clutch CHRYSLER VOYAGER 2004 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 450 of 2585

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor or Park/Neu-

tral Switch- Visually inspect the transmission

range sensor for indications of physical damage and

loose or corroded wire harness connections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH INTERLOCK

SWITCH (MAN TRANS)

FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE.10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

RSSTARTING8F-29

STARTING (Continued)

Page 453 of 2585

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (85) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position and

the clutch pedal is depressed (manual trans). Check

for battery voltage at the cavity for relay terminal 86

with the ignition switch in the Start position and the

clutch pedal is depressed (manual trans), and no

voltage when the ignition switch is released to the

On position. If OK, go to Step 5. If not OK, check for

an open or short circuit to the ignition switch and

repair, if required. If the circuit to the ignition switch

is OK, see the Ignition Switch Test procedure in this

group.

(5) The coil ground terminal (86) is connected to

the electromagnet in the relay. It is grounded by the

PCM if the conditions are right to start the car. For

automatic trans. cars the PCM must see Park Neu-

tral switch low and near zero engine speed (rpm).

For manual trans. cars the PCM only needs to see

near zero engine speed (rpm) and low clutch inter-

lock input and see near zero engine speed (rpm). To

diagnose the Park Neutral switch of the trans range

sensor refer to the transaxle section. Check for conti-

nuity to ground while the ignition switch is in the

start position and if equipped the clutch pedal

depressed. If not OK and the vehicle has an auto-

matic trans. verify Park Neutral switch operation. If

that checks OK check for continuity between PCM

and the terminal 86. Repair open circuit as required.

Also check the clutch interlock switch operation if

equipped with a manual transmission. If OK, the

PCM may be defective.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information.

If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) Gain access to battery terminals.

(3) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

8F - 32 STARTINGRS

STARTING (Continued)

Page 474 of 2585

test, be certain that the following procedures are

accomplished:² The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures. ² Fully engage the parking brake.

² If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position. ² Verify that all lamps and accessories are turned

off. ² To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Intelligent Power Module (IPM), in the

engine compartment. See the fuse and relay layout

label affixed to the underside of the IPM cover for

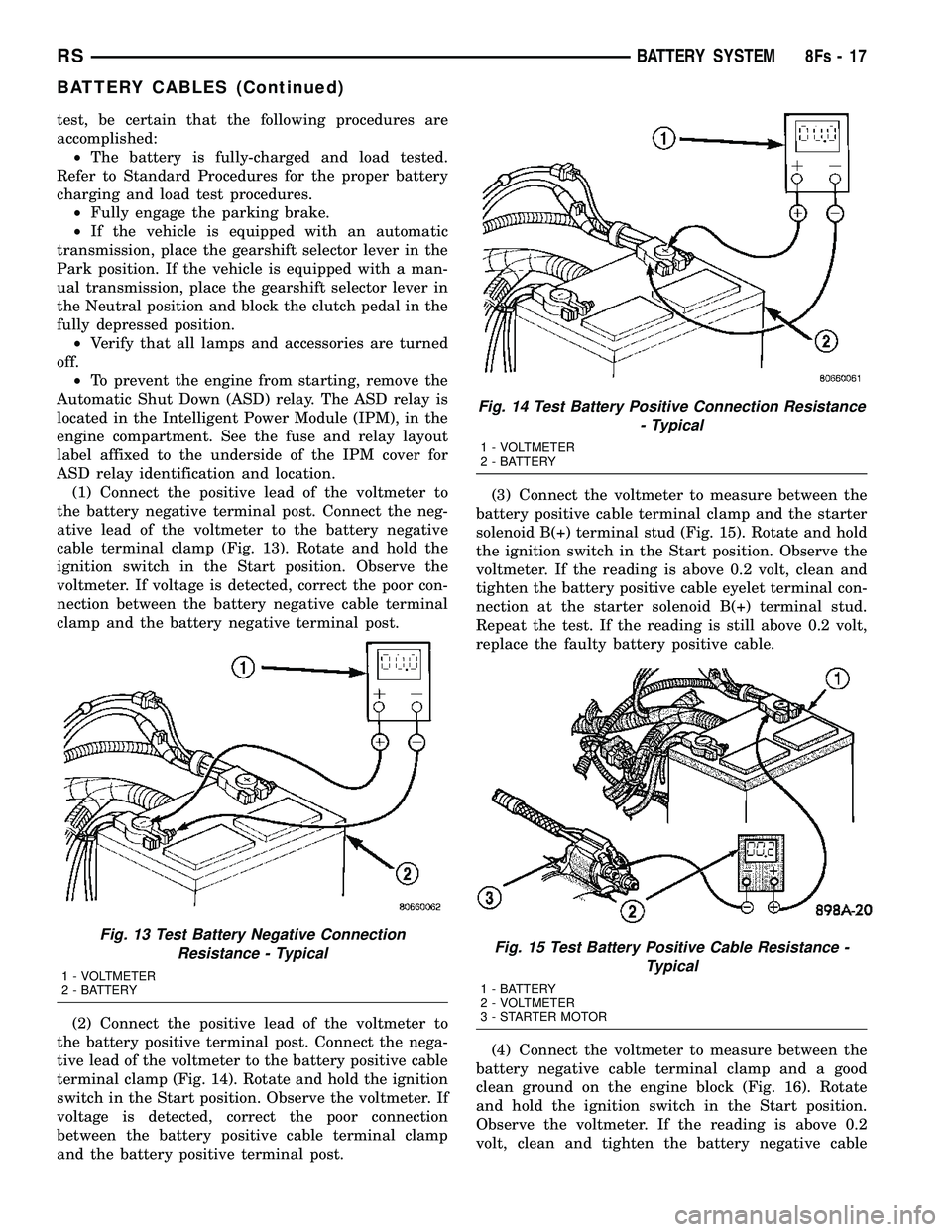

ASD relay identification and location. (1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 13). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 14). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post. (3) Connect the voltmeter to measure between the

battery positive cable terminal clamp and the starter

solenoid B(+) terminal stud (Fig. 15). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery positive cable eyelet terminal con-

nection at the starter solenoid B(+) terminal stud.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery positive cable.

(4) Connect the voltmeter to measure between the

battery negative cable terminal clamp and a good

clean ground on the engine block (Fig. 16). Rotate

and hold the ignition switch in the Start position.

Observe the voltmeter. If the reading is above 0.2

volt, clean and tighten the battery negative cable

Fig. 13 Test Battery Negative Connection Resistance - Typical

1 - VOLTMETER

2 - BATTERY

Fig. 14 Test Battery Positive Connection Resistance - Typical

1 - VOLTMETER

2 - BATTERY

Fig. 15 Test Battery Positive Cable Resistance -Typical

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

RS BATTERY SYSTEM8Fs-17

BATTERY CABLES (Continued)

Page 484 of 2585

(11) Install accessory drive belt, refer to the Cool-

ing System section for proper procedures. (12) Install the right front lower splash shield.

(13) Lower vehicle.

(14) Install wiring harness to the oil dip stick tube

(15) Connect battery negative cable.

(16) Verify generator output rate.

GENERATOR DECOUPLER

PULLEY

DESCRIPTION

The Generator Decoupler is a one way clutch (Fig.

11). It is attached to the generator and replaces the

standard pulley. It is a non-serviceable item and is to

be replaced as an assembly. It is a dry operation (no

grease or lubricants). The operation of it is not tem-

perature sensitive and has a low sensitivity to elec-

trical load.

OPERATION

The generator decoupler is a one way clutch and

should be replaced as an assembly. It is designed to help reduce belt tension fluctuation, reduce fatigue

loads, improve belt life, reduce hubloads on compo-

nents, and reduce noise.

DIAGNOSIS AND TESTING - GENERATOR DECOUPLER PULLEY

CONDITION VERIFICATION PROCEDURE POSSIBLE

CAUSESCORRECTION

Does not drive generator

(Generator not Charging) 1. Start engine and allow engine to idle. Clutch failure Replace Decoupler

2.Verify generator pulley is rotating.

3. View generator internal fins thru

generator housing.

4. Fins either do not rotate or rotate very

erratic.

5. Rotate decoupler pulley in clockwise

direction then quickly rotate in

counterclockwise direction to see if clutch

engages.

Noise from

generator at engine

shut down. 1. Start engine and allow engine to idle. Defective decoupler

pulley bearing.Replace decoupler

pulley.

2. Shutdown engine and listen to generator.

3. Noise heard just as engine stops.

Sounds like a click.

4. Remove accessory drive belt.

5. Verify rotation in counterclock wise

direction is rough.

Fig. 11 GENERATOR DECOUPLER 3.3/3.8L

RS CHARGING8Fs-27

GENERATOR (Continued)

Page 487 of 2585

STARTING

TABLE OF CONTENTS

page page

STARTING DESCRIPTION .........................30

OPERATION ...........................30

DIAGNOSIS AND TESTING DIAGNOSIS AND TESTING - STARTINGSYSTEM TEST .......................30

DIAGNOSIS AND TESTING - CONTROL CIRCUIT TEST ........................32

DIAGNOSIS AND TESTING - FEED CIRCUIT RESISTANCE TEST ....................34

DIAGNOSIS AND TESTING - FEED CIRCUIT TEST ...............................35 SPECIFICATIONS

Torques .............................35

STARTER ...........................36

STARTER MOTOR REMOVAL REMOVAL - 2.4L ......................36

REMOVAL - 3.3/3.8L ...................36

REMOVAL - 2.5L ......................36

INSTALLATION INSTALLATION - 2.4L ..................37

INSTALLATION - 3.3/3.8L ................37

INSTALLATION - 2.5L ..................38

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

² Starter motor (including an integral starter sole-

noid) Other components to be considered as part of start-

ing system are: ² Battery

² Battery cables

² Ignition switch and key lock cylinder

² Clutch pedal position switch (manual transmis-

sion) ² Park/neutral position switch (automatic trans-

mission) ² Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind. The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps. The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions: ² Battery - Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

8Fs - 30 STARTINGRS

Page 488 of 2585

the battery, if required. Refer to the Battery section

for more information.² Ignition Switch - Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections. ² Transmission Range Sensor or Park/Neu-

tral Switch - Visually inspect the transmission

range sensor for indications of physical damage and

loose or corroded wire harness connections. ² Starter Relay - Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections. ² Starter Motor - Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections. ²

Starter Solenoid - Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections. ² Wiring - Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post. ² Power Distribution Center (PDC) - Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE. 1. BATTERY

DISCHARGED OR

FAULTY. 1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY. 2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY. 3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY. 4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED. 5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH INTERLOCK

SWITCH (MAN TRANS)

FAULTY. 6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY. 7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY. 8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR. 9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE. 10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE. 1. BATTERY

DISCHARGED OR

FAULTY.

1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

RS

STARTING8Fs-31

STARTING (Continued)

Page 491 of 2585

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3. (3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required. (4) The coil battery terminal (85) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position and

the clutch pedal is depressed (manual trans). Check

for battery voltage at the cavity for relay terminal 86

with the ignition switch in the Start position and the

clutch pedal is depressed (manual trans), and no

voltage when the ignition switch is released to the

On position. If OK, go to Step 5. If not OK, check for

an open or short circuit to the ignition switch and

repair, if required. If the circuit to the ignition switch

is OK, see the Ignition Switch Test procedure in this

group. (5) The coil ground terminal (86) is connected to

the electromagnet in the relay. It is grounded by the

PCM if the conditions are right to start the car. For

automatic trans. cars the PCM must see Park Neu-

tral switch low and near zero engine speed (rpm).

For manual trans. cars the PCM only needs to see

near zero engine speed (rpm) and low clutch inter-

lock input and see near zero engine speed (rpm). To

diagnose the Park Neutral switch of the trans range

sensor refer to the transaxle section. Check for conti-

nuity to ground while the ignition switch is in the

start position and if equipped the clutch pedal

depressed. If not OK and the vehicle has an auto-

matic trans. verify Park Neutral switch operation. If

that checks OK check for continuity between PCM

and the terminal 86. Repair open circuit as required.

Also check the clutch interlock switch operation if

equipped with a manual transmission. If OK, the

PCM may be defective.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information. If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location. (2) Gain access to battery terminals.

(3) With all wiring harnesses and components

properly connected, perform the following: (a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post. (b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post. (c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

the START position. If voltage reads above 0.2 volt,

correct poor starter to engine ground. (a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid. Rotate and

hold the ignition switch in the START position. If

voltage reads above 0.2 volt, correct poor contact at

8Fs - 34 STARTINGRS

STARTING (Continued)

Page 578 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

Key fob, Outside Handle or

overhead console switches

do not power operate

liftgateBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery in key fob or

vehicle

Failure of latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Failure of Body Control Module

(BCM)Check electrical connections

Refer to the Body electrical troubleshooting

guide for additional checks

Replace BCM if necessary

Failure of key fob Reprogram key fob

Replace key fob if necessary

Failure of Power Liftgate Module Disconnect then reconnect battery to reset

module, function liftgate, if no function

exists check for loose wire connections,

see Body Diagnostic Manual for detailed

procedures

Failure of liftgate motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Motor clutch does not engage, replace

assembly

Full open switch inoperative, replace

switch, if necessary

Troubleshoot using Body Diagnostic

Manual Replace motor, if necessary

Liftgate does not stay open Failure of liftgate prop rods Replace prop rods, if necessary

Check for broken attachments

High inside/outside opening

effortFailure of liftgate prop rods Replace prop rods, if necessary

Check for broken attachments

Gear motor did not disengage Troubleshoot using Body Diagnostic

Manual Replace components, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

RSPOWER LIFTGATE SYSTEM8N-7

POWER LIFTGATE SYSTEM (Continued)

Page 597 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Cables worn and stretched Replace cables as necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Key fob, B-pillar or

overhead console switch

does not power operate

doorBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery

Failure of latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or

vehicle)Troubleshoot using electrical schematics.

Refer to wiring diagrams

Failure of body control module Check electrical connections

Refer to the body diagnostic manual for

additional checks

Replace BCM if necessary

Failure of key fob Replace key fob battery

Replace key fob if necessary

Failure of sliding door control

moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of door motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Gear motor clutch does not engage, replace

assembly

Full open switch inoperative, replace hold

open latch assembly

Replace motor assembly. if necessary

Door does not stay open Failure of hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Failure of hold open latch striker Replace hold open latch striker, if necessary

8N - 26 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

Page 601 of 2585

(2) Connect the lock actuator link rod on the latch

assembly.

(3) Connect the hold open latch cable on the latch

assembly. Refer to the procedure in this section for

detailed instructions.

(4) Connect the inside and outside handle cables

on the latch assembly. Refer to the procedure in the

Body section for detailed instructions.

(5) Connect all electrical connectors leading to the

latch assembly.

(6) With assistance from another person, position

the side door and install the door latch retaining

bolts. Torque to 10 - 12 N´m (100 in. lbs.).

(7) Install the weathershield if necessary. Refer to

the procedure in the Body section for detailed

instructions.

(8) Install the appropriate side door trim panel.

Refer to the procedure in the Body section for

detailed instructions.

(9) Connect the negative battery cable.

SLIDING DOOR MOTOR

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a door motor assembly. The door motor is located in

the center of the side door (Fig. 7) and is comprised

of three parts. The three parts of the door motor

assembly are the motor, gear reduction and clutch

assembly. The door motor assembly provides thepower and torque to move the sliding door from the

open/closed position to full closed/open position, after

the power latching mechanism has released.

The door motor is replaced as a complete assembly,

which includes the DC motor, gear reduction and

clutch assemblies. Consult your Mopar parts catalog

for specific part numbers.

OPERATION

With the push of a Power Side Door (PSD) com-

mand switch, the PSD control module will signal the

latch assembly to release the door from its primary

locked position. The drive motor will then take over

to provide the power to open the door to its full open

or closed position. The gear reduction portion of the

motor assembly reduces the speed of the motor from

5800 to 260 rpm and also increases the torque to the

lower drive unit. The clutch portion of the motor

assembly engages the motor to drive the door under

power and disengages it so the door can be moved

easily under manual operation.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

Fig. 6 Removing Latch Retaining Bolts

1 - Latch Retaining Bolts

2 - Side Door

Fig. 7 Side Door Components

1 - Sliding Door Control Module

2 - Module Retaining Screw

3 - Module Electrical Connectors

4 - Door Motor Assembly

5 - Flex Drive Assembly

6 - Door Motor Retaining Fasteners

7 - Door Motor Electrical Connector

8N - 30 POWER SLIDING DOOR SYSTEMRS

LATCH (Continued)