remove seats CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1479 of 2585

REMOVAL

REMOVAL - CYLINDER HEAD OFF

(1) With the cylinder head on a bench, position

Special Tool C-3422-D with 8464 Adapter on the

valve and spring retainer (Fig. 20).

(2) Compress the spring only enough to remove the

valve retainer locks.

(3) Slowly release the spring tension and remove

the valve spring and retainer.

(4) For removal of the valve stem seal (Refer to 9 -

ENGINE/CYLINDER HEAD/VALVE STEM SEALS -

REMOVAL).

REMOVAL - CYLINDER HEAD ON

(1) Disconnect negative cable from battery.

(2) Remove spark plug wires and all spark plugs.

(3) Remove cylinder head cover(s). (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(4) Remove rocker arms and shaft. (Refer to 9 -

ENGINE/CYLINDER HEAD/ROCKER ARMS -

REMOVAL)

(5) Rotate engine until the piston in the cylinder

bore requiring spring removal is at TDC.

(6) Install Special Tool 8453 to the cylinder head

(Fig. 21). Tighten the attaching bolts to 23 N´m (200

in. lbs.).

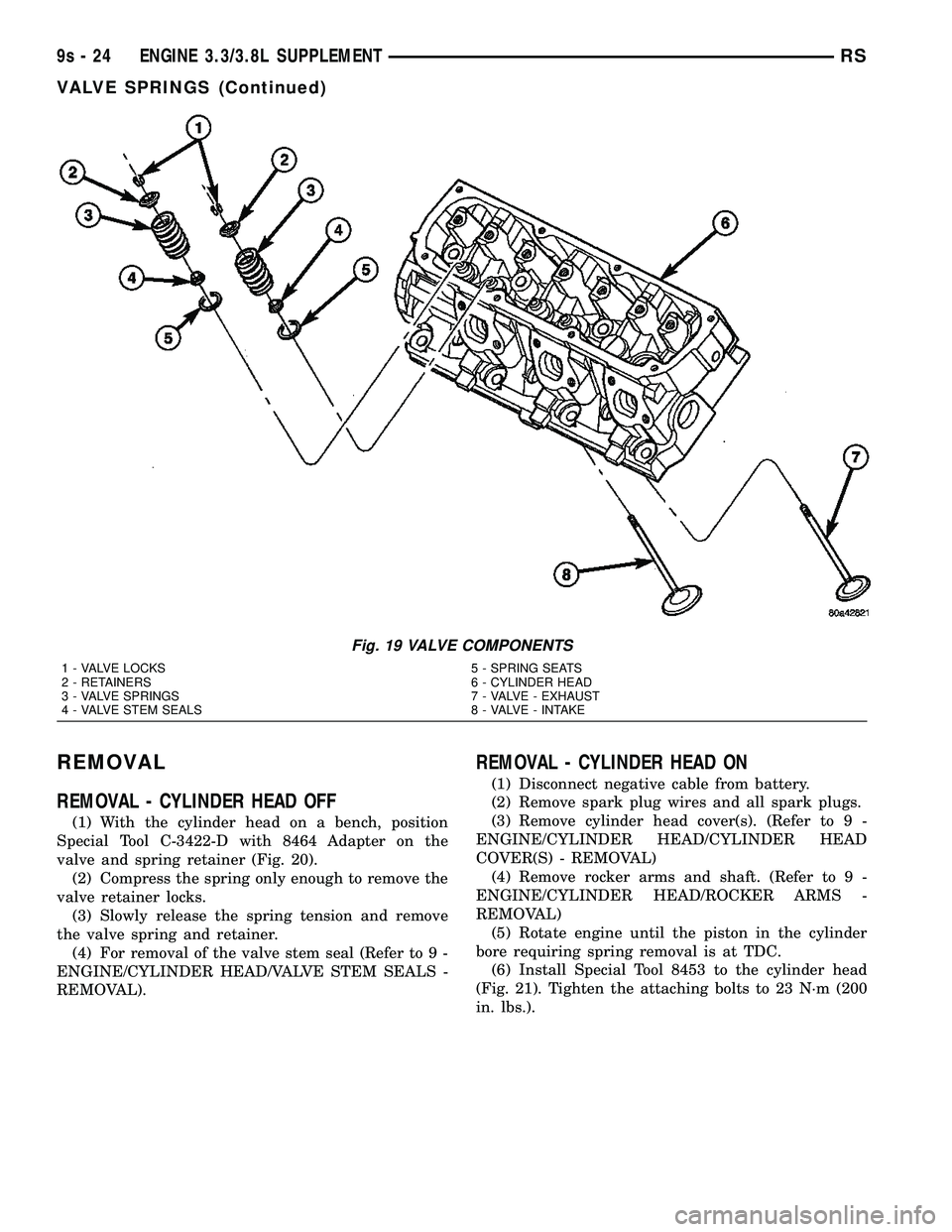

Fig. 19 VALVE COMPONENTS

1 - VALVE LOCKS 5 - SPRING SEATS

2 - RETAINERS 6 - CYLINDER HEAD

3 - VALVE SPRINGS 7 - VALVE - EXHAUST

4 - VALVE STEM SEALS 8 - VALVE - INTAKE

9s - 24 ENGINE 3.3/3.8L SUPPLEMENTRS

VALVE SPRINGS (Continued)

Page 2112 of 2585

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION - VEHICLE IDENTIFICATION....1

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 1

DIAGNOSIS AND TESTING - WIND NOISE . . . 2

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - HEAT STAKING . 10

SPECIFICATIONS

TORQUE............................11

BODY LUBRICATION...................12

SPECIAL TOOLS

BODY..............................13DOOR - FRONT.........................14

DOORS - SLIDING.......................24

DECKLID/HATCH/LIFTGATE/TAILGATE.......40

EXTERIOR.............................45

HOOD.................................60

INSTRUMENT PANEL.....................63

INTERIOR..............................73

PAINT.................................84

SEATS................................86

STATIONARY GLASS....................108

WEATHERSTRIP/SEALS..................113

SUNROOF.............................116

BODY STRUCTURE.....................124

BODY

DESCRIPTION - VEHICLE IDENTIFICATION

Throughout this group, references to the

DaimlerChrysler Corporation vehicle family identifi-

cation code are used when describing a procedure

that is unique to that vehicle. Refer to Introduction

Group of this manual for detailed information on

vehicle identification. If a procedure is common to all

vehicles covered in this manual, no reference will be

made to a vehicle family code.

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THAT

IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

RSBODY23-1

Page 2186 of 2585

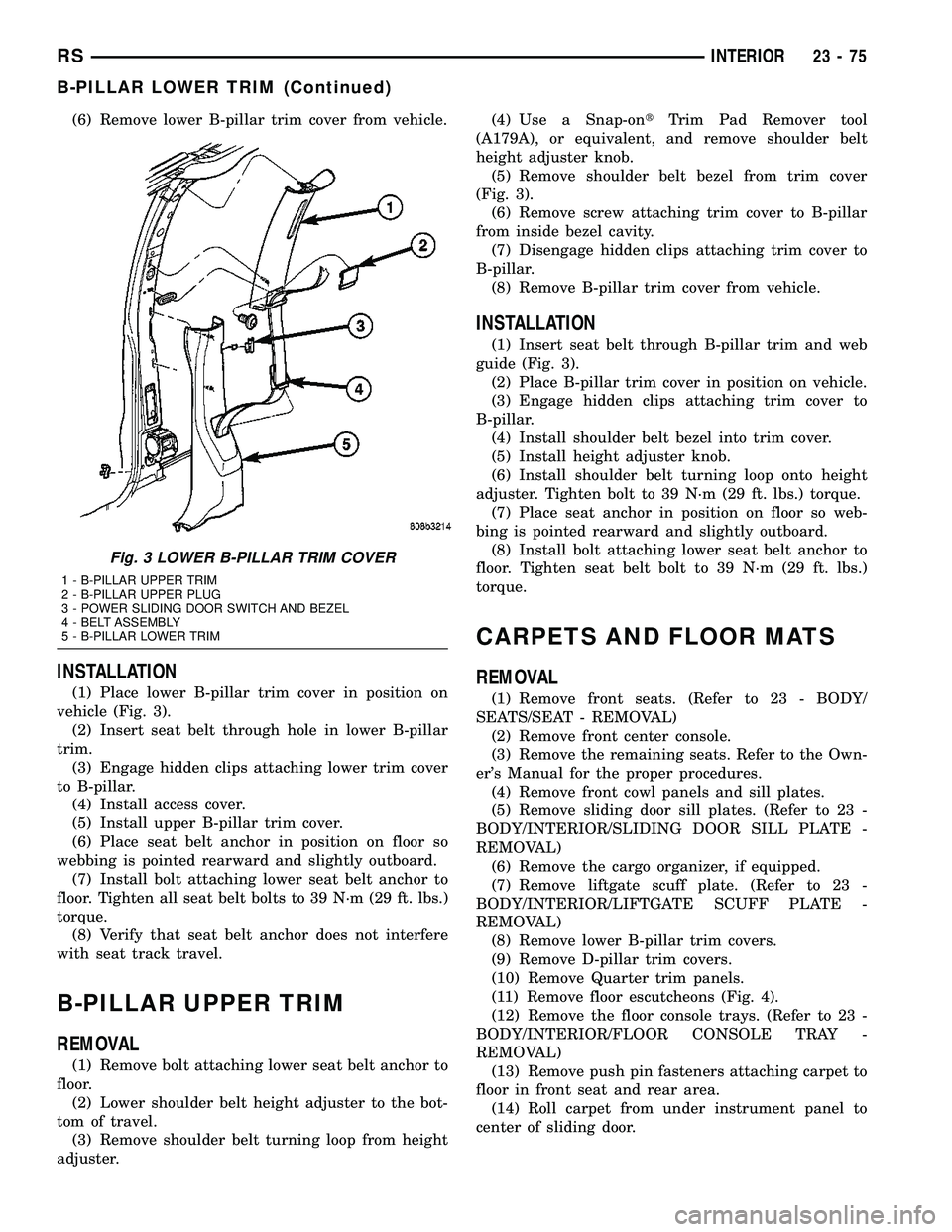

(6) Remove lower B-pillar trim cover from vehicle.

INSTALLATION

(1) Place lower B-pillar trim cover in position on

vehicle (Fig. 3).

(2) Insert seat belt through hole in lower B-pillar

trim.

(3) Engage hidden clips attaching lower trim cover

to B-pillar.

(4) Install access cover.

(5) Install upper B-pillar trim cover.

(6) Place seat belt anchor in position on floor so

webbing is pointed rearward and slightly outboard.

(7) Install bolt attaching lower seat belt anchor to

floor. Tighten all seat belt bolts to 39 N´m (29 ft. lbs.)

torque.

(8) Verify that seat belt anchor does not interfere

with seat track travel.

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove bolt attaching lower seat belt anchor to

floor.

(2) Lower shoulder belt height adjuster to the bot-

tom of travel.

(3) Remove shoulder belt turning loop from height

adjuster.(4) Use a Snap-ontTrim Pad Remover tool

(A179A), or equivalent, and remove shoulder belt

height adjuster knob.

(5) Remove shoulder belt bezel from trim cover

(Fig. 3).

(6) Remove screw attaching trim cover to B-pillar

from inside bezel cavity.

(7) Disengage hidden clips attaching trim cover to

B-pillar.

(8) Remove B-pillar trim cover from vehicle.

INSTALLATION

(1) Insert seat belt through B-pillar trim and web

guide (Fig. 3).

(2) Place B-pillar trim cover in position on vehicle.

(3) Engage hidden clips attaching trim cover to

B-pillar.

(4) Install shoulder belt bezel into trim cover.

(5) Install height adjuster knob.

(6) Install shoulder belt turning loop onto height

adjuster. Tighten bolt to 39 N´m (29 ft. lbs.) torque.

(7) Place seat anchor in position on floor so web-

bing is pointed rearward and slightly outboard.

(8) Install bolt attaching lower seat belt anchor to

floor. Tighten seat belt bolt to 39 N´m (29 ft. lbs.)

torque.

CARPETS AND FLOOR MATS

REMOVAL

(1) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(2) Remove front center console.

(3) Remove the remaining seats. Refer to the Own-

er's Manual for the proper procedures.

(4) Remove front cowl panels and sill plates.

(5) Remove sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(6) Remove the cargo organizer, if equipped.

(7) Remove liftgate scuff plate. (Refer to 23 -

BODY/INTERIOR/LIFTGATE SCUFF PLATE -

REMOVAL)

(8) Remove lower B-pillar trim covers.

(9) Remove D-pillar trim covers.

(10) Remove Quarter trim panels.

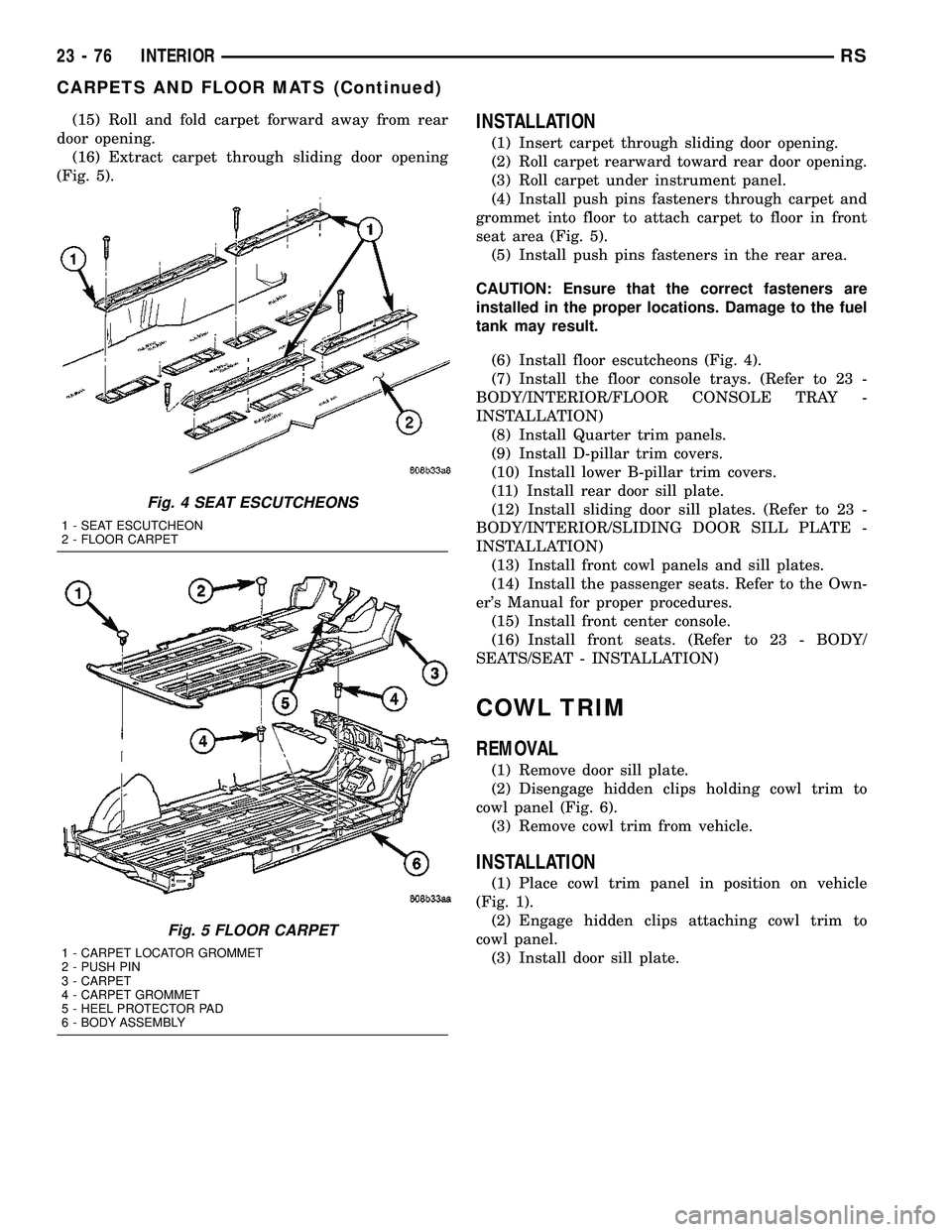

(11) Remove floor escutcheons (Fig. 4).

(12) Remove the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

REMOVAL)

(13) Remove push pin fasteners attaching carpet to

floor in front seat and rear area.

(14) Roll carpet from under instrument panel to

center of sliding door.

Fig. 3 LOWER B-PILLAR TRIM COVER

1 - B-PILLAR UPPER TRIM

2 - B-PILLAR UPPER PLUG

3 - POWER SLIDING DOOR SWITCH AND BEZEL

4 - BELT ASSEMBLY

5 - B-PILLAR LOWER TRIM

RSINTERIOR23-75

B-PILLAR LOWER TRIM (Continued)

Page 2187 of 2585

(15) Roll and fold carpet forward away from rear

door opening.

(16) Extract carpet through sliding door opening

(Fig. 5).INSTALLATION

(1) Insert carpet through sliding door opening.

(2) Roll carpet rearward toward rear door opening.

(3) Roll carpet under instrument panel.

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area (Fig. 5).

(5) Install push pins fasteners in the rear area.

CAUTION: Ensure that the correct fasteners are

installed in the proper locations. Damage to the fuel

tank may result.

(6) Install floor escutcheons (Fig. 4).

(7) Install the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

INSTALLATION)

(8) Install Quarter trim panels.

(9) Install D-pillar trim covers.

(10) Install lower B-pillar trim covers.

(11) Install rear door sill plate.

(12) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(13) Install front cowl panels and sill plates.

(14) Install the passenger seats. Refer to the Own-

er's Manual for proper procedures.

(15) Install front center console.

(16) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION)

COWL TRIM

REMOVAL

(1) Remove door sill plate.

(2) Disengage hidden clips holding cowl trim to

cowl panel (Fig. 6).

(3) Remove cowl trim from vehicle.

INSTALLATION

(1) Place cowl trim panel in position on vehicle

(Fig. 1).

(2) Engage hidden clips attaching cowl trim to

cowl panel.

(3) Install door sill plate.

Fig. 4 SEAT ESCUTCHEONS

1 - SEAT ESCUTCHEON

2 - FLOOR CARPET

Fig. 5 FLOOR CARPET

1 - CARPET LOCATOR GROMMET

2 - PUSH PIN

3 - CARPET

4 - CARPET GROMMET

5 - HEEL PROTECTOR PAD

6 - BODY ASSEMBLY

23 - 76 INTERIORRS

CARPETS AND FLOOR MATS (Continued)

Page 2198 of 2585

BENCH SEAT TRACK

REMOVAL............................104

INSTALLATION........................104

PLASTIC GROCERY BAG RETAINER

REMOVAL............................104

INSTALLATION........................105

UNDER SEAT STORAGE BIN

REMOVAL............................105

INSTALLATION........................105

UNDER SEAT STORAGE BIN GUIDE

REMOVAL............................105

INSTALLATION........................105

UNDER SEAT STORAGE BIN LOCK/LATCH

REMOVAL............................105INSTALLATION........................105

LUMBAR SUPPORT

REMOVAL............................106

INSTALLATION........................106

SEAT RISER LATCH LOCKING LINK

REMOVAL............................106

INSTALLATION........................106

QUAD BUCKET SEAT SIDE SHIELD/

CUPHOLDER - FLAP AND SPRING

ASSEMBLY

REMOVAL............................107

INSTALLATION........................107

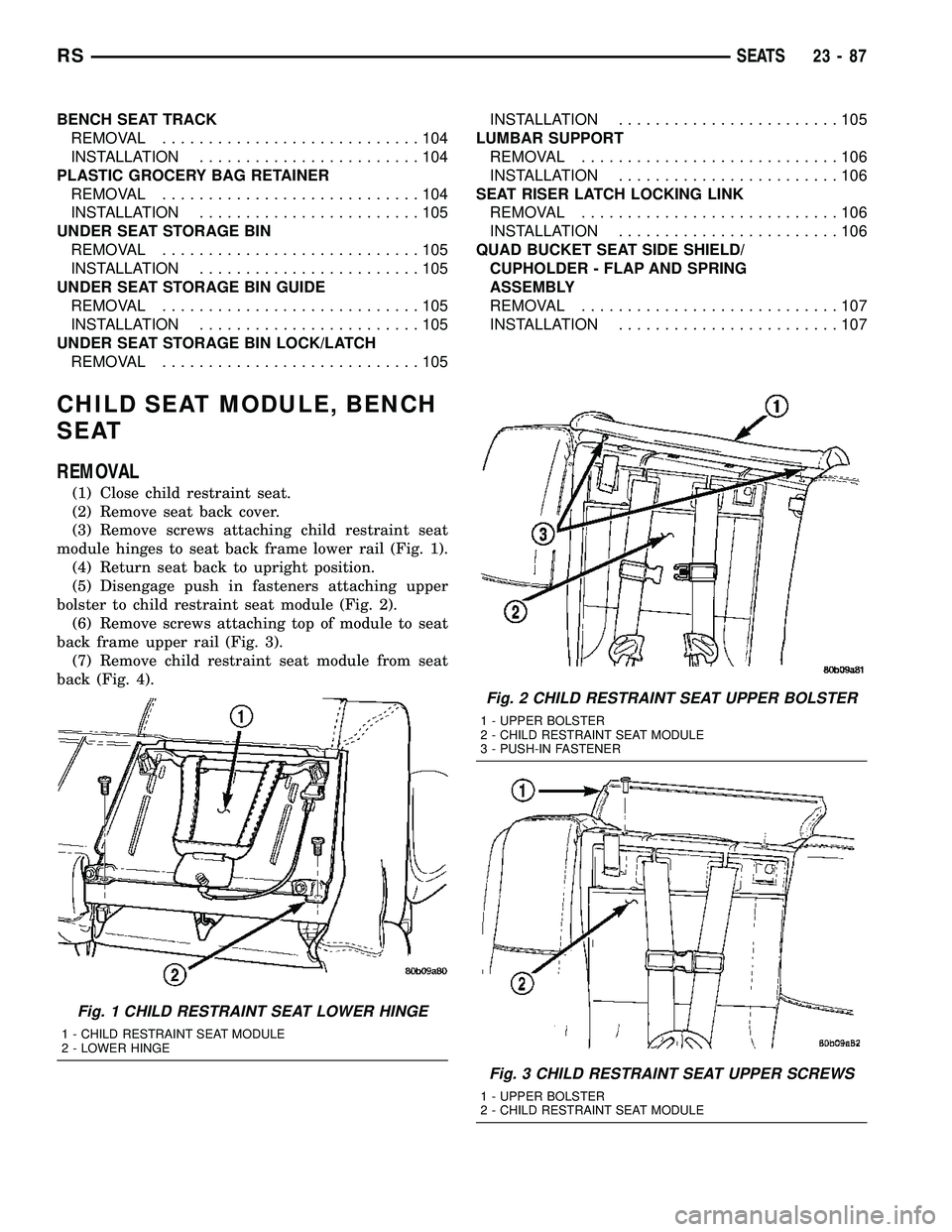

CHILD SEAT MODULE, BENCH

SEAT

REMOVAL

(1) Close child restraint seat.

(2) Remove seat back cover.

(3) Remove screws attaching child restraint seat

module hinges to seat back frame lower rail (Fig. 1).

(4) Return seat back to upright position.

(5) Disengage push in fasteners attaching upper

bolster to child restraint seat module (Fig. 2).

(6) Remove screws attaching top of module to seat

back frame upper rail (Fig. 3).

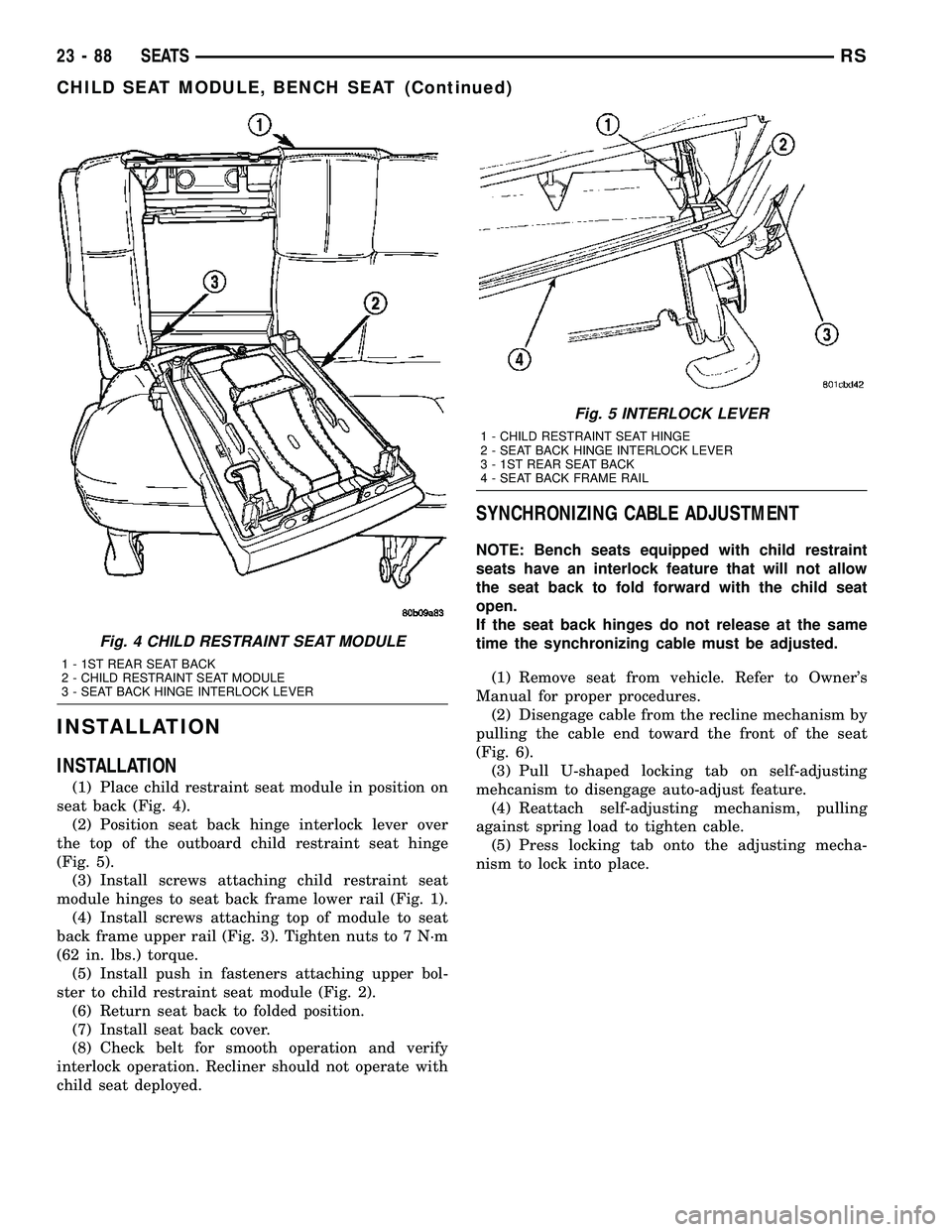

(7) Remove child restraint seat module from seat

back (Fig. 4).

Fig. 1 CHILD RESTRAINT SEAT LOWER HINGE

1 - CHILD RESTRAINT SEAT MODULE

2 - LOWER HINGE

Fig. 2 CHILD RESTRAINT SEAT UPPER BOLSTER

1 - UPPER BOLSTER

2 - CHILD RESTRAINT SEAT MODULE

3 - PUSH-IN FASTENER

Fig. 3 CHILD RESTRAINT SEAT UPPER SCREWS

1 - UPPER BOLSTER

2 - CHILD RESTRAINT SEAT MODULE

RSSEATS23-87

Page 2199 of 2585

INSTALLATION

INSTALLATION

(1) Place child restraint seat module in position on

seat back (Fig. 4).

(2) Position seat back hinge interlock lever over

the top of the outboard child restraint seat hinge

(Fig. 5).

(3) Install screws attaching child restraint seat

module hinges to seat back frame lower rail (Fig. 1).

(4) Install screws attaching top of module to seat

back frame upper rail (Fig. 3). Tighten nuts to 7 N´m

(62 in. lbs.) torque.

(5) Install push in fasteners attaching upper bol-

ster to child restraint seat module (Fig. 2).

(6) Return seat back to folded position.

(7) Install seat back cover.

(8) Check belt for smooth operation and verify

interlock operation. Recliner should not operate with

child seat deployed.

SYNCHRONIZING CABLE ADJUSTMENT

NOTE: Bench seats equipped with child restraint

seats have an interlock feature that will not allow

the seat back to fold forward with the child seat

open.

If the seat back hinges do not release at the same

time the synchronizing cable must be adjusted.

(1) Remove seat from vehicle. Refer to Owner's

Manual for proper procedures.

(2) Disengage cable from the recline mechanism by

pulling the cable end toward the front of the seat

(Fig. 6).

(3) Pull U-shaped locking tab on self-adjusting

mehcanism to disengage auto-adjust feature.

(4) Reattach self-adjusting mechanism, pulling

against spring load to tighten cable.

(5) Press locking tab onto the adjusting mecha-

nism to lock into place.

Fig. 4 CHILD RESTRAINT SEAT MODULE

1 - 1ST REAR SEAT BACK

2 - CHILD RESTRAINT SEAT MODULE

3 - SEAT BACK HINGE INTERLOCK LEVER

Fig. 5 INTERLOCK LEVER

1 - CHILD RESTRAINT SEAT HINGE

2 - SEAT BACK HINGE INTERLOCK LEVER

3 - 1ST REAR SEAT BACK

4 - SEAT BACK FRAME RAIL

23 - 88 SEATSRS

CHILD SEAT MODULE, BENCH SEAT (Continued)

Page 2200 of 2585

QUAD CHILD SEAT

REMOVAL

(1) Remove the seat. Refer to Owner's Manual for

proper procedures.

(2) Remove seat back cover (Fig. 7).

(3) Remove fasteners attaching quad child seat to

the seat (Fig. 8).

(4) Remove quad child seat from the seat.

INSTALLATION

(1) Place quad child seat in position.

(2) Install fasteners and tighten to 13.5 N´m (10 ft.

lbs.)

(3) Install seat back cover.

(4) Install seat in vehicle.

HEADREST

REMOVAL

(1) Lift head restraint to top of travel.

(2) Depress lock button on side of sleeve at top of

seat back (Fig. 9).

(3) Pull head restraint from top of seat back.

INSTALLATION

(1) Place head restraint in position.

(2) Depress lock button on side of sleeve at top of

seat back.

(3) Push heat restraint down into position.

Fig. 6 SYNCHRONIZING CABLE

1 - CABLE END

2 - LOCKING TAB

3 - SETBACK HINGE

Fig. 7 SEAT BACK COVER

1 - SEAT BACK COVER

Fig. 8 CHILD RESTRAINT SEAT BACK

1 - FASTENERS

2 - J-STRAPS

3 - FASTENERS

RSSEATS23-89

CHILD SEAT MODULE, BENCH SEAT (Continued)

Page 2201 of 2585

HEADREST SLEEVE

REMOVAL

(1) Remove head rest.

(2) Disengage closure attaching bottom of trim

cover together.

(3) Reach under trim cover through opening at

bottom of seat back.

(4) Pinch retainer barbs on end of head restraint

sleeve together (Fig. 10).

(5) Pull head restraint sleeve upward and out the

top of the seat back frame guide tube (Fig. 11).

INSTALLATION

(1) Insert head restraint sleeve into guide tube at

top of seat back.

(2) Push head restraint sleeve downward until

retainer clicks into lock position.

(3) Engage closure to hold bottom of trim cover

together.

(4) Install head restraint.

RECLINER HANDLE

REMOVAL

(1) Remove screw holding recliner handle to

recliner spline shaft (Fig. 12).

(2) Remove recliner handle from spline shaft.

INSTALLATION

(1) Place recliner handle in position on spline

shaft.

(2) Install screw to hold recliner handle to recliner

spline shaft (Fig. 12).

Fig. 9 HEAD RESTRAINT

1 - HEAD RESTRAINT

2 - SLEEVES

3 - LOCK BUTTON

Fig. 10 HEAD RESTRAINT SLEEVE RETAINER

1 - GUIDE TUBE

2 - PINCH RETAINER TO RELEASE

3 - SEAT BACK FRAME

Fig. 11 HEAD RESTRAINT SLEEVE

1 - SEAT BACK FRAME

2 - HEAD RESTRAINT SLEEVE

3 - RETAINER

4 - GUIDE TUBE

23 - 90 SEATSRS

HEADREST (Continued)

Page 2202 of 2585

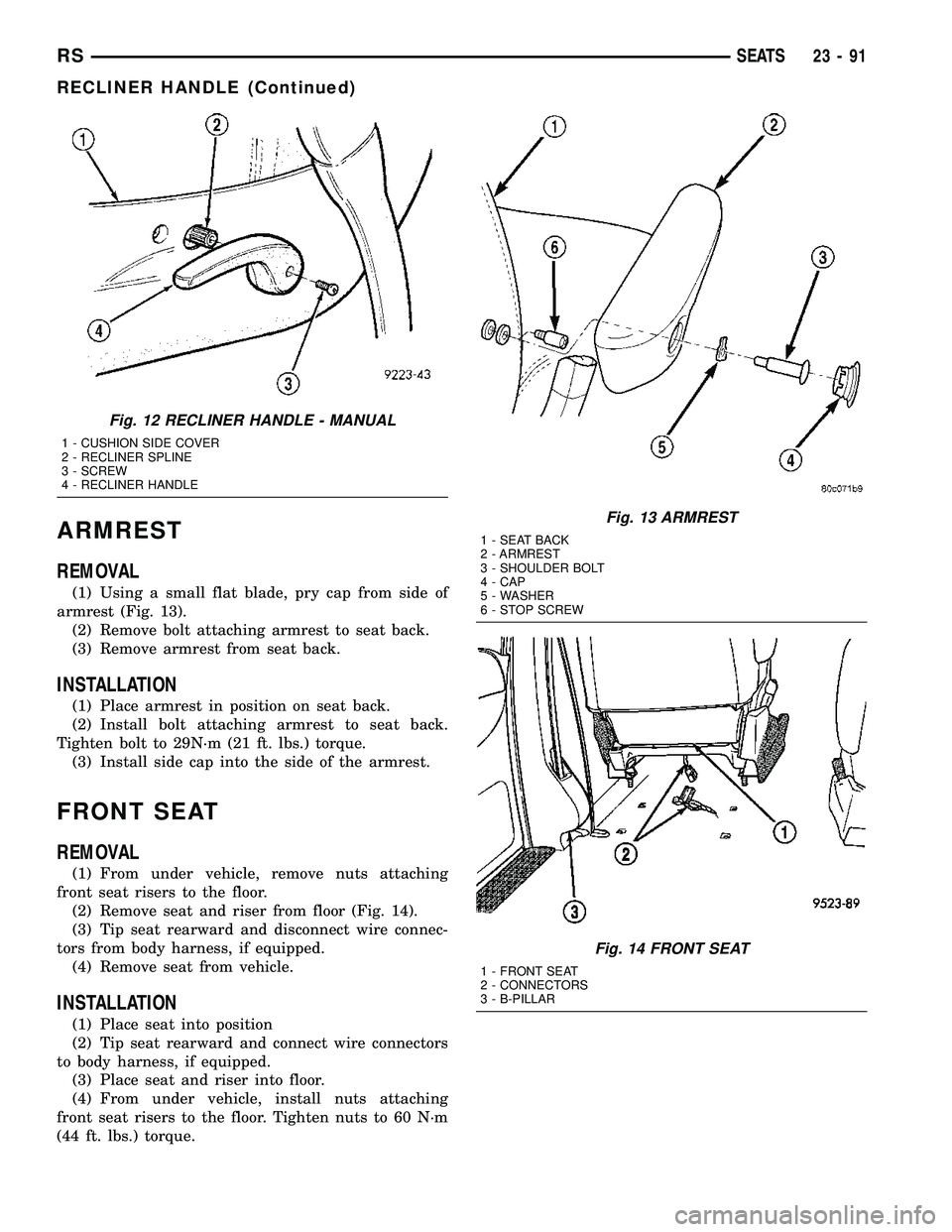

ARMREST

REMOVAL

(1) Using a small flat blade, pry cap from side of

armrest (Fig. 13).

(2) Remove bolt attaching armrest to seat back.

(3) Remove armrest from seat back.

INSTALLATION

(1) Place armrest in position on seat back.

(2) Install bolt attaching armrest to seat back.

Tighten bolt to 29N´m (21 ft. lbs.) torque.

(3) Install side cap into the side of the armrest.

FRONT SEAT

REMOVAL

(1) From under vehicle, remove nuts attaching

front seat risers to the floor.

(2) Remove seat and riser from floor (Fig. 14).

(3) Tip seat rearward and disconnect wire connec-

tors from body harness, if equipped.

(4) Remove seat from vehicle.

INSTALLATION

(1) Place seat into position

(2) Tip seat rearward and connect wire connectors

to body harness, if equipped.

(3) Place seat and riser into floor.

(4) From under vehicle, install nuts attaching

front seat risers to the floor. Tighten nuts to 60 N´m

(44 ft. lbs.) torque.

Fig. 12 RECLINER HANDLE - MANUAL

1 - CUSHION SIDE COVER

2 - RECLINER SPLINE

3 - SCREW

4 - RECLINER HANDLE

Fig. 13 ARMREST

1 - SEAT BACK

2 - ARMREST

3 - SHOULDER BOLT

4 - CAP

5 - WASHER

6 - STOP SCREW

Fig. 14 FRONT SEAT

1 - FRONT SEAT

2 - CONNECTORS

3 - B-PILLAR

RSSEATS23-91

RECLINER HANDLE (Continued)

Page 2203 of 2585

FRONT SEAT BACK

REMOVAL

NOTE: On front seats equipped with side air bags,

the seatback is serviced as an assembly.

(1) Remove head rest sleeves. (Refer to 23 - BODY/

SEATS/HEADREST SLEEVE - REMOVAL)

(2) Remove the armrest. (Refer to 23 - BODY/

SEATS/ARMREST - REMOVAL)

(3) Remove the seatback recliner lever.

(4) Remove the lumbar adjustment lever.

(5) Remove both seat cushion side covers. (Refer to

23 - BODY/SEATS/FRONT SEAT CUSHION SIDE

COVER - REMOVAL)

(6) Remove nut attaching the recliner to the seat-

back frame (Fig. 15).

(7) Remove both pivot bolts and remove seatback

from recliner.

INSTALLATION

(1) Place seat back into position.

(2) Install both pivot bolts attaching seat back

frame to seat track. Tighten bolts to 54 N´m (40 ft.

lbs.) torque.(3) Install nut attaching the recliner to the seat

back frame. Tighten nut to 12 N´m (105 in. lbs.)

torque.

(4) Install both seat cushion side covers. (Refer to

23 - BODY/SEATS/FRONT SEAT CUSHION SIDE

COVER - INSTALLATION)

(5) Install the lumbar adjustment lever.

(6) Install the seat back recliner lever.

(7) Install the armrest. (Refer to 23 - BODY/

SEATS/ARMREST - INSTALLATION)

(8) Install headrest sleeves. (Refer to 23 - BODY/

SEATS/HEADREST SLEEVE - INSTALLATION)

FRONT SEATBACK ASSIST

STRAP

REMOVAL

(1) Using a small screw driver, pry screw plugs

from ends of assist strap (Fig. 16).

(2) Remove screws attaching assist strap to seat-

back.

(3) Remove assist strap from vehicle.

INSTALLATION

(1) Place assist strap in position on vehicle.

(2) Install screws attaching assist strap to seat

back. Tighten screws to 2.5 N´m (22 in. lbs.).

(3) Insert screw plugs into ends of assist strap

(Fig. 16).

FRONT SEATBACK PANEL

REMOVAL

(1) Remove the screws (Fig. 17).

(2) Tip the top of the panel away from the seat

back and lift off the hooks at the bottom to remove.

Fig. 15 FRONT SEATBACK

Fig. 16 FRONT SEATBACK ASSIST STRAP

1 - ASSIST STRAP

2 - SCREW PLUG

3 - SEAT BACK

23 - 92 SEATSRS