ABS CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1978 of 2585

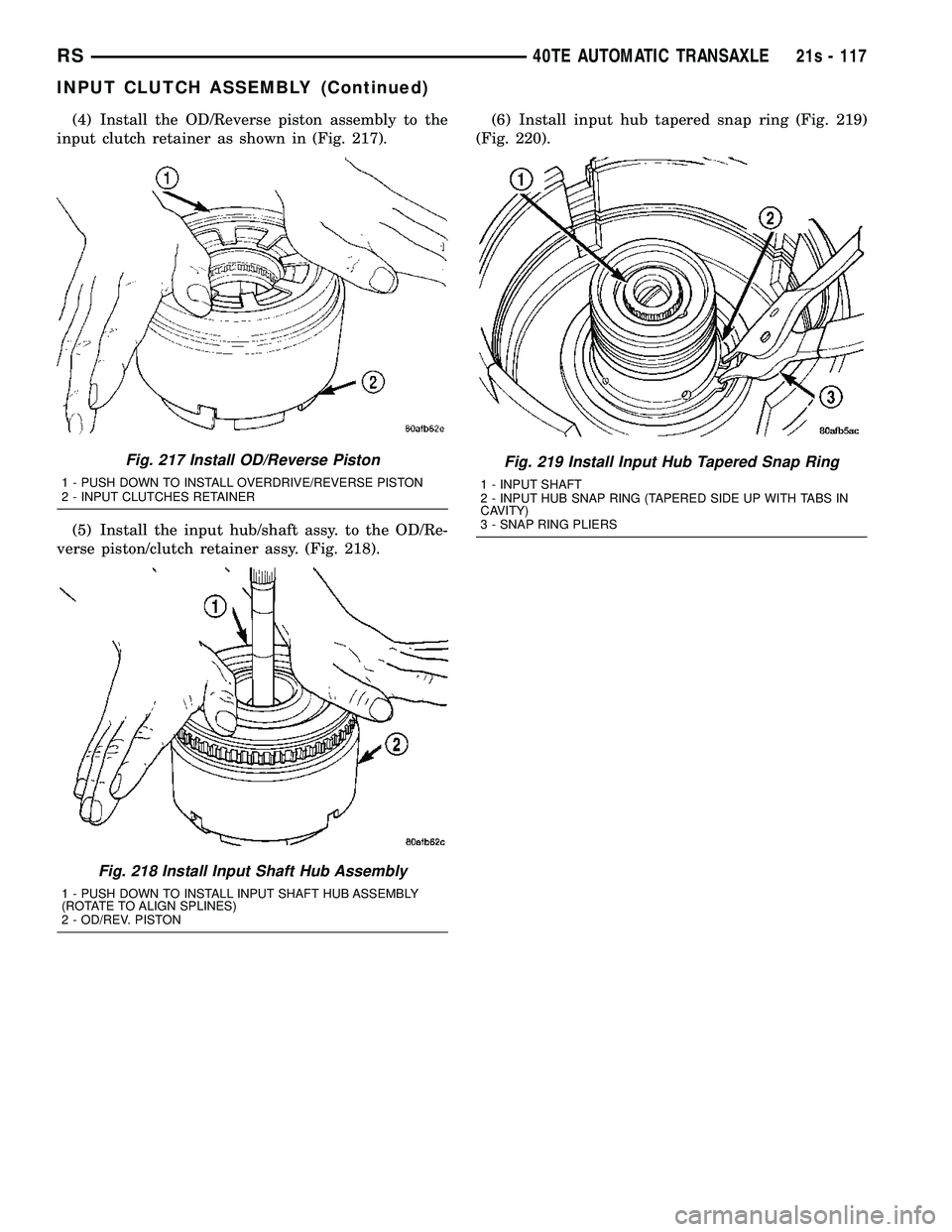

(4) Install the OD/Reverse piston assembly to the

input clutch retainer as shown in (Fig. 217).

(5) Install the input hub/shaft assy. to the OD/Re-

verse piston/clutch retainer assy. (Fig. 218). (6) Install input hub tapered snap ring (Fig. 219)

(Fig. 220).

Fig. 217 Install OD/Reverse Piston

1 - PUSH DOWN TO INSTALL OVERDRIVE/REVERSE PISTON

2 - INPUT CLUTCHES RETAINER

Fig. 218 Install Input Shaft Hub Assembly

1 - PUSH DOWN TO INSTALL INPUT SHAFT HUB ASSEMBLY

(ROTATE TO ALIGN SPLINES)

2 - OD/REV. PISTON

Fig. 219 Install Input Hub Tapered Snap Ring

1 - INPUT SHAFT

2 - INPUT HUB SNAP RING (TAPERED SIDE UP WITH TABS IN

CAVITY)

3 - SNAP RING PLIERS

RS 40TE AUTOMATIC TRANSAXLE21s - 117

INPUT CLUTCH ASSEMBLY (Continued)

Page 1989 of 2585

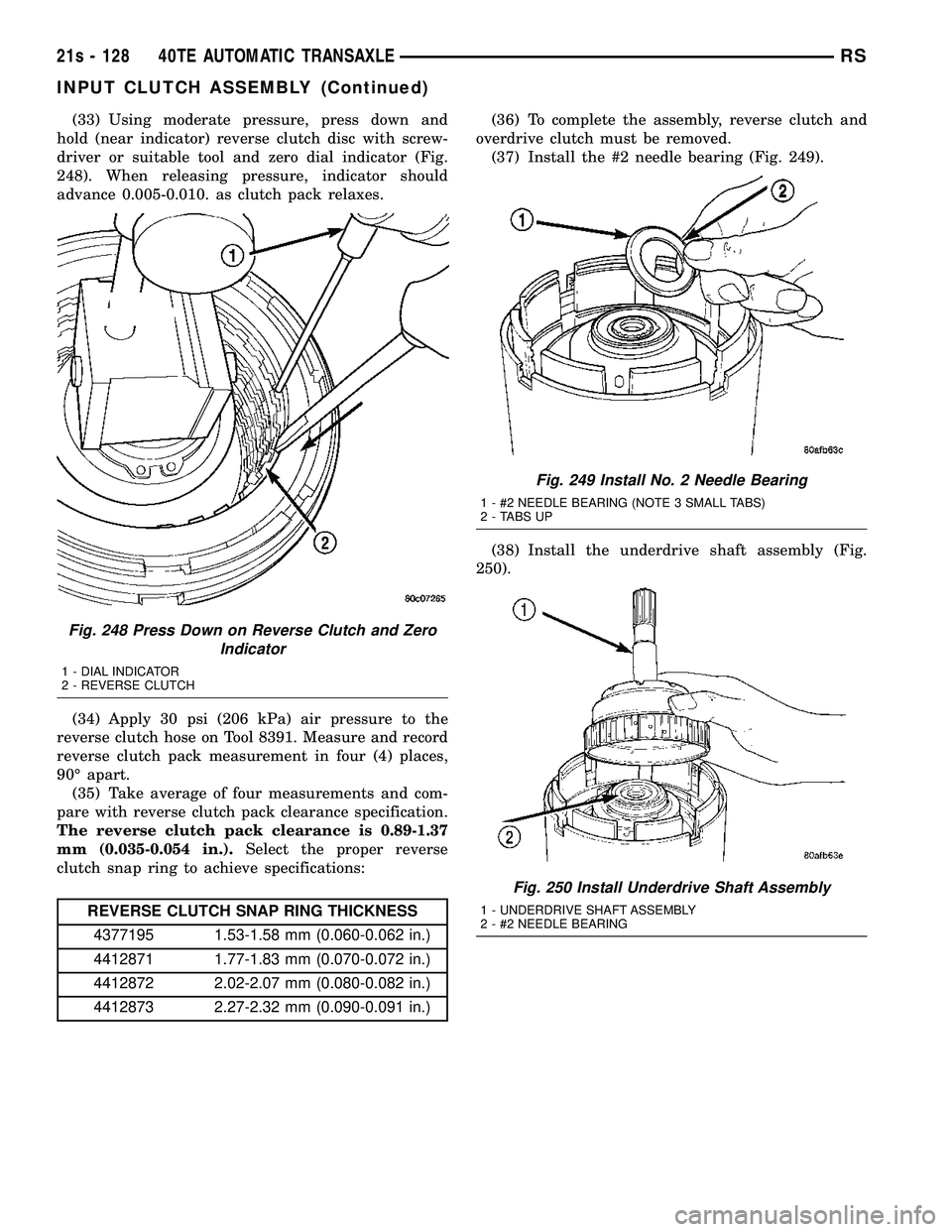

(33) Using moderate pressure, press down and

hold (near indicator) reverse clutch disc with screw-

driver or suitable tool and zero dial indicator (Fig.

248). When releasing pressure, indicator should

advance 0.005-0.010. as clutch pack relaxes.

(34) Apply 30 psi (206 kPa) air pressure to the

reverse clutch hose on Tool 8391. Measure and record

reverse clutch pack measurement in four (4) places,

90É apart. (35) Take average of four measurements and com-

pare with reverse clutch pack clearance specification.

The reverse clutch pack clearance is 0.89-1.37

mm (0.035-0.054 in.). Select the proper reverse

clutch snap ring to achieve specifications:

REVERSE CLUTCH SNAP RING THICKNESS

4377195 1.53-1.58 mm (0.060-0.062 in.)

4412871 1.77-1.83 mm (0.070-0.072 in.)

4412872 2.02-2.07 mm (0.080-0.082 in.)

4412873 2.27-2.32 mm (0.090-0.091 in.) (36) To complete the assembly, reverse clutch and

overdrive clutch must be removed. (37) Install the #2 needle bearing (Fig. 249).

(38) Install the underdrive shaft assembly (Fig.

250).

Fig. 248 Press Down on Reverse Clutch and Zero Indicator

1 - DIAL INDICATOR

2 - REVERSE CLUTCH

Fig. 249 Install No. 2 Needle Bearing

1 - #2 NEEDLE BEARING (NOTE 3 SMALL TABS)

2 - TABS UP

Fig. 250 Install Underdrive Shaft Assembly

1 - UNDERDRIVE SHAFT ASSEMBLY

2 - #2 NEEDLE BEARING

21s - 128 40TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

Page 1990 of 2585

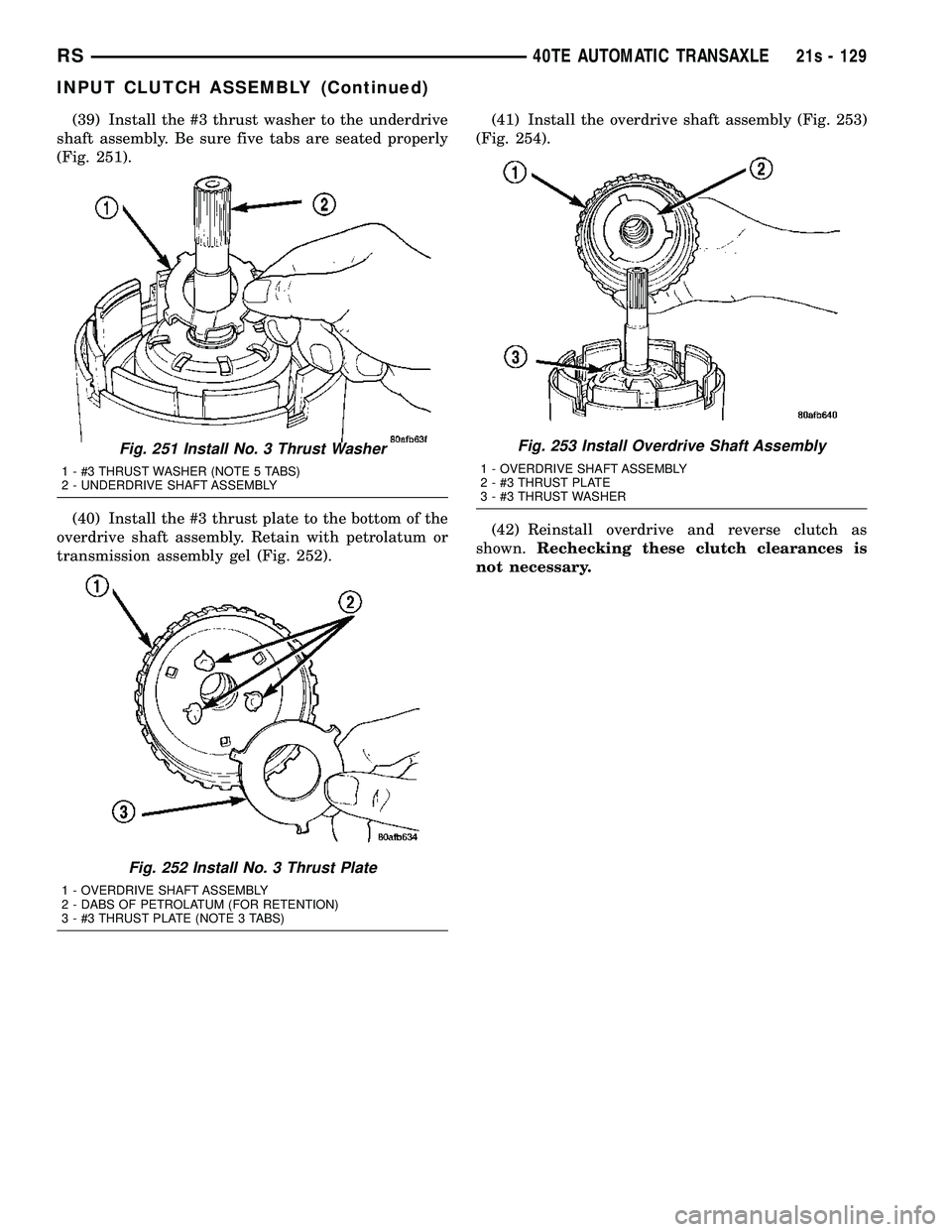

(39) Install the #3 thrust washer to the underdrive

shaft assembly. Be sure five tabs are seated properly

(Fig. 251).

(40) Install the #3 thrust plate to the bottom of the

overdrive shaft assembly. Retain with petrolatum or

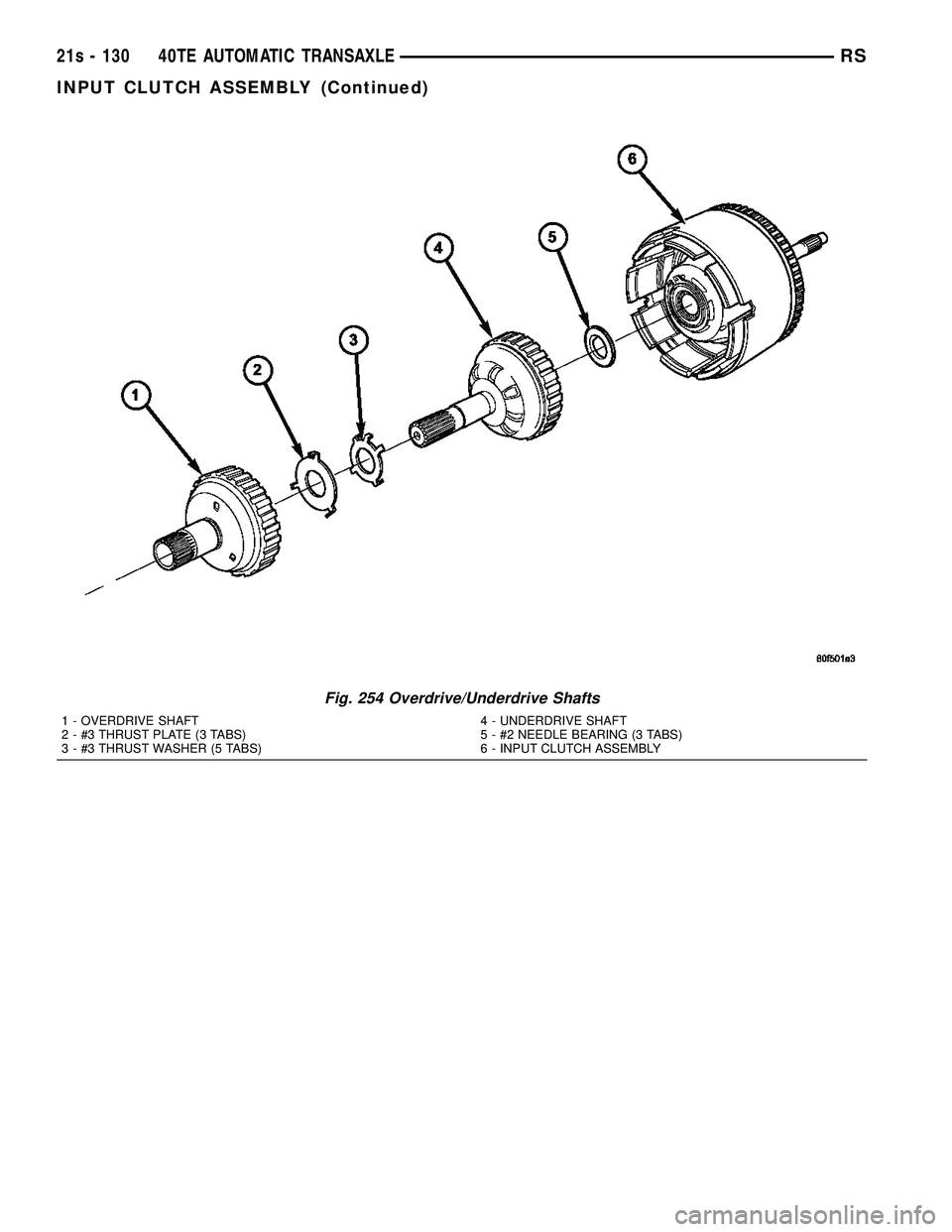

transmission assembly gel (Fig. 252). (41) Install the overdrive shaft assembly (Fig. 253)

(Fig. 254).

(42) Reinstall overdrive and reverse clutch as

shown. Rechecking these clutch clearances is

not necessary.

Fig. 251 Install No. 3 Thrust Washer

1 - #3 THRUST WASHER (NOTE 5 TABS)

2 - UNDERDRIVE SHAFT ASSEMBLY

Fig. 252 Install No. 3 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - DABS OF PETROLATUM (FOR RETENTION)

3 - #3 THRUST PLATE (NOTE 3 TABS)

Fig. 253 Install Overdrive Shaft Assembly

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #3 THRUST PLATE

3 - #3 THRUST WASHER

RS 40TE AUTOMATIC TRANSAXLE21s - 129

INPUT CLUTCH ASSEMBLY (Continued)

Page 1991 of 2585

Fig. 254 Overdrive/Underdrive Shafts

1 - OVERDRIVE SHAFT

2 - #3 THRUST PLATE (3 TABS)

3 - #3 THRUST WASHER (5 TABS)4 - UNDERDRIVE SHAFT

5 - #2 NEEDLE BEARING (3 TABS)

6 - INPUT CLUTCH ASSEMBLY

21s - 130 40TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

Page 2033 of 2585

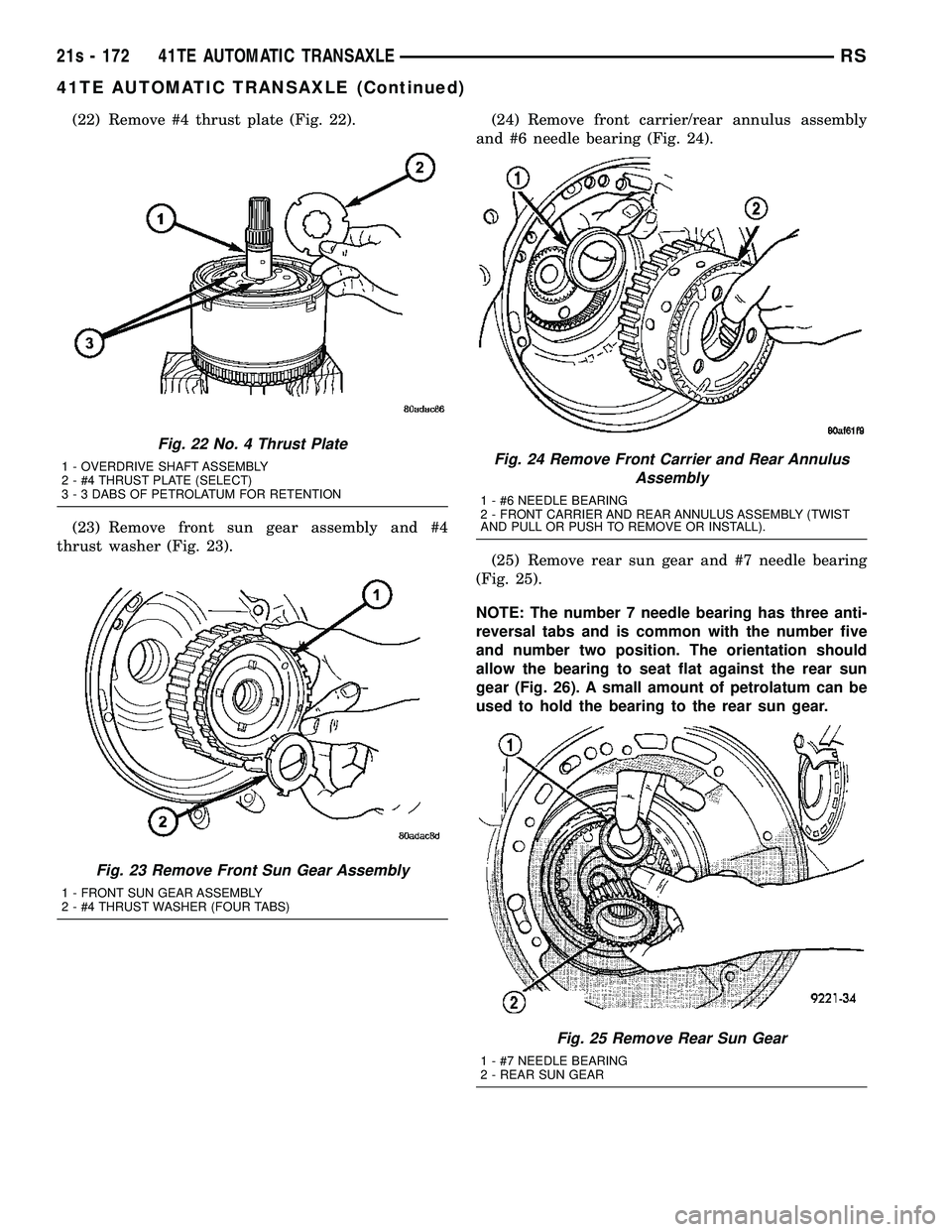

(22) Remove #4 thrust plate (Fig. 22).

(23) Remove front sun gear assembly and #4

thrust washer (Fig. 23). (24) Remove front carrier/rear annulus assembly

and #6 needle bearing (Fig. 24).

(25) Remove rear sun gear and #7 needle bearing

(Fig. 25).

NOTE: The number 7 needle bearing has three anti-

reversal tabs and is common with the number five

and number two position. The orientation should

allow the bearing to seat flat against the rear sun

gear (Fig. 26). A small amount of petrolatum can be

used to hold the bearing to the rear sun gear.

Fig. 22 No. 4 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #4 THRUST PLATE (SELECT)

3 - 3 DABS OF PETROLATUM FOR RETENTION

Fig. 23 Remove Front Sun Gear Assembly

1 - FRONT SUN GEAR ASSEMBLY

2 - #4 THRUST WASHER (FOUR TABS)

Fig. 24 Remove Front Carrier and Rear Annulus Assembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 25 Remove Rear Sun Gear

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

21s - 172 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2053 of 2585

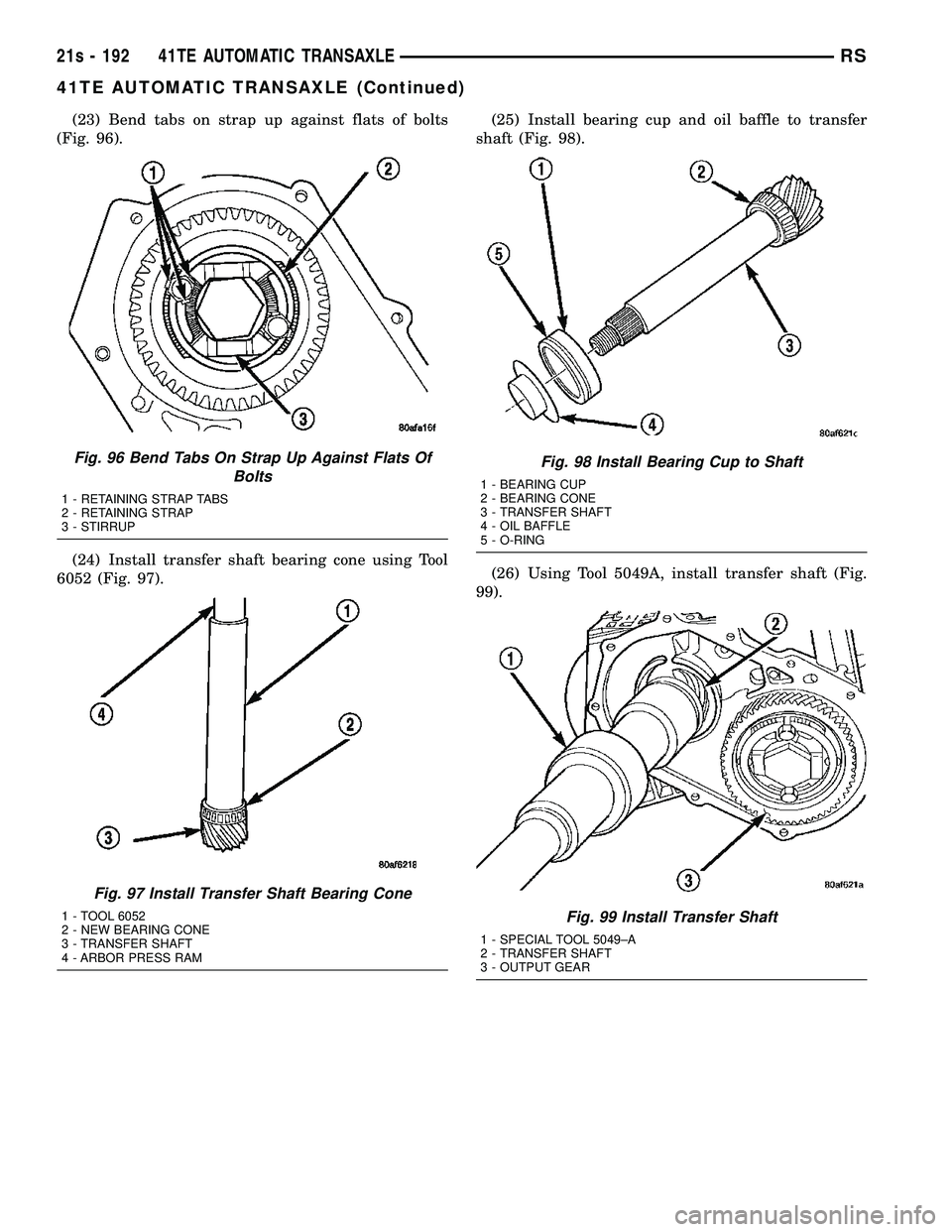

(23) Bend tabs on strap up against flats of bolts

(Fig. 96).

(24) Install transfer shaft bearing cone using Tool

6052 (Fig. 97). (25) Install bearing cup and oil baffle to transfer

shaft (Fig. 98).

(26) Using Tool 5049A, install transfer shaft (Fig.

99).

Fig. 96 Bend Tabs On Strap Up Against Flats Of Bolts

1 - RETAINING STRAP TABS

2 - RETAINING STRAP

3 - STIRRUP

Fig. 97 Install Transfer Shaft Bearing Cone

1 - TOOL 6052

2 - NEW BEARING CONE

3 - TRANSFER SHAFT

4 - ARBOR PRESS RAM

Fig. 98 Install Bearing Cup to Shaft

1 - BEARING CUP

2 - BEARING CONE

3 - TRANSFER SHAFT

4 - OIL BAFFLE

5 - O-RING

Fig. 99 Install Transfer Shaft

1 - SPECIAL TOOL 5049±A

2 - TRANSFER SHAFT

3 - OUTPUT GEAR

21s - 192 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2061 of 2585

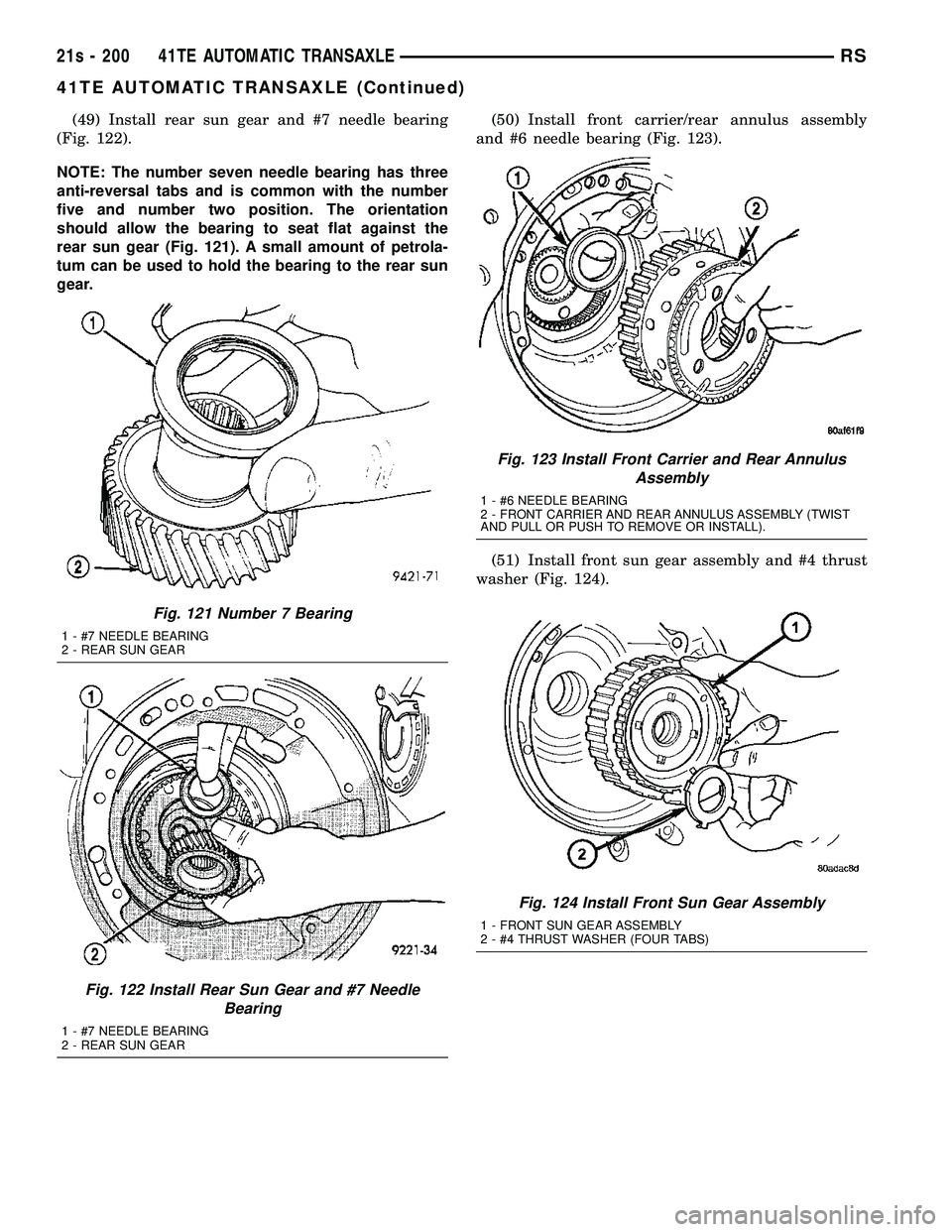

(49) Install rear sun gear and #7 needle bearing

(Fig. 122).

NOTE: The number seven needle bearing has three

anti-reversal tabs and is common with the number

five and number two position. The orientation

should allow the bearing to seat flat against the

rear sun gear (Fig. 121). A small amount of petrola-

tum can be used to hold the bearing to the rear sun

gear. (50) Install front carrier/rear annulus assembly

and #6 needle bearing (Fig. 123).

(51) Install front sun gear assembly and #4 thrust

washer (Fig. 124).

Fig. 121 Number 7 Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 122 Install Rear Sun Gear and #7 Needle Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 123 Install Front Carrier and Rear AnnulusAssembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 124 Install Front Sun Gear Assembly

1 - FRONT SUN GEAR ASSEMBLY

2 - #4 THRUST WASHER (FOUR TABS)

21s - 200 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2062 of 2585

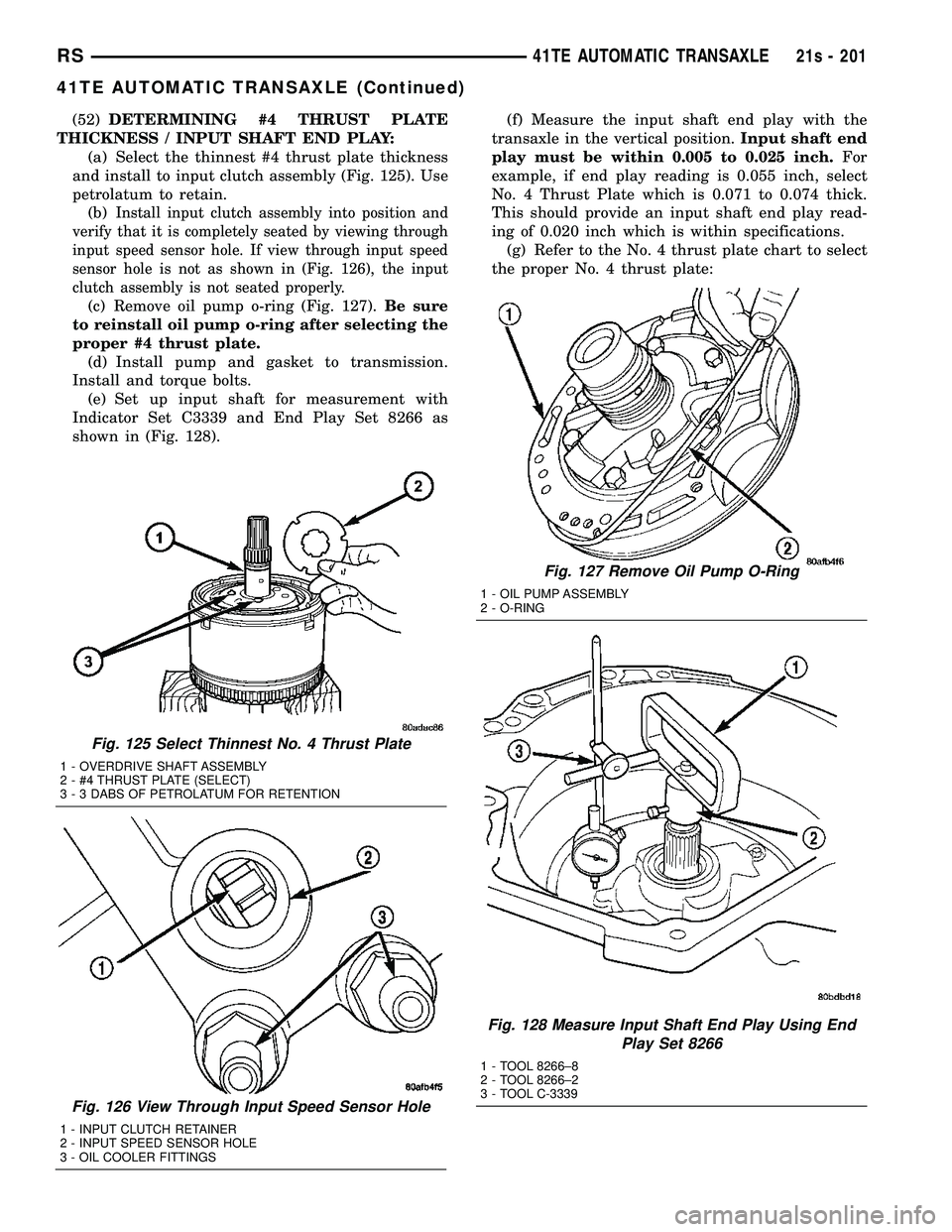

(52)DETERMINING #4 THRUST PLATE

THICKNESS / INPUT SHAFT END PLAY: (a) Select the thinnest #4 thrust plate thickness

and install to input clutch assembly (Fig. 125). Use

petrolatum to retain. (b)

Install input clutch assembly into position and

verify that it is completely seated by viewing through

input speed sensor hole. If view through input speed

sensor hole is not as shown in (Fig. 126), the input

clutch assembly is not seated properly.

(c) Remove oil pump o-ring (Fig. 127). Be sure

to reinstall oil pump o-ring after selecting the

proper #4 thrust plate. (d) Install pump and gasket to transmission.

Install and torque bolts. (e) Set up input shaft for measurement with

Indicator Set C3339 and End Play Set 8266 as

shown in (Fig. 128). (f) Measure the input shaft end play with the

transaxle in the vertical position. Input shaft end

play must be within 0.005 to 0.025 inch. For

example, if end play reading is 0.055 inch, select

No. 4 Thrust Plate which is 0.071 to 0.074 thick.

This should provide an input shaft end play read-

ing of 0.020 inch which is within specifications. (g) Refer to the No. 4 thrust plate chart to select

the proper No. 4 thrust plate:

Fig. 125 Select Thinnest No. 4 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #4 THRUST PLATE (SELECT)

3 - 3 DABS OF PETROLATUM FOR RETENTION

Fig. 126 View Through Input Speed Sensor Hole

1 - INPUT CLUTCH RETAINER

2 - INPUT SPEED SENSOR HOLE

3 - OIL COOLER FITTINGS

Fig. 127 Remove Oil Pump O-Ring

1 - OIL PUMP ASSEMBLY

2 - O-RING

Fig. 128 Measure Input Shaft End Play Using End Play Set 8266

1 - TOOL 8266±8

2 - TOOL 8266±2

3 - TOOL C-3339

RS 41TE AUTOMATIC TRANSAXLE21s - 201

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2087 of 2585

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

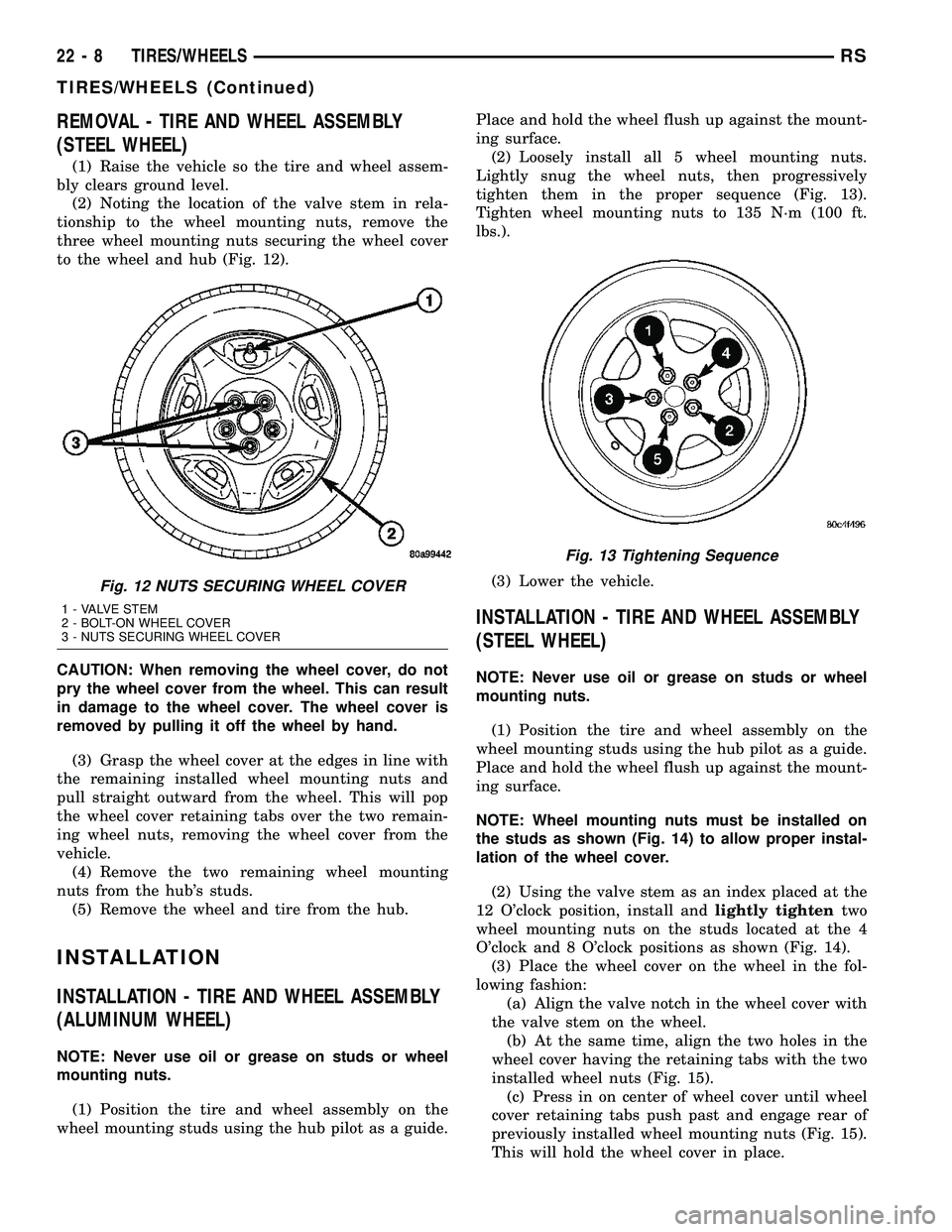

(2) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 12).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(3) Grasp the wheel cover at the edges in line with

the remaining installed wheel mounting nuts and

pull straight outward from the wheel. This will pop

the wheel cover retaining tabs over the two remain-

ing wheel nuts, removing the wheel cover from the

vehicle.

(4) Remove the two remaining wheel mounting

nuts from the hub's studs.

(5) Remove the wheel and tire from the hub.

INSTALLATION

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.Place and hold the wheel flush up against the mount-

ing surface.

(2) Loosely install all 5 wheel mounting nuts.

Lightly snug the wheel nuts, then progressively

tighten them in the proper sequence (Fig. 13).

Tighten wheel mounting nuts to 135 N´m (100 ft.

lbs.).

(3) Lower the vehicle.

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

NOTE: Wheel mounting nuts must be installed on

the studs as shown (Fig. 14) to allow proper instal-

lation of the wheel cover.

(2) Using the valve stem as an index placed at the

12 O'clock position, install andlightly tightentwo

wheel mounting nuts on the studs located at the 4

O'clock and 8 O'clock positions as shown (Fig. 14).

(3) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 15).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 15).

This will hold the wheel cover in place.

Fig. 12 NUTS SECURING WHEEL COVER

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 13 Tightening Sequence

22 - 8 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

Page 2088 of 2585

(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

TIRE PRESSURE MONITORING

DESCRIPTION

Some versions of this vehicle are equipped with a

Tire Pressure Monitoring (TPM) system. It monitors

air pressure in the four road tires (excludes spare).

Pressure in the spare tire is not monitored.

There is a sensor (transmitter) in each of the vehi-

cle's four road wheels. The system alerts the driver

when tire pressure falls outside predetermined

thresholds (pressure too low or too high). A message

is then displayed on the Electronic Vehicle Informa-

tion Center (EVIC) located in the overhead console.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit tire pressure read-

ings to a receiver located in the overhead console.

These transmissions occur once every minute at

speeds over 20 mph (32 km/h). The Tire Pressure

Monitoring system remains active even if no tire

pressure related message is displayed in the EVIC.

If any road tire pressure has exceeded the low or

high pressure threshold (refer to chart below), the

TPM system will display a message in the EVIC and

sound a chime. This message will be displayed for

the rest of the ignition cycle, or until either the Low/

High Tire pressure condition has been corrected. If

the C/T, MENU, STEP or RESET button is pressed,

the message is replaced by the new message

requested; however, if the Low/High Tire condition

has not been corrected, the Low/High Tire pressure

message will again be displayed.

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)