fuel CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2142 of 2585

point must not affect alignment. Striker should go

straight into the latching mechanism.

(2) On vehicles with left sliding doors, check the

fuel door blocker striker entry into latch. Striker at

this point must not affect alignment.

(3) Check C-post and B-post for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

1 mm.

(4) Check door for height using character lines as

a reference. Also check roof contour as a controlling

factor.

Using the procedures noted below, adjust the side

door in the order the individual steps are called out.

DOOR FLUSHNESS ADJUSTMENT

(1) Check sliding door flushness at the C-pillar

striker.

(2) If the sliding door is under or over flush,

remove striker assembly and move thread plate over

keeping one bolt in plate so it will not fall between

inner and outer panels.

(3) Adjust the C-pillar striker in or out until the

door is flush. Then, the on size hole can be elongated

in the direction required. This can be done by grind-

ing or filing the sheet metal and then painting raw

edge to prevent rusting.

(4) Check upper B-pillar flushness to A-pillar

cover.

(5) The sliding door upper hinge can only be

moved outboard by addinga1mmshim behind the

hinge mounting area once the too attachment bolts

are removed and reinstalled.

(6) Check flushness at upper C-pillar.

(7) If upper C-pillar flushness is out of specifica-

tion use a heavy rubber mallet on the door assembly

until door is in specifications.

DOOR GAP ADJUSTMENT - UP/DOWN

(1) Visually inspect the sliding door for fitting low

at the top of the door by checking the alignment of

the top contour of the door to the quarter panel.

(2) Fully open the sliding door.

(3) Verify that all center hinge bolts are tight.

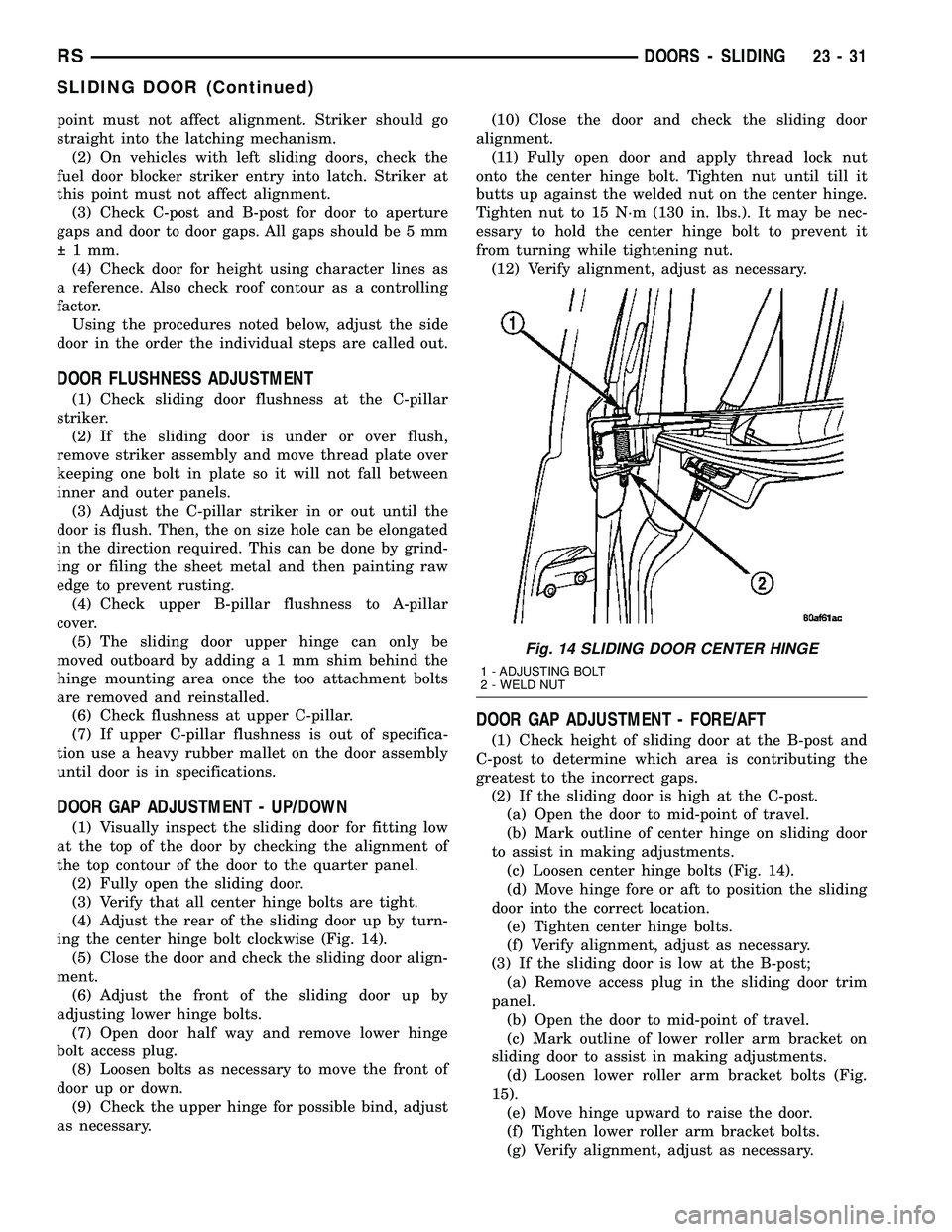

(4) Adjust the rear of the sliding door up by turn-

ing the center hinge bolt clockwise (Fig. 14).

(5) Close the door and check the sliding door align-

ment.

(6) Adjust the front of the sliding door up by

adjusting lower hinge bolts.

(7) Open door half way and remove lower hinge

bolt access plug.

(8) Loosen bolts as necessary to move the front of

door up or down.

(9) Check the upper hinge for possible bind, adjust

as necessary.(10) Close the door and check the sliding door

alignment.

(11) Fully open door and apply thread lock nut

onto the center hinge bolt. Tighten nut until till it

butts up against the welded nut on the center hinge.

Tighten nut to 15 N´m (130 in. lbs.). It may be nec-

essary to hold the center hinge bolt to prevent it

from turning while tightening nut.

(12) Verify alignment, adjust as necessary.

DOOR GAP ADJUSTMENT - FORE/AFT

(1) Check height of sliding door at the B-post and

C-post to determine which area is contributing the

greatest to the incorrect gaps.

(2) If the sliding door is high at the C-post.

(a) Open the door to mid-point of travel.

(b) Mark outline of center hinge on sliding door

to assist in making adjustments.

(c) Loosen center hinge bolts (Fig. 14).

(d) Move hinge fore or aft to position the sliding

door into the correct location.

(e) Tighten center hinge bolts.

(f) Verify alignment, adjust as necessary.

(3) If the sliding door is low at the B-post;

(a) Remove access plug in the sliding door trim

panel.

(b) Open the door to mid-point of travel.

(c) Mark outline of lower roller arm bracket on

sliding door to assist in making adjustments.

(d) Loosen lower roller arm bracket bolts (Fig.

15).

(e) Move hinge upward to raise the door.

(f) Tighten lower roller arm bracket bolts.

(g) Verify alignment, adjust as necessary.

Fig. 14 SLIDING DOOR CENTER HINGE

1 - ADJUSTING BOLT

2 - WELD NUT

RSDOORS - SLIDING23-31

SLIDING DOOR (Continued)

Page 2156 of 2585

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL.............................45

INSTALLATION.........................46

COWL GRILLE

REMOVAL.............................50

INSTALLATION.........................51

EXTERIOR NAME PLATES - TAPE ATTACHED

REMOVAL.............................51

INSTALLATION.........................51

EXTERIOR NAME PLATES - ADHESIVE

ATTACHED

REMOVAL.............................51

INSTALLATION.........................51

FRONT FENDER

REMOVAL.............................52

INSTALLATION.........................52

FUEL FILL DOOR

REMOVAL.............................52

INSTALLATION.........................52

FUEL FILL DOOR BLOCKER LATCH

REMOVAL.............................53

INSTALLATION.........................53

FUEL FILL DOOR BLOCKER LATCH STRIKER

REMOVAL.............................53

INSTALLATION.........................53

FUEL FILL DOOR BLOCKER LOCKOUT LINK

REMOVAL.............................53INSTALLATION.........................54

GRILLE OPENING REINFORCEMENT

REMOVAL.............................54

INSTALLATION.........................54

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL.............................55

INSTALLATION.........................55

LUGGAGE RACK RISER

REMOVAL.............................55

INSTALLATION.........................56

LUGGAGE RACK CROSSBAR

REMOVAL.............................56

INSTALLATION.........................57

REAR QUARTER PANEL/FENDER AIR

EXHAUSTER

DESCRIPTION.........................57

REMOVAL.............................57

INSTALLATION.........................58

ROOF JOINT MOLDING

REMOVAL.............................58

INSTALLATION.........................58

SIDE VIEW MIRROR

REMOVAL.............................59

INSTALLATION.........................59

SIDE VIEW MIRROR GLASS

REMOVAL.............................59

INSTALLATION.........................59

BODY SIDE MOLDINGS

REMOVAL

Refer to (Fig. 1), (Fig. 2), (Fig. 3), (Fig. 4) or (Fig.

5)for proper location of fasteners holding the molding

to the wheelhouse lip and rocker panels.

(1) Warm the affected stick on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.

(2) If equipped, remove pop rivets holding molding

edge to wheelhouse lip.(3) Pull stick on molding from painted surface.

(4) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Disc, or equivalent, to

clean adhesive residue from painted surfaces. These

products are available from automotive paint suppli-

ers. Refer to instructions supplied with the specific

product for proper usage.

RSEXTERIOR23-45

Page 2163 of 2585

FRONT FENDER

REMOVAL

(1) Remove headlamp housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(2) Remove mud guard.

(3) Remove inner splash shield.

(4) Remove fender to fascia nuts.

(5) Remove outboard cowl grille/fender bracket

screw.

(6) Remove fender bolt to lower rocker panel.

(7) Remove fender bolt to lower cowl.

(8) Pull fascia away from fender.

(9) Remove bolts attaching fender to upper rail.

(10) Remove fender from vehicle (Fig. 8).

INSTALLATION

(1) Place fender in position on vehicle.

(2) From inside engine compartment, start the

center upper rail bolt. install all the bolts attaching

fender to upper rail and tighten.

(3) Install fender to lower cowl panel bolt.

(4) Install fender to rocker panel bolt.

(5) Place fascia into position.

(6) Install outboard cowl grille/fender bracket

screw.

(7) Install fender to fascia nuts.

(8) Install inner splash shield.

(9) Install mud guard.

(10) Install headlamp assembly. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - INSTALLATION)(11) Check fender for flush and gap.

FUEL FILL DOOR

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12).

(4) Open fuel fill door.

(5) Remove screws holding fuel fill neck to fuel

filler housing.

(6) Position fuel fill neck out of the way.

(7) Reaching inside fuel filler housing, release clips

holding housing to quarter panel (Fig. 9).

(8) Remove fuel fill door from vehicle.

(9) Disengage clip holding link to fuel fill door

(Fig. 13).

(10) Remove link from fuel fill door.

INSTALLATION

(1) Install spring to housing and door

(2) Snap door into housing.

(3) Insert lockout link into clip on fuel fill door.

(4) Engage clip to hold link to fuel fill door.

(5) Insert lockout link through grommet in panel

between inner and outer quarter panel.

(6) Close fuel fill door.

(7) Install fuel filler housing to outer quarter

panel.

(8) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(9) Place fuel fill neck in position.

Fig. 8 FENDER

1 - FASTENERS

2 - FENDER

3 - FASTENERS

Fig. 9 FUEL FILLER HOUSING AND DOOR

1 - FUEL FILLER HOUSING W/LATCH

2 - CLIP

3 - FUEL FILLER HOUSING DOOR

4 - CLIPS

5 - FIX CLIP

23 - 52 EXTERIORRS

Page 2164 of 2585

(10) Install screws to hold fuel fill neck to fuel

filler housing.

(11) Engage latch release link into clip on fuel fill

blocker latch arm.

(12) Verify fuel fill blocker latch operation.

(13) Install water shield patch to cover access hole

in C-pillar.

(14) Install left quarter trim panel.

FUEL FILL DOOR BLOCKER

LATCH

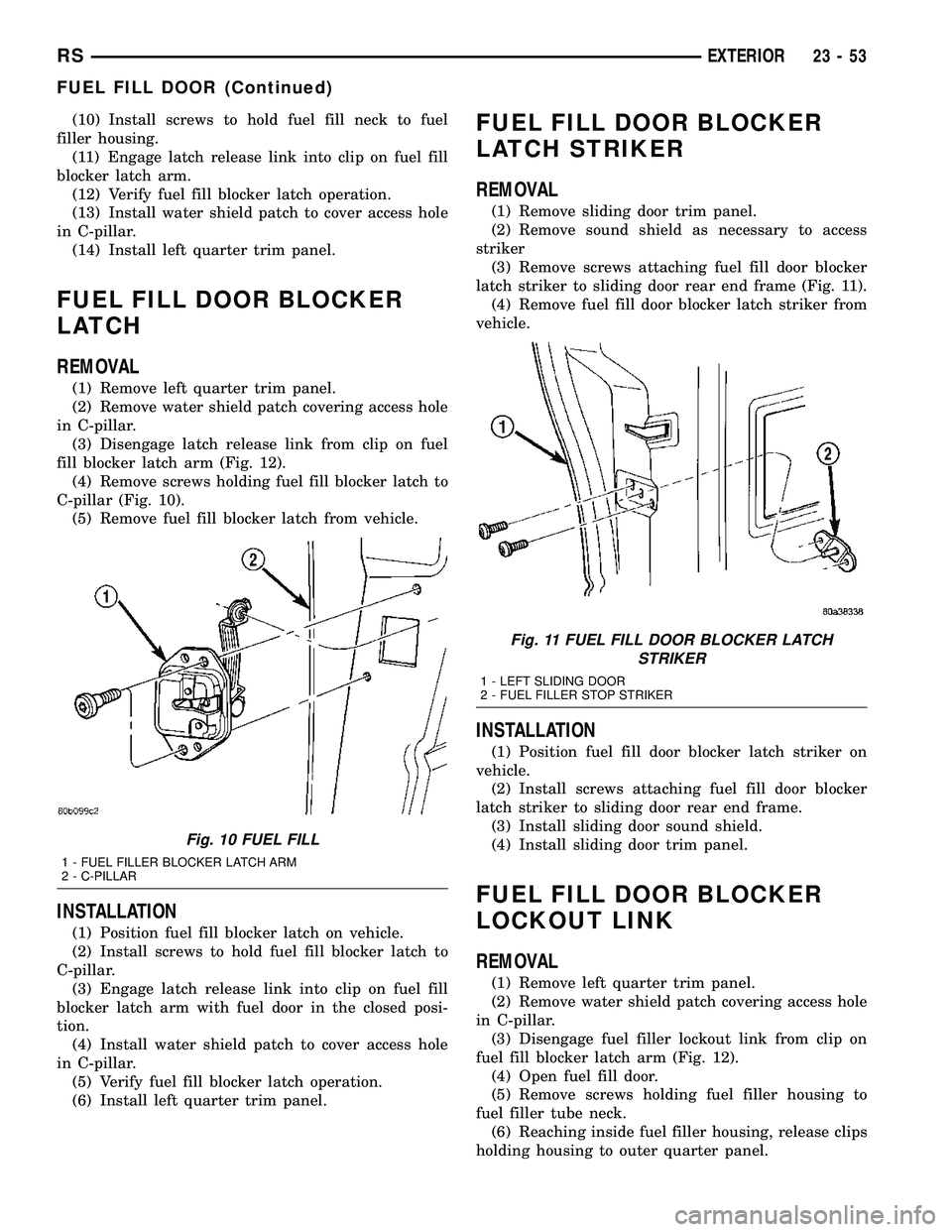

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12).

(4) Remove screws holding fuel fill blocker latch to

C-pillar (Fig. 10).

(5) Remove fuel fill blocker latch from vehicle.

INSTALLATION

(1) Position fuel fill blocker latch on vehicle.

(2) Install screws to hold fuel fill blocker latch to

C-pillar.

(3) Engage latch release link into clip on fuel fill

blocker latch arm with fuel door in the closed posi-

tion.

(4) Install water shield patch to cover access hole

in C-pillar.

(5) Verify fuel fill blocker latch operation.

(6) Install left quarter trim panel.

FUEL FILL DOOR BLOCKER

LATCH STRIKER

REMOVAL

(1) Remove sliding door trim panel.

(2) Remove sound shield as necessary to access

striker

(3) Remove screws attaching fuel fill door blocker

latch striker to sliding door rear end frame (Fig. 11).

(4) Remove fuel fill door blocker latch striker from

vehicle.

INSTALLATION

(1) Position fuel fill door blocker latch striker on

vehicle.

(2) Install screws attaching fuel fill door blocker

latch striker to sliding door rear end frame.

(3) Install sliding door sound shield.

(4) Install sliding door trim panel.

FUEL FILL DOOR BLOCKER

LOCKOUT LINK

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage fuel filler lockout link from clip on

fuel fill blocker latch arm (Fig. 12).

(4) Open fuel fill door.

(5) Remove screws holding fuel filler housing to

fuel filler tube neck.

(6) Reaching inside fuel filler housing, release clips

holding housing to outer quarter panel.

Fig. 10 FUEL FILL

1 - FUEL FILLER BLOCKER LATCH ARM

2 - C-PILLAR

Fig. 11 FUEL FILL DOOR BLOCKER LATCH

STRIKER

1 - LEFT SLIDING DOOR

2 - FUEL FILLER STOP STRIKER

RSEXTERIOR23-53

FUEL FILL DOOR (Continued)

Page 2165 of 2585

(7) Remove fuel filler housing and lockout link

from vehicle.

(8) Disengage clip holding link to fuel fill door

(Fig. 13).

(9) Remove link from fuel fill door.

INSTALLATION

(1) Insert link into clip on fuel fill door.

(2) Engage clip to hold link to fuel fill door.

(3) Insert lockout link through grommet in panel

between inner and outer quarter panel.

(4) Close fuel fill door.

(5) Install fuel filler housing to outer quarter

panel.(6) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(7) Engage fuel filler lockout link into clip on fuel

fill blocker latch arm.

(8) Install water shield patch covering access hole

in C-pillar.

(9) Install left quarter trim panel.

GRILLE OPENING

REINFORCEMENT

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to cross-

member and position latch out of the way.

(3) Remove radiator sight shield.

(4) Remove engine air inlet resonator.

(5) Remove hood cable.

(6) Remove hood prop rod.

(7) Remove screw attaching coolant recovery bottle

to crossmember.

(8) Remove bolts attaching radiator isolators to

crossmember.

(9) Remove bolts attaching ends of crossmember to

radiator closure panel (Fig. 14).

(10) Lift crossmember upward and away from

radiator closure panel.

(11) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

Fig. 12 FUEL FILLER LOCKOUT LINK AT LATCH

ARM

1 - FUEL FILLER LOCKOUT LINK

2 - C-PILLAR

3 - FUEL FILLER BLOCKER LATCH ARM

4 - PLASTIC LINK CLIP

5 - INNER QUARTER PANEL

Fig. 13 FUEL FILLER LOCKOUT LINK

1 - FUEL FILLER LOCKOUT LINK

2 - FUEL FILLER OPENING

3 - QUARTER PANELFig. 14 RADIATOR CLOSURE PANEL

CROSSMEMBER

1 - RADIATOR CLOSURE PANEL CROSSMEMBER

2 - FRONT FASCIA

23 - 54 EXTERIORRS

FUEL FILL DOOR BLOCKER LOCKOUT LINK (Continued)

Page 2187 of 2585

(15) Roll and fold carpet forward away from rear

door opening.

(16) Extract carpet through sliding door opening

(Fig. 5).INSTALLATION

(1) Insert carpet through sliding door opening.

(2) Roll carpet rearward toward rear door opening.

(3) Roll carpet under instrument panel.

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area (Fig. 5).

(5) Install push pins fasteners in the rear area.

CAUTION: Ensure that the correct fasteners are

installed in the proper locations. Damage to the fuel

tank may result.

(6) Install floor escutcheons (Fig. 4).

(7) Install the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

INSTALLATION)

(8) Install Quarter trim panels.

(9) Install D-pillar trim covers.

(10) Install lower B-pillar trim covers.

(11) Install rear door sill plate.

(12) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(13) Install front cowl panels and sill plates.

(14) Install the passenger seats. Refer to the Own-

er's Manual for proper procedures.

(15) Install front center console.

(16) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION)

COWL TRIM

REMOVAL

(1) Remove door sill plate.

(2) Disengage hidden clips holding cowl trim to

cowl panel (Fig. 6).

(3) Remove cowl trim from vehicle.

INSTALLATION

(1) Place cowl trim panel in position on vehicle

(Fig. 1).

(2) Engage hidden clips attaching cowl trim to

cowl panel.

(3) Install door sill plate.

Fig. 4 SEAT ESCUTCHEONS

1 - SEAT ESCUTCHEON

2 - FLOOR CARPET

Fig. 5 FLOOR CARPET

1 - CARPET LOCATOR GROMMET

2 - PUSH PIN

3 - CARPET

4 - CARPET GROMMET

5 - HEEL PROTECTOR PAD

6 - BODY ASSEMBLY

23 - 76 INTERIORRS

CARPETS AND FLOOR MATS (Continued)

Page 2237 of 2585

SPECIFICATIONS

ITEM LOCATION GAP FLUSH

A HOOD TO FASCIA (VOYAGER ONLY)

8.0 2.0

PARALLEL WITHIN 2.0 RIGHT TO

LEFT2.5 OVER FLUSH TO HOOD

1.5 CONSISTENT WITHIN 2.0

B HEADLAMP MODULE TO

HOOD8.0 2.0

PARALLEL WITHIN 2.0 RIGHT TO

LEFT

C HOOD TO FENDER (FORE &

AFT)0.0 1.5

LEFT TO RIGHT WITHIN 1.5

D HOOD TO FENDER 4.0 1.5

PARALLEL WITHIN 2.5 AND

WITHIN 1.5 LEFT TO RIGHTUNDER FLUSH 2.0

E FENDER TO DOOR 5.0 1.5

PARALLEL WITHIN 2.0UNDER FLUSH 0.5 1.5

CONSISTENT WITHIN 2.0

F FRONT DOOR TO9A9PILLAR

COVERUNDER FLUSH 0.5 2.0

G9A9PILLAR COVER TO

SLIDING DOOR5.0 2.0

PARALLEL WITHIN 1.01.0 UNDER FLUSH 2.0

CONSISTENT WITHIN 1.0

H FRONT DOOR APPLIQUE TO

SLIDING DOOR GLASS5.0 2.0

PARALLEL WITHIN 2.01.0 OVER FLUSH 2.0

CONSISTENT WITHIN 3.0

I FRONT DOOR TO SLIDING

DOOR5.0 2.0

PARALLEL WITHIN 2.0 2.0 CONSISTENT WITHIN

2.0

J SLIDING DOOR TO REAR

APERTURE GLASS5.0 2.0

PARALLEL WITHIN 1.5 3.0 CONSISTENT WITHIN

3.0

K SLIDING DOOR TO REAR

APERTURE5.0 1.5

PARALLEL WITHIN 2.0 1.5 CONSISTENT WITHIN

1.5

L TAIL LAMP TO BODY SIDE

APERTURE1.0 1.0

PARALLEL WITHIN 1.5OVER FLUSH

M TAIL LAMP TO LIFTGATE 4.0 2.0 OVER FLUSH

N LIFTGATE TO BODY SIDE

APERTURE4.0 1.5 UNDER FLUSH 1.0 2.5

CONSISTENT WITHIN 2.0

O LIFTGATE TO ROOF 8.0 2.0 1.5

P LIFTGATE TO FASCIA 8.0 2.5

PARALLEL WITHIN 3.0

Q LIFTGATE TO REAR FASCIA UNDER FLUSH TO 1.0

MAXIMUM OVER FLUSH

R FUEL FILLER DOOR TO BODY

SIDE APERTUREUNDER FLUSH 0.5 1.0

NOTE: All measurements are in mm.

23 - 126 BODY STRUCTURERS

GAP AND FLUSH (Continued)

Page 2277 of 2585

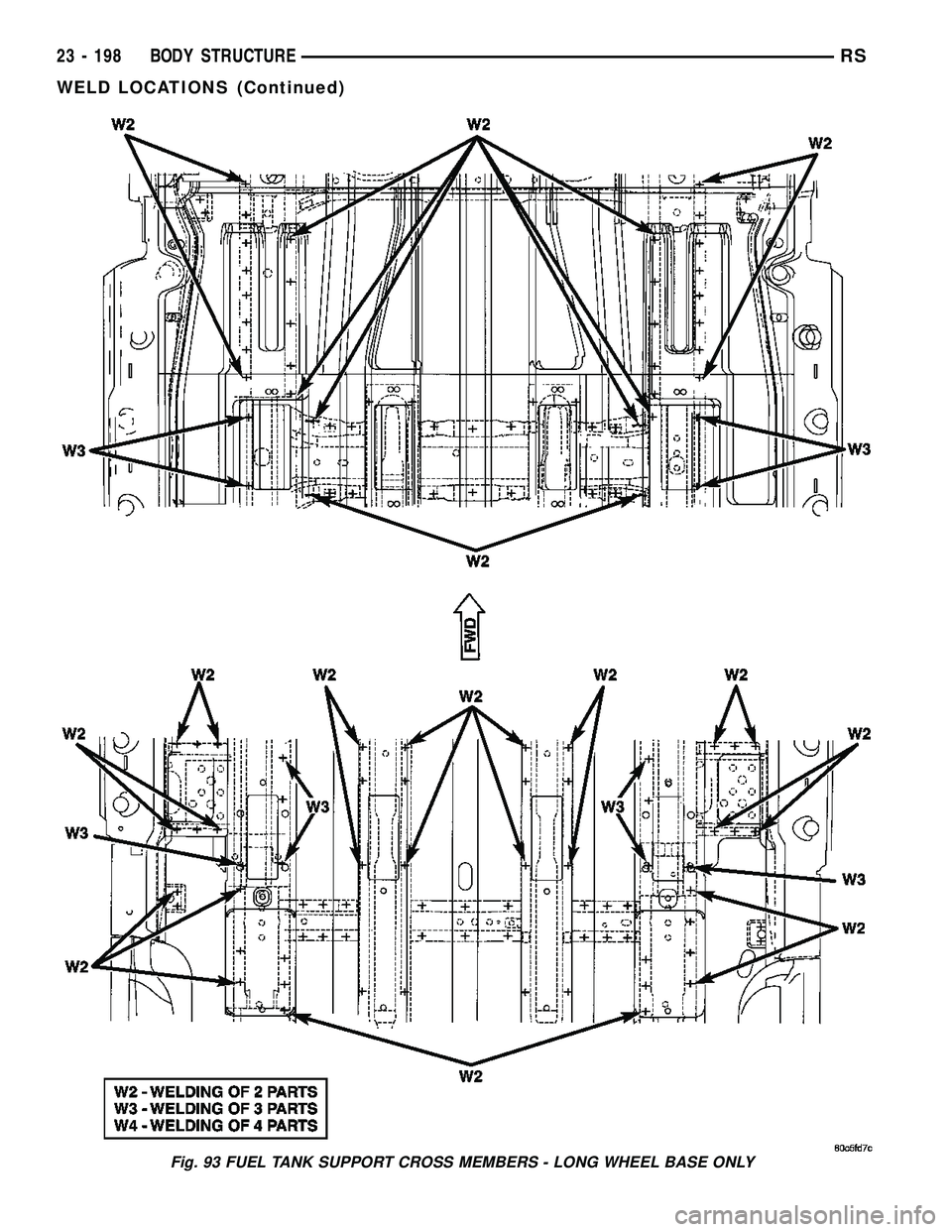

WELD LOCATIONS

SPECIFICATIONS - WELD LOCATIONS

INDEX

DESCRIPTION FIGURE

FRONT FENDER SHIELD - RIGHT 64

FRONT FENDER SHIELD - LEFT 65

STRUT TOWER AND REINFORCEMENTS - RIGHT 66

SUSPENSION RETAINERS AND REINFORCEMENTS - RIGHT 67

STRUT TOWER AND REINFORCEMENTS - LEFT 68

SUSPENSION RETAINERS AND REINFORCEMENTS - LEFT 69

FLOOR PAN REINFORCEMENTS - SIDE RAILS 70

REAR SUSPENSION BRACKETS 71

FLOOR PAN CROSS MEMBERS 72

SEAT REINFORCEMENTS - LONG WHEEL BASE ONLY 73

STRIKER REINFORCEMENTS - LONG WHEEL BASE ONLY 74

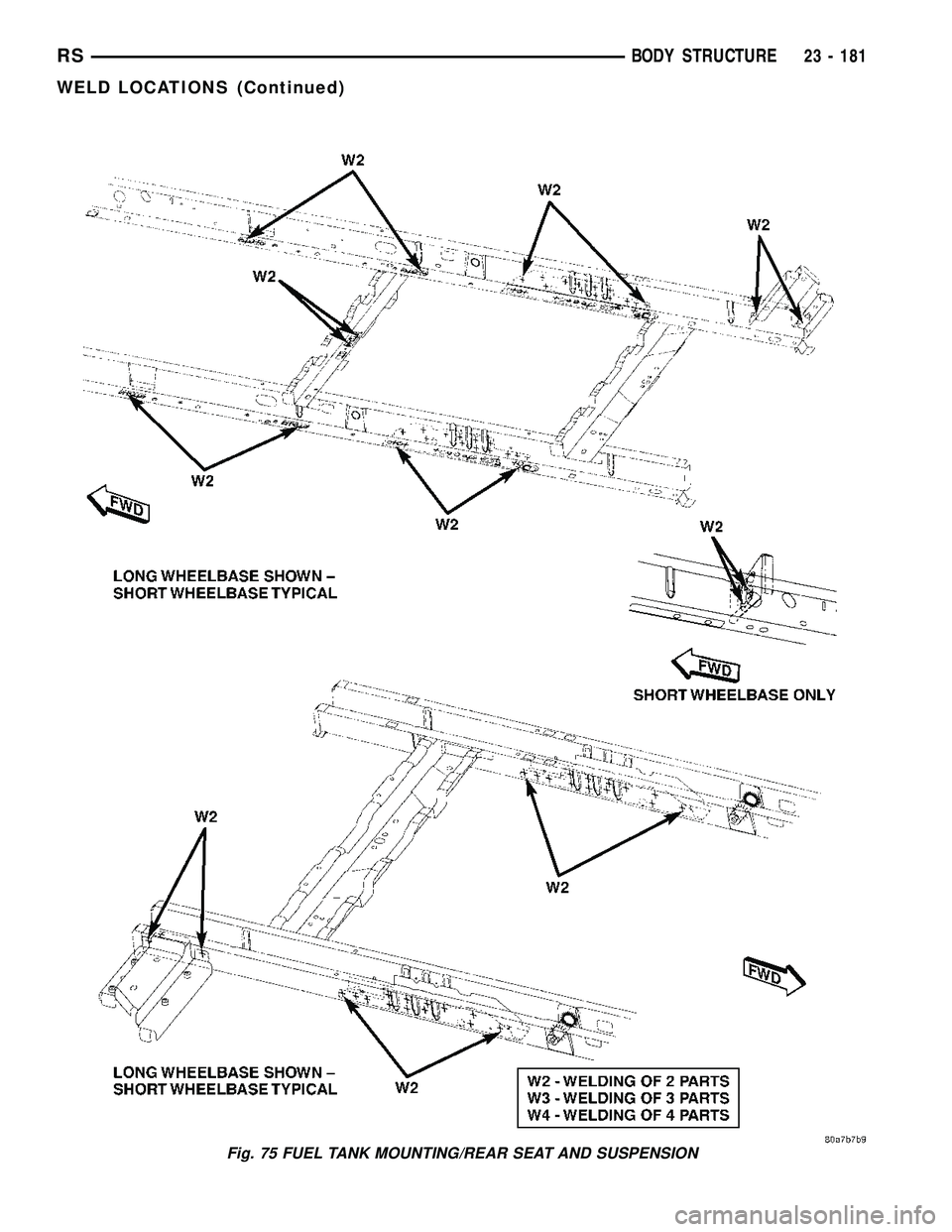

FUEL TANK MOUNTING/REAR SEAT AND SUSPENSION 75

REAR SUSPENSION HANGER BRACKETS - LONG WHEEL BASE 76

FRONT SEAT CROSS MEMBER 77

FLOOR PAN SIDE RAIL REINFORCEMENT 78

SILL BULKHEAD REINFORCEMENTS 79

FLOOR PAN CROSS MEMBER REINFORCEMENTS 80

FRONT SEAT CROSS MEMBER 81

SEAT REINFORCEMENT CROSS MEMBERS - SHORT WHEEL BASE 82

CENTER CONSOLE REINFORCEMENT - SHORT WHEEL BASE 83

REAR SUSPENSION HANGER BRACKETS - SHORT WHEEL BASE 84

LOWER LIFTGATE PANEL LATCH REINFORCEMENT 85

ENGINE MOUNTING PLATE AND TOW BRACKET 86

HEADLAMP MOUNTING PLATE 87

LOWER RADIATOR CROSS MEMBER BRACKETS 88

CROSS MEMBER EXTENSIONS 89

JACK MOUNTING BRACKET - LONG WHEEL BASE SHOWN, SHORT SIMILAR 90

FRONT SEAT CROSS MEMBER - LONG WHEELBASE ONLY 91

FRONT SEAT CROSS MEMBER - ALL WHEEL DRIVE ONLY 92

FUEL TANK SUPPORT CROSS MEMBERS - LONG WHEEL BASE ONLY 93

REAR SUPPORT AND TIRE STOWAGE CROSS MEMBERS - LONG WHEEL BASE

ONLY94

INNER SIDE SILLS - LONG WHEEL BASE ONLY 95

WHEELHOUSES, SIDE SILLS, SUSPENSION BRACKETS - LONG WHEEL BASE ONLY 96

REAR SEAT REINFORCEMENTS - SHORT WHEEL BASE ONLY 97

FUEL TANK SUPPORT AND TIRE STOWAGE - SHORT WHEEL BASE ONLY 98

INNER SIDE SILLS - SHORT WHEEL BASE ONLY 99

23 - 166 BODY STRUCTURERS

Page 2292 of 2585

Fig. 75 FUEL TANK MOUNTING/REAR SEAT AND SUSPENSION

RSBODY STRUCTURE23 - 181

WELD LOCATIONS (Continued)

Page 2309 of 2585

Fig. 93 FUEL TANK SUPPORT CROSS MEMBERS - LONG WHEEL BASE ONLY

23 - 198 BODY STRUCTURERS

WELD LOCATIONS (Continued)