torque CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1444 of 2585

²Mounting surface distortion by using a straight-

edge and thickness gauge.

INSTALLATION - UPPER INTAKE MANIFOLD

(1) If the following components were removed from

manifold, install and tighten to specifications:

CAUTION: The special screws used for the compos-

ite manifold attached components must be installed

slowly using hand tools only. This requirement is to

prevent the melting of material that causes stripped

threads. If threads become stripped, an oversize

repair screw is available. For more information and

procedure (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - STANDARD PROCEDURE - MAN-

IFOLD STRIPPED THREAD REPAIR).

²MAP sensor - 1.7 N´m (15 in. lbs.)

²Throttle cable bracket - 5.6 N´m (50 in. lbs.)

(2) Remove covering on lower intake manifold and

clean surfaces.

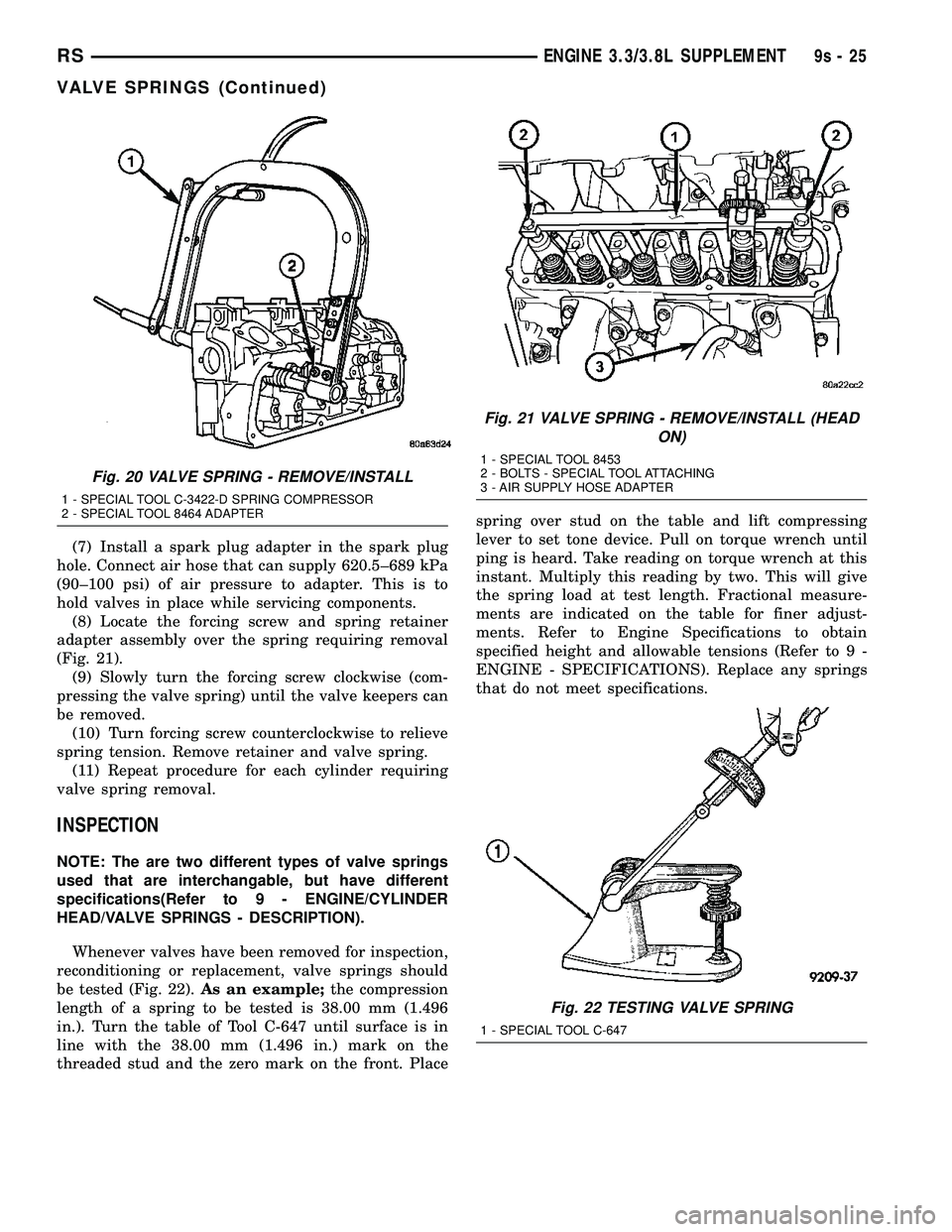

(3) Inspect manifold gasket condition. Gaskets can

be re-used, if not damaged. To replace, remove gasket

from upper manifold (Fig. 117). Position new gasket

in seal channel and press lightly in-place. Repeat

procedure for each gasket position.

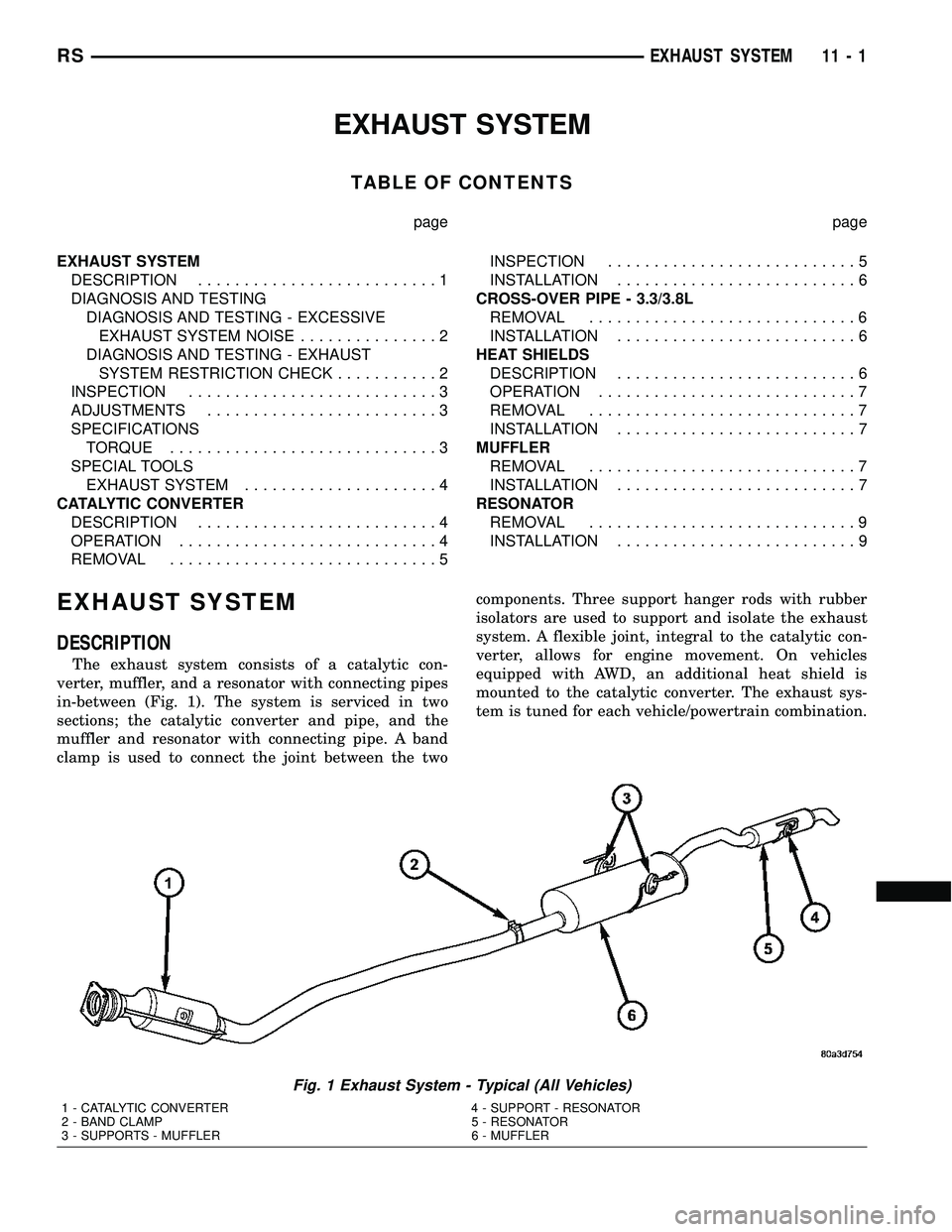

(4) Position upper manifold on lower manifold (Fig.

117). Apply MopartLock & Seal Adhesive (Medium

Strength Threadlocker) to each upper intake mani-

fold bolt. Install and tighten bolts to 12 N´m (105 in.

lbs.) following torque sequence in (Fig. 118).

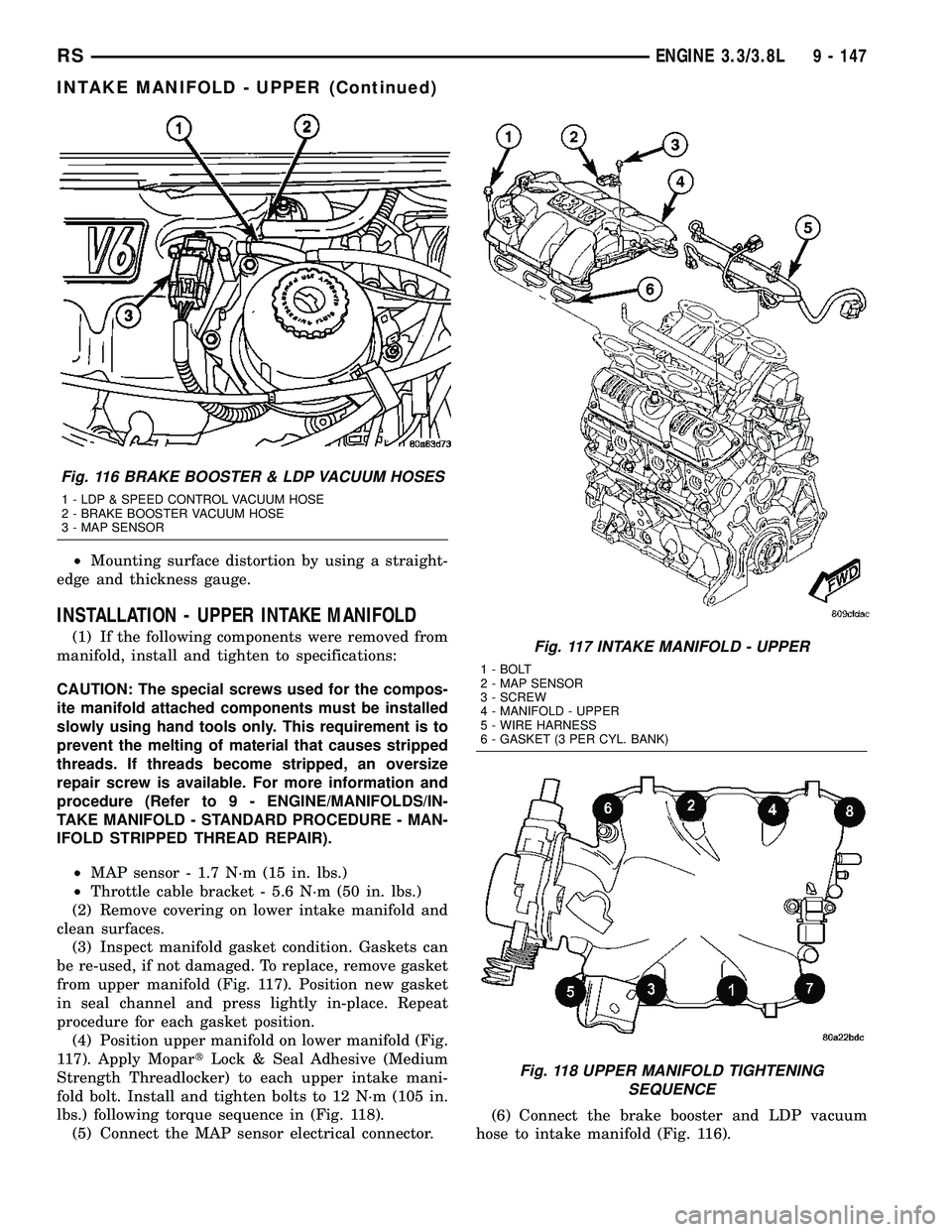

(5) Connect the MAP sensor electrical connector.(6) Connect the brake booster and LDP vacuum

hose to intake manifold (Fig. 116).

Fig. 116 BRAKE BOOSTER & LDP VACUUM HOSES

1 - LDP & SPEED CONTROL VACUUM HOSE

2 - BRAKE BOOSTER VACUUM HOSE

3 - MAP SENSOR

Fig. 117 INTAKE MANIFOLD - UPPER

1 - BOLT

2 - MAP SENSOR

3 - SCREW

4 - MANIFOLD - UPPER

5 - WIRE HARNESS

6 - GASKET (3 PER CYL. BANK)

Fig. 118 UPPER MANIFOLD TIGHTENING

SEQUENCE

RSENGINE 3.3/3.8L9 - 147

INTAKE MANIFOLD - UPPER (Continued)

Page 1446 of 2585

²Check for cylinder head mounting surface distor-

tion using a straightedge and thickness gauge. (Refer

to 9 - ENGINE/CYLINDER HEAD - INSPECTION)

INSTALLATION - LOWER INTAKE MANIFOLD

(1) Place a bead (approximately 1/4 in. diameter)

of MopartEngine RTV GEN II onto each of thefour

manifold to cylinder head gasket corners (Fig. 122).

(2) Carefully install the new intake manifold gas-

ket (Fig. 121). Tighten end seal retainer screws to 12

N´m (105 in. lbs.).

(3) Install lower intake manifold (Fig. 121). Install

the bolts and torque to 1 N´m (10 in. lbs.). Then

torque bolts to 22 N´m (200 in. lbs.) in sequence

shown in (Fig. 123). Then torque again to 22 N´m

(200 in. lbs.). After intake manifold is in place,

inspect to make sure seals are in place.

(4) Install the fuel injectors and rail assembly.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL RAIL - INSTALLATION)

(5) Connect fuel injector electrical harness.

(6) Connect the engine coolant temperature sensor

(Fig. 120).

(7) Connect the heater supply (Fig. 120) and radi-

ator upper hoses to manifold.

(8) Connect the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)(9) Install the upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

(10) Connect negative battery cable.

Fig. 120 ECT SENSOR & HEATER SUPPLY

1 - ENGINE COOLANT TEMPERATURE SENSOR

2 - CONNECTOR - ENGINE COOLANT SENSOR

3 - FITTING - HEATER SUPPLY

Fig. 121 INTAKE MANIFOLD - LOWER

1 - INTAKE MANIFOLD - LOWER

2 - BOLT - GASKET END SEAL RETAINER

3 - GASKET

4 - BOLT - LOWER INTAKE MANIFOLD

Fig. 122 Intake Manifold Gasket Sealing

1 - SEALER LOCATIONS

RSENGINE 3.3/3.8L9 - 149

INTAKE MANIFOLD - LOWER (Continued)

Page 1450 of 2585

VALVE TIMING

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE TIMING

VERIFICATION

(1) Remove front cylinder head cover and all 6

spark plugs.

(2) Rotate engine until the #2 piston is at TDC of

the compression stroke.

(3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial indicator

into #2 spark plug hole. Using the indicator find TDC

on the compression stroke.

(5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole.

(7) Place a 5.08 mm (0.200 in.) spacer between the

valve stem tip of #2 intake valve and rocker arm pad.

Allow tappet to bleed down to give a solid tappet

effect.

(8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator.

(9) Rotate the engine clockwise until the intake

valve has lifted .254 mm (0.010 in.).

CAUTION: Do not turn crankshaft any further clock-

wise as intake valve might bottom and result in

serious damage.

(10) Degree wheel should read 6 degrees BTDC to

6 degrees ATDC.

STANDARD PROCEDURE - MEASURING

TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed (Refer to 9 - ENGINE/

VALVE TIMING/TIMING CHAIN COVER - REMOVAL).

(1) Position a scale next to timing chain so that

any movement of chain may be measured (Fig. 132).

(2) Position a torque wrench and socket on the

camshaft sprocket attaching bolt. Apply force in the

direction of crankshaft rotation to take up slack to

the following torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removed

NOTE: With torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block crankshaft to

prevent rotation.

(3) Holding a measuring scale along edge of chain

links (Fig. 132).(4) Apply force in the reverse direction to the fol-

lowing torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removed

(5) Measure amount of sprocket/chain movement.

(6) Install a new timing chain and sprockets if

movement exceeds 3.175 mm (1/8 in.).

TIMING CHAIN COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(3) Raise vehicle on hoist.

(4) Drain engine oil.

(5) Remove right wheel and inner splash shield.

(6) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(7) Remove oil pick-up tube (Fig. 133).

(8) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Remove A/C compressor and set aside.

(10) Remove crankshaft vibration damper. (Refer

to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)

(11) Remove radiator lower hose.

(12) Remove heater hose from timing chain cover

housing (Fig. 134) or water pump inlet tube (if

engine oil cooler equipped) (Fig. 135).

(13) Remove the right side engine mount. (Refer to

9 - ENGINE/ENGINE MOUNTING/RIGHT MOUNT

- REMOVAL)

(14) Remove idler pulley from engine bracket (Fig.

136).

(15) Remove the engine mount bracket (Fig. 136).

Fig. 132 Measuring Timing Chain Wear

1 - TORQUE WRENCH

RSENGINE 3.3/3.8L9 - 153

Page 1463 of 2585

(1) Install the main bearing upper shells with the

lubrication groove and oil hole in the engine block

(Fig. 6).

(2) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block

tab slots.

NOTE: If the crankshaft is sent out for machine

work, it must be balenced as an assembly with the

target ring installed.

(3) Clean crankshaft and target ring with

MOPARtbrake parts cleaner and dry with com-

pressed air to ensure that the crankshaft mating sur-

face and target ring mounting holes are free from oil

and lock patch debris.

NOTE: Always use NEW mounting screws whether

installing original or new target ring.

(4) InstallNEWmounting screws finger tight

starting with the #1 location. (Fig. 7) Make sure

engagment occurs with the shoulder of the screw and

mounting hole before starting all other screws.

(5) Torque all mounting screws with T30 torx bit

to 13 Nm (110 in-lbs) following the torque sequence.

CAUTION: Use extreme care when handling crank-

shaft. Tone wheel damage can occur if crankshaft is

mis-handled.

CAUTION: Do not get oil on the bed plate mating

surface. It will affect the ability of the sealer to seal

the bed plate to cylinder block.(6) Oil the bearings and journals. Install crank-

shaft in the engine block.

CAUTION: Use only MoparTBed Plate Sealant on

the bed plate or damage may occur to the engine.

(7) Install lower main bearings into main bearing

cap/bed plate. Make certain the bearing tabs are

seated into the bed plate slots and apply oil.

(8) Apply 1.5 to 2.0 mm (0.059 to 0.078 in.) bead of

MopartBed Plate Sealant to bed plate as shown in

(Fig. 8).

Fig. 6 Installing Main Bearing Upper Shell

1 - LUBRICATION GROOVES

2 - OIL HOLESFig. 7 Target Ring Torque Sequence

Fig. 8 Bed Plate Sealing

9s - 8 ENGINE 2.4L SUPPLEMENTRS

CRANKSHAFT (Continued)

Page 1464 of 2585

(9) Install the main bearing/bed plate into engine

block.

(10) Before installing the bolts the threads should

be oiled with clean engine oil, wipe off any excess oil.

(11) Install main bearing bed plate to engine

block bolts 11, 17, and 20 finger tight. Tighten these

bolts down together until the bed plate contacts the

cylinder block.

(12) To ensure correct thrust bearing alignment,

perform the following steps:

²Step 1: Rotate crankshaft until number 4 piston

is at TDC.

²Step 2: Move crankshaft rearward to limits of

travel.

²Step 3: Then, move crankshaft forward to limits

of travel.

²Step 4: Wedge an appropriate tool between the

rear of the cylinder block(NOT BED PLATE)and

the rear crankshaft counterweight. This will hold the

crankshaft in it's furthest forward position.

²Step 5: Install and tighten bolts (1±10) in

sequence shown in (Fig. 9) to 41 N´m (30 ft. lbs.).

²Step 6: Remove wedge tool used to hold crank-

shaft.

(13) Tighten bolts (1±10) again to 41 N´m (30 ft.

lbs.) in sequence shown in (Fig. 9).

CAUTION: Do Not use a torque wrench for the fol-

lowing step.

(14) Turn bolts (1±10) an additional 1/4 turn in

sequence shown in (Fig. 9).(15) Install main bearing bed plate to engine

block bolts (11±20), and torque each bolt to 28 N´m

(250 in. lbs.) in sequence shown in. (Fig. 9)

(16) Tighten bolts (11±20) again to 28 N´m (250 in.

lbs.) in sequence shown in (Fig. 9).

(17) After the main bearing bed plate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(18) Check crankshaft end play (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT - STAN-

DARD PROCEDURE).

(19) Install connecting rod bearings and caps.Do

Not Reuse Connecting Rod Bolts.Torque connect-

ing rod bolts to 27 N´m (20 ft. lbs.) plus 1/4 turn.

(20) Install balance shafts and housing assembly

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - INSTALLATION).

(21) Install the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - INSTALLATION).

(22) Install oil pump pick-up tube. Torque fastener

to 28 N´m (20 ft.. lbs.).

(23) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(24) Install crankshaft position sensor.

(25) Install cylinder head if it was removed (Refer

to 9 - ENGINE/CYLINDER HEAD - INSTALLA-

TION).

(26) Install the timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(27) Install crankshaft sprocket (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT AND

SPROCKETS - INSTALLATION).

(28) Install the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

INSTALLATION).

(29) Install the timing belt front covers (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - INSTALLATION).

(30) Install engine mount support bracket.

(31) InstallNEWoil filter.

(32) Install crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - INSTALLATION).

(33) Install flex plate. Apply MopartLock & Seal

Adhesive to bolt threads and tighten to 95 N´m (70

ft. lbs.).

(34) Attach transaxle to engine. Tighten attaching

bolts to 101 N´m (75 ft. lbs.).

(35) Install the engine assembly (Refer to 9 -

ENGINE - INSTALLATION).

Fig. 9 Main Bearing Caps/Bed Plate Bolt Torque

Sequence

RSENGINE 2.4L SUPPLEMENT9s-9

CRANKSHAFT (Continued)

Page 1473 of 2585

²Standard dimension = less than 0.05 mm (0.002

inch.)

²Service Limit = 0.2 mm (0.008 inch.)

²Grinding Limit = Maximum of 0.2 mm (0.008

inch.) is permitted.

CAUTION: 0.20 mm (0.008 in.) MAX is a combined

total dimension of the stock removal limit from cyl-

inder head and block top surface (Deck) together.

INSTALLATION - CYLINDER HEAD

(1) Clean all sealing surfaces of engine block and

cylinder heads. (Refer to 9 - ENGINE - STANDARD

PROCEDURE)

(2) Position new gasket(s) on engine block (Fig. 4).

The left bank gasket is identified with the ªLº

stamped in the exposed area of the gasket located at

front of engine (shown in (Fig. 4)). The right bank

gasket is identified with a ªRº stamped in the

exposed area of the gasket also, but is located at the

rear of the engine.(3)The cylinder head bolts are torqued using

the torque yield method, they should be exam-

ined BEFORE reuse. If the threads are necked

down, the bolts must be replaced(Fig. 5).

(4) Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt should be replaced.

(5) Tighten the cylinder head bolts 1±8 in the

sequence shown in (Fig. 6). Using the 4 step torque

turn method, tighten according to the following val-

ues:

²Step 1: Bolts1±8to61N´m(45ft.lbs.)

²Step 2: Bolts1±8to88N´m(65ft.lbs.)

²Step 3: Bolts1±8(again) to 88 N´m (65 ft. lbs.)

²Step 4: Bolts1±8turn an additional 1/4 Turn.

(Do not use a torque wrench for this step.)

NOTE: Bolt torque after 1/4 turn should be over 122

N´m (90 ft. lbs.). If not, replace the bolt.

(6) Inspect push rods and replace worn or bent

rods.

(7) Install the push rods.

(8) Install the rocker arm and shaft assemblies.

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARMS - INSTALLATION)

(9) Install the cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

Fig. 3 Checking Cylinder Head FlatnessÐTypical

Fig. 4 Head Gasket Installation

1 - CYLINDER HEAD GASKET

2 - LOCATION IDENTIFICATION (L = LEFT BANK, R = RIGHT

BANK)

Fig. 5 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 6 CYLINDER HEAD TIGHTENING SEQUENCE

9s - 18 ENGINE 3.3/3.8L SUPPLEMENTRS

CYLINDER HEAD (Continued)

Page 1474 of 2585

(10) Install the exhaust manifolds. (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION)

(11) Install new O-ring on dipstick tube. Install

dipstick tube assembly (Fig. 2).

(12) Install the spark plugs.

(13) Install upper and lower intake manifolds.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - INSTALLATION)

(14) Fill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(15) Connect negative cable to battery.

CYLINDER HEAD COVER(S)

DESCRIPTION

The cylinder head covers are made of stamped

steel. The covers are sealed with steel reinforced sil-

icon rubber gaskets. The cylinder head cover uses

rubber isolators at each fastener location (Fig. 7).

NOTE: Due to the tight packaging near the cylinder

head covers, which makes spill clean-up difficult, a

spill during an engine oil change may be misinter-

preted as an oil leak. When investigating an oil leak

in the location of the cylinder head covers and

intake manifold, follow the procedure found in Oil

Leak Diagnosis (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING) for determining the source of a leak.

CYLINDER HEAD COVER-

RIGHT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL)

(3) Disconnect spark plug wires from plugs.

(4) Disconnect PCV hose from cylinder head cover

(Fig. 8).

(5) Remove cylinder head cover bolts.

(6) Remove cylinder head cover and gasket (Fig.

7).

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Inspect seal on the cover bolt for wear or dam-

age (Fig. 9). Replace bolt assembly as necessary.

NOTE: The cylinder head cover bolts contain a

torque limiter sleeve and a seal (Fig. 9). The seal

and torque sleeve is replaced with the bolt.

Fig. 7 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - BOLT

Fig. 8 PCV Hose

1 - HOSE - PCV

2 - P C V VA LV E

RSENGINE 3.3/3.8L SUPPLEMENT9s-19

CYLINDER HEAD (Continued)

Page 1480 of 2585

(7) Install a spark plug adapter in the spark plug

hole. Connect air hose that can supply 620.5±689 kPa

(90±100 psi) of air pressure to adapter. This is to

hold valves in place while servicing components.

(8) Locate the forcing screw and spring retainer

adapter assembly over the spring requiring removal

(Fig. 21).

(9) Slowly turn the forcing screw clockwise (com-

pressing the valve spring) until the valve keepers can

be removed.

(10) Turn forcing screw counterclockwise to relieve

spring tension. Remove retainer and valve spring.

(11) Repeat procedure for each cylinder requiring

valve spring removal.

INSPECTION

NOTE: The are two different types of valve springs

used that are interchangable, but have different

specifications(Refer to 9 - ENGINE/CYLINDER

HEAD/VALVE SPRINGS - DESCRIPTION).

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested (Fig. 22).As an example;the compression

length of a spring to be tested is 38.00 mm (1.496

in.). Turn the table of Tool C-647 until surface is in

line with the 38.00 mm (1.496 in.) mark on the

threaded stud and the zero mark on the front. Placespring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length. Fractional measure-

ments are indicated on the table for finer adjust-

ments. Refer to Engine Specifications to obtain

specified height and allowable tensions (Refer to 9 -

ENGINE - SPECIFICATIONS). Replace any springs

that do not meet specifications.

Fig. 20 VALVE SPRING - REMOVE/INSTALL

1 - SPECIAL TOOL C-3422-D SPRING COMPRESSOR

2 - SPECIAL TOOL 8464 ADAPTER

Fig. 21 VALVE SPRING - REMOVE/INSTALL (HEAD

ON)

1 - SPECIAL TOOL 8453

2 - BOLTS - SPECIAL TOOL ATTACHING

3 - AIR SUPPLY HOSE ADAPTER

Fig. 22 TESTING VALVE SPRING

1 - SPECIAL TOOL C-647

RSENGINE 3.3/3.8L SUPPLEMENT9s-25

VALVE SPRINGS (Continued)

Page 1486 of 2585

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EXCESSIVE

EXHAUST SYSTEM NOISE...............2

DIAGNOSIS AND TESTING - EXHAUST

SYSTEM RESTRICTION CHECK...........2

INSPECTION...........................3

ADJUSTMENTS.........................3

SPECIFICATIONS

TORQUE.............................3

SPECIAL TOOLS

EXHAUST SYSTEM.....................4

CATALYTIC CONVERTER

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................5INSPECTION...........................5

INSTALLATION..........................6

CROSS-OVER PIPE - 3.3/3.8L

REMOVAL.............................6

INSTALLATION..........................6

HEAT SHIELDS

DESCRIPTION..........................6

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

MUFFLER

REMOVAL.............................7

INSTALLATION..........................7

RESONATOR

REMOVAL.............................9

INSTALLATION..........................9

EXHAUST SYSTEM

DESCRIPTION

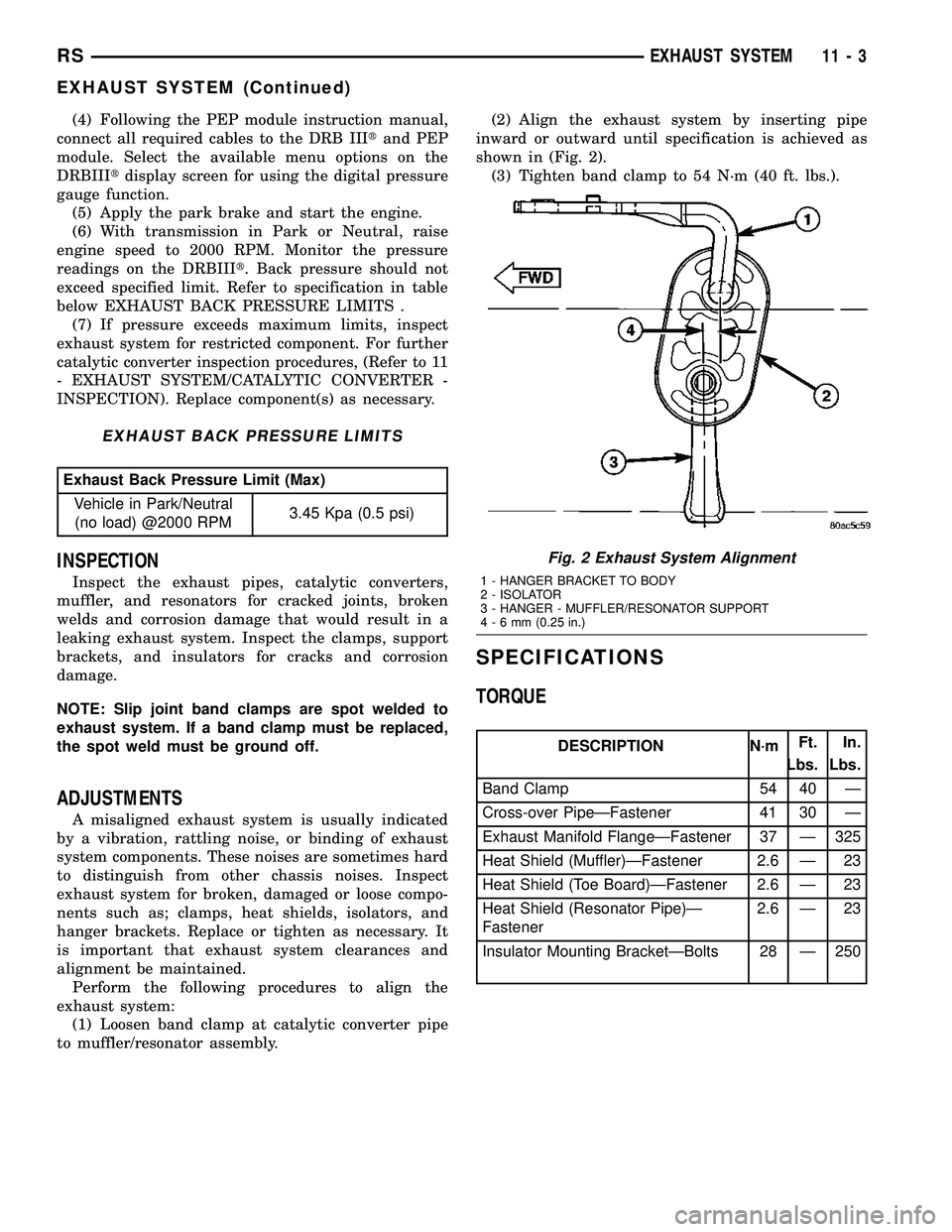

The exhaust system consists of a catalytic con-

verter, muffler, and a resonator with connecting pipes

in-between (Fig. 1). The system is serviced in two

sections; the catalytic converter and pipe, and the

muffler and resonator with connecting pipe. A band

clamp is used to connect the joint between the twocomponents. Three support hanger rods with rubber

isolators are used to support and isolate the exhaust

system. A flexible joint, integral to the catalytic con-

verter, allows for engine movement. On vehicles

equipped with AWD, an additional heat shield is

mounted to the catalytic converter. The exhaust sys-

tem is tuned for each vehicle/powertrain combination.

Fig. 1 Exhaust System - Typical (All Vehicles)

1 - CATALYTIC CONVERTER 4 - SUPPORT - RESONATOR

2 - BAND CLAMP 5 - RESONATOR

3 - SUPPORTS - MUFFLER 6 - MUFFLER

RSEXHAUST SYSTEM11-1

Page 1488 of 2585

(4) Following the PEP module instruction manual,

connect all required cables to the DRB IIItand PEP

module. Select the available menu options on the

DRBIIItdisplay screen for using the digital pressure

gauge function.

(5) Apply the park brake and start the engine.

(6) With transmission in Park or Neutral, raise

engine speed to 2000 RPM. Monitor the pressure

readings on the DRBIIIt. Back pressure should not

exceed specified limit. Refer to specification in table

below EXHAUST BACK PRESSURE LIMITS .

(7) If pressure exceeds maximum limits, inspect

exhaust system for restricted component. For further

catalytic converter inspection procedures, (Refer to 11

- EXHAUST SYSTEM/CATALYTIC CONVERTER -

INSPECTION). Replace component(s) as necessary.

EXHAUST BACK PRESSURE LIMITS

Exhaust Back Pressure Limit (Max)

Vehicle in Park/Neutral

(no load) @2000 RPM3.45 Kpa (0.5 psi)

INSPECTION

Inspect the exhaust pipes, catalytic converters,

muffler, and resonators for cracked joints, broken

welds and corrosion damage that would result in a

leaking exhaust system. Inspect the clamps, support

brackets, and insulators for cracks and corrosion

damage.

NOTE: Slip joint band clamps are spot welded to

exhaust system. If a band clamp must be replaced,

the spot weld must be ground off.

ADJUSTMENTS

A misaligned exhaust system is usually indicated

by a vibration, rattling noise, or binding of exhaust

system components. These noises are sometimes hard

to distinguish from other chassis noises. Inspect

exhaust system for broken, damaged or loose compo-

nents such as; clamps, heat shields, isolators, and

hanger brackets. Replace or tighten as necessary. It

is important that exhaust system clearances and

alignment be maintained.

Perform the following procedures to align the

exhaust system:

(1) Loosen band clamp at catalytic converter pipe

to muffler/resonator assembly.(2) Align the exhaust system by inserting pipe

inward or outward until specification is achieved as

shown in (Fig. 2).

(3) Tighten band clamp to 54 N´m (40 ft. lbs.).

SPECIFICATIONS

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Band Clamp 54 40 Ð

Cross-over PipeÐFastener 41 30 Ð

Exhaust Manifold FlangeÐFastener 37 Ð 325

Heat Shield (Muffler)ÐFastener 2.6 Ð 23

Heat Shield (Toe Board)ÐFastener 2.6 Ð 23

Heat Shield (Resonator Pipe)Ð

Fastener2.6 Ð 23

Insulator Mounting BracketÐBolts 28 Ð 250

Fig. 2 Exhaust System Alignment

1 - HANGER BRACKET TO BODY

2 - ISOLATOR

3 - HANGER - MUFFLER/RESONATOR SUPPORT

4-6mm(0.25 in.)

RSEXHAUST SYSTEM11-3

EXHAUST SYSTEM (Continued)