oxygen CHRYSLER VOYAGER 2004 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1099 of 2585

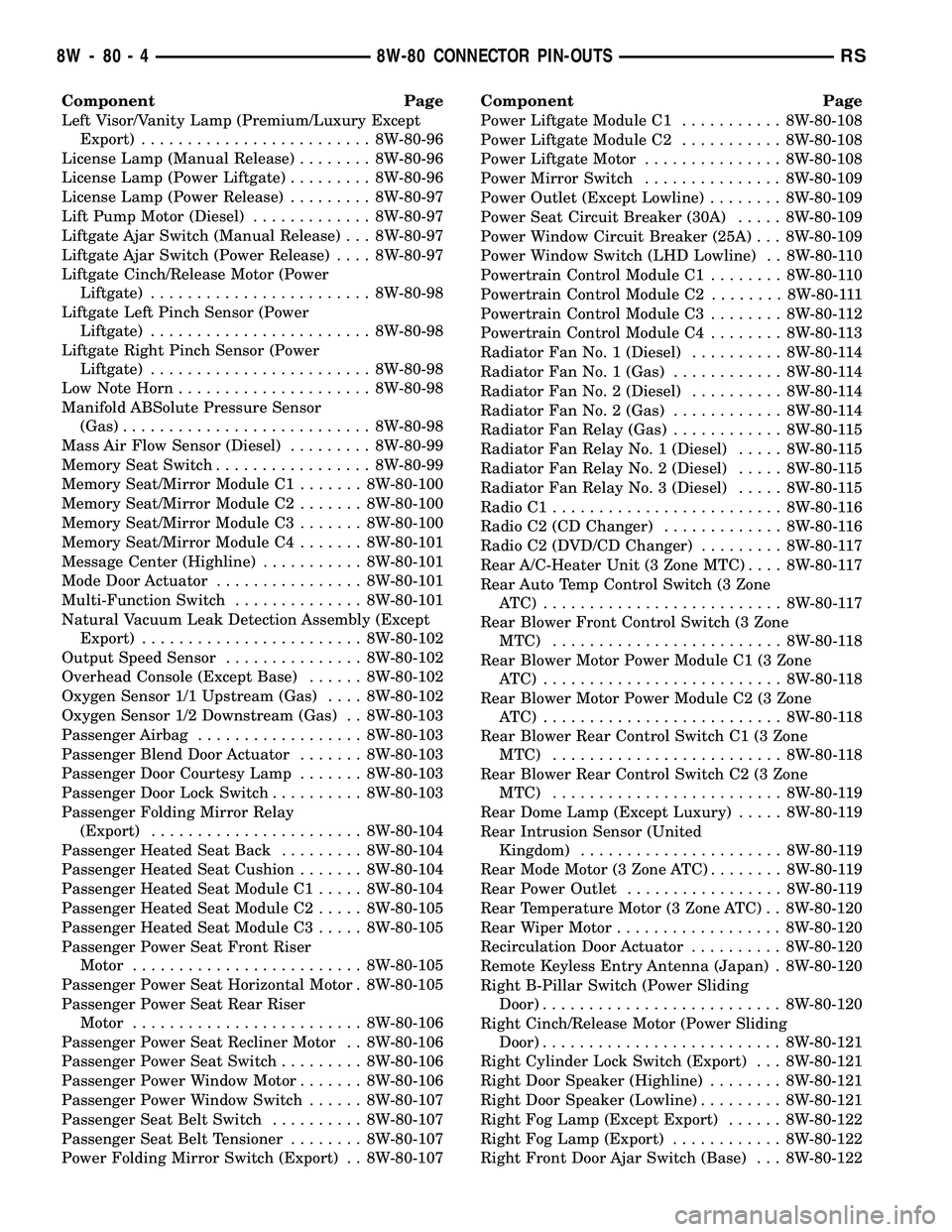

Component Page

Left Visor/Vanity Lamp (Premium/Luxury Except

Export)......................... 8W-80-96

License Lamp (Manual Release)........ 8W-80-96

License Lamp (Power Liftgate)......... 8W-80-96

License Lamp (Power Release)......... 8W-80-97

Lift Pump Motor (Diesel)............. 8W-80-97

Liftgate Ajar Switch (Manual Release) . . . 8W-80-97

Liftgate Ajar Switch (Power Release).... 8W-80-97

Liftgate Cinch/Release Motor (Power

Liftgate)........................ 8W-80-98

Liftgate Left Pinch Sensor (Power

Liftgate)........................ 8W-80-98

Liftgate Right Pinch Sensor (Power

Liftgate)........................ 8W-80-98

Low Note Horn..................... 8W-80-98

Manifold ABSolute Pressure Sensor

(Gas)........................... 8W-80-98

Mass Air Flow Sensor (Diesel)......... 8W-80-99

Memory Seat Switch................. 8W-80-99

Memory Seat/Mirror Module C1....... 8W-80-100

Memory Seat/Mirror Module C2....... 8W-80-100

Memory Seat/Mirror Module C3....... 8W-80-100

Memory Seat/Mirror Module C4....... 8W-80-101

Message Center (Highline)........... 8W-80-101

Mode Door Actuator................ 8W-80-101

Multi-Function Switch.............. 8W-80-101

Natural Vacuum Leak Detection Assembly (Except

Export)........................ 8W-80-102

Output Speed Sensor............... 8W-80-102

Overhead Console (Except Base)...... 8W-80-102

Oxygen Sensor 1/1 Upstream (Gas).... 8W-80-102

Oxygen Sensor 1/2 Downstream (Gas) . . 8W-80-103

Passenger Airbag.................. 8W-80-103

Passenger Blend Door Actuator....... 8W-80-103

Passenger Door Courtesy Lamp....... 8W-80-103

Passenger Door Lock Switch.......... 8W-80-103

Passenger Folding Mirror Relay

(Export)....................... 8W-80-104

Passenger Heated Seat Back......... 8W-80-104

Passenger Heated Seat Cushion....... 8W-80-104

Passenger Heated Seat Module C1..... 8W-80-104

Passenger Heated Seat Module C2..... 8W-80-105

Passenger Heated Seat Module C3..... 8W-80-105

Passenger Power Seat Front Riser

Motor......................... 8W-80-105

Passenger Power Seat Horizontal Motor . 8W-80-105

Passenger Power Seat Rear Riser

Motor......................... 8W-80-106

Passenger Power Seat Recliner Motor . . 8W-80-106

Passenger Power Seat Switch......... 8W-80-106

Passenger Power Window Motor....... 8W-80-106

Passenger Power Window Switch...... 8W-80-107

Passenger Seat Belt Switch.......... 8W-80-107

Passenger Seat Belt Tensioner........ 8W-80-107

Power Folding Mirror Switch (Export) . . 8W-80-107Component Page

Power Liftgate Module C1........... 8W-80-108

Power Liftgate Module C2........... 8W-80-108

Power Liftgate Motor............... 8W-80-108

Power Mirror Switch............... 8W-80-109

Power Outlet (Except Lowline)........ 8W-80-109

Power Seat Circuit Breaker (30A)..... 8W-80-109

Power Window Circuit Breaker (25A) . . . 8W-80-109

Power Window Switch (LHD Lowline) . . 8W-80-110

Powertrain Control Module C1........ 8W-80-110

Powertrain Control Module C2........ 8W-80-111

Powertrain Control Module C3........ 8W-80-112

Powertrain Control Module C4........ 8W-80-113

Radiator Fan No. 1 (Diesel).......... 8W-80-114

Radiator Fan No. 1 (Gas)............ 8W-80-114

Radiator Fan No. 2 (Diesel).......... 8W-80-114

Radiator Fan No. 2 (Gas)............ 8W-80-114

Radiator Fan Relay (Gas)............ 8W-80-115

Radiator Fan Relay No. 1 (Diesel)..... 8W-80-115

Radiator Fan Relay No. 2 (Diesel)..... 8W-80-115

Radiator Fan Relay No. 3 (Diesel)..... 8W-80-115

Radio C1......................... 8W-80-116

Radio C2 (CD Changer)............. 8W-80-116

Radio C2 (DVD/CD Changer)......... 8W-80-117

Rear A/C-Heater Unit (3 Zone MTC).... 8W-80-117

Rear Auto Temp Control Switch (3 Zone

ATC) .......................... 8W-80-117

Rear Blower Front Control Switch (3 Zone

MTC)......................... 8W-80-118

Rear Blower Motor Power Module C1 (3 Zone

ATC) .......................... 8W-80-118

Rear Blower Motor Power Module C2 (3 Zone

ATC) .......................... 8W-80-118

Rear Blower Rear Control Switch C1 (3 Zone

MTC)......................... 8W-80-118

Rear Blower Rear Control Switch C2 (3 Zone

MTC)......................... 8W-80-119

Rear Dome Lamp (Except Luxury)..... 8W-80-119

Rear Intrusion Sensor (United

Kingdom)...................... 8W-80-119

Rear Mode Motor (3 Zone ATC)........ 8W-80-119

Rear Power Outlet................. 8W-80-119

Rear Temperature Motor (3 Zone ATC) . . 8W-80-120

Rear Wiper Motor.................. 8W-80-120

Recirculation Door Actuator.......... 8W-80-120

Remote Keyless Entry Antenna (Japan) . 8W-80-120

Right B-Pillar Switch (Power Sliding

Door).......................... 8W-80-120

Right Cinch/Release Motor (Power Sliding

Door).......................... 8W-80-121

Right Cylinder Lock Switch (Export) . . . 8W-80-121

Right Door Speaker (Highline)........ 8W-80-121

Right Door Speaker (Lowline)......... 8W-80-121

Right Fog Lamp (Except Export)...... 8W-80-122

Right Fog Lamp (Export)............ 8W-80-122

Right Front Door Ajar Switch (Base) . . . 8W-80-122

8W - 80 - 4 8W-80 CONNECTOR PIN-OUTSRS

Page 1197 of 2585

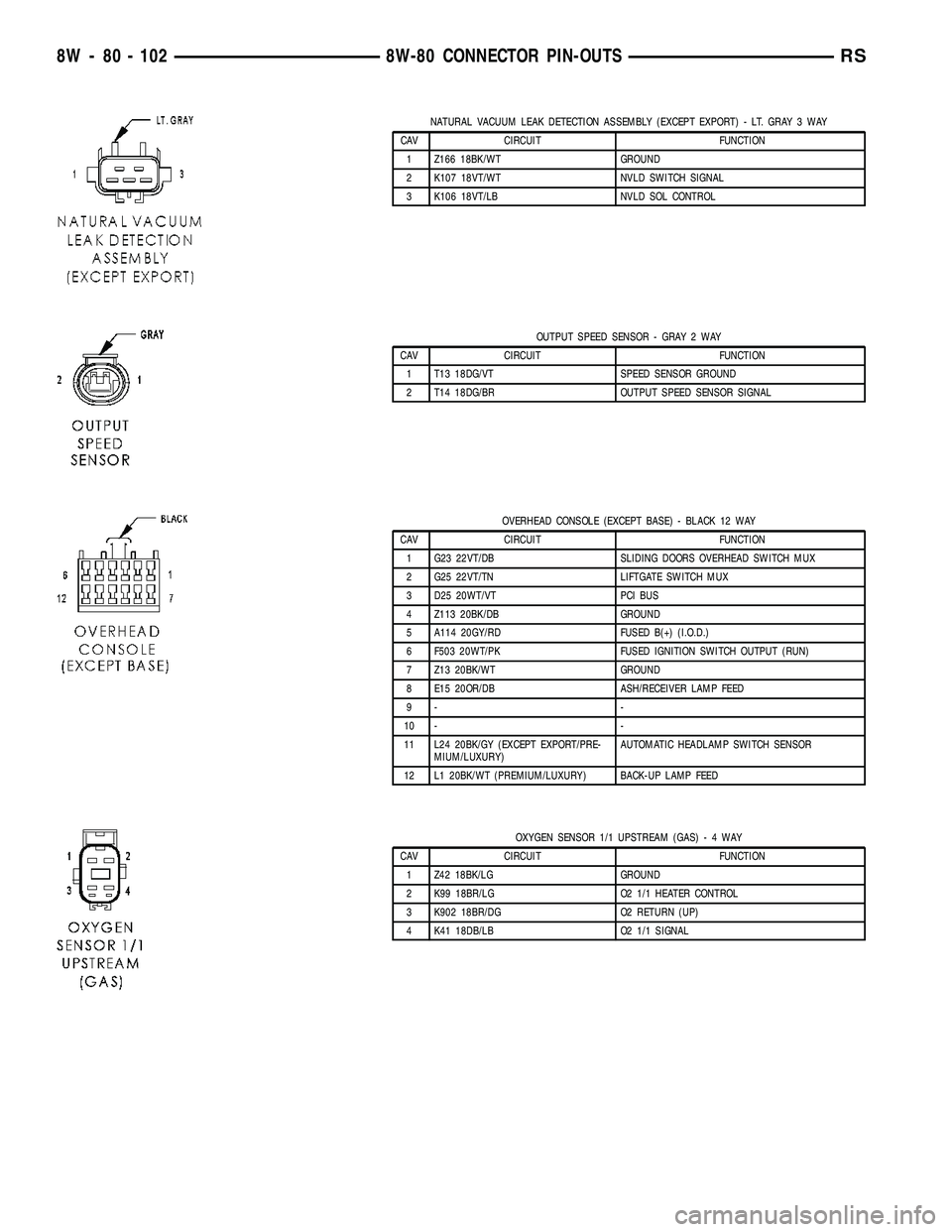

NATURAL VACUUM LEAK DETECTION ASSEMBLY (EXCEPT EXPORT) - LT. GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 Z166 18BK/WT GROUND

2 K107 18VT/WT NVLD SWITCH SIGNAL

3 K106 18VT/LB NVLD SOL CONTROL

OUTPUT SPEED SENSOR - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 T13 18DG/VT SPEED SENSOR GROUND

2 T14 18DG/BR OUTPUT SPEED SENSOR SIGNAL

OVERHEAD CONSOLE (EXCEPT BASE) - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 G23 22VT/DB SLIDING DOORS OVERHEAD SWITCH MUX

2 G25 22VT/TN LIFTGATE SWITCH MUX

3 D25 20WT/VT PCI BUS

4 Z113 20BK/DB GROUND

5 A114 20GY/RD FUSED B(+) (I.O.D.)

6 F503 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

7 Z13 20BK/WT GROUND

8 E15 20OR/DB ASH/RECEIVER LAMP FEED

9- -

10 - -

11 L24 20BK/GY (EXCEPT EXPORT/PRE-

MIUM/LUXURY)AUTOMATIC HEADLAMP SWITCH SENSOR

12 L1 20BK/WT (PREMIUM/LUXURY) BACK-UP LAMP FEED

OXYGEN SENSOR 1/1 UPSTREAM (GAS)-4WAY

CAV CIRCUIT FUNCTION

1 Z42 18BK/LG GROUND

2 K99 18BR/LG O2 1/1 HEATER CONTROL

3 K902 18BR/DG O2 RETURN (UP)

4 K41 18DB/LB O2 1/1 SIGNAL

8W - 80 - 102 8W-80 CONNECTOR PIN-OUTSRS

Page 1198 of 2585

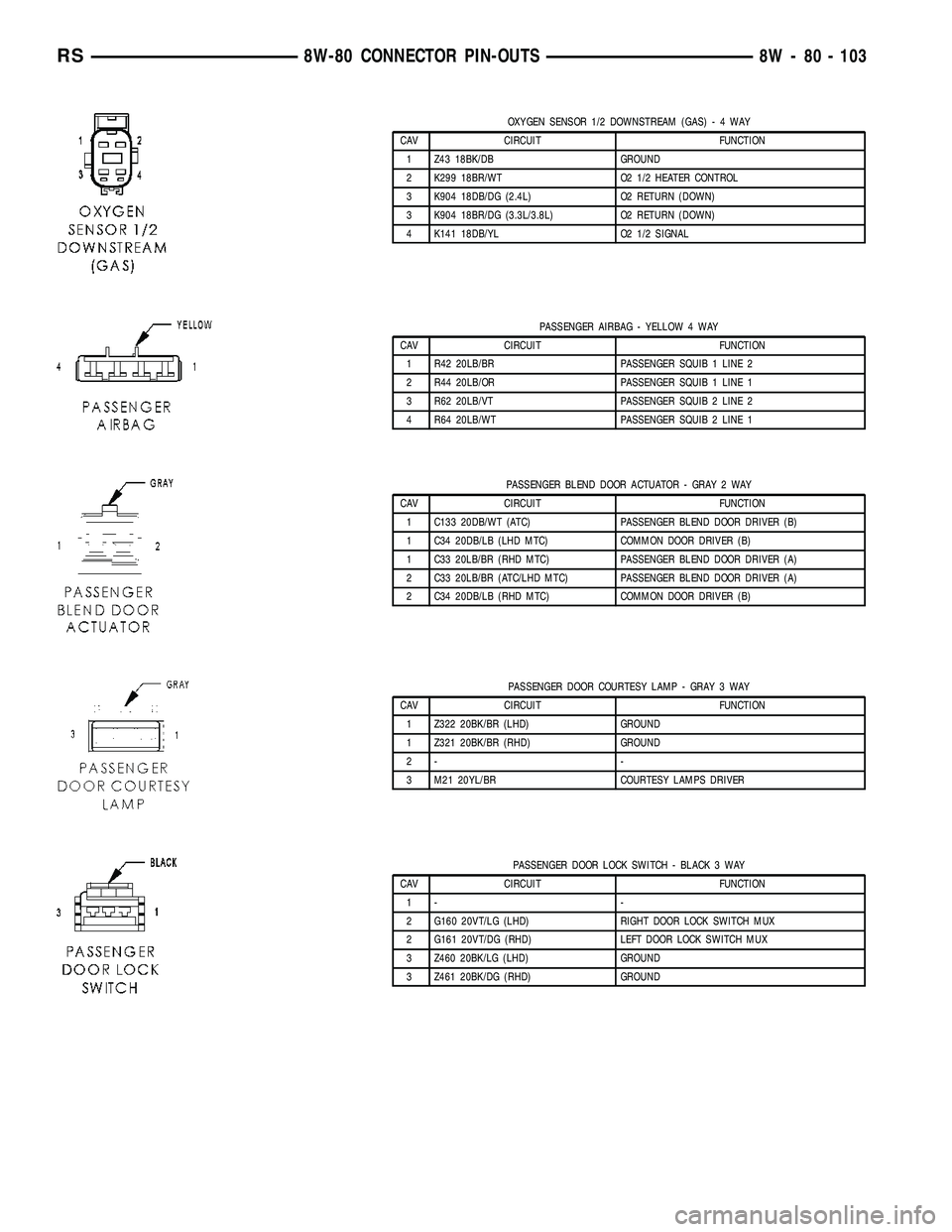

OXYGEN SENSOR 1/2 DOWNSTREAM (GAS)-4WAY

CAV CIRCUIT FUNCTION

1 Z43 18BK/DB GROUND

2 K299 18BR/WT O2 1/2 HEATER CONTROL

3 K904 18DB/DG (2.4L) O2 RETURN (DOWN)

3 K904 18BR/DG (3.3L/3.8L) O2 RETURN (DOWN)

4 K141 18DB/YL O2 1/2 SIGNAL

PASSENGER AIRBAG - YELLOW 4 WAY

CAV CIRCUIT FUNCTION

1 R42 20LB/BR PASSENGER SQUIB 1 LINE 2

2 R44 20LB/OR PASSENGER SQUIB 1 LINE 1

3 R62 20LB/VT PASSENGER SQUIB 2 LINE 2

4 R64 20LB/WT PASSENGER SQUIB 2 LINE 1

PASSENGER BLEND DOOR ACTUATOR - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 C133 20DB/WT (ATC) PASSENGER BLEND DOOR DRIVER (B)

1 C34 20DB/LB (LHD MTC) COMMON DOOR DRIVER (B)

1 C33 20LB/BR (RHD MTC) PASSENGER BLEND DOOR DRIVER (A)

2 C33 20LB/BR (ATC/LHD MTC) PASSENGER BLEND DOOR DRIVER (A)

2 C34 20DB/LB (RHD MTC) COMMON DOOR DRIVER (B)

PASSENGER DOOR COURTESY LAMP - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 Z322 20BK/BR (LHD) GROUND

1 Z321 20BK/BR (RHD) GROUND

2- -

3 M21 20YL/BR COURTESY LAMPS DRIVER

PASSENGER DOOR LOCK SWITCH - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1- -

2 G160 20VT/LG (LHD) RIGHT DOOR LOCK SWITCH MUX

2 G161 20VT/DG (RHD) LEFT DOOR LOCK SWITCH MUX

3 Z460 20BK/LG (LHD) GROUND

3 Z461 20BK/DG (RHD) GROUND

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 103

Page 1239 of 2585

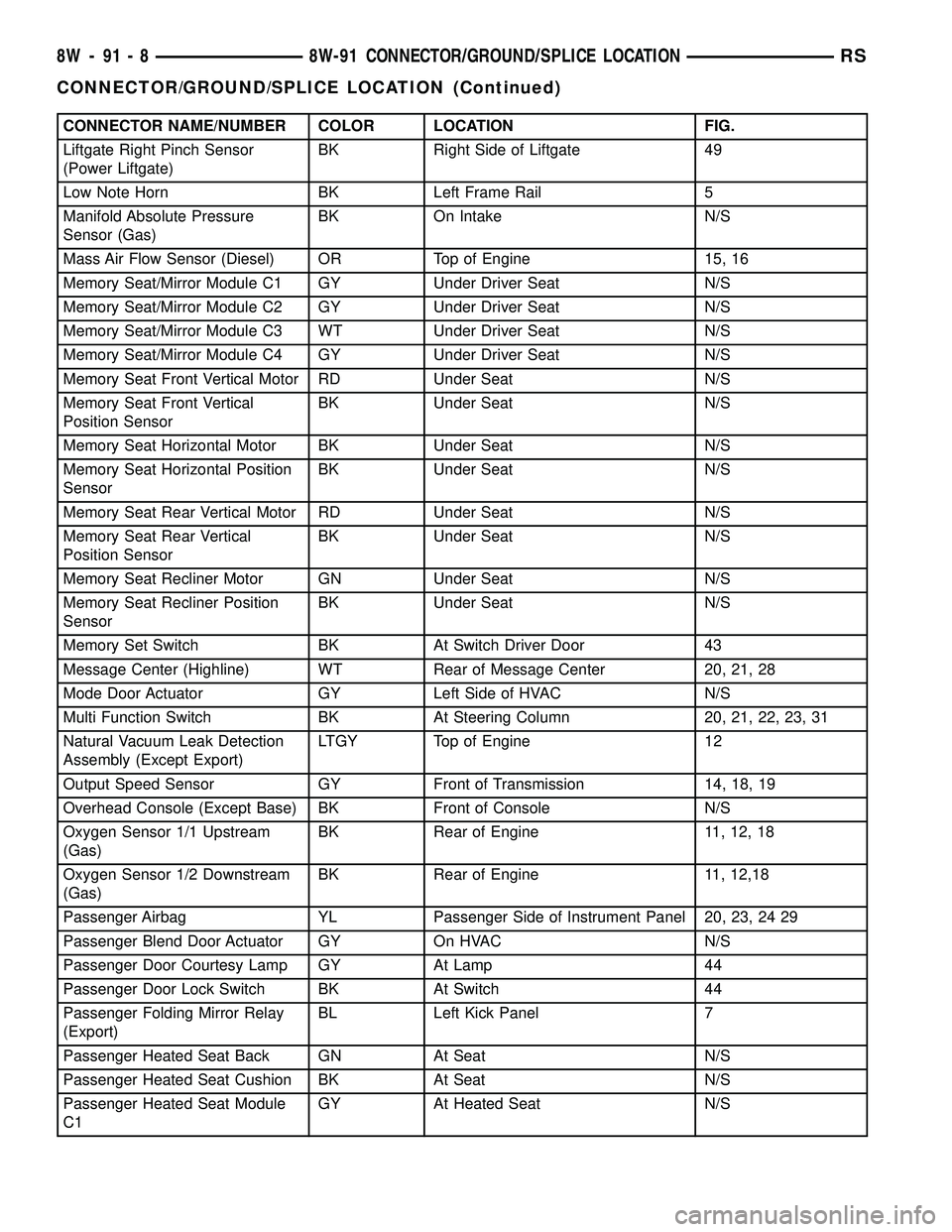

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Liftgate Right Pinch Sensor

(Power Liftgate)BK Right Side of Liftgate 49

Low Note Horn BK Left Frame Rail 5

Manifold Absolute Pressure

Sensor (Gas)BK On Intake N/S

Mass Air Flow Sensor (Diesel) OR Top of Engine 15, 16

Memory Seat/Mirror Module C1 GY Under Driver Seat N/S

Memory Seat/Mirror Module C2 GY Under Driver Seat N/S

Memory Seat/Mirror Module C3 WT Under Driver Seat N/S

Memory Seat/Mirror Module C4 GY Under Driver Seat N/S

Memory Seat Front Vertical Motor RD Under Seat N/S

Memory Seat Front Vertical

Position SensorBK Under Seat N/S

Memory Seat Horizontal Motor BK Under Seat N/S

Memory Seat Horizontal Position

SensorBK Under Seat N/S

Memory Seat Rear Vertical Motor RD Under Seat N/S

Memory Seat Rear Vertical

Position SensorBK Under Seat N/S

Memory Seat Recliner Motor GN Under Seat N/S

Memory Seat Recliner Position

SensorBK Under Seat N/S

Memory Set Switch BK At Switch Driver Door 43

Message Center (Highline) WT Rear of Message Center 20, 21, 28

Mode Door Actuator GY Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 20, 21, 22, 23, 31

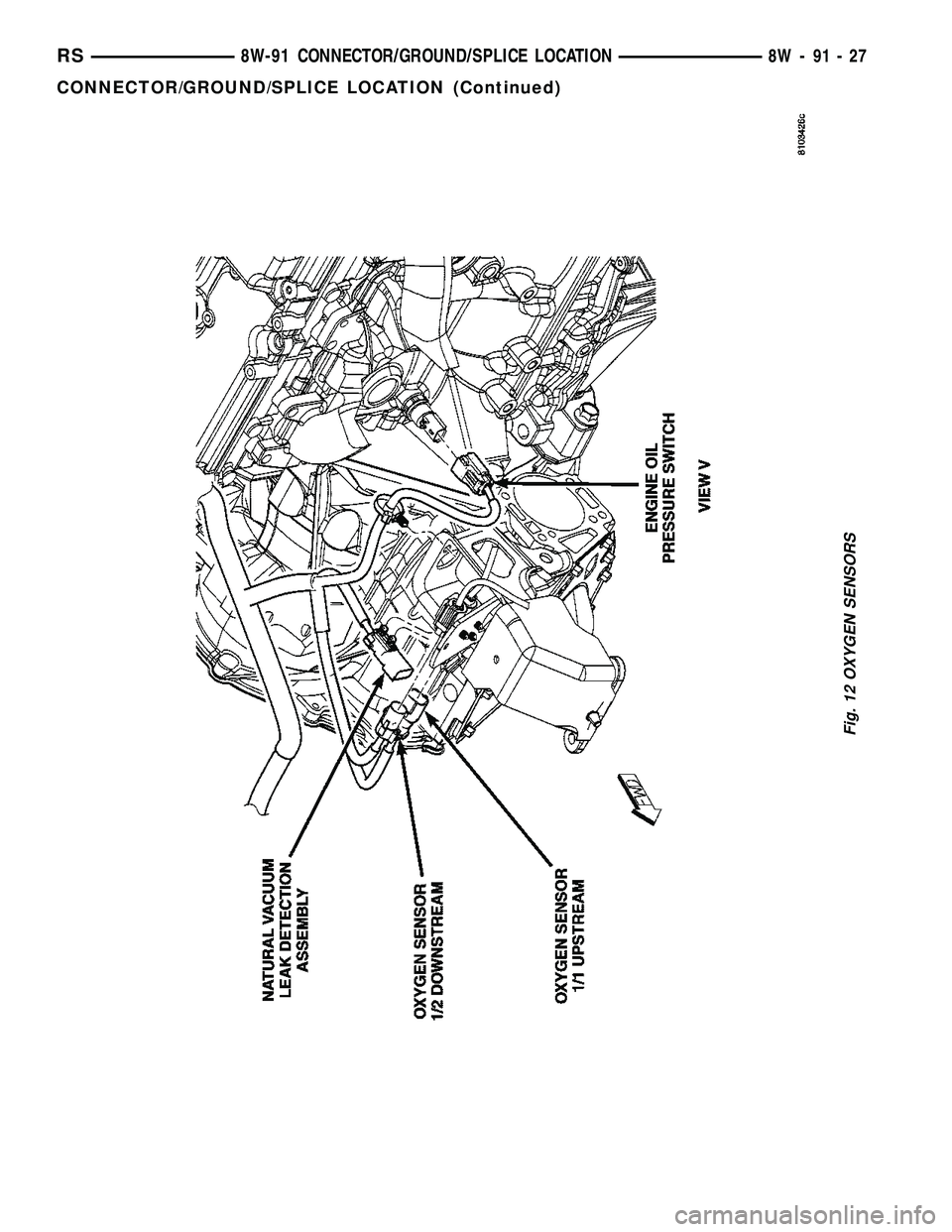

Natural Vacuum Leak Detection

Assembly (Except Export)LTGY Top of Engine 12

Output Speed Sensor GY Front of Transmission 14, 18, 19

Overhead Console (Except Base) BK Front of Console N/S

Oxygen Sensor 1/1 Upstream

(Gas)BK Rear of Engine 11, 12, 18

Oxygen Sensor 1/2 Downstream

(Gas)BK Rear of Engine 11, 12,18

Passenger Airbag YL Passenger Side of Instrument Panel 20, 23, 24 29

Passenger Blend Door Actuator GY On HVAC N/S

Passenger Door Courtesy Lamp GY At Lamp 44

Passenger Door Lock Switch BK At Switch 44

Passenger Folding Mirror Relay

(Export)BL Left Kick Panel 7

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module

C1GY At Heated Seat N/S

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1258 of 2585

Fig. 12 OXYGEN SENSORS

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-27

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1358 of 2585

EXHAUST MANIFOLD

REMOVAL

(1) Raise vehicle and disconnect exhaust pipe from

the exhaust manifold.

(2) Disconnect upstream oxygen sensor connector

at the rear of exhaust manifold.

(3) Remove the bolts attaching the manifold to the

cylinder head.

(4) Remove exhaust manifold.

(5) Inspect the manifold. (Refer to 9 - ENGINE/

MANIFOLDS/EXHAUST MANIFOLD - INSPEC-

TION)

CLEANING

(1) Discard gasket (if equipped) and clean all sur-

faces of manifold and cylinder head.

INSPECTION

(1) Inspect manifold gasket surfaces for flatness

with straight edge. Surface must be flat within 0.15

mm per 300 mm (0.006 in. per foot) of manifold

length.

(2) Inspect manifolds for cracks or distortion.

Replace manifold as necessary.

INSTALLATION

(1) Install exhaust manifold with a new gasket.

Tighten attaching nuts in the sequence shown in

(Fig. 109) to 19 N´m (170 in. lbs.).

(2) Attach exhaust pipe to exhaust manifold and

tighten fasteners to 37 N´m (27 ft. lbs.).

(3) Install and connect the oxygen sensor. (Refer to

14 - FUEL SYSTEM/FUEL INJECTION/O2 SENSOR

- COMPONENT LOCATION)

TIMING BELT COVER(S)

REMOVAL

FRONT COVER - UPPER

(1) Remove upper timing belt cover fasteners (Fig.

110) and remove cover.

FRONT COVER - LOWER

(1) Remove crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(2) Remove generator drive belt tensioner assem-

bly (Refer to 7 - COOLING/ACCESSORY DRIVE/

BELT TENSIONERS - REMOVAL).

(3) Remove timing belt front cover bolts (Fig. 110)

and remove covers.

REAR COVER

(1) Remove front covers.

(2) Remove engine mount bracket (Fig. 111).

(3) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

REMOVAL).

Fig. 109 Exhaust Manifold Tightening Sequence

Fig. 110 Front Timing Belt Covers

1 - BOLTS - UPPER FRONT COVER 6 N´m (50 in. lbs.)

2 - BOLTS - LOWER FRONT COVER 6 N´m (50 in. lbs.)

RSENGINE 2.4L9-61

Page 1447 of 2585

(11) Fill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

EXHAUST MANIFOLD - RIGHT

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL)

(3) Disconnect spark plug wires.

(4) Remove bolts fastening crossover pipe to

exhaust manifold (Fig. 124).

(5) Disconnect and remove the upstream oxygen

sensor (Fig. 127).(6) Remove the heat shield attaching screws (Fig.

127).

(7) Remove the upper heat shield (Fig. 127).

(8) Raise vehicle on hoist and remove drive belt

shield.

(9) Loosen the power steering pump support strut

lower bolt (Fig. 125).

(10) Disconnect downstream oxygen sensor connec-

tor.

(11) Disconnect catalytic converter pipe from

exhaust manifold (Fig. 126).

Fig. 123 LOWER MANIFOLD TIGHTENING

SEQUENCE

Fig. 124 CROSS-OVER PIPE

1 - CROSS-OVER PIPE

2 - BOLT

3 - GASKET

4 - FLAG NUT

Fig. 125 P/S PUMP STRUT

1 - BOLT - LOWER

2 - STRUT - P/S PUMP

3 - BOLT - UPPER

Fig. 126 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

9 - 150 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - LOWER (Continued)

Page 1448 of 2585

(12) Lower vehicle and remove the power steering

pump support strut upper bolt (Fig. 125).

(13) Remove bolts attaching exhaust manifold to

cylinder head and remove manifold (Fig. 127).

(14) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

CLEANING) (Refer to 9 - ENGINE/MANIFOLDS/

EXHAUST MANIFOLD - INSPECTION)

CLEANING

(1) Discard gasket (if equipped) and clean all sur-

faces of manifold and cylinder head.

INSPECTION

Inspect exhaust manifolds for damage or cracks

and check distortion of the cylinder head mounting

surface and exhaust crossover mounting surface with

a straightedge and thickness gauge (Fig. 128).

Manifold surface flatness limits should not exceed

1.0 mm (0.039 in.).

INSTALLATION

(1) Position exhaust manifold on cylinder head and

install bolts to center runner (cylinder #3) and initial

tighten to 2.8 N´m (25 in. lbs.) (Fig. 127)

(2) Using a new gasket, attach crossover pipe to

exhaust manifold and tighten bolts to 41 N´m (30 ft.

lbs.) (Fig. 124).NOTE: Inspect crossover pipe fasteners for damage

from heat and corrosion. The cross-over bolts are

made of a special stainless steel alloy. If replace-

ment is required, OEM bolts are highly recom-

mended.

(3) Install the remaining manifold attaching bolts.

Tighten all bolts to 23 N´m (200 in. lbs.).

(4) Position the power steering pump support strut

and install upper bolt (Fig. 125).

(5) Install heat shield and attaching screws (Fig.

127).

(6) Install and connect upstream oxygen sensor

(Fig. 127).

(7) Raise the vehicle.

(8) Attach catalytic converter pipe to exhaust man-

ifold using new gasket and tighten bolts to 37 N´m

(27 ft. lbs.) (Fig. 126).

(9) Connect downstream oxygen sensor connector.

(10) Tighten the power steering pump support

strut lower bolt (Fig. 125).

(11) Install the belt splash shield and lower the

vehicle.

(12) Install the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION)

(13) Connect battery negative cable.

Fig. 127 EXHAUST MANIFOLD - RIGHT

1 - SCREW - HEAT SHIELD

2 - HEAT SHIELD - UPPER

3 - BOLT - EXHAUST MANIFOLD

4 - HEAT SHIELD - LOWER

5 - EXHAUST MANIFOLD - RIGHT

6 - OXYGEN SENSOR - UPSTREAM

Fig. 128 Check Exhaust Manifold Mounting

1 - STRAIGHT EDGE

2 - CROSSOVER PIPE MOUNTING SURFACE

3 - FEELER GAUGE

RSENGINE 3.3/3.8L9 - 151

EXHAUST MANIFOLD - RIGHT (Continued)

Page 1487 of 2585

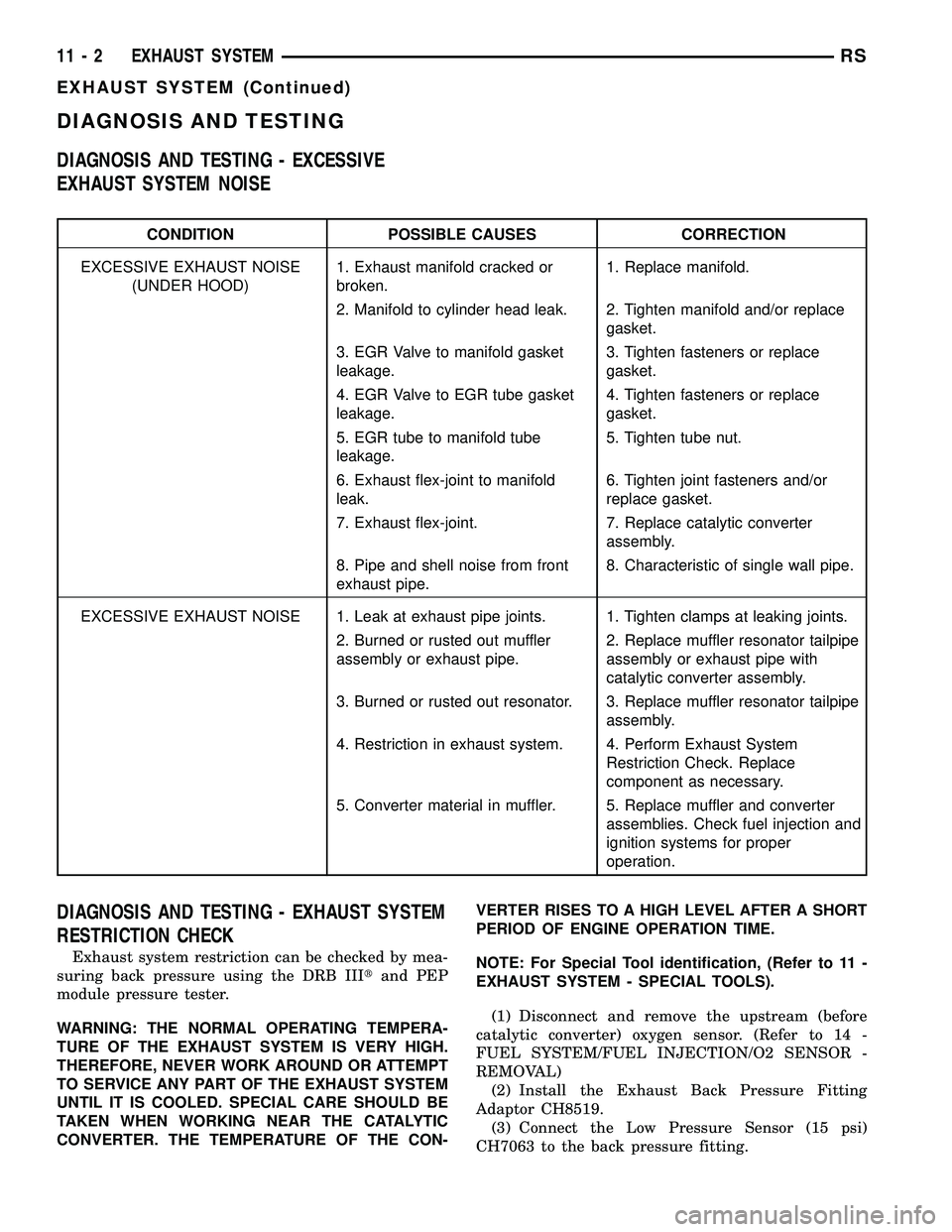

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EXCESSIVE

EXHAUST SYSTEM NOISE

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or

broken.1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace

gasket.

3. EGR Valve to manifold gasket

leakage.3. Tighten fasteners or replace

gasket.

4. EGR Valve to EGR tube gasket

leakage.4. Tighten fasteners or replace

gasket.

5. EGR tube to manifold tube

leakage.5. Tighten tube nut.

6. Exhaust flex-joint to manifold

leak.6. Tighten joint fasteners and/or

replace gasket.

7. Exhaust flex-joint. 7. Replace catalytic converter

assembly.

8. Pipe and shell noise from front

exhaust pipe.8. Characteristic of single wall pipe.

EXCESSIVE EXHAUST NOISE 1. Leak at exhaust pipe joints. 1. Tighten clamps at leaking joints.

2. Burned or rusted out muffler

assembly or exhaust pipe.2. Replace muffler resonator tailpipe

assembly or exhaust pipe with

catalytic converter assembly.

3. Burned or rusted out resonator. 3. Replace muffler resonator tailpipe

assembly.

4. Restriction in exhaust system. 4. Perform Exhaust System

Restriction Check. Replace

component as necessary.

5. Converter material in muffler. 5. Replace muffler and converter

assemblies. Check fuel injection and

ignition systems for proper

operation.

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

RESTRICTION CHECK

Exhaust system restriction can be checked by mea-

suring back pressure using the DRB IIItand PEP

module pressure tester.

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

NOTE: For Special Tool identification, (Refer to 11 -

EXHAUST SYSTEM - SPECIAL TOOLS).

(1) Disconnect and remove the upstream (before

catalytic converter) oxygen sensor. (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/O2 SENSOR -

REMOVAL)

(2) Install the Exhaust Back Pressure Fitting

Adaptor CH8519.

(3) Connect the Low Pressure Sensor (15 psi)

CH7063 to the back pressure fitting.

11 - 2 EXHAUST SYSTEMRS

EXHAUST SYSTEM (Continued)

Page 1489 of 2585

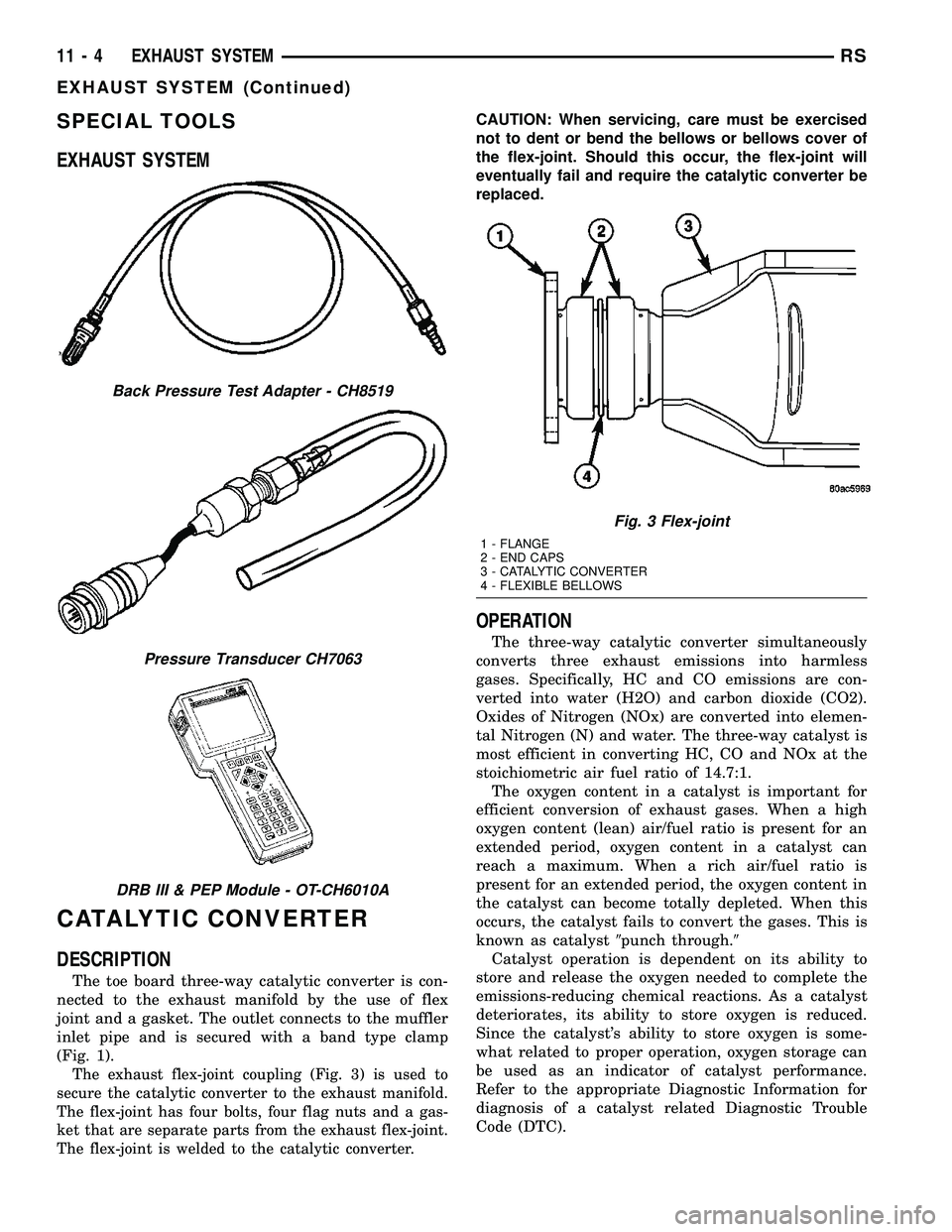

SPECIAL TOOLS

EXHAUST SYSTEM

CATALYTIC CONVERTER

DESCRIPTION

The toe board three-way catalytic converter is con-

nected to the exhaust manifold by the use of flex

joint and a gasket. The outlet connects to the muffler

inlet pipe and is secured with a band type clamp

(Fig. 1).

The exhaust flex-joint coupling (Fig. 3) is used to

secure the catalytic converter to the exhaust manifold.

The flex-joint has four bolts, four flag nuts and a gas-

ket that are separate parts from the exhaust flex-joint.

The flex-joint is welded to the catalytic converter.

CAUTION: When servicing, care must be exercised

not to dent or bend the bellows or bellows cover of

the flex-joint. Should this occur, the flex-joint will

eventually fail and require the catalytic converter be

replaced.

OPERATION

The three-way catalytic converter simultaneously

converts three exhaust emissions into harmless

gases. Specifically, HC and CO emissions are con-

verted into water (H2O) and carbon dioxide (CO2).

Oxides of Nitrogen (NOx) are converted into elemen-

tal Nitrogen (N) and water. The three-way catalyst is

most efficient in converting HC, CO and NOx at the

stoichiometric air fuel ratio of 14.7:1.

The oxygen content in a catalyst is important for

efficient conversion of exhaust gases. When a high

oxygen content (lean) air/fuel ratio is present for an

extended period, oxygen content in a catalyst can

reach a maximum. When a rich air/fuel ratio is

present for an extended period, the oxygen content in

the catalyst can become totally depleted. When this

occurs, the catalyst fails to convert the gases. This is

known as catalyst9punch through.9

Catalyst operation is dependent on its ability to

store and release the oxygen needed to complete the

emissions-reducing chemical reactions. As a catalyst

deteriorates, its ability to store oxygen is reduced.

Since the catalyst's ability to store oxygen is some-

what related to proper operation, oxygen storage can

be used as an indicator of catalyst performance.

Refer to the appropriate Diagnostic Information for

diagnosis of a catalyst related Diagnostic Trouble

Code (DTC).

Back Pressure Test Adapter - CH8519

Pressure Transducer CH7063

DRB III & PEP Module - OT-CH6010A

Fig. 3 Flex-joint

1 - FLANGE

2 - END CAPS

3 - CATALYTIC CONVERTER

4 - FLEXIBLE BELLOWS

11 - 4 EXHAUST SYSTEMRS

EXHAUST SYSTEM (Continued)