brake CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 275 of 2585

Use only brake fluid that was stored in a tightly-

sealed container. DO NOT use petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only Mopar tBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped with

ABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is located

on the driver's side of the front suspension cradle/

crossmember below the master cylinder (Fig. 44).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block. (2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following: (a) Disconnect the battery positive cable.

(b) Remove the battery (Refer t o 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL). (c) Disconnect the vacuum hose connector at the

tank built into the battery tray. (d) Remove the screw securing the coolant filler

neck to the battery tray. (e) Remove the battery tray (Refer t o 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL). (f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system. (4) Remove the four chassis brake tubes from the

top of the junction block (Fig. 44). (5) Remove the primary and secondary brake

tubes from the top of the junction block. (6) Remove the bolts attaching the junction block

mounting bracket to the front suspension crossmem-

ber (Fig. 44), then remove the junction block.

INSTALLATION - NON-ABS JUNCTION BLOCK

(1) Install the junction block and mounting bracket

on the front suspension crossmember (Fig. 44).

Install the mounting bolts and tighten to a torque of

28 N´m (250 in. lbs.). (2) Install the primary and secondary brake tubes

from the master cylinder in their ports. Tighten tube

nuts to a torque of 17 N´m (145 in. lbs.). Take care

not to twist tubes when tightening tube nuts.

They must be properly positioned to allow free

movement with rubber isolated suspension

crossmember.

5s - 32 BRAKESRS

FLUID (Continued)

Page 276 of 2585

(3) Install the four chassis brake tubes into the

outlet ports of the junction block. Tighten all 6 tube

nuts to a torque of 17 N´m (145 in. lbs.). (4) If the vehicle is equipped with speed control,

perform the following: (a) Install the speed control servo with its

mounting nuts. (b) Connect the wiring harness to the speed con-

trol servo. (c) Install the battery tray (Refer t o 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION). (d) Install the screw securing the coolant filler

neck to the battery tray. (e) Reconnect the vacuum hose connector at the

tank built into the battery tray. (f) Install the battery (Refer t o 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION). (g) Install the battery shield.

(5) Remove the brake pedal holder.

(6) Connect negative cable back on negative post of

the battery. (7) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-

tem. (Refer t o 5 - BRAKES - STANDARD PROCE-

DURE). (8) Road test the vehicle to verify proper operation

of the brake system.

MASTER CYLINDER

DESCRIPTION

DESCRIPTION

The master cylinder is located on the power brake

booster in the engine compartment on the driver's

side (Fig. 45). This vehicle uses 3 different master

cylinders. Master cylinder usage depends on what

type of brake system the vehicle is equipped with.

CAUTION: Master cylinders are not interchangeable

between systems. Performance and stopping dis-

tance issues will result if the incorrect master cyl-

inder is installed on the vehicle.

For information on master cylinder application,

bore and type, view the following table:

BRAKE SYSTEM MASTER CYLINDER

BORE/TYPE

Disc/Drum - ABS 23.8 mm (15/16 in.)

Conventional

Compensating Port

Disc/Drum - Non-ABS 23.8 mm (15/16 in.)

Conventional

Compensating Port

Disc/Disc - ABS 25.4 mm (1.0 in.)

Conventional

Compensating Port

Disc/Disc ABS With

Traction Control 25.4 mm (1.0 in.) Dual

Center Port

Fig. 44 NON-ABS JUNCTION BLOCK

1 - MASTER CYLINDER

2 - JUNCTION BLOCK

3 - SUSPENSION CROSSMEMBER

4 - MOUNTING BOLTS

Fig. 45 Master Cylinder And Booster Location

1 - MASTER CYLINDER

2 - POWER BRAKE BOOSTER

RS BRAKES5s-33

JUNCTION BLOCK (Continued)

Page 277 of 2585

CAUTION: When replacing a master cylinder, be

sure to use the correct master cylinder for the type

of brake system the vehicle is equipped with.The body of the master cylinder is an anodized alu-

minum casting. It has a machined bore to accept the

master cylinder pistons and threaded ports with

seats for the hydraulic brake line connections. The brake fluid reservoir is mounted on the top of

the master cylinder. It is made of a see-through

polypropylene type plastic for easy fluid level view-

ing. A brake fluid level switch is attached to the

brake fluid reservoir. The master cylinder is not a repairable component

and must be replaced if diagnosed to be functioning

improperly. The brake fluid reservoir and brake fluid

level switch can be replaced separately.

CAUTION: Do not hone the bore of the cylinder as

this will remove the anodized surface from the bore.

DESCRIPTION - RHD

The master cylinder used on right hand drive

(RHD) vehicles functions similarly to that used on

left hand drive (LHD) vehicles. The RHD master cyl-

inder, as well as the RHD power brake booster, is

located in the same area, but lower in the engine

compartment than LHD models (Fig. 46). For that

reason an extension manifold is placed between the

fluid reservoir and master cylinder housing allowing

the fluid reservoir to be positioned in the same loca-

tion as on LHD models.

OPERATION

When the brake pedal is depressed, the master cyl-

inder primary and secondary pistons apply brake

pressure through the chassis tubes to the brakes at

each tire and wheel assembly. The master cylinder primary outlet port supplies

hydraulic pressure to the right front and left rear

brakes. The secondary outlet port supplies hydraulic

pressure to the left front and right rear brakes.

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING

CAUTION: When clamping master cylinder in vise,

only clamp master cylinder by its mounting flange.

Do not clamp master cylinder piston rod, reservoir,

seal or body.

(1) Clamp master cylinder in a vise.

NOTE: Use correct bleeder tubes when bleeding

master cylinder. Master cylinder outlet ports vary in

size and type depending on whether master cylin-

der is for a vehicle equipped with traction control or

not. Traction control equipped master cylinders

require the additional use of ISO style flare adapt-

ers supplied in Special Tool Package 8822 to be

used in conjunction with Bleeder Tubes, Special

Tool Package 8358. (2) Attach special tools for bleeding master cylin-

der in the following fashion: (a)For non-traction control equipped mas-

ter cylinders , thread a Bleeder Tube, Special Tool

8358±1, into each outlet port. Tighten each tube to

17 N´m (145 in. lbs.) torque. Flex bleeder tubes and

place open ends into mouth of fluid reservoir as far

down as possible (Fig. 47). (b) For traction control equipped master

cylinders , thread one Adapter, Special Tool

8822±2, in each outlet port. Tighten Adapters to 17

N´m (145 in. lbs.) torque. Next, thread a Bleeder

Tube, Special Tool 8358±1, into each Adapter.

Tighten each tube to 17 N´m (145 in. lbs.) torque.

Flex bleeder tubes and place open ends into mouth

of fluid reservoir as far down as possible (Fig. 47).

NOTE: Make sure open ends of bleeder tubes stay

below surface of brake fluid once reservoir is filled

to proper level. (3) Fill brake fluid reservoir with Mopar tbrake

fluid or equivalent conforming to DOT 3 (DOT 4 and

DOT 4+ are acceptable) specifications. Make sure

fluid level is above tips of bleeder tubes in reservoir

to ensure no air is ingested during bleeding.

Fig. 46 RHD MASTER CYLINDER AND POWER BRAKE BOOSTER

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

5s - 34 BRAKESRS

MASTER CYLINDER (Continued)

Page 278 of 2585

(4) Using a wooden dowel as a pushrod (Fig. 47),

slowly depress master cylinder pistons, then release

pressure, allowing pistons to return to released posi-

tion. Repeat several times until all air bubbles are

expelled. Make sure fluid level stays above tips of

bleeder tubes in reservoir while bleeding. (5) Remove bleeder tubes from master cylinder

outlet ports, then plug outlet ports and install fill cap

on reservoir. (6) Remove master cylinder from vise.

(7) Install master cylinder on vehicle. (Refer to 5 -

BRAKES - BASE/HYDRAULIC/MECHANICAL/MAS-

TER CYLINDER - INSTALLATION)

REMOVAL

REMOVAL - LHD

CAUTION: Vacuum in the power brake booster must

be pumped down (removed) before removing mas-

ter cylinder from power brake booster. This is nec-

essary to prevent the power brake booster from

sucking in any contamination as the master cylin-

der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump brake pedal

until a firm pedal is achieved (4-5 strokes). (2) Disconnect negative battery terminal. (3) Disconnect positive battery terminal.

(4) Remove battery shield.

(5) Remove nut and clamp securing battery to tray,

remove battery. (6) Thoroughly clean all surfaces of the brake fluid

reservoir and master cylinder. Use only solvent such

as Mopar tBrake Parts Cleaner or equivalent.

(7) Remove wiring harness connector from brake

fluid level switch in master cylinder brake fluid res-

ervoir (Fig. 48).

(8) Disconnect primary and secondary brake tubes

from master cylinder housing (Fig. 48). Install seal-

ing plugs in the now open brake tube outlet ports.

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(9) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as Mopar tBrake Parts Cleaner or equivalent.

(10) Remove two nuts attaching master cylinder to

power brake booster (Fig. 49). (11) Slide master cylinder straight out of power

brake booster.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

Fig. 47 Master Cylinder Set Up For Bleeding

1 - BLEEDER TUBES 8358

2 - WOODEN DOWEL

3 - ADAPTER 8822-2 (USE ONLY ON TRACTION CONTROL

EQUIPPED MASTER CYLINDERS)

4 - ADAPTER 8822-2 (USE ONLY ON TRACTION CONTROL

EQUIPPED MASTER CYLINDERS)

Fig. 48 MASTER CYLINDER AND BOOSTER

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

RS BRAKES5s-35

MASTER CYLINDER (Continued)

Page 279 of 2585

(12) Remove vacuum seal located on the mounting

flange of the master cylinder. The vacuum seal is

removed from master cylinder by carefullypulling it

off the rear of master cylinder. Do not attempt to

pry the seal off the master cylinder by inserting

a sharp tool between seal and master cylinder

casting.

REMOVAL - RHD

CAUTION: Vacuum in the power brake booster must

be pumped down (removed) before removing mas-

ter cylinder from power brake booster. This is nec-

essary to prevent the power brake booster from

sucking in any contamination as the master cylin-

der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump brake pedal

until a firm pedal is achieved (4 or 5 strokes). (2) Disconnect negative battery terminal.

(3) Disconnect positive battery terminal.

(4) Remove battery shield.

(5) Remove nut and clamp securing battery to tray,

remove battery. (6) Thoroughly clean all surfaces of the brake fluid

reservoir and master cylinder. Use only solvent such

as Mopar tBrake Parts Cleaner or equivalent.

(7) Remove wiring harness connector from brake

fluid level switch in master cylinder brake fluid res-

ervoir (Fig. 46). (8) Disconnect primary and secondary brake tubes

from master cylinder housing (Fig. 50). Install seal-

ing plugs in the now open brake tube outlet ports. CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(9) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as Mopar tBrake Parts Cleaner or equivalent.

(10) Remove two nuts attaching master cylinder to

power brake booster (Fig. 50). (11) Slide master cylinder straight out of power

brake booster.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

(12) Remove vacuum seal located on the mounting

flange of the master cylinder. The vacuum seal is

removed from master cylinder by carefullypulling it

off the rear of master cylinder. Do not attempt to

pry the seal off the master cylinder by inserting

a sharp tool between seal and master cylinder

casting.

DISASSEMBLY - MASTER CYLINDER (FLUID

RESERVOIR)

(1) Clean master cylinder housing and brake fluid

reservoir. Use only a solvent such as Mopar Brake

Parts Cleaner or an equivalent.

Fig. 49 MASTER CYLINDER MOUNTING

1 - MASTER CYLINDER MOUNTING NUTS

2 - MASTER CYLINDER

3 - SECONDARY TUBE NUT AT ICU

4 - PRIMARY TUBE NUT AT ICU

Fig. 50 RHD MASTER CYLINDER MOUNTING

1 - PRIMARY BRAKE TUBE NUT

2 - SECONDARY BRAKE TUBE NUT

3 - MASTER CYLINDER MOUNTING NUTS

5s - 36 BRAKESRS

MASTER CYLINDER (Continued)

Page 280 of 2585

(2) Remove brake fluid reservoir cap. Using a

syringe or equivalent type tool empty as much brake

fluid as possible from the reservoir.

CAUTION: When removing fluid reservoir from the

master cylinder, do not pry off using any type of

tool. This can damage the fluid reservoir or master

cylinder housing.

(3) Remove the master cylinder assembly from the

power brake vacuum booster. (Refer t o 5 - BRAKES -

BASE/HYDRAULIC/MECHANICAL/MASTER CYL-

INDER - REMOVAL). (4) Mount the master cylinder in a vise using the

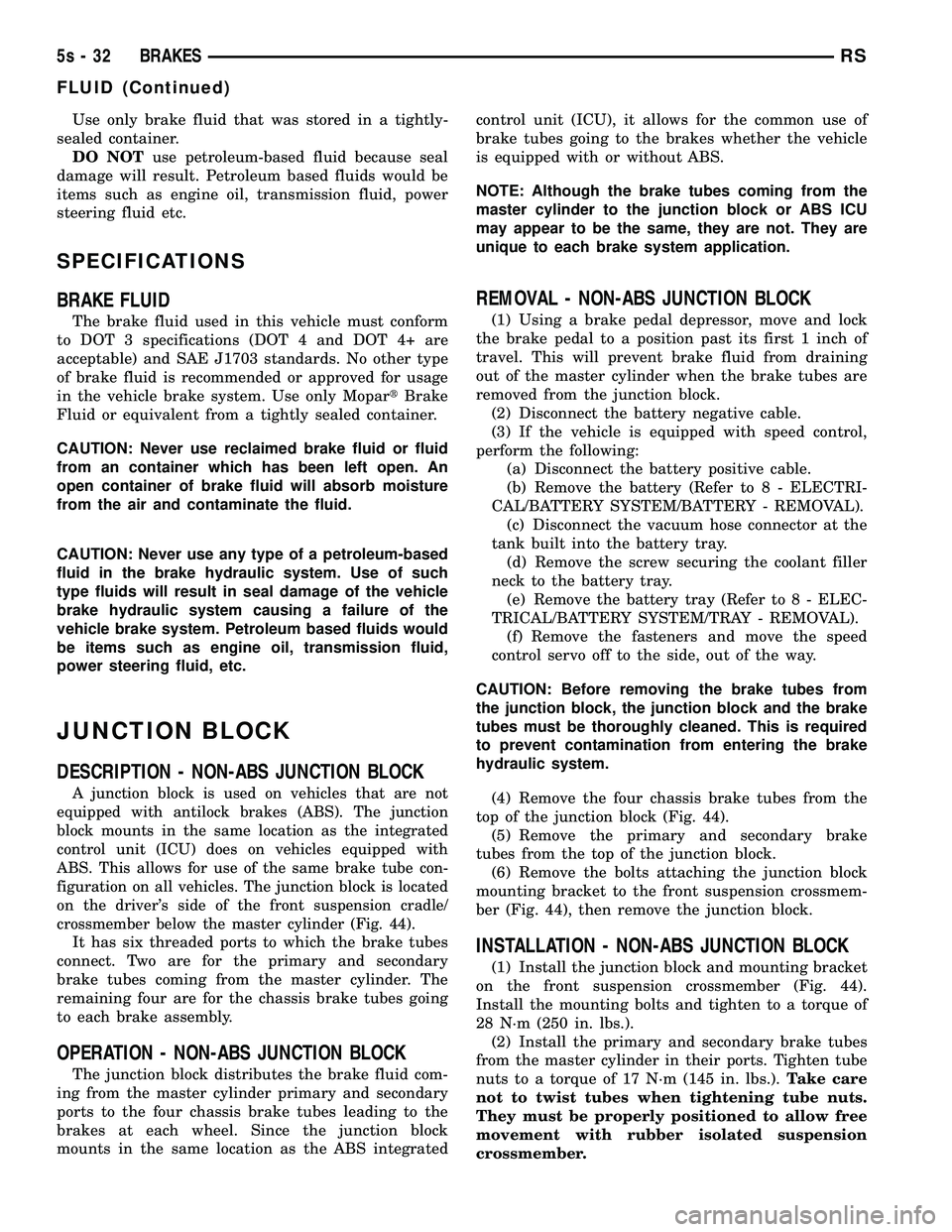

master cylinder mounting flange. (5) Using correct size pin punch, remove the two

retaining pins between the fluid reservoir and master

cylinder housing (Fig. 51).

(6) Rock the brake fluid reservoir from side to side

while pulling up to remove it from the seal grommets

in master cylinder housing. (7) Remove the two master cylinder housing to

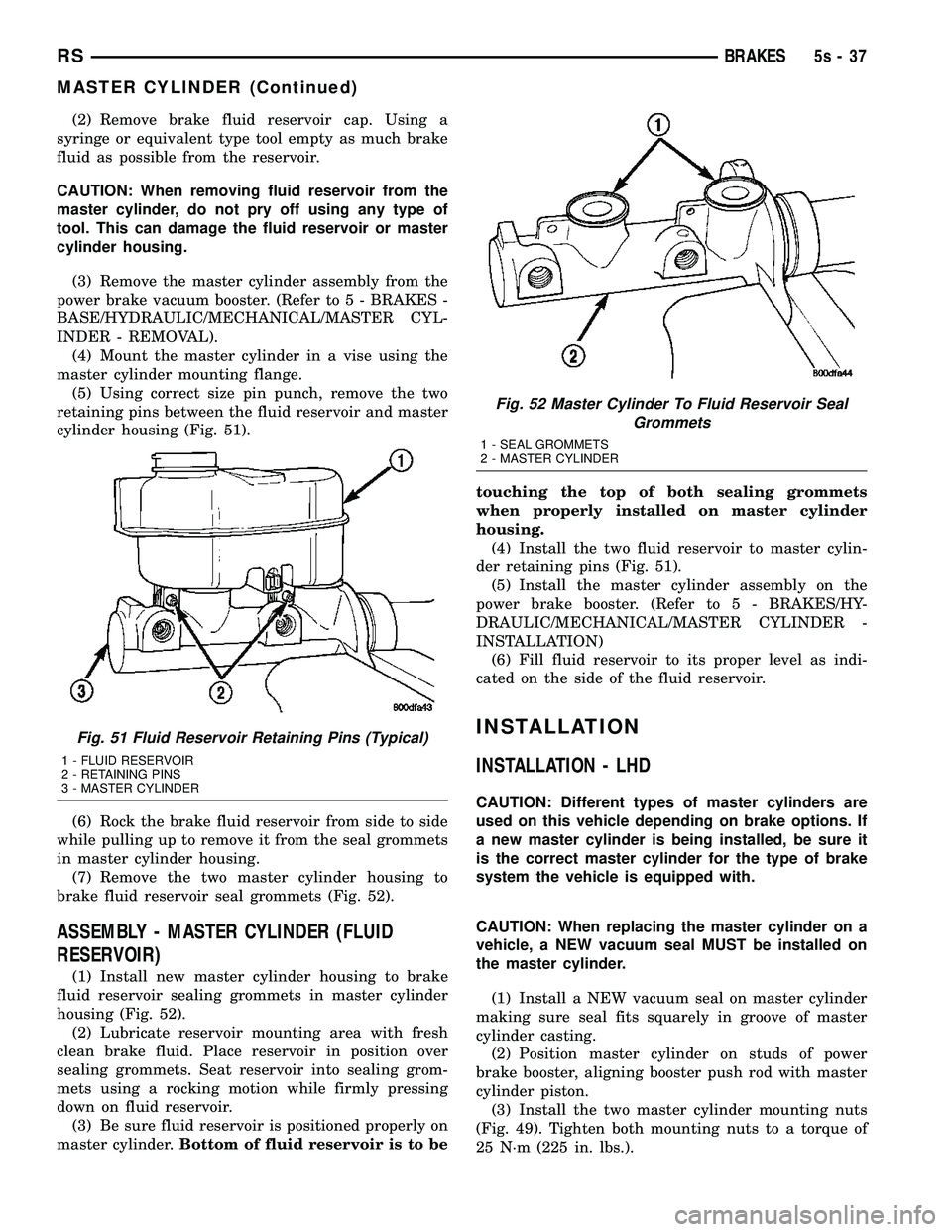

brake fluid reservoir seal grommets (Fig. 52).

ASSEMBLY - MASTER CYLINDER (FLUID

RESERVOIR)

(1) Install new master cylinder housing to brake

fluid reservoir sealing grommets in master cylinder

housing (Fig. 52). (2) Lubricate reservoir mounting area with fresh

clean brake fluid. Place reservoir in position over

sealing grommets. Seat reservoir into sealing grom-

mets using a rocking motion while firmly pressing

down on fluid reservoir. (3) Be sure fluid reservoir is positioned properly on

master cylinder. Bottom of fluid reservoir is to be touching the top of both sealing grommets

when properly installed on master cylinder

housing.

(4) Install the two fluid reservoir to master cylin-

der retaining pins (Fig. 51). (5) Install the master cylinder assembly on the

power brake booster. (Refer t o 5 - BRAKES/HY-

DRAULIC/MECHANICAL/MASTER CYLINDER -

INSTALLATION) (6) Fill fluid reservoir to its proper level as indi-

cated on the side of the fluid reservoir.

INSTALLATION

INSTALLATION - LHD

CAUTION: Different types of master cylinders are

used on this vehicle depending on brake options. If

a new master cylinder is being installed, be sure it

is the correct master cylinder for the type of brake

system the vehicle is equipped with.

CAUTION: When replacing the master cylinder on a

vehicle, a NEW vacuum seal MUST be installed on

the master cylinder.

(1) Install a NEW vacuum seal on master cylinder

making sure seal fits squarely in groove of master

cylinder casting. (2) Position master cylinder on studs of power

brake booster, aligning booster push rod with master

cylinder piston. (3) Install the two master cylinder mounting nuts

(Fig. 49). Tighten both mounting nuts to a torque of

25 N´m (225 in. lbs.).

Fig. 51 Fluid Reservoir Retaining Pins (Typical)

1 - FLUID RESERVOIR

2 - RETAINING PINS

3 - MASTER CYLINDER

Fig. 52 Master Cylinder To Fluid Reservoir Seal Grommets

1 - SEAL GROMMETS

2 - MASTER CYLINDER

RS BRAKES5s-37

MASTER CYLINDER (Continued)

Page 281 of 2585

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion.(4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

48). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.). (5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

48). (6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopar t

Brake Fluid or equivalent. (11) Road test vehicle to ensure proper operation of

brakes.

INSTALLATION - RHD

CAUTION: Different types of master cylinders are

used on this vehicle depending on brake options. If

a new master cylinder is being installed, be sure it

is the correct master cylinder for the type of brake

system the vehicle is equipped with.

CAUTION: When replacing the master cylinder on a

vehicle, a NEW vacuum seal MUST be installed on

the master cylinder.

(1) Install a NEW vacuum seal on master cylinder

making sure seal fits squarely in groove of master

cylinder casting. (2) Position master cylinder on studs of power

brake booster, aligning booster push rod with master

cylinder piston. (3) Install the two master cylinder mounting nuts

(Fig. 50). Tighten both mounting nuts to a torque of

25 N´m (225 in. lbs.).

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion. (4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

50). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.). (5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

46). (6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopar t

Brake Fluid or equivalent. (11) Road test vehicle to ensure proper operation of

brakes.

PEDALS - ADJUSTABLE

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Move driver's seat to full rearward position.

(2) Disconnect negative battery cable from battery

post and isolate. (3) Remove throttle cable from throttle body lever.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

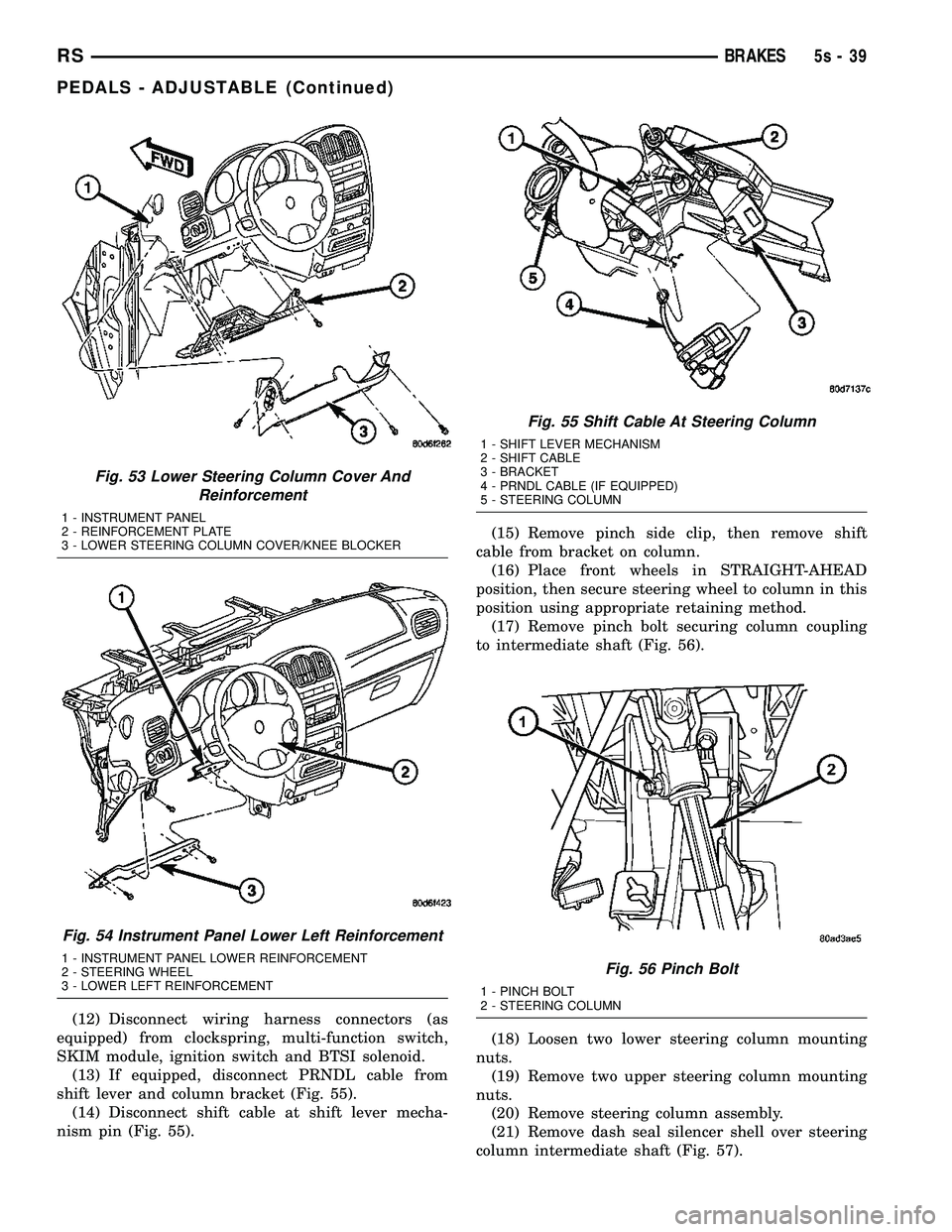

THROTTLE CONTROL CABLE - REMOVAL) (4) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 53). (5) Disconnect parking brake release link at

release handle. (6) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate. (7) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 53). (8) Remove hood release from lower left reinforce-

ment. (9) Remove screws securing instrument panel

lower left reinforcement in place, then remove rein-

forcement (Fig. 54). (10) Remove brake lamp switch. Discard original

switch; it must not be reused. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL) (11) Remove upper and lower steering column

shrouds. (Refer to 19 - STEERING/COLUMN/

LOWER SHROUD - REMOVAL)

5s - 38 BRAKESRS

MASTER CYLINDER (Continued)

Page 282 of 2585

(12) Disconnect wiring harness connectors (as

equipped) from clockspring, multi-function switch,

SKIM module, ignition switch and BTSI solenoid. (13) If equipped, disconnect PRNDL cable from

shift lever and column bracket (Fig. 55). (14) Disconnect shift cable at shift lever mecha-

nism pin (Fig. 55). (15) Remove pinch side clip, then remove shift

cable from bracket on column. (16) Place front wheels in STRAIGHT-AHEAD

position, then secure steering wheel to column in this

position using appropriate retaining method. (17) Remove pinch bolt securing column coupling

to intermediate shaft (Fig. 56).

(18) Loosen two lower steering column mounting

nuts. (19) Remove two upper steering column mounting

nuts. (20) Remove steering column assembly.

(21) Remove dash seal silencer shell over steering

column intermediate shaft (Fig. 57).

Fig. 53 Lower Steering Column Cover And Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

Fig. 54 Instrument Panel Lower Left Reinforcement

1 - INSTRUMENT PANEL LOWER REINFORCEMENT

2 - STEERING WHEEL

3 - LOWER LEFT REINFORCEMENT

Fig. 55 Shift Cable At Steering Column

1 - SHIFT LEVER MECHANISM

2 - SHIFT CABLE

3 - BRACKET

4 - PRNDL CABLE (IF EQUIPPED)

5 - STEERING COLUMN

Fig. 56 Pinch Bolt

1 - PINCH BOLT

2 - STEERING COLUMN

RS BRAKES5s-39

PEDALS - ADJUSTABLE (Continued)

Page 283 of 2585

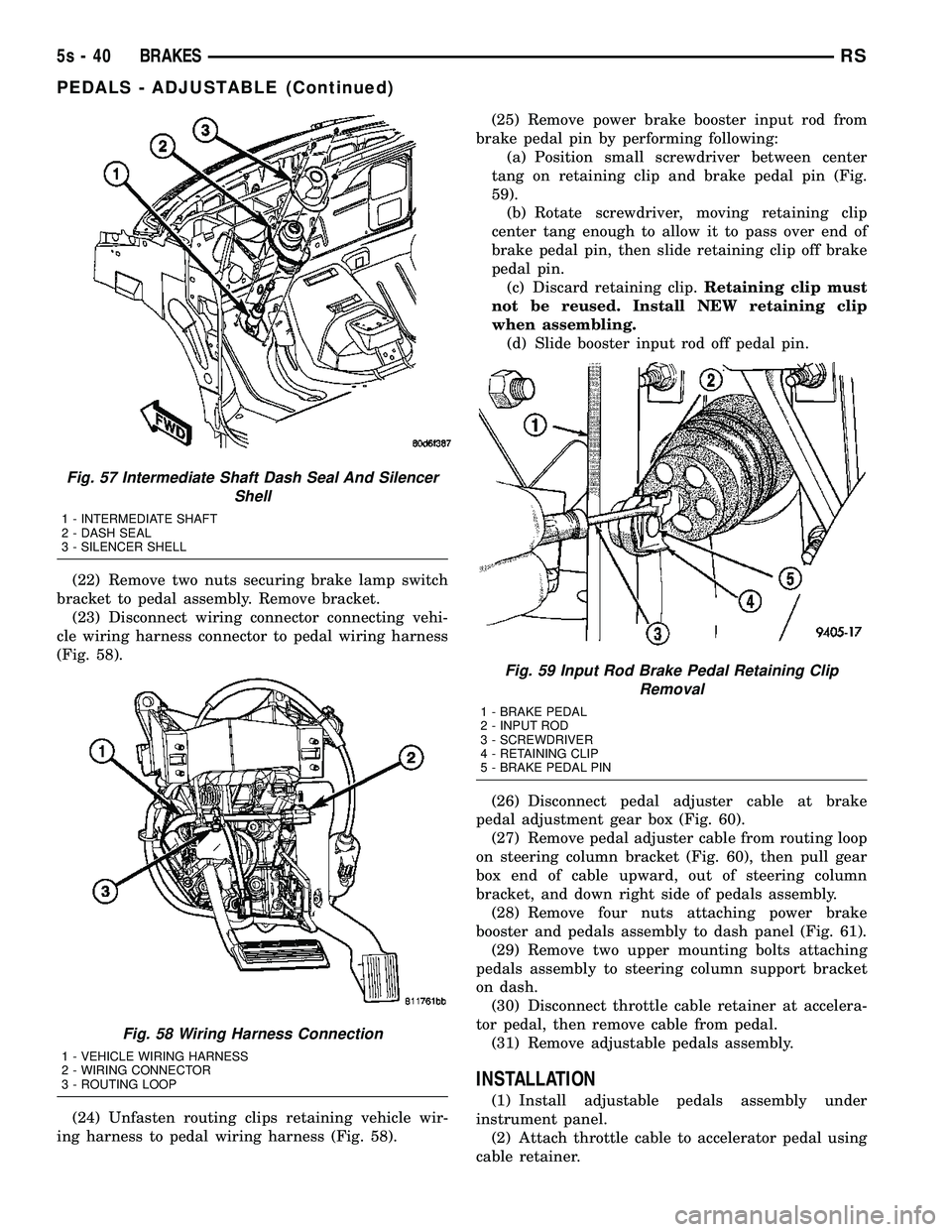

(22) Remove two nuts securing brake lamp switch

bracket to pedal assembly. Remove bracket. (23) Disconnect wiring connector connecting vehi-

cle wiring harness connector to pedal wiring harness

(Fig. 58).

(24) Unfasten routing clips retaining vehicle wir-

ing harness to pedal wiring harness (Fig. 58). (25) Remove power brake booster input rod from

brake pedal pin by performing following: (a) Position small screwdriver between center

tang on retaining clip and brake pedal pin (Fig.

59). (b) Rotate screwdriver, moving retaining clip

center tang enough to allow it to pass over end of

brake pedal pin, then slide retaining clip off brake

pedal pin. (c) Discard retaining clip. Retaining clip must

not be reused. Install NEW retaining clip

when assembling. (d) Slide booster input rod off pedal pin.

(26) Disconnect pedal adjuster cable at brake

pedal adjustment gear box (Fig. 60). (27) Remove pedal adjuster cable from routing loop

on steering column bracket (Fig. 60), then pull gear

box end of cable upward, out of steering column

bracket, and down right side of pedals assembly. (28) Remove four nuts attaching power brake

booster and pedals assembly to dash panel (Fig. 61). (29) Remove two upper mounting bolts attaching

pedals assembly to steering column support bracket

on dash. (30) Disconnect throttle cable retainer at accelera-

tor pedal, then remove cable from pedal. (31) Remove adjustable pedals assembly.

INSTALLATION

(1) Install adjustable pedals assembly under

instrument panel. (2) Attach throttle cable to accelerator pedal using

cable retainer.

Fig. 57 Intermediate Shaft Dash Seal And Silencer Shell

1 - INTERMEDIATE SHAFT

2 - DASH SEAL

3 - SILENCER SHELL

Fig. 58 Wiring Harness Connection

1 - VEHICLE WIRING HARNESS

2 - WIRING CONNECTOR

3 - ROUTING LOOP

Fig. 59 Input Rod Brake Pedal Retaining ClipRemoval

1 - BRAKE PEDAL

2 - INPUT ROD

3 - SCREWDRIVER

4 - RETAINING CLIP

5 - BRAKE PEDAL PIN

5s - 40 BRAKESRS

PEDALS - ADJUSTABLE (Continued)

Page 284 of 2585

(3) Install two upper mounting bolts attaching

pedals assembly to steering column support bracket

on dash panel. Do not fully tighten at this time.

(4) Install four nuts attaching pedals assembly and

power brake booster to dash panel (Fig. 61). (5) Tighten four booster mounting nuts and two

upper mounting bolts to 28 N´m (21 ft. lbs.) torque. (6) Route pedal adjuster cable up and over right

side of pedals assembly and steering column bracket, then down through hole in steering column bracket

as shown (Fig. 60). Attach end of cable to gear box.

(7) Place adjuster cable through loop on right side

of steering column bracket as shown (Fig. 60). (8) Install booster input rod onto brake pedal pin

and install a NEW retaining clip. (9) Connect wiring connector connecting vehicle

wiring harness to pedal wiring harness (Fig. 58). (10) Connect routing clips retaining vehicle wiring

harness to pedal wiring harness (Fig. 58). (11) Install brake lamp switch bracket on pedals

assembly. Tighten mounting nuts to 6 N´m (50 in.

lbs.) torque. (12) Install dash seal silencer shell over steering

column intermediate shaft and fasten in place (Fig.

57). (13) Install steering column onto lower mounting

studs with nuts started, then install column onto

upper mounting studs and install two upper mount-

ing nuts. Tighten upper, then lower mounting nuts to

12 N´m (105 in. lbs.) torque. (14) Install column shaft coupling onto intermedi-

ate shaft and install pinch bolt. Make sure rounded

side of intermediate shaft is matched to the curva-

ture of the coupling. Tighten pinch bolt to 28 N´m

(250 in. lbs.) torque. (15) Remove retainer holding steering wheel in

place on steering column. (16) Attach shift cable to bracket on column.

(17) Connect shift cable end to shift lever mecha-

nism pin (Fig. 55). (18) If equipped, connect PRNDL cable to end of

shift lever mechanism pin and column bracket (Fig.

55). (19) Connect column wiring harness connectors (as

equipped) to SKIM, BTSI solenoid, ignition switch,

multi-function switch, and clockspring. (20) Install lower and upper steering column

shrouds. (Refer to 19 - STEERING/COLUMN/

LOWER SHROUD - INSTALLATION)

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(21) Install and adjust NEW brake lamp switch.

(Refer t o 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - INSTALLA-

TION) (22) Install instrument panel lower left reinforce-

ment (Fig. 54). (23) Attach hood release to lower left reinforce-

ment.

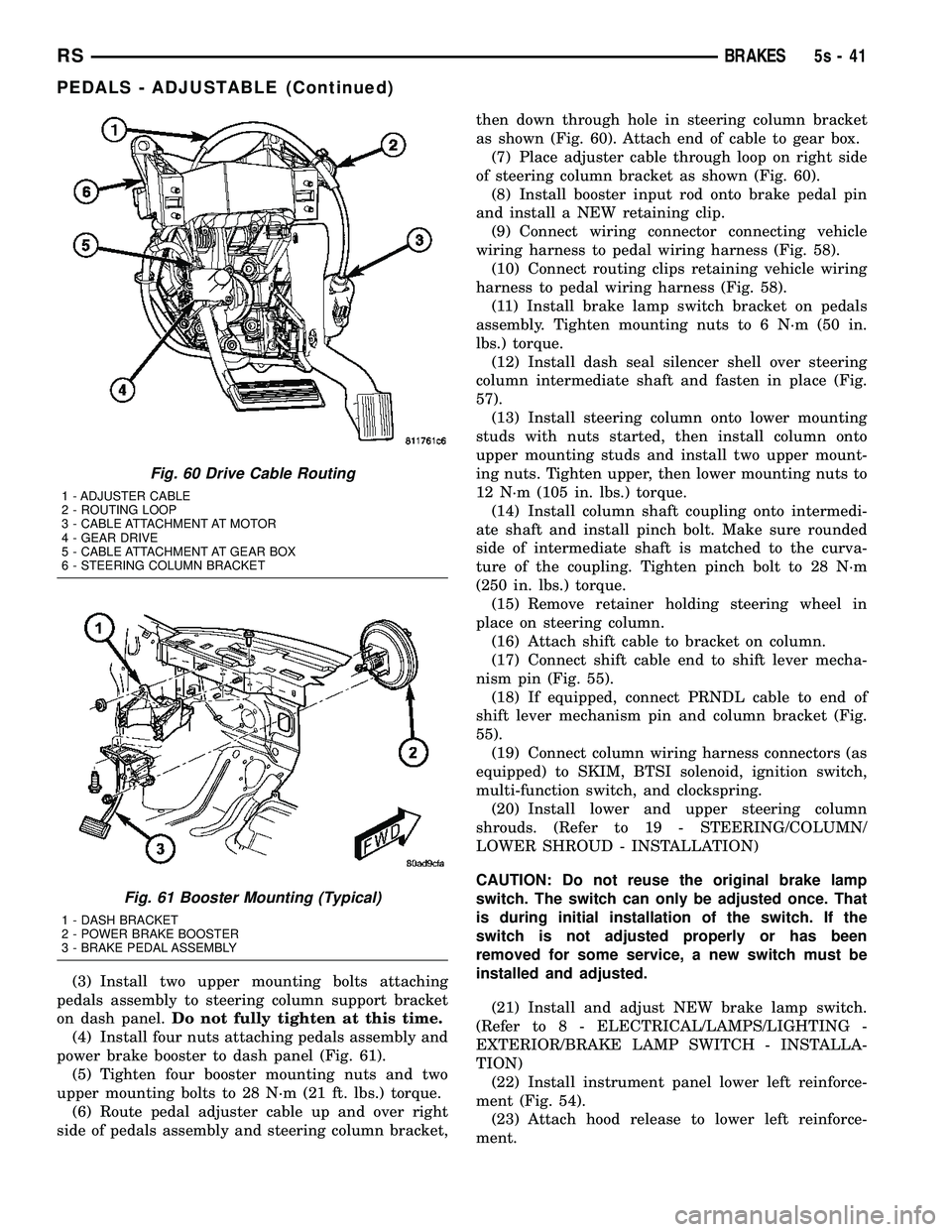

Fig. 60 Drive Cable Routing

1 - ADJUSTER CABLE

2 - ROUTING LOOP

3 - CABLE ATTACHMENT AT MOTOR

4 - GEAR DRIVE

5 - CABLE ATTACHMENT AT GEAR BOX

6 - STEERING COLUMN BRACKET

Fig. 61 Booster Mounting (Typical)

1 - DASH BRACKET

2 - POWER BRAKE BOOSTER

3 - BRAKE PEDAL ASSEMBLY

RS BRAKES5s-41

PEDALS - ADJUSTABLE (Continued)