl

and ratchet switches are part of the latch assembly.

The pinch sensor or sensors are located along theright and left sides of the power liftgate, just above

the body line. The liftgate handle switch is an power

release switch and is located in the rear light bar

assembly, just above the license plate. The overhead

console switch is an power open and close command

switch located in the vehicles overhead console.

Safety is of the utmost concern with the power lift-

gate system. Software technology has enabled the

power liftgate control module to detect resistance to

liftgate travel, which allows the power liftgate to stop

and reverse direction anytime an obstruction is felt

or any of the command switches are operated (only in

closing direction). Battery voltage is supplied to the

power liftgate system through a 40 amp fuse, located

in the Intelligent Power Module (IPM) assembly (Fig.

3). In the unlikely event that the power liftgate sys-

tem develops a fault the power liftgate can still be

operated manually with a key, just like a standard

manual liftgate.

The power liftgate control module communicates

on the J1850 Programmable Communication Inter-

face (PCI) Bus Circuit. Therefore, the power liftgate

control module can generate and store its own Diag-

nostic Trouble Codes (DTC). The vehicles Body Con-

trol Module (BCM) receives and supplies messages to

the power liftgate control module via the PCI bus cir-

cuit. A diagnostic scan tool, such as the DRB IIItis

Fig. 1 POWER LIFTGATE INTRODUCTION

8N - 2 POWER LIFTGATE SYSTEMRS

Page 574 of 2585

used to read and troubleshoot these Diagnostic Trou-

ble Codes (DTC). Refer to the Body Diagnostic Man-

ual for a complete list of diagnostic routines.

For additional information refer to Power Liftgate

Operation. For a complete system wiring schematic

refer to Wiring Diagrams. For system operationinstructions refer to the vehicles owner manual.

Refer to the Body section of the service manual

for additional information on liftgate components

such as the prop rods, hinges, door alignment and

striker alignment.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS (NOTED BELOW) IN POWER LIFT-

GATE SYSTEM OPERATION BEFORE ATTEMPTING

ANY SERVICE OF THE POWER LIFTGATE SYSTEM

OR COMPONENTS.

OPERATION

With the push of a power liftgate open/close com-

mand switch (key fob or overhead console mounted) a

signal is sent out on the J1850 PCI Data Bus circuit.

This signal is detected at the body control module

(BCM). The BCM then sends a signal out on the

J1850 PCI Data Bus circuit to the power liftgate

module. The power liftgate module then signals the

power liftgate motor to start an open or close cycle,

depending on what position the liftgate is in open or

closed.

During a liftgate open or close cycle, if the power

liftgate module detects sufficient resistance to liftgate

travel, such as an obstruction in the liftgates path,

the power liftgate control module will immediately

stop the liftgate movement and reverse travel to the

full open or closed position. The ability for the power

liftgate module to detect resistance to liftgate travel

is accomplished by hall effect sensors, drive motor

speed and pinch sensors (tape switches).

The power liftgate control module has the ability to

learn. Anytime the liftgate is opened or closed using

the power liftgate system the module learns from its

cycle. If a replacement power liftgate component is

installed or a liftgate adjustment is made, the mod-

ule will relearn the effort and/or time required to

open or close the door. This learn cycle can be per-

formed with a Diagnostic Scan Tool, such as the

DRB IIItor with a complete cycle of the liftgate,

using any one of the command switches. Refer to

Standard Procedures in this section for detailed

instructions.

The power liftgate system is designed with a num-

ber of system inhibitors. These inhibitors are neces-

sary for safety and / or feasibility of the power

liftgate system. Refer to power liftgate system inhib-

itors noted below:

POWER LIFTGATE SYSTEM INHIBITORS

²The Power Liftgate may not operate in extreme

temperatures. These extreme temperatures will be

approximately -12É F (-24.4É C) on the low side and

143É F (61.6É C) for the high side. A chime/thermister

Fig. 2 KEY FOB

1 - Left Sliding Door Switch

2 - Right Sliding Door Switch

3 - Liftgate Switch

Fig. 3 LIFTGATE FUSE LOCATION

RSPOWER LIFTGATE SYSTEM8N-3

POWER LIFTGATE SYSTEM (Continued)