check engine CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1335 of 2585

The crankshaft journals should be checked for

excessive wear, taper and scoring (Fig. 46). Limits of

taper or out of round on any crankshaft journals

should be held to 0.025 mm (0.001 in.). Journal

grinding should not exceed 0.305 mm (0.012 in.)

under the standard journal diameter. DO NOT grind

thrust faces of No. 3 main bearing. DO NOT nick

crank pin or bearing fillets. After grinding, remove

rough edges from crankshaft oil holes and clean out

all passages.

CAUTION: With the nodular cast iron crankshafts, it

is important that the final paper or cloth polish be

in the same direction as normal rotation in the

engine.

The crankshaft is supported in five main bearings.

All upper and lower bearing shells in the crankcase

have oil grooves. Crankshaft end play is controlled by

a flanged bearing on the number three main bearing

journal (Fig. 47).

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOTinterchangeable with any other bearing halves

in the engine (Fig. 47). All bearing cap bolts removedduring service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.025 mm

(0.001 in.) and 0.250 mm (0.010 in.). Never install an

undersize bearing that will reduce clearance below

specifications. Replace or machine the crankshaft as

necessary to obtain proper bearing clearances.

INSTALLATION - CRANKSHAFT

CRANKSHAFT MAIN BEARING LOCATION

The crankshaft is supported in five main bearings.

All upper and lower bearing shells in the crankcase

have oil grooves and holes (Fig. 48). Crankshaft end

play is controlled by a flanged bearing on the number

three main bearing journal.

Fig. 45 Bedplate Bolt Tightenening Sequence

Fig. 46 Crankshaft Journal Measurements

Fig. 47 Main Bearing Identification

1 - OIL GROOVE

2 - MAIN BEARINGS

3 - OIL HOLE

Fig. 48 Main Bearing Identification

1 - OIL GROOVE

2 - MAIN BEARINGS

3 - OIL HOLE

9 - 38 ENGINE 2.4LRS

CRANKSHAFT (Continued)

Page 1337 of 2585

(13) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(14) Check crankshaft end play (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT - STAN-

DARD PROCEDURE).

(15) Install connecting rod bearings and caps.Do

Not Reuse Connecting Rod Bolts.Torque connect-

ing rod bolts to 27 N´m (20 ft. lbs.) plus 1/4 turn.

(16) Install balance shafts and housing assembly

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - INSTALLATION).

(17) Install the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - INSTALLATION).

(18) Install oil pump pick-up tube. Torque fastener

to 28 N´m (20 ft.. lbs.).

(19) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(20) Install crankshaft position sensor.

(21) Install cylinder head if it was removed (Refer

to 9 - ENGINE/CYLINDER HEAD - INSTALLA-

TION).

(22) Install the timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(23) Install crankshaft sprocket (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT AND

SPROCKETS - INSTALLATION).

(24) Install the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

INSTALLATION).

(25) Install the timing belt front covers (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - INSTALLATION).

(26) Install engine mount support bracket.

(27) InstallNEWoil filter.

(28) Install crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - INSTALLATION).

(29) Install flex plate. Apply MopartLock & Seal

Adhesive to bolt threads and tighten to 95 N´m (70

ft. lbs.).

(30) Attach transaxle to engine. Tighten attaching

bolts to 101 N´m (75 ft. lbs.).

(31) Install the engine assembly (Refer to 9 -

ENGINE - INSTALLATION).

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Remove the crankshaft vibration damper.

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 52).

CAUTION: Do not nick shaft seal surface or seal

bore.

(4) Using Tool 6771 to remove front crankshaft oil

seal (Fig. 53). Be careful not to damage the seal sur-

face of cover.

INSTALLATION

(1) Install new seal by using Special Tool 6780

(Fig. 54).

(2) Place seal into opening with seal spring

towards the inside of engine. Install seal until flush

with cover.

Fig. 52 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - SPECIAL TOOL C-4685±C2

3 - CRANKSHAFT SPROCKET

Fig. 53 Front Crankshaft Oil Seal - Removal

1 - SPECIAL TOOL 6771

2 - REAR TIMING BELT COVER

9 - 40 ENGINE 2.4LRS

CRANKSHAFT (Continued)

Page 1340 of 2585

Cylinder bores should be measured halfway down

the cylinder bore and transverse (measurement loca-

tion B) to the engine crankshaft center line shown in

(Fig. 61). Refer to for Engine Specifications (Refer to

9 - ENGINE - SPECIFICATIONS). Correct piston to

bore clearance must be established in order to assure

quiet and economical operation.

REMOVAL

(1) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(2) Remove oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(3) Remove Balance Shaft Carrier Assembly (Refer

to 9 - ENGINE/VALVE TIMING/BALANCE SHAFT

CARRIER - REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation.

(5) Pistons have a directional stamping in the

front half of the piston facing towards thefrontof

engine (Fig. 62).

Fig. 59 Rear Crankshaft SealÐInstallation

1 - SPECIAL TOOL 6926±2 INSTALLER

Fig. 60 Piston Measurement

1 - PISTON DIAMETER

2 - 14 mm (0.551 in.)

Fig. 61 Checking Cylinder Bore

Fig. 62 Piston Markings

1 - DIRECTIONAL ARROW WILL BE IMPRINTED IN THIS AREA

RSENGINE 2.4L9-43

PISTON & CONNECTING ROD (Continued)

Page 1342 of 2585

(7) Install connecting rod upper bearing half into

connecting rod. Install Special Tool 8189, connecting

rod guides onto connecting rod (Fig. 64).

(8) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(9) Remove Special Tool 8189, connecting rod

guides.

NOTE: The connecting rod cap bolts should not be

reused.

(10) Before installing theNEWbolts, the threads

should be coated with clean engine oil.

(11) Install connecting rod lower bearing half into

connecting rod cap. Install connecting rod cap.

(12) Install each bolt finger tight then alternately

torque each bolt to assemble the cap properly.

(13) Tighten the connecting rod bolts using the 2

step torque-turn method. Tighten according to the

following values:

CAUTION: Do not use a torque wrench for the sec-

ond step.

1. Tighten the bolts to 27 N´m (20 ft. lbs.).

2. Tighten the connecting rod bolts an additional

1/4 TURN.

(14) Using a feeler gauge, check connecting rod

side clearance (Fig. 67). (Refer to 9 - ENGINE -

SPECIFICATIONS) for connecting rod side clearance.

(15) Install Balance Shaft Carrier Assembly (Refer

to 9 - ENGINE/VALVE TIMING/BALANCE SHAFT

CARRIER - INSTALLATION).

(16) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(17) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

CONNECTING ROD BEARINGS

STANDARD PROCEDURE

CONNECTING ROD - FITTING

(1) For measuring connecting rod bearing clear-

ance procedure and use of Plastigage (Refer to 9 -

ENGINE - STANDARD PROCEDURE). For bearing

clearance refer to Engine Specifications. (Refer to 9 -

ENGINE - SPECIFICATIONS)

NOTE: The rod bearing bolts should not be reused.

(2) Before installing theNEWbolts the threads

should be oiled with clean engine oil.

(3) Install each bolt finger tight then alternately

torque each bolt to assemble the cap properly.

(4) Tighten the connecting rod bolts using the 2

step torque-turn method. Tighten according to the

following values:

CAUTION: Do not use a torque wrench for the sec-

ond step.

1. Tighten the bolts to 27 N´m (20 ft. lbs.).

2. Tighten the connecting rod bolts an additional

1/4 TURN.

(5) Using a feeler gauge, check connecting rod side

clearance (Fig. 67). Refer to clearance specifications

(Refer to 9 - ENGINE - SPECIFICATIONS).

PISTON RINGS

STANDARD PROCEDURE

PISTON RING - FITTING

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

Fig. 66 PistonÐInstallation

Fig. 67 Connecting Rod Side Clearance

RSENGINE 2.4L9-45

PISTON & CONNECTING ROD (Continued)

Page 1343 of 2585

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 inch) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 68).

Refer to Engine Specifications.

(2) Check piston ring to groove side clearance (Fig.

69). Refer to Engine Specifications.

REMOVAL

(1) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 70).

(2) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(3) Clean ring grooves of any carbon deposits.

INSTALLATION

NOTE: The identification mark on face of upper and

intermediate piston rings must point toward top of

piston.

Install rings with manufacturers identification

mark facing up, to the top of the piston (Fig. 71).

CAUTION: Install piston rings in the following order:

1. Oil ring expander.

2. Upper oil ring side rail.

3. Lower oil ring side rail.

Fig. 68 Piston Ring Gap

1 - FEELER GAUGE

Fig. 69 Piston Ring Side Clearance

1 - FEELER GAUGE

Fig. 70 Piston RingsÐRemoving and Installing

Fig. 71 Piston Ring Installation

1 - NO. 1 PISTON RING

2 - NO. 2 PISTON RING

3 - SIDE RAIL

4 - OIL RING

5 - SPACER EXPANDER

9 - 46 ENGINE 2.4LRS

PISTON RINGS (Continued)

Page 1349 of 2585

LUBRICATION

DESCRIPTION

The lubrication system is a full-flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

OPERATION

Engine oil drawn up through the pickup tube and is

pressurized by the oil pump and routed through the

full-flow filter to the main oil gallery running the

length of the cylinder block. A diagonal hole in each

bulkhead feeds oil to each main bearing. Drilled pas-

sages within the crankshaft route oil from main bear-

ing journals to connecting rod journals. Balance shaft

lubrication is provided through an oil passage from

the number one main bearing cap through the balance

shaft carrier support leg. This passage directly sup-

plies oil to the front bearings and internal machined

passages in the shafts that routes oil from front to the

rear shaft bearing journals. A vertical hole at the

number five bulkhead routes pressurized oil through a

restrictor (integral to the cylinder head gasket) up

past a cylinder head bolt to an oil gallery running the

length of the cylinder head. The camshaft journals arepartially slotted to allow a predetermined amount of

pressurized oil to pass into the bearing cap cavities.

Lubrication of the camshaft lobes are provided by

small holes in the camshaft bearing caps that are

directed towards each lobe. Oil returning to the pan

from pressurized components supplies lubrication to

the valve stems. Cylinder bores and wrist pins are

splash lubricated from directed slots on the connecting

rod thrust collars (Fig. 85).

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE

(1) Disconnect and remove oil pressure switch.

(Refer to 9 - ENGINE/LUBRICATION/OIL PRES-

SURE SENSOR/SWITCH - REMOVAL)

(2) Install Special Tools C-3292 Gauge with 8406

Adaptor fitting.

(3) Start engine and record oil pressure. Refer to

Specifications for correct oil pressure requirements.

(Refer to 9 - ENGINE - SPECIFICATIONS)

CAUTION: If oil pressure is 0 at idle, do not perform

the 3000 RPM test

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

(5) After test is complete, remove test gauge and

fitting.

(6) Install oil pressure switch and connector. (Refer

to 9 - ENGINE/LUBRICATION/OIL PRESSURE

SENSOR/SWITCH - INSTALLATION)

Fig. 84 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 85 Engine Lubrication System

9 - 52 ENGINE 2.4LRS

RIGHT MOUNT (Continued)

Page 1350 of 2585

OIL

STANDARD PROCEDURE

ENGINE OIL LEVEL CHECK

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick and observe oil level. Add

oil only when the level is at or below the ADD mark

(Fig. 86).

STANDARD PROCEDURE - ENGINE OIL AND

FILTER CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. (Refer to

LUBRICATION & MAINTENANCE/MAINTE-

NANCE SCHEDULES - DESCRIPTION)

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Remove oil fill cap.

(3) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Remove oil filter. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL)

(7) Install and tighten drain plug in crankcase.

(8) Install new oil filter. (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION)

(9) Lower vehicle and fill crankcase with specified

type and amount of engine oil. (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES -

DESCRIPTION)

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

NOTE: Care should be exercised when disposing

used engine oil after it has been drained from a

vehicle engine. Refer to the WARNING listed above.

OIL FILTER

DESCRIPTION

The engine oil filter (Fig. 87) is a high quality full-

flow, disposable type. Replace the oil filter with a

Mopartor the equivalent.

REMOVAL

(1) Raise vehicle on hoist.

(2) Position an oil collecting container under oil fil-

ter location.

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can to base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.

(3) Using a suitable filter wrench, turn oil filter

(Fig. 87) counterclockwise to remove.

INSTALLATION

(1) Clean and check filter mounting surface. The

surface must be smooth, flat and free of debris or

pieces of gasket.

(2) Lubricate new oil filter gasket with clean

engine oil.

(3) Screw oil filter (Fig. 87) on until the gasket

contacts base. Tighten to 12 N´m (105 in. lbs.).

Fig. 86 Oil Level

1 - ENGINE OIL LEVEL DIPSTICK

RSENGINE 2.4L9-53

Page 1351 of 2585

OIL PAN

REMOVAL

(1) Raise vehicle on hoist and drain engine oil.

(2) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

(3) Remove air conditioning compressor bracket to

oil pan bolt.

(4) Remove bolts attaching oil pan.

(5) Remove oil pan.

(6) Clean oil pan and all gasket surfaces.

INSTALLATION

(1) Apply MopartEngine RTV GEN II at the oil

pump to engine block parting line (Fig. 88).

(2) Install the oil pan gasket to the block.

(3) Install pan and tighten the screws to 12 N´m

(105 in. lbs.).

(4) Install air conditioning compressor bracket to

oil pan bolt.

(5) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(6) Lower vehicle and fill engine crankcase with

proper oil to correct level.

OIL PRESSURE SWITCH

REMOVAL

(1) Raise vehicle.

(2) Position oil collecting container under pressure

switch location.

(3) Disconnect oil pressure switch electrical con-

nector and remove switch (Fig. 89).

INSTALLATION

(1) Install oil pressure switch. Torque switch to 21

N´m (190 in. lbs.) (Fig. 89).

(2) Connect electrical connector

(3) Lower vehicle.

(4) Start engine and allow to run a minimum of 2

minutes.

(5) Shut engine off and check engine oil level.

Adjust level as necessary.

Fig. 87 Oil Filter

Fig. 88 Oil Pan Sealing - Typical

1 - SEALER LOCATIONS

Fig. 89 Engine Oil Pressure Switch

9 - 54 ENGINE 2.4LRS

OIL FILTER (Continued)

Page 1353 of 2585

(2) Remove oil pump cover fasteners, and lift off

cover (Fig. 94) .

(3) Remove pump rotors (Fig. 94) .

(4) Wash all parts in a suitable solvent and

inspect carefully for damage or wear.

CLEANING

(1) Clean all parts thoroughly in a suitable sol-

vent.

INSPECTION

(1) Inspect the mating surfaces of the oil pump

cover. Surface should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 95). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between cover and straight edge,

cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 9.40 mm (0.370 in.)

or less (Fig. 96), or if the diameter is 79.95 mm

(3.148 in.) or less, replace outer rotor.

(4) If inner rotor measures 9.40 mm (0.370 in.) or

less replace inner rotor (Fig. 97).

ASSEMBLY

(1) Assemble pump, using new parts as required.

Install the inner rotor with chamfer facing the

cast iron oil pump cover.

(2) Prime oil pump before installation by filling

rotor cavity with engine oil.

(3) Install cover and tighten fasteners to 12 N´m

(105 in. lbs.) (Fig. 94).

Fig. 94 Oil Pump

1 - O-RING

2 - SEAL

3 - INNER ROTOR

4 - OIL PUMP COVER

5 - FASTENER

6 - OUTER ROTOR

7 - OIL PUMP BODY

Fig. 95 Checking Oil Pump Cover Flatness

1 - STRAIGHT EDGE

2 - FEELER GAUGE

3 - OIL PUMP COVER

Fig. 96 Measuring Outer Rotor Thickness

Fig. 97 Measuring Inner Rotor Thickness

9 - 56 ENGINE 2.4LRS

OIL PUMP (Continued)

Page 1356 of 2585

(9) Disconnect throttle and speed control (if

equipped) cables from throttle lever and bracket.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL)

(10) Remove the EGR tube. (Refer to 25 - EMIS-

SIONS CONTROL/EXHAUST GAS RECIRCULA-

TION/TUBE - REMOVAL)

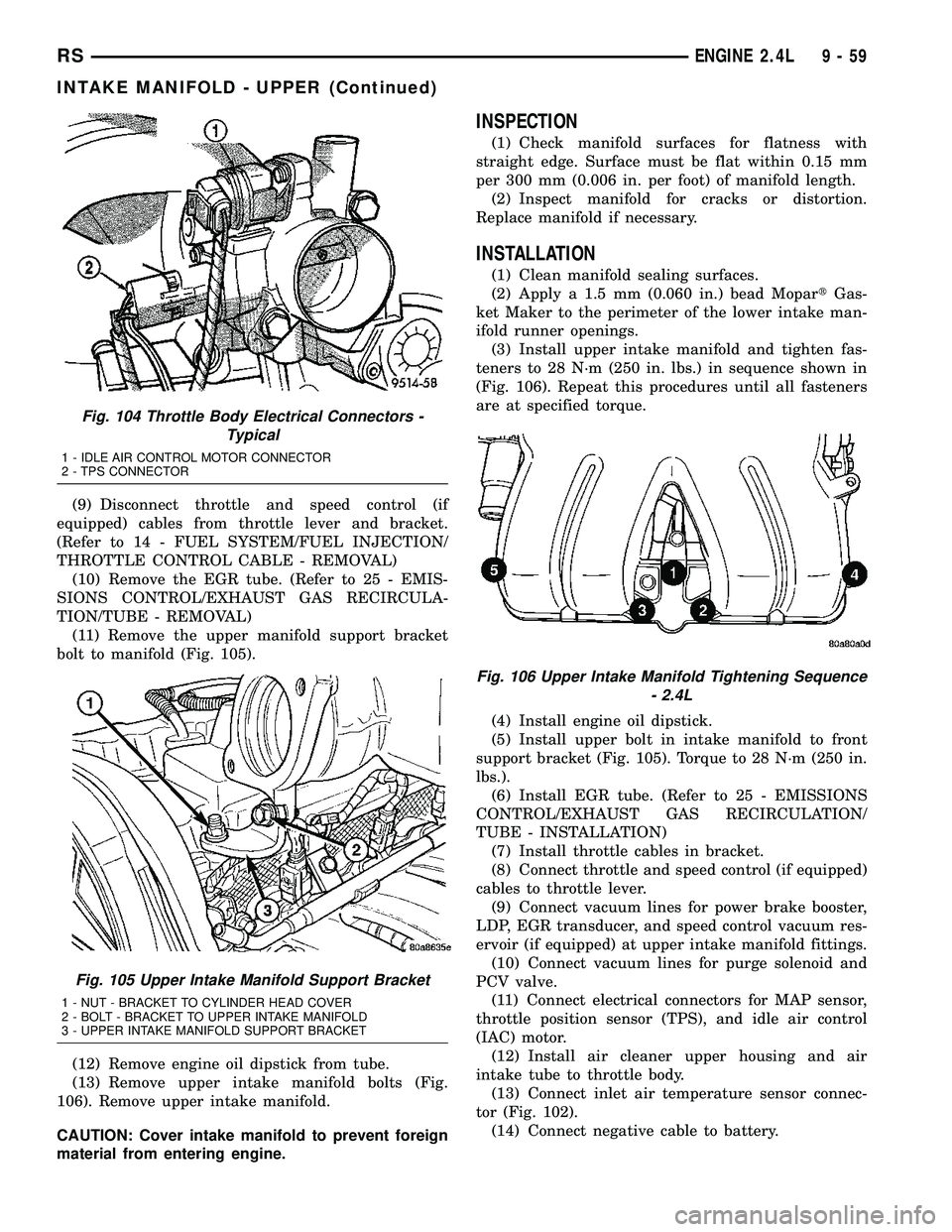

(11) Remove the upper manifold support bracket

bolt to manifold (Fig. 105).

(12) Remove engine oil dipstick from tube.

(13) Remove upper intake manifold bolts (Fig.

106). Remove upper intake manifold.

CAUTION: Cover intake manifold to prevent foreign

material from entering engine.

INSPECTION

(1) Check manifold surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (0.006 in. per foot) of manifold length.

(2) Inspect manifold for cracks or distortion.

Replace manifold if necessary.

INSTALLATION

(1) Clean manifold sealing surfaces.

(2) Apply a 1.5 mm (0.060 in.) bead MopartGas-

ket Maker to the perimeter of the lower intake man-

ifold runner openings.

(3) Install upper intake manifold and tighten fas-

teners to 28 N´m (250 in. lbs.) in sequence shown in

(Fig. 106). Repeat this procedures until all fasteners

are at specified torque.

(4) Install engine oil dipstick.

(5) Install upper bolt in intake manifold to front

support bracket (Fig. 105). Torque to 28 N´m (250 in.

lbs.).

(6) Install EGR tube. (Refer to 25 - EMISSIONS

CONTROL/EXHAUST GAS RECIRCULATION/

TUBE - INSTALLATION)

(7) Install throttle cables in bracket.

(8) Connect throttle and speed control (if equipped)

cables to throttle lever.

(9) Connect vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at upper intake manifold fittings.

(10) Connect vacuum lines for purge solenoid and

PCV valve.

(11) Connect electrical connectors for MAP sensor,

throttle position sensor (TPS), and idle air control

(IAC) motor.

(12) Install air cleaner upper housing and air

intake tube to throttle body.

(13) Connect inlet air temperature sensor connec-

tor (Fig. 102).

(14) Connect negative cable to battery.

Fig. 104 Throttle Body Electrical Connectors -

Typical

1 - IDLE AIR CONTROL MOTOR CONNECTOR

2 - TPS CONNECTOR

Fig. 105 Upper Intake Manifold Support Bracket

1 - NUT - BRACKET TO CYLINDER HEAD COVER

2 - BOLT - BRACKET TO UPPER INTAKE MANIFOLD

3 - UPPER INTAKE MANIFOLD SUPPORT BRACKET

Fig. 106 Upper Intake Manifold Tightening Sequence

- 2.4L

RSENGINE 2.4L9-59

INTAKE MANIFOLD - UPPER (Continued)