engine oil CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1846 of 2585

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 329)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

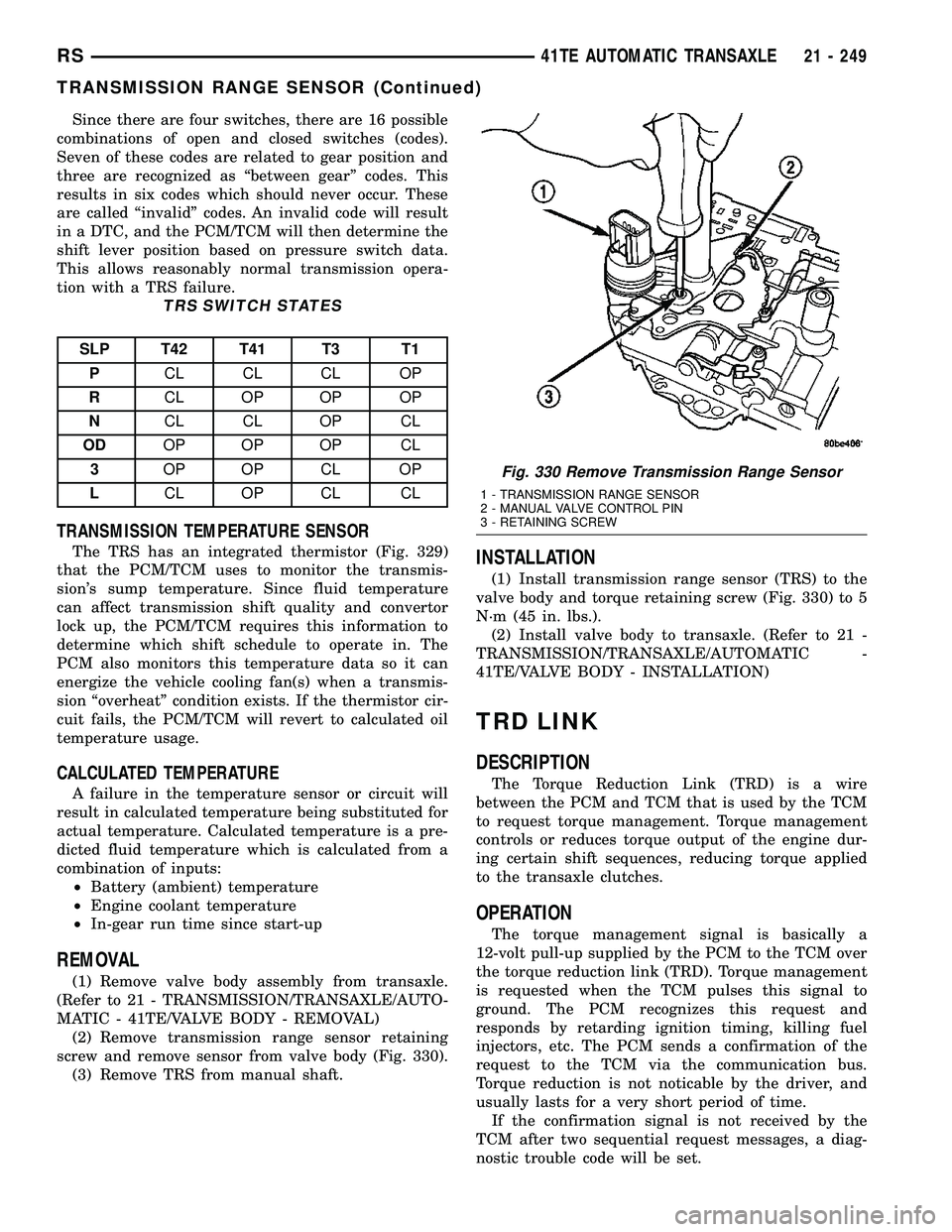

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 330).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 330) to 5

N´m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

TRD LINK

DESCRIPTION

The Torque Reduction Link (TRD) is a wire

between the PCM and TCM that is used by the TCM

to request torque management. Torque management

controls or reduces torque output of the engine dur-

ing certain shift sequences, reducing torque applied

to the transaxle clutches.

OPERATION

The torque management signal is basically a

12-volt pull-up supplied by the PCM to the TCM over

the torque reduction link (TRD). Torque management

is requested when the TCM pulses this signal to

ground. The PCM recognizes this request and

responds by retarding ignition timing, killing fuel

injectors, etc. The PCM sends a confirmation of the

request to the TCM via the communication bus.

Torque reduction is not noticable by the driver, and

usually lasts for a very short period of time.

If the confirmation signal is not received by the

TCM after two sequential request messages, a diag-

nostic trouble code will be set.

Fig. 330 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS41TE AUTOMATIC TRANSAXLE21 - 249

TRANSMISSION RANGE SENSOR (Continued)

Page 1892 of 2585

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE

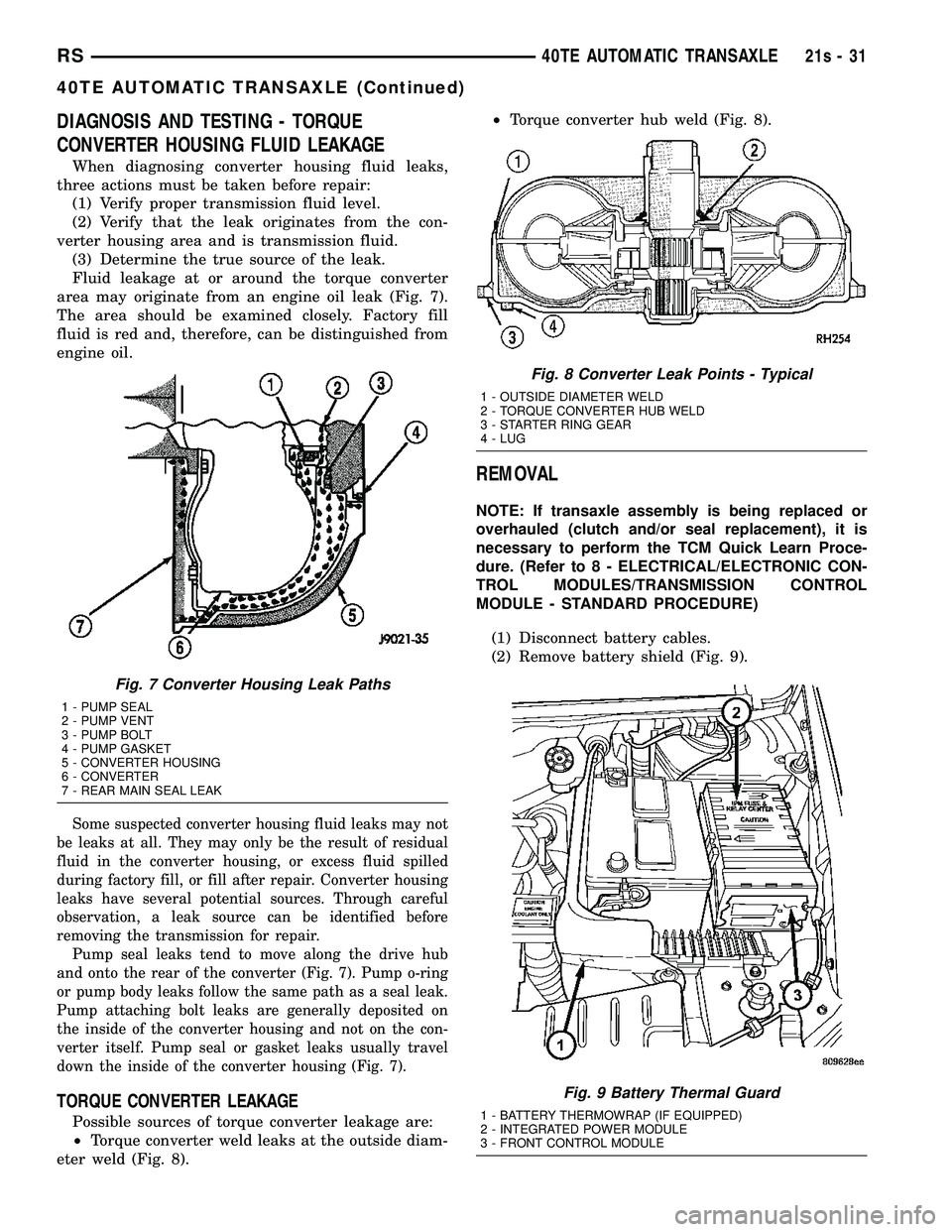

When diagnosing converter housing fluid leaks,

three actions must be taken before repair: (1) Verify proper transmission fluid level.

(2) Verify that the leak originates from the con-

verter housing area and is transmission fluid. (3) Determine the true source of the leak.

Fluid leakage at or around the torque converter

area may originate from an engine oil leak (Fig. 7).

The area should be examined closely. Factory fill

fluid is red and, therefore, can be distinguished from

engine oil.

Some suspected converter housing fluid leaks may not

be leaks at all. They may only be the result of residual

fluid in the converter housing, or excess fluid spilled

during factory fill, or fill after repair. Converter housing

leaks have several potential sources. Through careful

observation, a leak source can be identified before

removing the transmission for repair. Pump seal leaks tend to move along the drive hub

and onto the rear of the converter (Fig. 7). Pump o-ring

or pump body leaks follow the same path as a seal leak.

Pump attaching bolt leaks are generally deposited on

the inside of the converter housing and not on the con-

verter itself. Pump seal or gasket leaks usually travel

down the inside of the converter housing (Fig. 7).

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the outside diam-

eter weld (Fig. 8). ²

Torque converter hub weld (Fig. 8).

REMOVAL

NOTE: If transaxle assembly is being replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perform the TCM Quick Learn Proce-

dure. (Refer t o 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Disconnect battery cables.

(2) Remove battery shield (Fig. 9).

Fig. 7 Converter Housing Leak Paths

1 - PUMP SEAL

2 - PUMP VENT

3 - PUMP BOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

Fig. 8 Converter Leak Points - Typical

1 - OUTSIDE DIAMETER WELD

2 - TORQUE CONVERTER HUB WELD

3 - STARTER RING GEAR

4 - LUG

Fig. 9 Battery Thermal Guard

1 - BATTERY THERMOWRAP (IF EQUIPPED)

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RS 40TE AUTOMATIC TRANSAXLE21s-31

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1894 of 2585

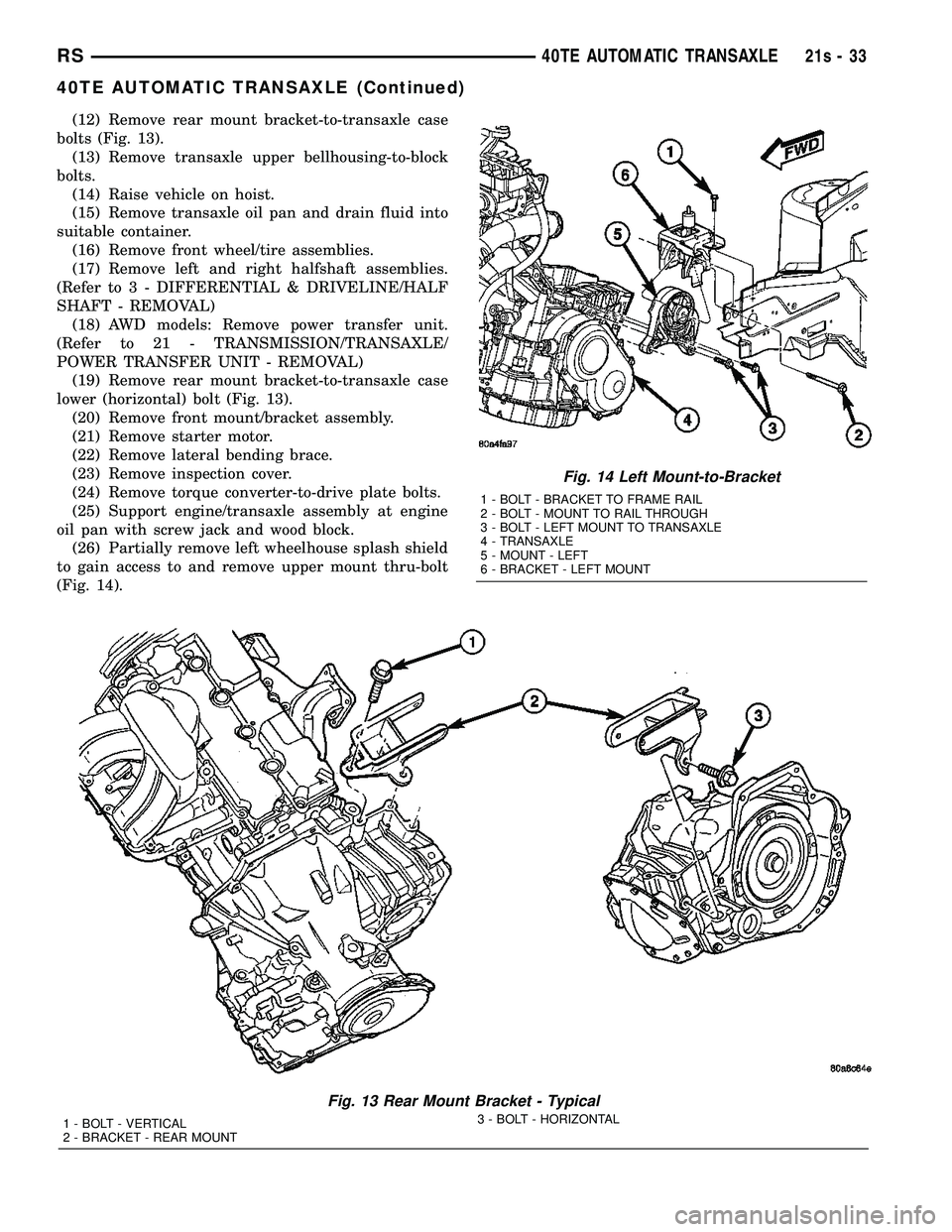

(12) Remove rear mount bracket-to-transaxle case

bolts (Fig. 13). (13) Remove transaxle upper bellhousing-to-block

bolts. (14) Raise vehicle on hoist.

(15) Remove transaxle oil pan and drain fluid into

suitable container. (16) Remove front wheel/tire assemblies.

(17) Remove left and right halfshaft assemblies.

(Refer t o 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - REMOVAL) (18) AWD models: Remove power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - REMOVAL) (19) Remove rear mount bracket-to-transaxle case

lower (horizontal) bolt (Fig. 13). (20) Remove front mount/bracket assembly.

(21) Remove starter motor.

(22) Remove lateral bending brace.

(23) Remove inspection cover.

(24) Remove torque converter-to-drive plate bolts.

(25) Support engine/transaxle assembly at engine

oil pan with screw jack and wood block. (26) Partially remove left wheelhouse splash shield

to gain access to and remove upper mount thru-bolt

(Fig. 14).

Fig. 13 Rear Mount Bracket - Typical

1 - BOLT - VERTICAL

2 - BRACKET - REAR MOUNT 3 - BOLT - HORIZONTAL

Fig. 14 Left Mount-to-Bracket

1 - BOLT - BRACKET TO FRAME RAIL

2 - BOLT - MOUNT TO RAIL THROUGH

3 - BOLT - LEFT MOUNT TO TRANSAXLE

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

RS

40TE AUTOMATIC TRANSAXLE21s-33

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1895 of 2585

(27) Lower engine/transaxle assembly with screw

jack. (28) Obtain helper and/or transmission jack.

Secure transmission jack to transaxle assembly. (29) Remove upper mount bracket from transaxle

(Fig. 14). (30) Remove remaining transaxle bellhousing-to-

engine bolts. (31) Remove transaxle assembly from vehicle.

DISASSEMBLY

NOTE: If transaxle is being overhauled (clutch

and/or seal replacement) or replaced, it is neces-

sary to perform the PCM/TCM Quick Learn Proce-

dure. (Refer t o 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/POWERTRAIN/TRANSMIS-

SION CONTROL MODULE - STANDARD PROCE-

DURE)

NOTE: This procedure does not include final drive

(differential) disassembly.

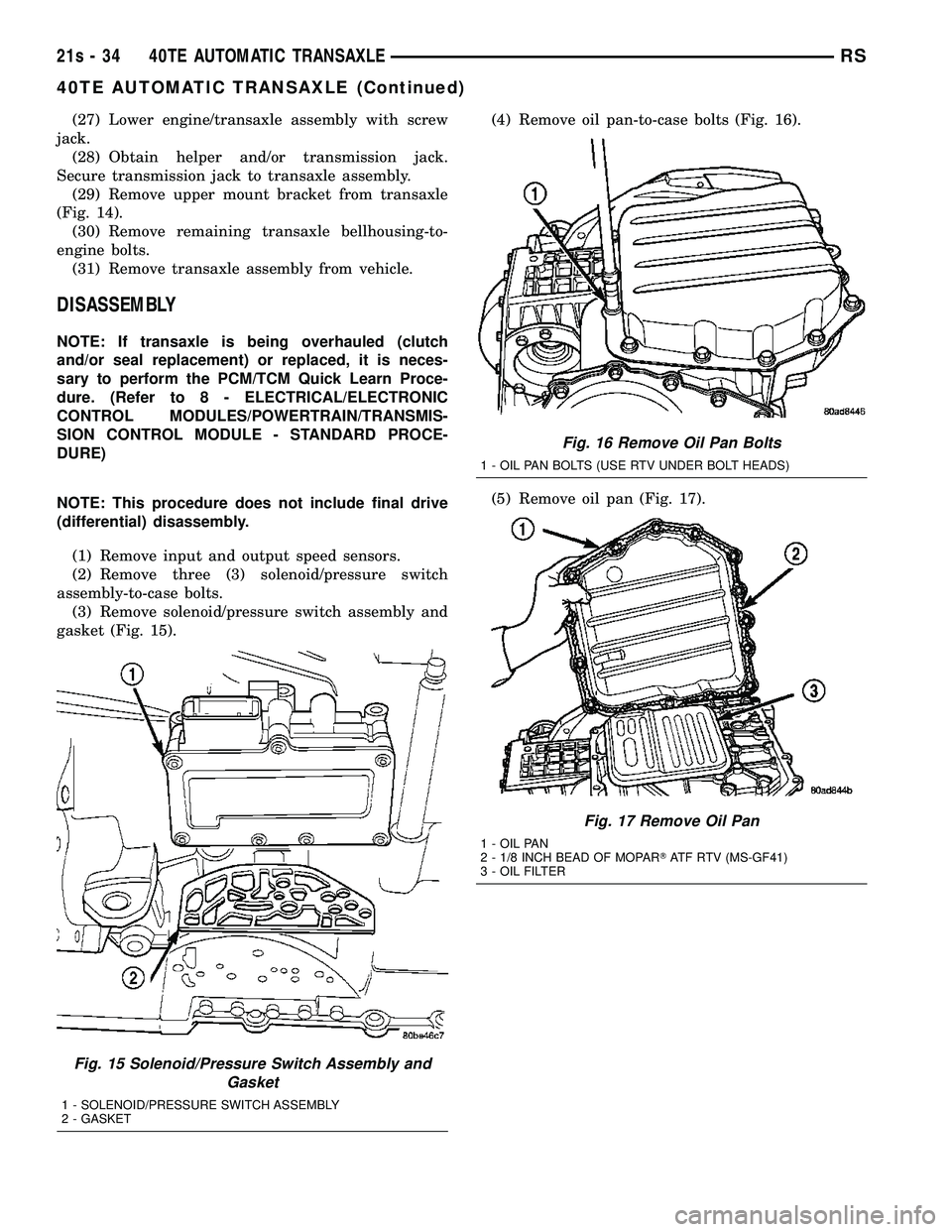

(1) Remove input and output speed sensors.

(2) Remove three (3) solenoid/pressure switch

assembly-to-case bolts. (3) Remove solenoid/pressure switch assembly and

gasket (Fig. 15). (4) Remove oil pan-to-case bolts (Fig. 16).

(5) Remove oil pan (Fig. 17).

Fig. 15 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 16 Remove Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 17 Remove Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF MOPAR TATF RTV (MS-GF41)

3 - OIL FILTER

21s - 34 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1896 of 2585

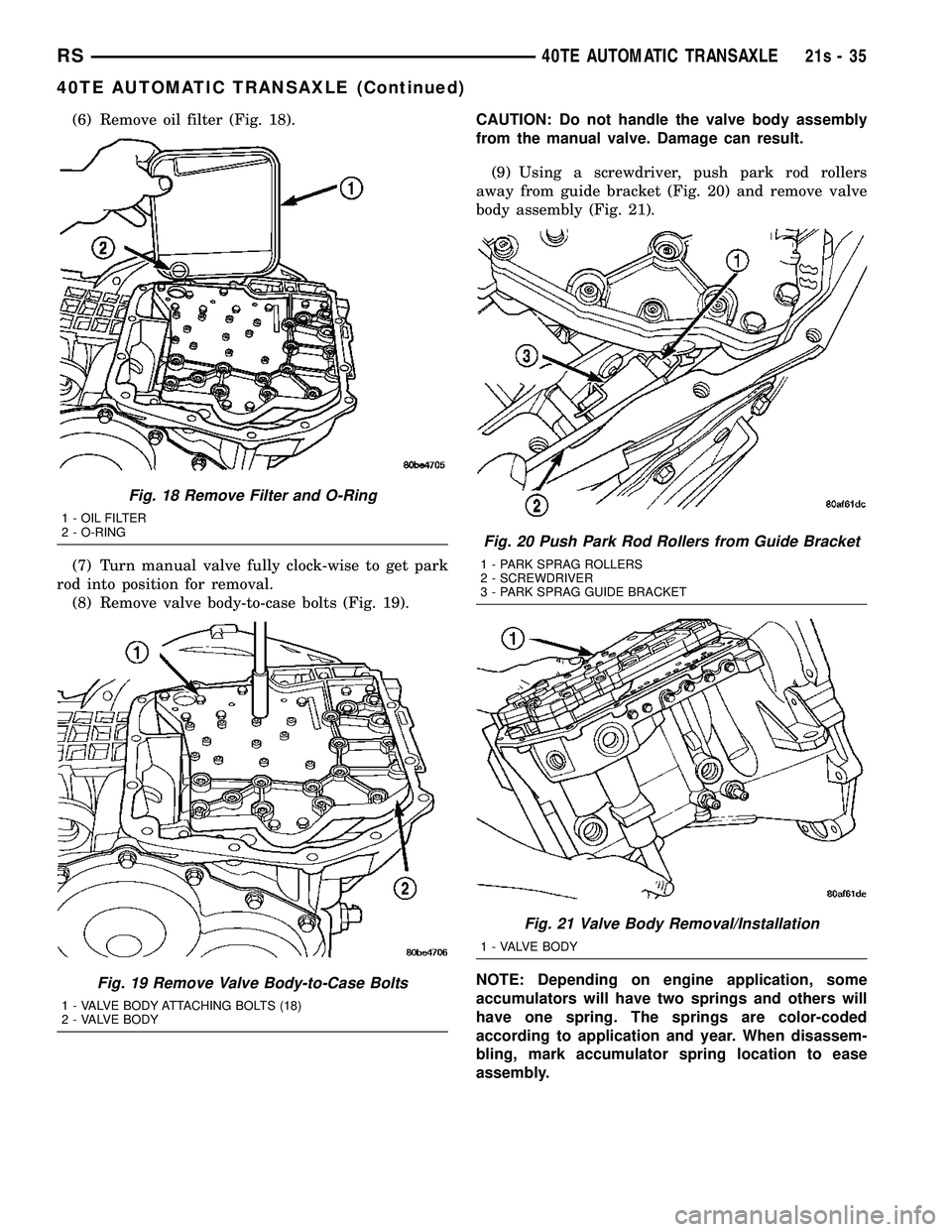

(6) Remove oil filter (Fig. 18).

(7) Turn manual valve fully clock-wise to get park

rod into position for removal. (8) Remove valve body-to-case bolts (Fig. 19). CAUTION: Do not handle the valve body assembly

from the manual valve. Damage can result.

(9) Using a screwdriver, push park rod rollers

away from guide bracket (Fig. 20) and remove valve

body assembly (Fig. 21).

NOTE: Depending on engine application, some

accumulators will have two springs and others will

have one spring. The springs are color-coded

according to application and year. When disassem-

bling, mark accumulator spring location to ease

assembly.

Fig. 18 Remove Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 19 Remove Valve Body-to-Case Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 20 Push Park Rod Rollers from Guide Bracket

1 - PARK SPRAG ROLLERS

2 - SCREWDRIVER

3 - PARK SPRAG GUIDE BRACKET

Fig. 21 Valve Body Removal/Installation

1 - VALVE BODY

RS 40TE AUTOMATIC TRANSAXLE21s-35

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1963 of 2585

PRELOAD ADJUSTMENT W/O SHIM(1) Remove the bearing cup from the differential

bearing retainer using Miller special Tool 6062A. (2) Remove existing shim from under bearing cup.

(3) Reinstall the bearing cup into the retainer

using Miller Special Tool 6061, and C-4171.

NOTE: Oil baffle is not required when making the

shim calculation.

(4) Install the bearing retainer into the case.

Torque bolts to 28 N ²m (250 in. lbs.).

(5) Position the transaxle assembly vertically on

the support stand and install Miller Special Tool

L-4436-A into the bearing retainer. (6) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated. (7) Attach a dial indicator to the case and zero the

dial. Place the tip on the end of Special Tool

L-4436-A. (8) Place a large screwdriver to each side of the

ring gear and lift. Check the dial indicator for the

amount of end play.

CAUTION: Do not damage the transaxle case and/or

differential retainer sealing surface.

(9) Using the end play measurement that was

determined, add 0.18mm (0.007 inch). This should

give you between 5 and 18 inch pounds of bearing

preload. Refer to the Differential Bearing Shim Chart

to determine which shim to use. (10) Remove the differential bearing retainer.

Remove the bearing cup. (11) Install the oil baffle. Install the proper shim

combination under the bearing cup. (12) Install the differential bearing retainer. Seal

the retainer to the housing with Mopar tSilicone

Rubber Adhesive Sealant. Torque bolts to 28 N ²m

(250 in. lbs.). (13) Using Miller Special Tool L-4436-A and an

inch-pound torque wrench, check the turning torque

of the differential (Fig. 186). The turning torque

should be between 5-18 inch-pounds.

NOTE: If turning torque is too high install a 0.05mm

(0.002 inch) thicker shim. If the turning torque is too

low, install a 0.05mm (0.002 inch) thinner shim.

Repeat until 5-18 inch-pounds of turning torque is

obtained.FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid)

should be used in this transaxle.

FLUID LEVEL CHECK

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing. The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate. The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground. At normal operating temperature 82É C

(180É F), the fluid level is correct if it is in the HOT

region on the oil level indicator (Fig. 187). The fluid

level should be within the COLD region of the dip-

stick at 27É C (80É F) fluid temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.

Fig. 187 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21s - 102 40TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1964 of 2585

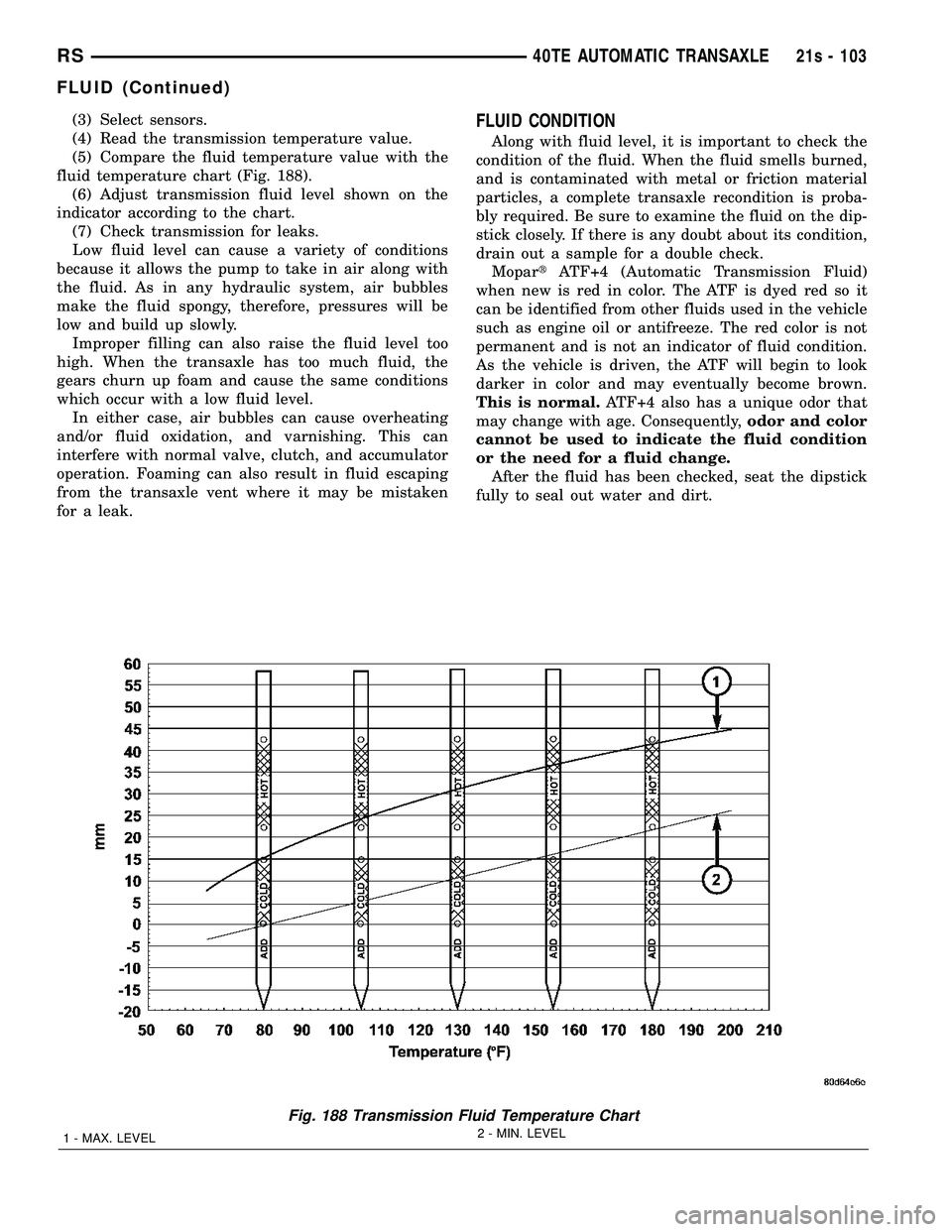

(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 188). (6) Adjust transmission fluid level shown on the

indicator according to the chart. (7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level. In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check. Mopar tATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal. ATF+4 also has a unique odor that

may change with age. Consequently, odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

Fig. 188 Transmission Fluid Temperature Chart

1 - MAX. LEVEL 2 - MIN. LEVEL

RS

40TE AUTOMATIC TRANSAXLE21s - 103

FLUID (Continued)

Page 1965 of 2585

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparTATF+4

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

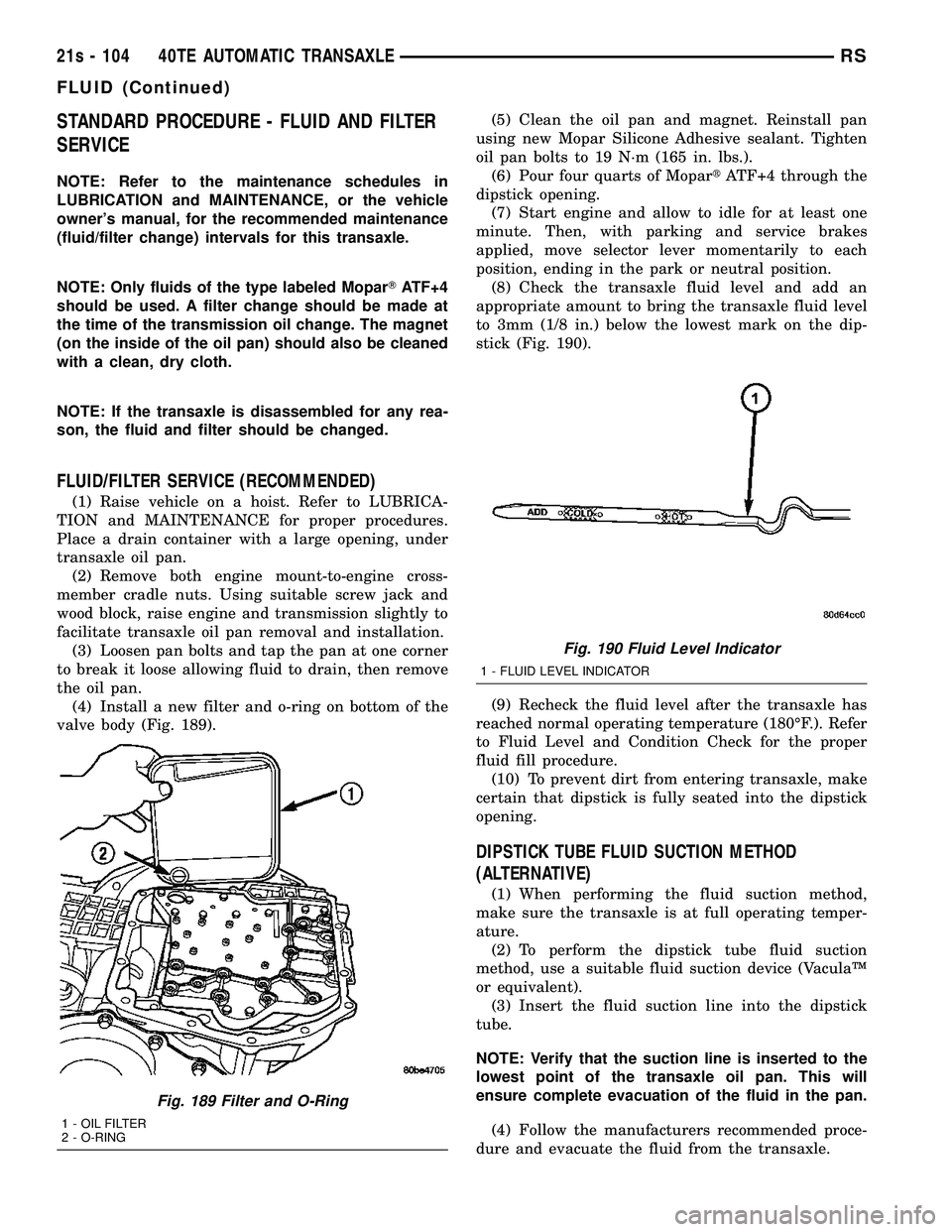

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Refer to LUBRICA-

TION and MAINTENANCE for proper procedures.

Place a drain container with a large opening, under

transaxle oil pan. (2) Remove both engine mount-to-engine cross-

member cradle nuts. Using suitable screw jack and

wood block, raise engine and transmission slightly to

facilitate transaxle oil pan removal and installation. (3) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan. (4) Install a new filter and o-ring on bottom of the

valve body (Fig. 189). (5) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.). (6) Pour four quarts of Mopar tATF+4 through the

dipstick opening. (7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position. (8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the lowest mark on the dip-

stick (Fig. 190).

(9) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.). Refer

to Fluid Level and Condition Check for the proper

fluid fill procedure. (10) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature. (2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent). (3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

Fig. 189 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 190 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21s - 104 40TE AUTOMATIC TRANSAXLERS

FLUID (Continued)

Page 2001 of 2585

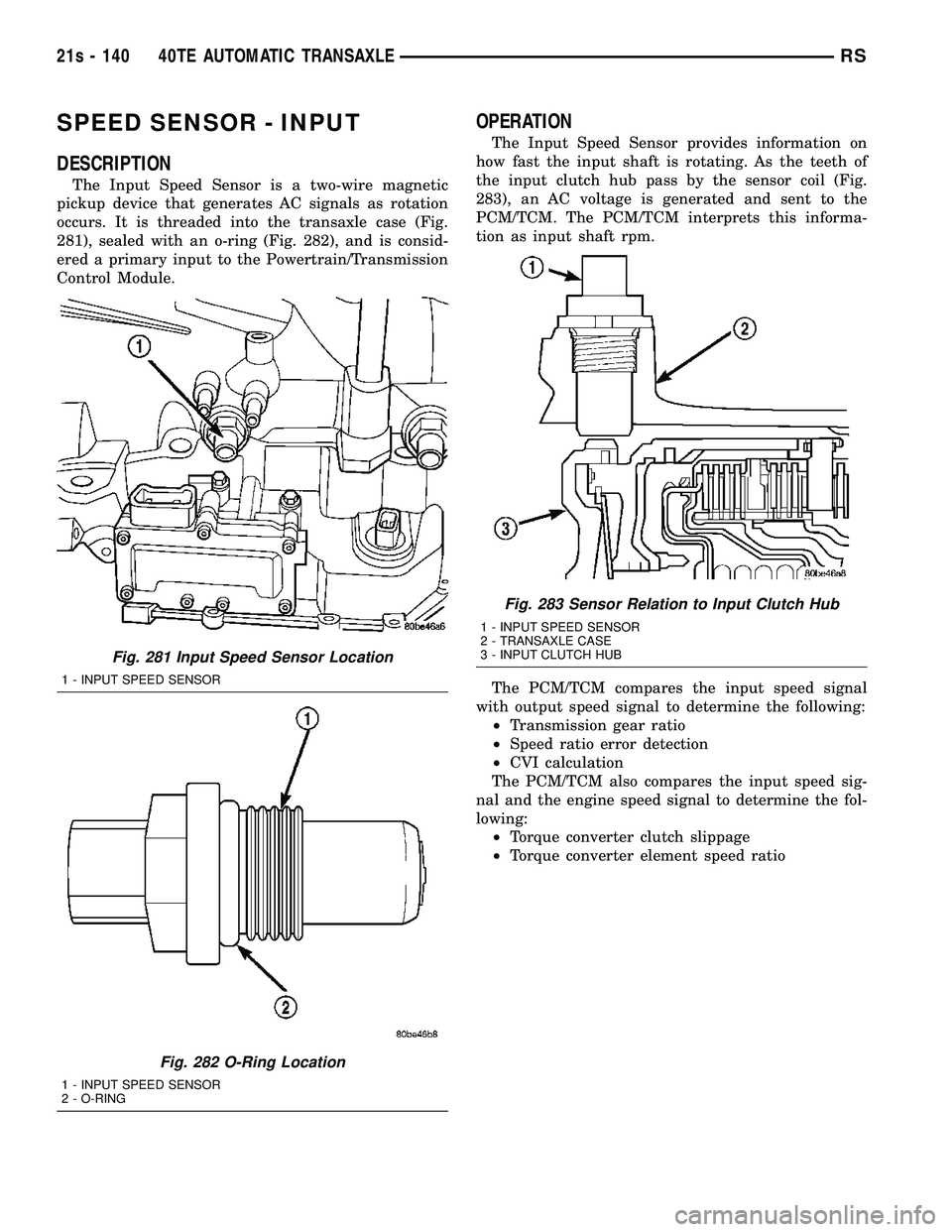

SPEED SENSOR - INPUT

DESCRIPTION

The Input Speed Sensor is a two-wire magnetic

pickup device that generates AC signals as rotation

occurs. It is threaded into the transaxle case (Fig.

281), sealed with an o-ring (Fig. 282), and is consid-

ered a primary input to the Powertrain/Transmission

Control Module.

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil (Fig.

283), an AC voltage is generated and sent to the

PCM/TCM. The PCM/TCM interprets this informa-

tion as input shaft rpm.

The PCM/TCM compares the input speed signal

with output speed signal to determine the following: ² Transmission gear ratio

² Speed ratio error detection

² CVI calculation

The PCM/TCM also compares the input speed sig-

nal and the engine speed signal to determine the fol-

lowing: ² Torque converter clutch slippage

² Torque converter element speed ratio

Fig. 281 Input Speed Sensor Location

1 - INPUT SPEED SENSOR

Fig. 282 O-Ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

Fig. 283 Sensor Relation to Input Clutch Hub

1 - INPUT SPEED SENSOR

2 - TRANSAXLE CASE

3 - INPUT CLUTCH HUB

21s - 140 40TE AUTOMATIC TRANSAXLERS

Page 2005 of 2585

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 293) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump. The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

Fig. 293 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21s - 144 40TE AUTOMATIC TRANSAXLERS